ASTM D6082-23

(Test Method)Standard Test Method for High Temperature Foaming Characteristics of Lubricating Oils

Standard Test Method for High Temperature Foaming Characteristics of Lubricating Oils

SIGNIFICANCE AND USE

5.1 The tendency of oils to foam at high temperature can be a serious problem in systems such as high-speed gearing, high volume pumping, and splash lubrication. Foaming can cause inadequate lubrication, cavitation, and loss of lubricant due to overflow, and these events can lead to mechanical failure.

5.2 Correlation between the amount of foam created or the time for foam to collapse, or both, and actual lubrication failure has not been established. Such relations should be empirically determined for foam sensitive applications.

SCOPE

1.1 This test method covers the procedure for determining the foaming characteristics of lubricating oils (specifically transmission fluid and motor oil) at 150 °C.

1.2 Foaming characteristics of lubricating oils at temperatures up to 93.5 °C are determined by Test Method D892 or IP 146.

1.3 The values stated in SI units are to be regarded as standard.

1.3.1 Exception—The values given in parentheses are provided for information only.

1.4 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6082 − 23

Standard Test Method for

High Temperature Foaming Characteristics of Lubricating

1

Oils

This standard is issued under the fixed designation D6082; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the procedure for determining

D892 Test Method for Foaming Characteristics of Lubricat-

the foaming characteristics of lubricating oils (specifically

ing Oils

transmission fluid and motor oil) at 150 °C.

D4175 Terminology Relating to Petroleum Products, Liquid

1.2 Foaming characteristics of lubricating oils at tempera-

Fuels, and Lubricants

tures up to 93.5 °C are determined by Test Method D892 or IP

E128 Test Method for Maximum Pore Diameter and Perme-

146.

ability of Rigid Porous Filters for Laboratory Use

E1272 Specification for Laboratory Glass Graduated Cylin-

1.3 The values stated in SI units are to be regarded as

ders

standard.

3

2.2 Energy Institute Standards:

1.3.1 Exception—The values given in parentheses are pro-

IP 146 Standard Method of Test for Foaming Characteristics

vided for information only.

of Lubricating Oils

1.4 WARNING—Mercury has been designated by many

3. Terminology

regulatory agencies as a hazardous substance that can cause

serious medical issues. Mercury, or its vapor, has been dem-

3.1 Definitions:

onstrated to be hazardous to health and corrosive to materials. 3.1.1 For definitions of terms used in this test method, refer

Use caution when handling mercury and mercury-containing

to Terminology D4175.

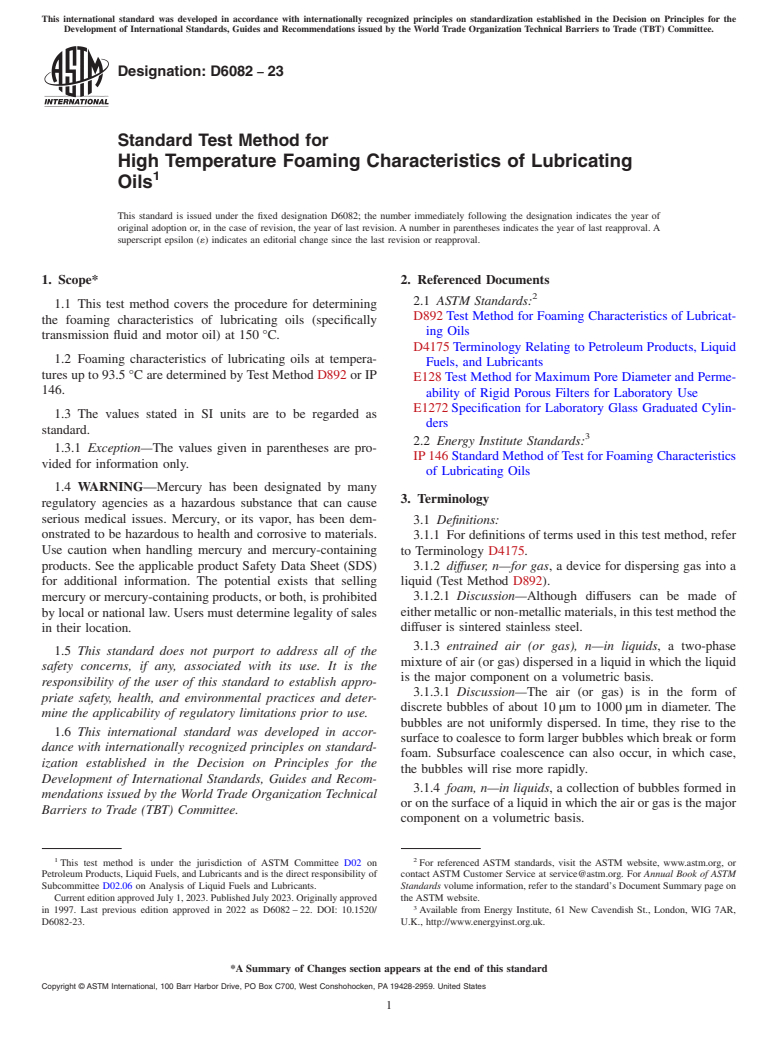

products. See the applicable product Safety Data Sheet (SDS) 3.1.2 diffuser, n—for gas, a device for dispersing gas into a

for additional information. The potential exists that selling liquid (Test Method D892).

