ASTM E77-98(2003)

(Test Method)Standard Test Method for Inspection and Verification of Thermometers

Standard Test Method for Inspection and Verification of Thermometers

SIGNIFICANCE AND USE

The test method described in this standard will ensure that the thermometers listed in Specification E 1 will indicate temperatures within the maximum scale errors listed, be compatible with the apparatus, and serve the purpose for which they were designed.Fig. 1

Thermometers that do not pass the visual and dimensional inspection tests may give erroneously high or low temperature readings, or may not fit into existing equipment used in ASTM methods. If the pigment in the scale etchings washes out or fades, the thermometer will be difficult to read. Improper annealing of the bulb, as determined by the bulb stability test, will result in thermometer readings rapidly changing with time and use. For accurate temperature measurements the scale readings of the thermometer should be verified as described in this test method.

FIG. 1 Oven for Permanency of Pigment Test

SCOPE

1.1 This test method covers visual and dimensional inspection, test for permanency of pigment, test for bulb stability, and test for scale accuracy to be used in the verification of liquid-in-glass thermometers as specified in Specification E 1. However, these procedures may be applied to other liquid-in-glass thermometers.

Note 1—The use of NIST SP250-23 is recommended.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 77 – 98 (Reapproved 2003)

Standard Test Method for

Inspection and Verification of Thermometers

ThisstandardisissuedunderthefixeddesignationE77;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.3 partial-immersion thermometer, n—a liquid-in-glass

thermometer designed to indicate temperature correctly when

1.1 This test method covers visual and dimensional inspec-

the bulb and a specified part of the stem are exposed to the

tion,testforpermanencyofpigment,testforbulbstability,and

temperature being measured.

test for scale accuracy to be used in the verification of

3.1.4 total-immersion thermometer, n—a liquid-in-glass

liquid-in-glass thermometers as specified in Specification E1.

thermometer designed to indicate temperature correctly when

However, these procedures may be applied to other liquid-in-

just that portion of the thermometer containing the liquid is

glass thermometers.

exposed to the temperature being measured.

NOTE 1—The use of NIST SP250-23 is recommended.

3.2 Definitions of Terms Specific to This Standard:

1.2 This standard does not purport to address all of the 3.2.1 calibration, n—thedeterminationoftheindicationsof

safety problems, if any, associated with its use. It is the a thermometer with respect to temperatures established by a

responsibility of the user of this standard to establish appro- standard resulting in scale corrections to be applied when

priate safety and health practices and determine the applica- maximum accuracy is required.

bility of regulatory limitations prior to use. 3.2.2 reference point, n—a temperature at which a ther-

mometer is checked for changes in the bulb volume.

2. Referenced Documents

3.2.3 verification, n—the process of testing a thermometer

2.1 ASTM Standards:

for compliance with specifications.

E1 Specification for ASTM Thermometers 3.2.4 verification temperatures, n—the specified tempera-

E344 Terminology Relating to Thermometry and Hydrom-

tures at which thermometers are tested for compliance with

etry scale error limits.

3.2.5 Other descriptions of terms relating to thermometers

3. Terminology

are included in Sections 3 and 17 of Specification E1.

3.1 Definitions:

4. Significance and Use

3.1.1 The definitions given in Terminology E344 apply.

Some that are considered essential to this standard are given

4.1 The test method described in this standard will ensure

below. that the thermometers listed in Specification E1 will indicate

3.1.2 complete-immersion thermometer, n—a liquid-in-

temperatures within the maximum scale errors listed, be

glass thermometer, not specified in ASTM documents, de- compatiblewiththeapparatus,andservethepurposeforwhich

signed to indicate temperature correctly when the entire

they were designed.Fig. 1

thermometer is exposed to the temperature being measured. 4.2 Thermometers that do not pass the visual and dimen-

sional inspection tests may give erroneously high or low

temperature readings, or may not fit into existing equipment

This test method is under the jurisdiction of ASTM Committee E20 on

used in ASTM methods. If the pigment in the scale etchings

Temperature Measurement and is the direct responsibility of Subcommittee E20.05

on Liquid-in-Glass Thermometers and Hydrometers. washes out or fades, the thermometer will be difficult to read.

