ASTM D8127-23

(Test Method)Standard Test Method for Coupled Particulate and Elemental Analysis using X-ray Fluorescence (XRF) for In-Service Lubricants

Standard Test Method for Coupled Particulate and Elemental Analysis using X-ray Fluorescence (XRF) for In-Service Lubricants

SIGNIFICANCE AND USE

5.1 It has been shown in many industries that separating information regarding small or dissolved elemental materials in the lubricant from suspended particulate is crucial. In many cases only an overall elemental analysis is provided, which may not capture significant wear or even machinery failure events. Such events are often accompanied by a sudden increase in the production of large particulate, which is suspended in and can be detected in the machinery’s lubricant. This test method specifically targets such particulate, which has historically been difficult to quantify. Users of the technique include numerous military organizations, and maintainers of wind turbines, nuclear power facilities, and offshore rigs.

SCOPE

1.1 This automatic wear particle analysis2 test method for in-service lubricants describes using a combination of pore blockage particle counting and energy dispersive X-ray fluorescence (EDXRF) spectrometry for the quantitative determination of solid particle counts larger than four (4) micrometres, and elemental content of suspended particulate of iron (Fe) and copper (Cu) in such lubricants.

1.2 This test method provides for the determination of the elemental content of suspended particulate of Fe greater than 4 μm in the range of 6 mg/kg to 223 mg/kg. Suspended particulate of copper greater than 4 μm is determined in the range of 3.5 mg/kg to 92.4 mg/kg in the lubricant. Total particle count greater than 4 μm is determined in the range of 11 495 particles/mL greater than 4 μm to 2 169 500 particles/mL greater than 4 μm in the lubricant.

1.3 This test method is applicable to all known in-service lubricants (API Groups I-V) at any stage of degradation.

1.4 This test method uses an empirical inter-element correction methodology.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8127 − 23

Standard Test Method for

Coupled Particulate and Elemental Analysis using X-ray

1

Fluorescence (XRF) for In-Service Lubricants

This standard is issued under the fixed designation D8127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

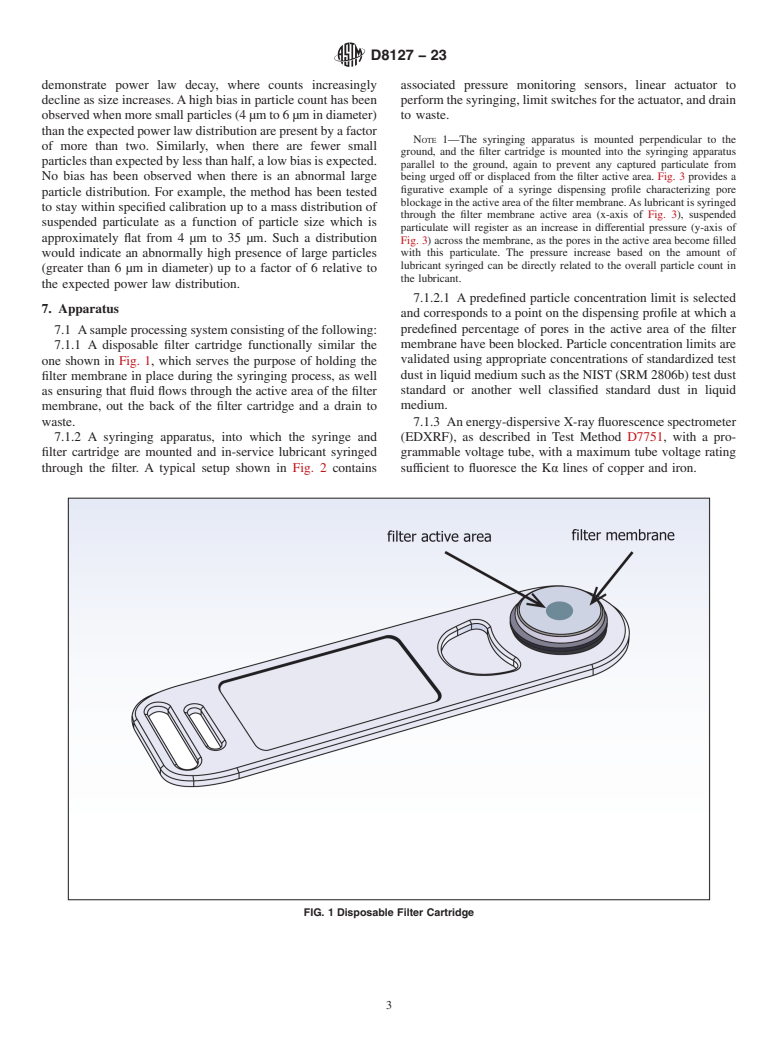

1. Scope* ization established in the Decision on Principles for the

2 Development of International Standards, Guides and Recom-

1.1 This automatic wear particle analysis test method for

mendations issued by the World Trade Organization Technical

in-service lubricants describes using a combination of pore

Barriers to Trade (TBT) Committee.

blockage particle counting and energy dispersive X-ray fluo-

rescence (EDXRF) spectrometry for the quantitative determi-

2. Referenced Documents

nation of solid particle counts larger than four (4) micrometres,

and elemental content of suspended particulate of iron (Fe) and 2.1 ASTM Standards:

copper (Cu) in such lubricants. D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.2 This test method provides for the determination of the

D4175 Terminology Relating to Petroleum Products, Liquid

elemental content of suspended particulate of Fe greater than

Fuels, and Lubricants

4 μm in the range of 6 mg/kg to 223 mg/kg. Suspended

D4177 Practice for Automatic Sampling of Petroleum and

particulate of copper greater than 4 μm is determined in the

Petroleum Products

range of 3.5 mg/kg to 92.4 mg/kg in the lubricant. Total particle

D5854 Practice for Mixing and Handling of Liquid Samples

count greater than 4 μm is determined in the range of

of Petroleum and Petroleum Products

11 495 particles ⁄mL greater than 4 μm to 2 169 500 parti-

D7669 Guide for Practical Lubricant Condition Data Trend

cles ⁄mL greater than 4 μm in the lubricant.