3.1.2.1 Discussion—Although diffusers can be made of

mercury or mercury-containing products, or both, is prohibited

either metallic or non-metallic materials, in this test method the

by local or national law. Users must determine legality of sales

diffuser is sintered stainless steel.

in their location.

3.1.3 entrained air (or gas), n—in liquids, a two-phase

1.5 This standard does not purport to address all of the

mixture of air (or gas) dispersed in a liquid in which the liquid

safety concerns, if any, associated with its use. It is the

is the major component on a volumetric basis.

responsibility of the user of this standard to establish appro-

3.1.3.1 Discussion—The air (or gas) is in the form of

priate safety, health, and environmental practices and deter-

discrete bubbles of about 10 μm to 1000 μm in diameter. The

mine the applicability of regulatory limitations prior to use.

bubbles are not uniformly dispersed. In time, they rise to the

1.6 This international standard was developed in accor-

surface to coalesce to form larger bubbles which break or form

dance with internationally recognized principles on standard-

foam. Subsurface coalescence can also occur, in which case,

ization established in the Decision on Principles for the

the bubbles will rise more rapidly.

Development of International Standards, Guides and Recom-

3.1.4 foam, n—in liquids, a collection of bubbles formed in

mendations issued by the World Trade Organization Technical

or on the surface of a liquid in which the air or gas is the major

Barriers to Trade (TBT) Committee.

component on a volumetric basis.

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.06 on Analysis of Liquid Fuels and Lubricants. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2023. Published July 2023. Originally approved the ASTM website.

3

in 1997. Last previous edition approved in 2022 as D6082 – 22. DOI: 10.1520/ Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