Current edition approved Nov. 1, 2003. Published November 2003. Originally

Improper annealing of the bulb, as determined by the bulb

approved in 1949. Last previous edition approved in 1998 as E 77–98.

stability test, will result in thermometer readings rapidly

“Liquid-in-GlassThermometer Calibration Service,” NISTSpecial Publication

changing with time and use. For accurate temperature mea-

250-23, 1988, Superintendent of Documents, U.S. Government Printing Office,

Washington, DC 20402-9325.

surements the scale readings of the thermometer should be

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

verified as described in this test method.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 77 – 98 (2003)

FIG. 1 Oven for Permanency of Pigment Test

5. Apparatus 5.5 Metal Block Baths—The bulb stability test may be

conducted with a variety of devices. Metal block baths and the

5.1 Graduated Metal Scales or Templates—Maximum and

salt and tin comparator baths, described in Appendix X1, are

minimum specified linear dimensions are measured with

examples of the type of equipment that has been found to be

graduatedmetalsalesandtemplatesonwhichlinesareruledat

suitable for this purpose.

suitable distances from reference points corresponding to the

5.6 Primary Standard Thermometer—Theprimarystandard

maximumandminimumvaluesoftheseveralspecifieddimen-

thermometer in the range from−183 to 630 °C (−297 to 1166

sions.

°F) is the platinum-resistance thermometer. Temperatures are

5.2 Micrometers and Ring Gages—Specified diameters of

not measured directly with this instrument. Its electrical

ASTM thermometers are checked using micrometers, or more

resistance is determined by comparison with a standard resis-

conveniently with ring gages consisting of metal plates in

tor, using a potentiometer, a Kelvin-type double bridge, or a

which holes have been formed corresponding to the maximum

Wheatstone bridge, (preferably of the Mueller type) or an AC

and minimum values of the several specified dimensions. The

resistance bridge. Temperatures may then be calculated using

thickness of such gages should approximate the diameters of

suitable resistance-temperature equations. In order that it shall

the holes to minimize errors resulting from the axis of the

be satisfactory for such use, the thermometer should meet the

thermometer stem being other than normal to the plane of the

requirement that the ratio of resistances at the steam and ice

gage. When specified, diameters may also be checked with

pointsshallbegreaterthan1.3925.Morecompleteinformation

conventional snap gages having plane parallel working faces.

on the construction and use of primary standard thermometers

5.3 Comparators—Comparators are required for verifica-

may be obtained from NIST SP250-22.

tionofscaleaccuracyofliquid-in-glassthermometers.Suitable

types are described in Appendix X1.

