ASTM D2783-03(2014)

(Test Method)Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-Ball Method)

Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-Ball Method)

SIGNIFICANCE AND USE

5.1 This test method, used for specification purposes, differentiates between lubricating fluids having low, medium, and high level of extreme-pressure properties. The user of this method should determine to his own satisfaction whether results of this test procedure correlate with field performance or other bench test machines.

SCOPE

1.1 This test method covers the determination of the load-carrying properties of lubricating fluids. The following two determinations are made:

1.1.1 Load-wear index (formerly Mean-Hertz load).

1.1.2 Weld point by means of the four-ball extreme-pressure (EP) tester.

1.2 For the determination of the load-carrying properties of lubricating greases, see Test Method D2596.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2783 − 03 (Reapproved 2014)

Standard Test Method for

Measurement of Extreme-Pressure Properties of Lubricating

Fluids (Four-Ball Method)

This standard is issued under the fixed designation D2783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

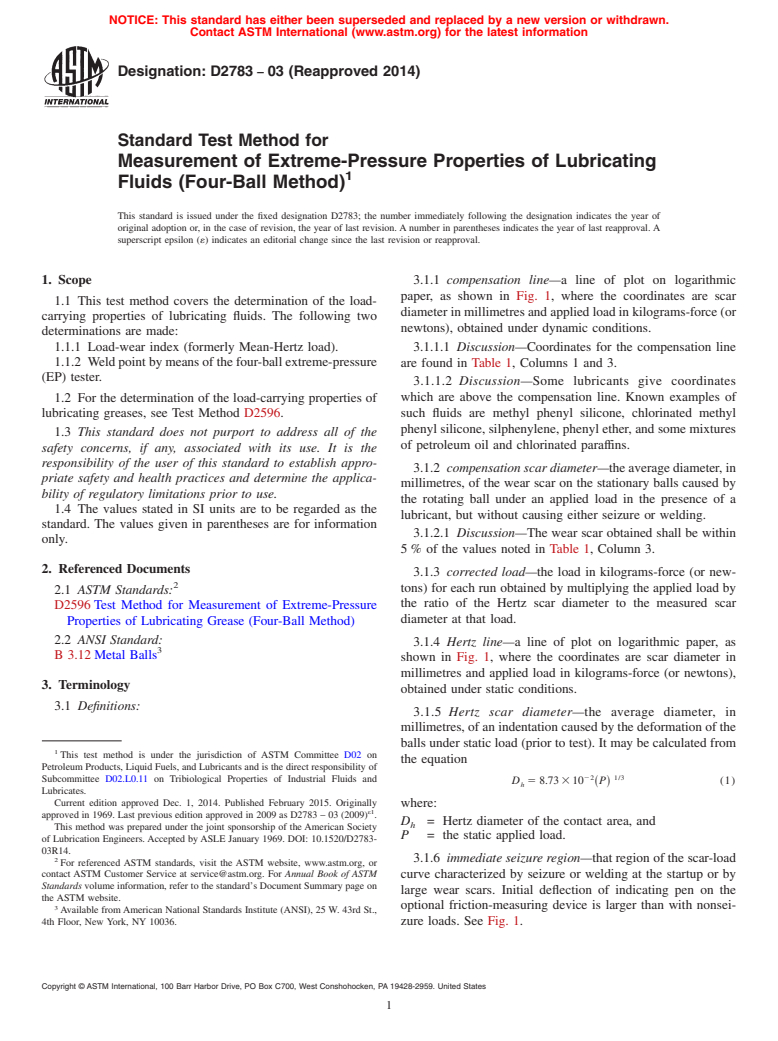

1. Scope 3.1.1 compensation line—a line of plot on logarithmic

paper, as shown in Fig. 1, where the coordinates are scar

1.1 This test method covers the determination of the load-

diameter in millimetres and applied load in kilograms-force (or

carrying properties of lubricating fluids. The following two

newtons), obtained under dynamic conditions.

determinations are made:

1.1.1 Load-wear index (formerly Mean-Hertz load). 3.1.1.1 Discussion—Coordinates for the compensation line

1.1.2 Weldpointbymeansofthefour-ballextreme-pressure

are found in Table 1, Columns 1 and 3.