D6082-23. U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

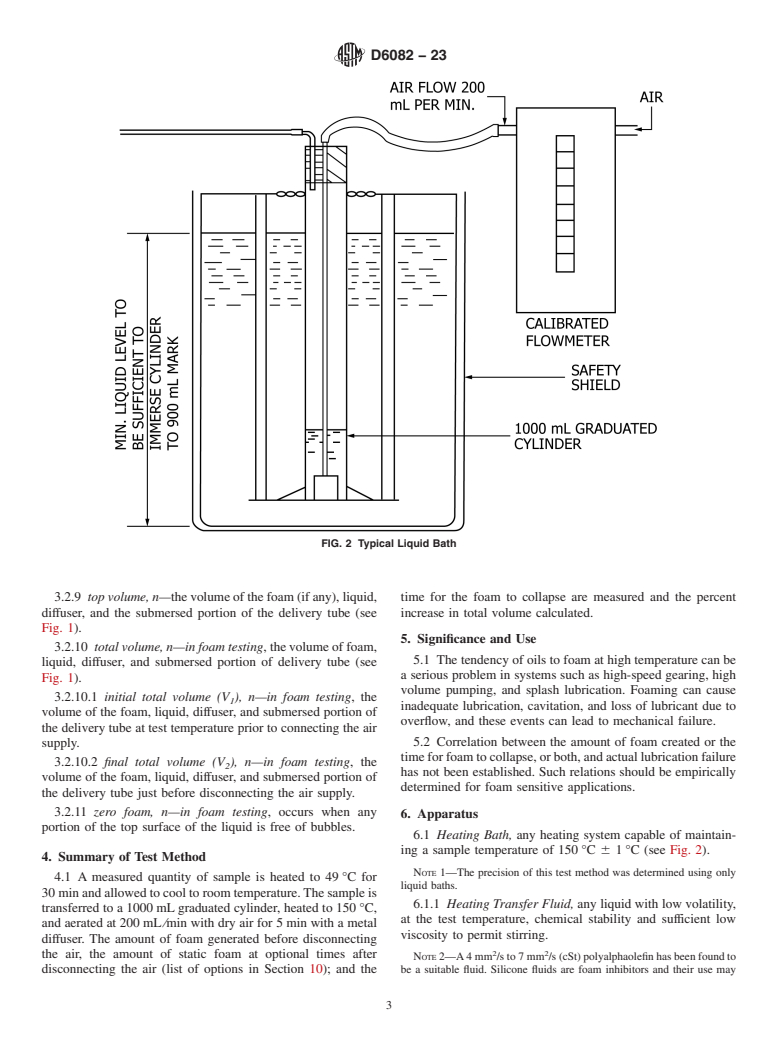

D6082 − 23

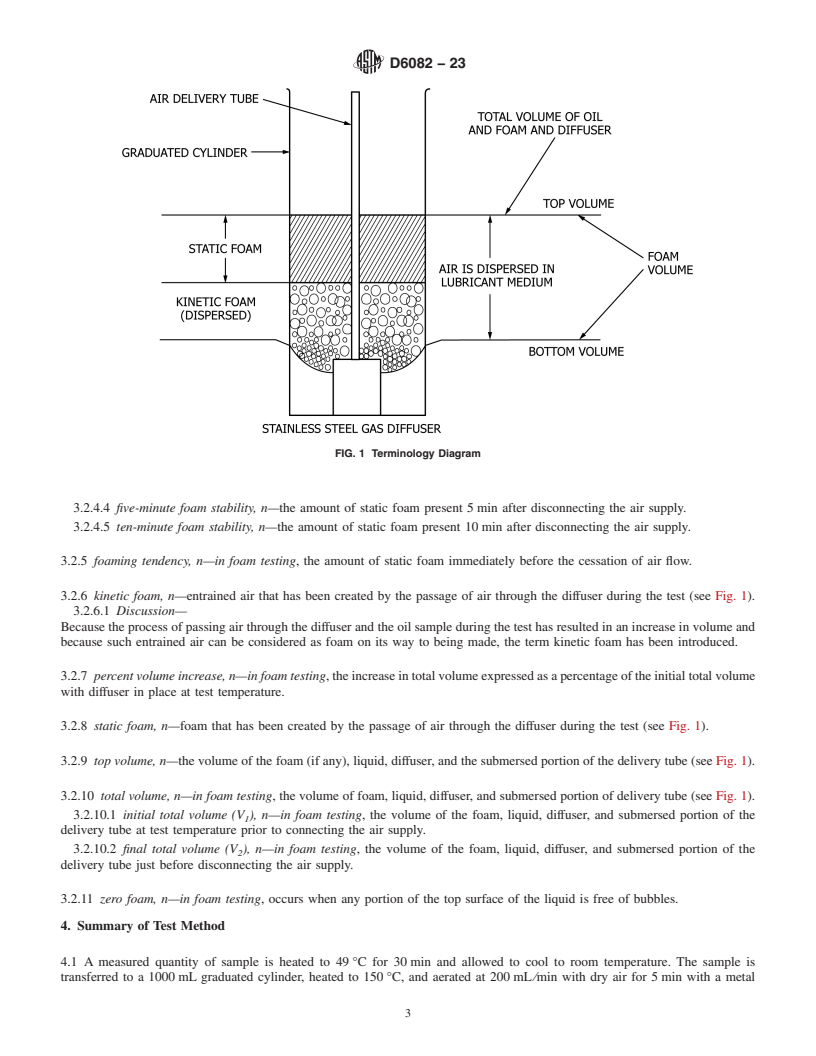

FIG. 1 Terminology Diagram

3.1.5 gas, n—a fluid (such as air) that has

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6082 − 22 D6082 − 23

Standard Test Method for

High Temperature Foaming Characteristics of Lubricating

1

Oils

This standard is issued under the fixed designation D6082; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the procedure for determining the foaming characteristics of lubricating oils (specifically transmission

fluid and motor oil) at 150 °C.

1.2 Foaming characteristics of lubricating oils at temperatures up to 93.5 °C are determined by Test Method D892 or IP 146.

1.3 The values stated in SI units are to be regarded as standard.

1.3.1 Exception—The values given in parentheses are provided for information only.

1.4 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious

medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution

when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional

information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national

law. Users must determine legality of sales in their location.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D892 Test Method for Foaming Characteristics of Lubricating Oils

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

E128 Test Method for Maximum Pore Diameter and Permeability of Rigid Porous Filters for Laboratory Use

E1272 Specification for Laboratory Glass Graduated Cylinders

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.06 on Analysis of Liquid Fuels and Lubricants.

Current edition approved Nov. 1, 2022July 1, 2023. Published November 2022July 2023. Originally approved in 1997. Last previous edition approved in 20172022 as

D6082 – 12 (2017).D6082 – 22. DOI: 10.1520/D6082-22.10.1520/D6082-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6082 − 23

3

2.2 Energy Institute Standards:

IP 146 Standard Method of Test for Foaming Characteristics of Lubricating Oils

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4175.

3.1.2 diffuser, n—for gas, a device for dispersing gas into a liquid (Test Method D892).

3.1.2.1 Discussion—

Although diffusers can be made of either metallic or non-metallic materials, in this test method the diffuser is sintered stainless

steel.

3.1.3 entrained air (or gas), n—in liquids, a two-phase mixture of air (or gas) dispersed in a liquid in which the liquid is the major

component on a volumetric basis.

3.1.3.1 Discussion—

The air (or gas) is in the form of discrete bubbles of about 10 μm to 1000 μm in diameter. The bubbles are not uniformly dispersed.

In time, they rise to the surface to coalesce to form larger bubbles which break or form foam. Subsurface coalescence can also

occur, in which case, the bubbles will rise more rapidly.

3.1.4 foam, n—in liquids, a collection of bubbles formed in or on the surface of a liquid in which the air or gas is the major

component on a volumetric basis.

3.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.