ASTM E1060-85(1995)E01

(Practice)Practice for Interlaboratory Testing of Spectrochemical Methods of Analysis (Withdrawn 1997)

Practice for Interlaboratory Testing of Spectrochemical Methods of Analysis (Withdrawn 1997)

General Information

Standards Content (Sample)

ASTM ELObO 85 m 0759530 0554905 048 -

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation: E 1060 - 85 (Reapproved 1995)”

1916 Race St Phlladeiphla, Pa I 9103

Reprinted from the Annual Book 01 ASTM Standards Copyrght ASTM

If not llsted m the current combmed Index, will appear I” the neXt edltton.

Standard Practice for

Interlaboratory Testing of Spectrochemical Methods of

Analysis’

This standard is issued under the lixed designation E 1060; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (t) indicates an editorial change since the last revision or reapproval.

(1 NOTE-.%&On 11 was added editorially in March 1995.

E 876 Practice for Use of Statistics in the Evaluation of

1. Scope

Spectrochemical Data6

1.1 This practice describes techniques for planning and

conducting an interlaboratory study of a spectrochemical

3. Terminology

method of analysis. It provides instructions for analyzing and

3.1 Definitions-For definitions of terms used in this

interpreting the results, and for writing precision and accu-

practice, refer to Terminology E 135 and Practice E 876.

racy statements.

3.2 Descriptions of Terms Specijk to This Standard:

1.2 The statistical definitions and procedures presented in

3.2.1 repeatability-the precision obtained for analyses

this practice are limited, and are not intended to be exact or

performed within the same laboratory on different days.

rigorous. If statistical procedures beyond the scope of this

NOTE l-In the event a question arises about the uniformity of

practice are required, consult Practices E 177, E 180, E 305,

variances across laboratories, refer to Practice E 69 I.

E 69 1, E 876, or other practices published by ASTM Com-

mittee E-l 1 on Statistical Methods; and STP 335.2

3.2.2 reproducibility-the precision obtained for analyses

1.3 This standard does not purport to address all of the

performed in different laboratories.

safety problems, ly any, associated with its use. It is the

NOTE 2-In the event a question arises about the uniformity of

responsibility of the user of this standard to establish appro-

variances across laboratories, refer to Practice E 69 I.

priate safety and health practices and determine the applica-

3.2.3 systematic error-a displacement of all or most of

bility of regulatory limitations prior to use.

the analytical results from the “true” or reference value that

is caused by some constant or proportional error (bias) in the

analytical method or procedure.

2. Referenced Documents

2.1 ASTM Standards: 4. Significance and Use

135 Terminology Relating to Analytical Chemistry for

4.1 This practice is useful for designing an interlaboratory

Metals, Ores, and Related Materials3

test, for evaluating the precision and accuracy of spectro-

173 Practice for Conducting Interlaboratory Studies of

chemical methods of analysis, and for writing precision and

Methods for Chemical Analysis of Metals3

accuracy statements.

177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods4

5. Procedure for Cooperative Testing

180 Practice for Determining Precision of ASTM

5.1 The procedures described in this section shall be

Methods for Analysis and Testing of Industrial

performed or administered by a task group with a chairman:

Chemicals5

5.1.1 Select cooperating laboratories. Five or more labora-

305 Practice for Establishing and Controlling Spectro-

tories are recommended to demonstrate the reliability of the

chemical Analytical Curves3

method. (See Note 3.) Fewer laboratories may be used;

69 1 Practice for Conducting an Interlaboratory Study to

however, no fewer than three laboratories shall participate in

Determine the Precision of a Test Method4

any evaluation. Also, the product of the number of laborato-

826 Practice for Testing Homogeneity of Materials for

ries, test specimens, and determinations per element shall

the Development of Reference Material@

equal 45 or greater. For supporting information, refer to STP

335.

NOTE 3-k is the opinion of some that with data from fewer than

1 Ttxs prachce IS under the jurisdiction of ASTM CommIttee E-I on AnalytIcal

eight laboratories, reproducibility calculations are not reliable, conse-

Chemistry of Metals, Ores and Related Materials and is the dwect responsibihty of

Subcommittee EOI .22 on Statistics and Quality Control.

quently statements on reproducibility should not be included in the

Current edition approved Aug. I, 1985. Published October 1985.

standard method.