(EP) tester.

3.1.1.2 Discussion—Some lubricants give coordinates

1.2 For the determination of the load-carrying properties of which are above the compensation line. Known examples of

lubricating greases, see Test Method D2596. such fluids are methyl phenyl silicone, chlorinated methyl

phenyl silicone, silphenylene, phenyl ether, and some mixtures

1.3 This standard does not purport to address all of the

of petroleum oil and chlorinated paraffins.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.2 compensation scar diameter—the average diameter, in

priate safety and health practices and determine the applica-

millimetres, of the wear scar on the stationary balls caused by

bility of regulatory limitations prior to use.

the rotating ball under an applied load in the presence of a

1.4 The values stated in SI units are to be regarded as the

lubricant, but without causing either seizure or welding.

standard. The values given in parentheses are for information

3.1.2.1 Discussion—The wear scar obtained shall be within

only.

5 % of the values noted in Table 1, Column 3.

2. Referenced Documents

3.1.3 corrected load—the load in kilograms-force (or new-

tons) for each run obtained by multiplying the applied load by

2.1 ASTM Standards:

the ratio of the Hertz scar diameter to the measured scar

D2596 Test Method for Measurement of Extreme-Pressure

diameter at that load.

Properties of Lubricating Grease (Four-Ball Method)

2.2 ANSI Standard:

3.1.4 Hertz line—a line of plot on logarithmic paper, as

B 3.12 Metal Balls

shown in Fig. 1, where the coordinates are scar diameter in

millimetres and applied load in kilograms-force (or newtons),

3. Terminology

obtained under static conditions.

3.1 Definitions:

3.1.5 Hertz scar diameter—the average diameter, in

millimetres, of an indentation caused by the deformation of the

balls under static load (prior to test). It may be calculated from

This test method is under the jurisdiction of ASTM Committee D02 on

the equation

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

22 1/3

Subcommittee D02.L0.11 on Tribiological Properties of Industrial Fluids and

D 5 8.73 310 P (1)

~ !

h

Lubricates.

Current edition approved Dec. 1, 2014. Published February 2015. Originally

where:

ε1

approved in 1969. Last previous edition approved in 2009 as D2783 – 03 (2009) .

D = Hertz diameter of the contact area, and

h

This method was prepared under the joint sponsorship of the American Society

P = the static applied load.

of Lubrication Engineers. Accepted by ASLE January 1969. DOI: 10.1520/D2783-

03R14.

2 3.1.6 immediate seizure region—that region of the scar-load

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

curve characterized by seizure or welding at the startup or by

Standards volume information, refer to the standard’s Document Summary page on

large wear scars. Initial deflection of indicating pen on the

the ASTM website.

3 optional friction-measuring device is larger than with nonsei-

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. zure loads. See Fig. 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2783 − 03 (2014)

index is the average of the sum of the corrected loads

determinedforthetenappliedloadsimmediatelyprecedingthe

weld point.

3.1.10 weld point—under the conditions of this test, the

lowest applied load in kilograms at which the rotating ball

welds to the three stationary balls, indicating the extreme-

pressure level of the lubricants-force (or newtons) has been

exceeded.

3.1.10.1 Discussion—Some lubricants do not allow true

welding, and extreme scoring of the three stationary balls

results. In such cases, the applied load which produces a

maximum scar diameter of 4 mm is reported as the weld point.

ABE—Compensation line.

B—Point of last nonseizure load.

4. Summary of Test Method

BC—Region of incipient seizure.

CD—Region of immediate seizure.

4.1 The tester is operated with one steel ball under load

D—Weld point.

rotating against three steel balls held stationary in the form of

FIG. 1 Schematic Plot of Scar Diameter Versus Applied Load

a cradle. Test lubricant covers the lower three balls. The

rotating speed is 1760 6 40 rpm. The machine and test

TABLE 1 Suggested Form for Recording Test Results

lubricant are brought to 18 to 35°C (65 to 95°F) and then a

Column 2 Column 3 Column 5

Column 1

series of tests of 10-s duration are made at increasing loads

Column4

Applied Average Scar Compensation Corrected

LD until welding occurs. Ten tests are made below the welding

h

A

Diameter, Scar Diameter, Load,

Load, kg

Factor

A

(L) point. If ten loads have not been run when welding occurs and

mm (X) mm kg (LD /X)

h

the scars at loads below seizure are within 5 % of the

6 0.95

8 1.40

compensation line (AB Fig. 1) no further runs are necessary.

