ASTM D178-01(2005)

(Specification)Standard Specification for Rubber Insulating Matting

Standard Specification for Rubber Insulating Matting

ABSTRACT

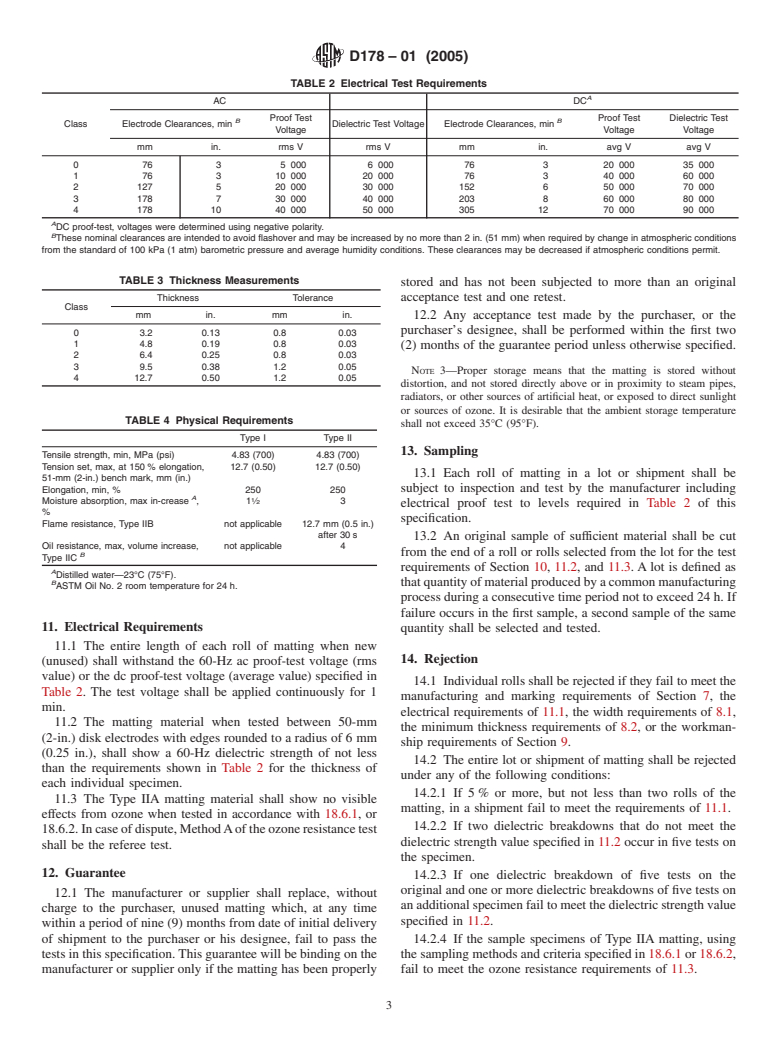

This specification covers the acceptance testing of insulating rubber matting that are used as a floor covering for the personal protection of workers. The sheeting shall be made from any elastomer or combination of elastomeric compounds. Two types of matting, differing in chemical and physical characteristics, are provided and are designated as Type I, which has been properly vulcanized, and Type II, which has one or more of the following special properties: (A) ozone resistance; (B) flame resistance; and (C) oil resistance. Five classes of matting, designated as Classes 0, 1, 2, 3, and 4, are assigned according to electrical protection characteristics. When evaluated in accordance with the test procedures detailed herein, the matting shall adhere to the following property requirements: electrical properties such as phase-phase maximum use voltage, AC and DC proof-test voltages, AC and DC dielectric breakdown test voltages, and AC and DC electrode clearances; an physical and chemical properties such as moisture absorption, oil resistance, tensile strength, tension set, elongation, resistance to accelerated heat aging, and flame resistance.

SCOPE

1.1 This specification covers acceptance testing of rubber insulating matting for use as a floor covering for protection of workers.

1.2 Two types of matting, differing in chemical and physical characteristics, are provided and are designated as Type I and Type II matting.

The following safety hazards caveat applies only to the test method portion, Sections to , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1

Rubber insulating matting should remain flexible for use through normal temperature ranges.Note 2

Rubber as used in this specification is a generic term that includes elastomers and elastomer compounds, regardless of origin.

1.3 This test method covers a small-scale horizontal laboratory screening procedure for measuring the rate, extent, or time, or a combination thereof, of burning of rigid or flexible cellular plastics in accordance with this test procedure.