2 Manual for Conducmzg an Interlaboramry Study of a Test Method, ASTM

5.1.2 Contact each of the laboratories selected and obtain

STP 335, ASTM, 1963. Available from University Microfilms International. 300

North Zeeb Road, Ann Arbor, MI 48 106.

a commitment to cooperate in the test program.

J Annrral Book oJASTM SIanduds, Vol 03.05.

5.1.3 Send a copy of the method to be evaluated to each

4 Annml Book ofASTM Standards, Vol 14.02.

of the cooperating laboratories. This is to ensure that each

5 Annual Book oJASTM Srandard.7, Vol 15.05.

6 Annual Book o/ASTM Standards, Vol 03.06. laboratory understands the procedure, and has the necessary

ASTM ELObO 85 N 0759530 0554906 TBY -

that are to be reported by the cooperating laboratory (see Fig.

equipment and qualified personnel. A laboratory should

X2.1).

practice an unfamiliar procedure prior to performing the

5.1.8.7 Instructions from the task group specifying the

interlaboratory test. All cooperating laboratories must agree

exact order for analyzing reference materials and specimens

upon the exact manner in which the test method is to be

to randomize data, the element(s) to be determined in each

implemented. Resolve any question concerning the method or

specimen, and the number of determinations for each

how it is to be implemented prior to starting the test.

element.

5.1.3.1 “Practice” test specimens will be furnished by the

5.1.8.8 Instructions specifying the number of replications

task group when requested.

for reference materials and specimens. Generally, the analyt-

5.1.4 Establish a timetable with firm deadlines (see Fig.

ical curve for each element shall be established with four

X 1.1). The task group is responsible for timely data evalua-

replications (runs) on each reference material. Use the “4n”

tion and publication of results.

rule given in Practice E 305 for the cooperative test, unless

5.1.5 Select test specimens to adequately cover the analyt-

the task group specifies otherwise. Define the number of

ical range of each element as specified in the scope of the

replications (runs) that will be averaged to produce an

method being tested. The test specimens shall span the low,

analysis (average result). The task group shall specify how

medium, and high portions of the specified range. However,

individual laboratories are to treat outliers that may occur

for narrow ranges, test specimens at two levels of concentra-

during the replications.

tion may be adequate. Specimens for testing shall be certified

5.1.8.9 Instructions for documenting any specific depar-

reference materials if possible. If it is necessary to use

ture(s) from the method being used (see Fig. X2.2).

uncertified reference materials for testing, the composition

5.1.8.10 Instructions specifying the number of significant

shall be established using the following guidelines:

figures that are to be reported for each element. For purposes

5.1.5.1 Confirm the homogeneity of the test specimens, as

of statistical evaluation, the number of significant figures

heterogeneous specimens will affect the precision estimates

should be one more than normally is required.

of the method. If a homogeneity test is required, refer to

5.1.8.11 Instructions for reporting the final results (see

Practice E 826.

Fig. X2.3). To simplify data evaluation, report all values for

5.1.5.2 Determine each element using more than one

an element on the same form. Use a separate form for each

analytical technique when possible, excluding the technique

element.

being tested.

5.1.9 Whenever possible, specify allowable (acceptable)

5.1.6 Select reference materials to be used for calibration

analytical tolerance for the method in advance of testing.

of the instrument. Where possible, use reference materials

These tolerances shall be determined by the task group and

and test specimens that have similar compositions, metallur-

should be based on:

gical structure and other features.

5.1.9.1 The analytical performance required to meet the

5.1.7 Provide the same reference materials and test speci-

need.

mens to all participants:

5.1.9.2 Previous experience with similar methods of anal-

5.1.7.1 If solutions are to be analyzed, send a separate set

ysis, if available.

of reference and specimen solutions to each cooperating

5.1.9.3 Knowledge of typical bias between laboratories for

laboratory.

the material analyzed and analytical technique used.