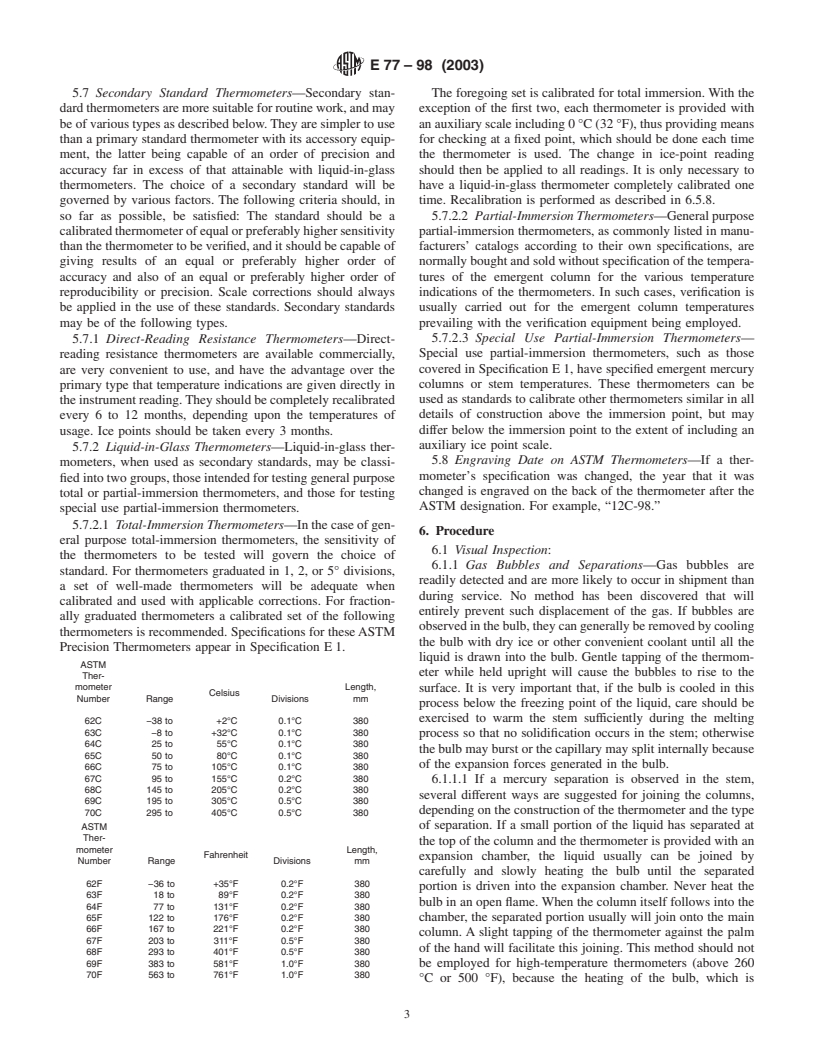

5.4 Oven—The test for permanency of pigment may be

“Platinum Resistance Thermometer Calibrations,” NIST Special Publication

conducted with any suitable oven, such as the type shown in

250-22, Superintendent of Documents, U.S. Government Printing Office, Washing-

Fig. 1. ton, DC 20402-9325.

E 77 – 98 (2003)

5.7 Secondary Standard Thermometers—Secondary stan- The foregoing set is calibrated for total immersion.With the

dardthermometersaremoresuitableforroutinework,andmay exception of the first two, each thermometer is provided with

beofvarioustypesasdescribedbelow.Theyaresimplertouse anauxiliaryscaleincluding0°C(32°F),thusprovidingmeans

than a primary standard thermometer with its accessory equip- for checking at a fixed point, which should be done each time

ment, the latter being capable of an order of precision and the thermometer is used. The change in ice-point reading

accuracy far in excess of that attainable with liquid-in-glass should then be applied to all readings. It is only necessary to

thermometers. The choice of a secondary standard will be have a liquid-in-glass thermometer completely calibrated one

governed by various factors. The following criteria should, in time. Recalibration is performed as described in 6.5.8.

so far as possible, be satisfied: The standard should be a 5.7.2.2 Partial-Immersion Thermometers—Generalpurpose

calibratedthermometerofequalorpreferablyhighersensitivity partial-immersion thermometers, as commonly listed in manu-

thanthethermometertobeverified,anditshouldbecapableof facturers’ catalogs according to their own specifications, are

giving results of an equal or preferably higher order of normallyboughtandsoldwithoutspecificationofthetempera-

accuracy and also of an equal or preferably higher order of tures of the emergent column for the various temperature

reproducibility or precision. Scale corrections should always indications of the thermometers. In such cases, verification is

be applied in the use of these standards. Secondary standards usually carried out for the emergent column temperatures

may be of the following types. prevailing with the verification equipment being employed.

5.7.2.3 Special Use Partial-Immersion Thermometers—

5.7.1 Direct-Reading Resistance Thermometers—Direct-

Special use partial-immersion thermometers, such as those

reading resistance thermometers are available commercially,

covered in Specification E1, have specified emergent mercury

are very convenient to use, and have the advantage over the

columns or stem temperatures. These thermometers can be

primary type that temperature indications are given directly in

used as standards to calibrate other thermometers similar in all

theinstrumentreading.Theyshouldbecompletelyrecalibrated

details of construction above the immersion point, but may

every 6 to 12 months, depending upon the temperatures of

differ below the immersion point to the extent of including an

usage. Ice points should be taken every 3 months.

auxiliary ice point scale.

5.7.2 Liquid-in-Glass Thermometers—Liquid-in-glass ther-

5.8 Engraving Date on ASTM Thermometers—If a ther-

mometers, when used as secondary standards, may be classi-

mometer’s specification was changed, the year that it was

fiedintotwogroups,thoseintendedfortestinggeneralpurpose

changed is engraved on the back of the thermometer after the

total or partial-immersion thermometers, and those for testing

ASTM designation. For example, “12C-98.”

special use partial-immersion thermometers.