Analysis

1.3 This test method is applicable to all known in-service

D7720 Guide for Statistically Evaluating Measurand Alarm

lubricants (API Groups I-V) at any stage of degradation.

Limits when Using Oil Analysis to Monitor Equipment

and Oil for Fitness and Contamination

1.4 This test method uses an empirical inter-element correc-

D7751 Test Method for Determination of Additive Elements

tion methodology.

in Lubricating Oils by EDXRF Analysis

1.5 The values stated in SI units are to be regarded as

D7874 Guide for Applying Failure Mode and Effect Analy-

standard. No other units of measurement are included in this

sis (FMEA) to In-Service Lubricant Testing

standard.

E1621 Guide for Elemental Analysis by Wavelength Disper-

1.6 This standard does not purport to address all of the

sive X-Ray Fluorescence Spectrometry

safety concerns, if any, associated with its use. It is the

3

2.2 ISO Standards:

responsibility of the user of this standard to establish appro-

ISO 21018:3 Hydraulic fluid power—Monitoring the level

priate safety, health, and environmental practices and deter-

of particulate contamination of the fluid—Part 3: Use of

mine the applicability of regulatory limitations prior to use.

the filter blockage technique

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Terminology

3.1 Definitions:

1

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.1 For definitions of terms used in this test method, refer

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

to Terminology D4175.

Current edition approved May 1, 2023. Published May 2023. Originally

3.2 Definitions of Terms Specific to This Standard:

ɛ1

approved in 2017. Last previous edition approved in 2017 as D8127 – 17 . DOI:

3.2.1 contaminant particles, n—particles introduced from

10.1520/D8127-23.

2

an extraneous source into the lubricant of a machine or engine.

Iron (Fe) and copper (Cu) alloy metals are common elements for machine load

bearing surfaces including bearings, gears, pistons, rings, valves, pins, couplings,

and cylinders. This in-service lubricant analysis method addresses common chal-

lenges associated with extracting, counting, sizing, and elementally analyzing

3

telltale wear debris so that appropriate observations and actions may be recom- Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

mended. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO B

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D8127 − 17 D8127 − 23

Standard Test Method for

Coupled Particulate and Elemental Analysis using X-ray

1

Fluorescence (XRF) for In-Service Lubricants

This standard is issued under the fixed designation D8127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—A heading in Table 3 was corrected editorially in April 2018.

1. Scope Scope*

2

1.1 This automatic wear particle analysis test method for in-service lubricants describes using a combination of pore blockage

particle counting and energy dispersive X-ray fluorescence (EDXRF) spectrometry for the quantitative determination of solid

particle counts larger than four (4) micrometres, and elemental content of suspended particulate of iron (Fe) and copper (Cu) in

such lubricants.

1.2 This test method provides for the determination of the elemental content of suspended particulate of Fe greater than 4 μm in

the range of 6 mg/kg to 223 mg/kg. Suspended particulate of copper greater than 4 μm is determined in the range of 3.5 mg/kg

to 92.4 mg/kg in the lubricant. Total particle count greater than 4 μm is determined in the range of 11 495 particles ⁄mL greater than

4 μm to 2 169 500 particles ⁄mL greater than 4 μm in the lubricant.

1.3 This test method is applicable to all known in-service lubricants (API Groups I-V) at any stage of degradation.

1.4 This test method uses an empirical inter-element correction methodology.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved July 1, 2017May 1, 2023. Published August 2017May 2023. Originally approved in 2017. Last previous edition approved in 2017 as

ɛ1

D8127 – 17 . DOI: 10.1520/D8127-17E01.10.1520/D8127-23.

2

Iron (Fe) and copper (Cu) alloy metals are common elements for machine load bearing surfaces including bearings, gears, pistons, rings, valves, pins, couplings, and

cylinders. This in-service lubricant analysis method addresses common challenges associated with extracting, counting, sizing, and elementally analyzing telltale wear debris

so that appropriate observations and actions may be recommended.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8127 − 23

D5854D4175 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum ProductsTerminology Relating

to Petroleum Products, Liquid Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D7669 Guide for Practical Lubricant Condition Data Trend Analysis

D7720 Guide for Statistically Evaluating Measurand Alarm Limits when Using Oil Analysis to Monitor Equipment and Oil for

Fitness and Contamination

D7751 Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis

D7874 Guide for Applying Failure Mode and Effect Analysis (FMEA) to In-Service Lubricant Testing

E1621 Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry

3

2.2 ISO Standards:

ISO 21018:3 Hydraulic fluid power—Monitoring the level of particulate contamination of the fluid—Part 3: Use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.