5.1.7.2 If powders or chips are to be analyzed, send

separate portions of the reference materials and specimens to

NOTE 4-The analytical tolerance of a method may be very broad or

each cooperating laboratory.

narrow depending on its intended use. It is the responsibility of the task

5.1.7.3 If solid specimens (such as disks) are employed, group to determine the acceptable tolerance, recognizing that in some

cases it may not be possible to establish a tolerance prior to evaluation.

send the same set of reference materials and test specimens

Similarly, the criteria for laboratory bias should be defined in advance of

to each laboratory. However, when certified reference mate-

the test, for example, by establishing a difference allowed between the

rials of known and acceptable homogeneity are used, send

extreme laboratory and the next closest laboratory.

separate pieces to each cooperator. This will expedite testing.

When all laboratories must test the same reference materials

5.1.10 Maintain records identifying the cooperating labo-

and specimens, send them to Laboratory A and request that

ratories and analysts. Assign a code to each laboratory (see

they be returned to the task group. The task group will then Fig. X1.1).

send the same reference materials and specimens to Labora-

5.1.11 Maintain data from all laboratories for each ele-

tory B for analysis. This round-robin procedure will be

ment determined on a copy of the evaluation form shown in

continued until all cooperators have completed the test.

Fig. X1.3.

5.1.8 Send the items listed below to each of the cooper-

5.1.12 Evaluate the cooperative test data as described in

ating laboratories, preferably in the same package or at the

Section 6 and recommend the disposition of the method

same time (see Fig. Xl .2):

including, but not limited to, the following: (I) acceptance,

5.1.8.1 Reference materials to be used. (2) rejection, (3) additional testing, or (4) acceptance of the

5.1.8.2 Test specimens to be analyzed. method, but with reduced analytical tolerances as defined in

5.1.8.3 Instructions specifying the method or procedure to 5.1.9. Submit all test data, along with a summary of the test

be tested. data and the recommendation to the subcommittee

5.1.8.4 Copy of the method or procedure to be used. chairman, who, in turn, submits the material to the

5.1.8.5 Forms to be completed by cooperators (see Figs. Chairman of ASTM Committee E-2.

X2.1, X2.2, and X2.3). 5.1.13 Following the guidelines given in Sections 7 and 8,