1.4 Materials that exhibit pronounced shrinking, curling, or melting away upon heating cannot be evaluated by this test method.

1.5 This test method is not applicable to materials that cannot be ignited under the conditions of this test, or to materials that exhibit progressive combustion without flame (continued glowing or charring).Note 3

The rate of burning or extent of burning of rigid cellular plastics also may be determined by Test Method D 3014 where the specimen is supported vertically.

1.5.1 Warning-During the course of combustion, gases or vapors, are evolved that may be hazardous to personnel. Adequate precautions should be taken to protect the operator.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D178 – 01 (Reapproved 2005)

Standard Specification for

1

Rubber Insulating Matting

This standard is issued under the fixed designation D178; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D570 Test Method for Water Absorption of Plastics

D573 Test Method for Rubber—Deterioration in an Air

1.1 This specification covers acceptance testing of rubber

Oven

insulating matting for use as a floor covering for protection of

D1692 Discontinued 1978; Method of Test for Rate of

workers.

BurningorExtentandTimeofBurningofCellularPlastics

1.2 Twotypesofmatting,differinginchemicalandphysical

3

Using a Specimen Supported by a Horizontal Screen

characteristics, are provided and are designated as Type I and

4

2.2 American National Standard:

Type II matting.

ANSI C84.1 Voltage Ratings for Electric Power Systems

1.3 The following safety hazards caveat applies only to the

and Equipment (60 Hz)

test method portion, Sections 17 to 19, of this specification:

This standard does not purport to address all of the safety

3. Terminology

concerns, if any, associated with its use. It is the responsibility

3.1 Definitions:

of the user of this standard to establish appropriate safety and

3.1.1 user, n—as used in 4.3.1, the entity employing the

health practices and determine the applicability of regulatory

actual worker(s) utilizing the equipment; if no separate em-

limitations prior to use.

ployer, then the individual.

NOTE 1—Rubber insulating matting should remain flexible for use

3.1.2 voltage, maximum retest, n—voltage, either ac rms or

through normal temperature ranges.

dc avg, which is equal to the proof-test voltage for new

NOTE 2—Rubber as used in this specification is a generic term that

protective equipment.

includes elastomers and elastomer compounds, regardless of origin.

3.1.3 voltage, retest, n—voltage, either ac rms or dc avg,

2. Referenced Documents that used protective equipment must be capable of withstand-

2

ing for a specified test period without breakdown.

2.1 ASTM Standards:

3.1.4 voltage, nominal design, n—a nominal value consis-

D149 Test Method for Dielectric Breakdown Voltage and

tent with the latest revision of ANSI C84.1, assigned to the

Dielectric Strength of Solid Electrical Insulating Materials

circuit or system for the purpose of conveniently designating

at Commercial Power Frequencies

its voltage class.

D297 TestMethodsforRubberProducts—ChemicalAnaly-

3.1.5 voltage, maximum use, n—the ac voltage (rms) clas-

sis

sification of the protective equipment that designates the

D412 Test Methods for Vulcanized Rubber and Thermo-

maximum nominal design voltage of the energized system that

plastic Elastomers—Tension

may be safely worked. The nominal design voltage is equal to

D471 Test Method for Rubber Property—Effect of Liquids

phase-to-phase voltage on multiphase circuits.

D518 Test Method for Rubber Deterioration—Surface

3

3.1.5.1 If there is no multiphase exposure in a system area,

Cracking

and the voltage exposure is limited to phase (polarity on dc

systems) to ground potential, the phase (polarity on dc sys-

1 tems) to ground potential shall be considered to be the nominal

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of design voltage.

Subcommittee F18.25 on Insulating Cover-Up Equipment. This standard replaces

3.1.5.2 If electrical equipment and devices are insulated, or

ANSI Standard J 6.7, which is no longer available.

isolated, or both, such that the multiphase exposure on a

Current edition approved Nov. 15, 2005. Published November 2005. Originally

´2.

grounded wye circuit is removed, then the nominal design

approved in 1923. Last previous edition approved in 2001 as D178 – 01 DOI:

10.1520/D0178-01R05.

voltage may be considered as the phase-to-ground voltage on

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that circuit.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced Available from American National Standards Institute, 11 West 42nd Street,

on www.astm.org. 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D178 – 01 (20

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.