5.7.2.1 Total-Immersion Thermometers—Inthecaseofgen-

6. Procedure

eral purpose total-immersion thermometers, the sensitivity of

6.1 Visual Inspection:

the thermometers to be tested will govern the choice of

6.1.1 Gas Bubbles and Separations—Gas bubbles are

standard. For thermometers graduated in 1, 2, or 5° divisions,

readily detected and are more likely to occur in shipment than

a set of well-made thermometers will be adequate when

during service. No method has been discovered that will

calibrated and used with applicable corrections. For fraction-

entirely prevent such displacement of the gas. If bubbles are

ally graduated thermometers a calibrated set of the following

observedinthebulb,theycangenerallyberemovedbycooling

thermometers is recommended. Specifications for theseASTM

the bulb with dry ice or other convenient coolant until all the

Precision Thermometers appear in Specification E1.

liquid is drawn into the bulb. Gentle tapping of the thermom-

ASTM

eter while held upright will cause the bubbles to rise to the

Ther-

mometer Length,

surface. It is very important that, if the bulb is cooled in this

Celsius

Number Range Divisions mm

process below the freezing point of the liquid, care should be

exercised to warm the stem sufficiently during the melting

62C −38 to +2°C 0.1°C 380

63C −8 to +32°C 0.1°C 380

process so that no solidification occurs in the stem; otherwise

64C 25 to 55°C 0.1°C 380

thebulbmayburstorthecapillarymaysplitinternallybecause

65C 50 to 80°C 0.1°C 380

of the expansion forces generated in the bulb.

66C 75 to 105°C 0.1°C 380

67C 95 to 155°C 0.2°C 380

6.1.1.1 If a mercury separation is observed in the stem,

68C 145 to 205°C 0.2°C 380

several different ways are suggested for joining the columns,

69C 195 to 305°C 0.5°C 380

dependingontheconstructionofthethermometerandthetype

70C 295 to 405°C 0.5°C 380

of separation. If a small portion of the liquid has separated at

ASTM

Ther-

the top of the column and the thermometer is provided with an

mometer Length,

Fahrenheit

expansion chamber, the liquid usually can be joined by

Number Range Divisions mm

carefully and slowly heating the bulb until the separated

62F −36 to +35°F 0.2°F 380

portion is driven into the expansion chamber. Never heat the

63F 18 to 89°F 0.2°F 380

bulb in an open flame.When the column itself follows into the

64F 77 to 131°F 0.2°F 380

65F 122 to 176°F 0.2°F 380 chamber, the separated portion usually will join onto the main

66F 167 to 221°F 0.2°F 380

column. A slight tapping of the thermometer against the palm

67F 203 to 311°F 0.5°F 380

of the hand will facilitate this joining. This method should not

68F 293 to 401°F 0.5°F 380

69F 383 to 581°F 1.0°F 380 be employed for high-temperature thermometers (above 260

70F 563 to 761°F 1.0°F 380

°C or 500 °F), because the heating of the bulb, which is

E 77 – 98 (2003)

necessary to drive the liquid into the expansion chamber, may Undertheseconditionsoxidationofthemercurywilloccurand

overheat the glass and either break the bulb, because of the willnormallybeevidencedbytheproductionofcrystalsofred

pressureofthegas,ordestroytheaccuracyofthethermometer oxide of mercury after 10 to 12 h of exposure.

by expanding the bulb. Thermometers that have a contraction

6.1.4 Glass Faults—Glass faults may be of various types.

chamber below the lowest graduation are likely to develop

Any stones or striae that distort the bore or its appearance

separations either in the chamber or above it. It is frequently

should be cause for rejection. Strains in the glass as observed

possibletojoinsuchseparationsbycoolingthethermometerso

withapolarizedlightstraingagenearenlargementsinthestem

that the separated portion as well as the main column both

orbore,oratthetopofthethermometer,aredetrimental.Ifso,

stand in the chamber. Tapping the tube against the hand or the

severe fire cracks may later occur. Strains near the bulb are

bulb on a soft spongy material, such as a rubber stopper,

indicativeofincompleteglassstabilizationandareparticularly

usually will bring the liquid together. For more stubborn

objectionable in thermometers for use above 150 °C (302 °F).

separations it may be necessary to cool the bulb in dry ice to a The test for bulb stability will normally serve to reject high

point low enough to bring all of the liquid into the bulb itself.

range thermometers in which this defect is most significant.

Bysoftlytappingonasoftspongymaterialoragainstthehand

6.2 Dimensional Inspection

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.