5.1.8.6 Instructions that specify the operating conditions

write precision and accuracy statements for inclusion in the

ASTM ELObO 85 - 0759510 0554907 910 m

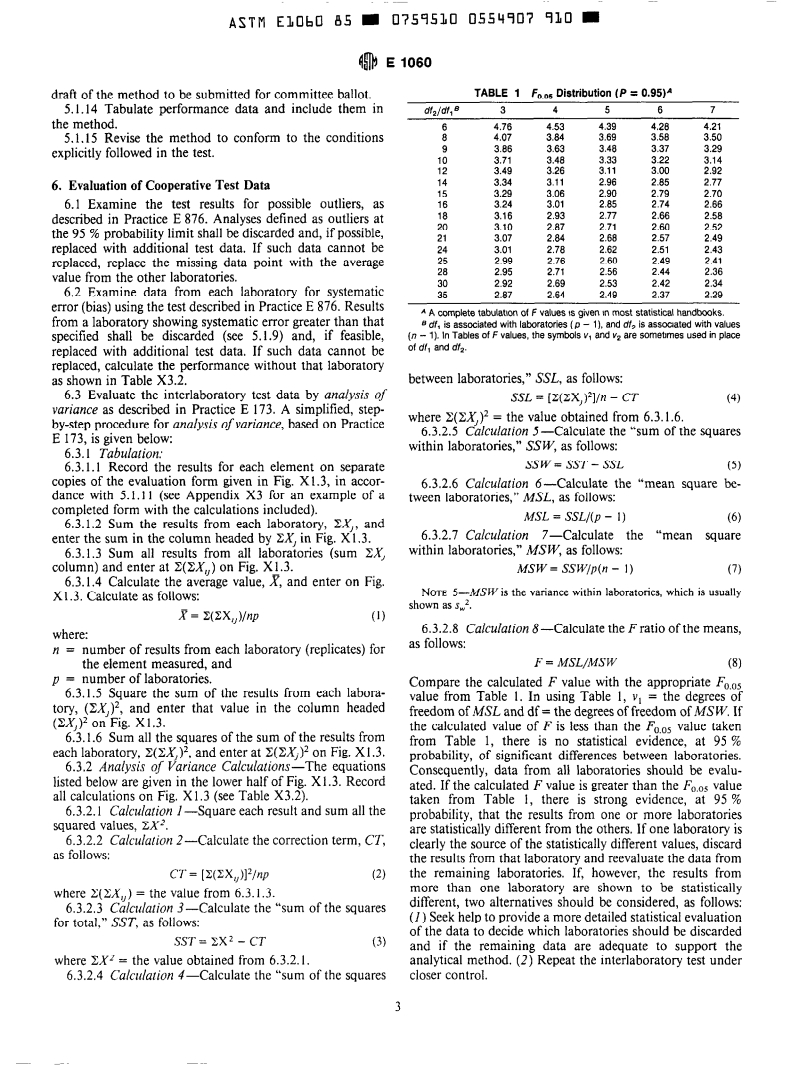

TABLE 1 f0.05 Distribution (P = 0.95)”

draft of the method to be submitted for committee ballot.

3 4 5 6 7

5.1.14 Tabulate performance data and include them in df,/df,B

the method.

6 4.76 4.53 4.39 4.26 4.21

4.07 3.84 3.69 3.50 3.50

5.1.15 Revise the method to conform to the conditions

9 3.86 3.63 3.48 3.37 3.29

explicitly followed in the test.

10 3.71 3.48 3.33 3.22 3.14

3.49 3.26 3.11 3.00 2.92

14 3.34 3.11 2.96 2.05 2.77

6. Evaluation of Cooperative Test Data

15 3.29 3.06 2.90 2.79 2.70

16 3.24 3.01 2.05 2.74 2.66

6.1 Examine the test results for possible outliers, as

18 3.16 2.93 2.77 2.66 2.50

described in Practice E 876. Analyses defined as outliers at

3.10 2.07 2.71 2.60 2.52

the 95 % probability limit shall be discarded and, if possible,

21 3.07 2.04 2.68 2.57 2.49

replaced with additional test data. If such data cannot be 24 3.01 2.70 2.62 2.51 2.43

25 2.99 2.76 2.60 2.49 2.41

replaced, replace the missing data point with the average

28 2.95 2.71 2.56 2.44 2.36

value from the other laboratories.

2.92 2.69 2.53 2.42 2.34

6.2 Examine data from each laboratory for systematic

35 2.87 2.64 2.49 2.37 2.29

error (bias) using the test described in Practice E 876. Results

* A complete tabulation of F values !s given tn most statistical handbooks.

from a laboratory showing systematic error greater than that 8 df, is associated with laboratories (p - 1). and df, is associated with values

(n - 1). In Tables of F values, the symbols V, and V, are SometImes used in place

specified shall be discarded (see 5.1.9) and, if feasible,

of df, and df,.

replaced with additional test data. If such data cannot be

replaced, calculate the performance without that laboratory

between laboratories,” SSL, as follows:

as shown in Table X3.2.

6.3 Evaluate the interlaboratory test data by analysis of

SSL = [.Z(ZX,)2]/n - CT

(4)

variance as described in Practice E 173. A simplified, step-

where Z(ZX,)’ = the value obtained from 6.3.1.6.

by-step procedure for analysis of variance, based on Practice

6.3.2.5 Calculation 5-Calculate the “sum of the squares

E 173, is given below:

within laboratories,” SSW, as follows:

6.3.1 Tabulation.

SSW = SST - SSL

(5)

6.3.1.1 Record the results for each element on separate

copies of the evaluation form given in Fig. X1.3, in accor-

6.3.2.6 Calculation 6-Calculate the “mean square be-

dance with 5.1.11 (see Appendix X3 for an example of a

tween laboratories,” MSL, as follows:

completed form with the calculations included).

MSL = SSL/(p - 1)

(6)

6.3.1.2 Sum the results from each laboratory, ZX,, and

6.3.2.7 Calculation 7-Calculate the “mean square

enter the sum in the column headed by ZX, in Fig. Xl .3.

within laboratories,” MS W, as follows:

6.3.1.3 Sum all results from all laboratories (sum ZX,

column) and enter at Z(ZX,,) on Fig. X1.3.

MSW = SSW/p(n - 1)

(7)

6.3.1.4 Calculate the average value, x, and enter on Fig.

NOTE 5-MSW is the variance wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.