10 0.21 1.88

The total can be brought to ten by assuming that loads below

13 0.23 2.67

16 0.25 3.52 the last nonseizure load will produce wear scars equal to the

20 0.27 4.74

“compensationscardiameter.”Valuesofthese“assumed”scars

24 0.28 6.05

are given in Table 1. For clarification of “last nonseizure load”

32 0.31 8.87

and “weld point” see Fig. 1.

40 0.33 11.96

50 0.36 16.10

63 0.39 21.86

5. Significance and Use

80 0.42 30.08

100 0.46 40.5

5.1 This test method, used for specification purposes, dif-

126 0.50 55.2

ferentiates between lubricating fluids having low, medium, and

160 0.54 75.8

high level of extreme-pressure properties. The user of this

200 0.59 102.2

250 137.5

method should determine to his own satisfaction whether

315 187.1

resultsofthistestprocedurecorrelatewithfieldperformanceor

400 258

other bench test machines.

500 347

620 462

800 649

6. Apparatus

A

To convert from kilograms-force to newtons, multiply by 9.806. 5

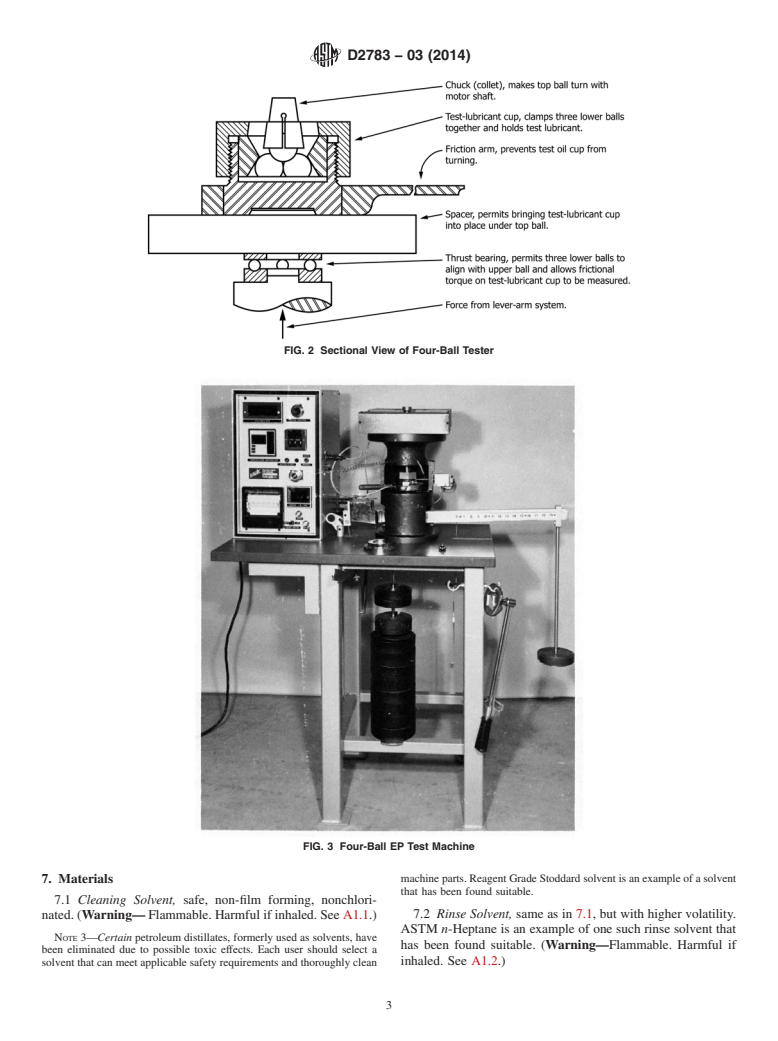

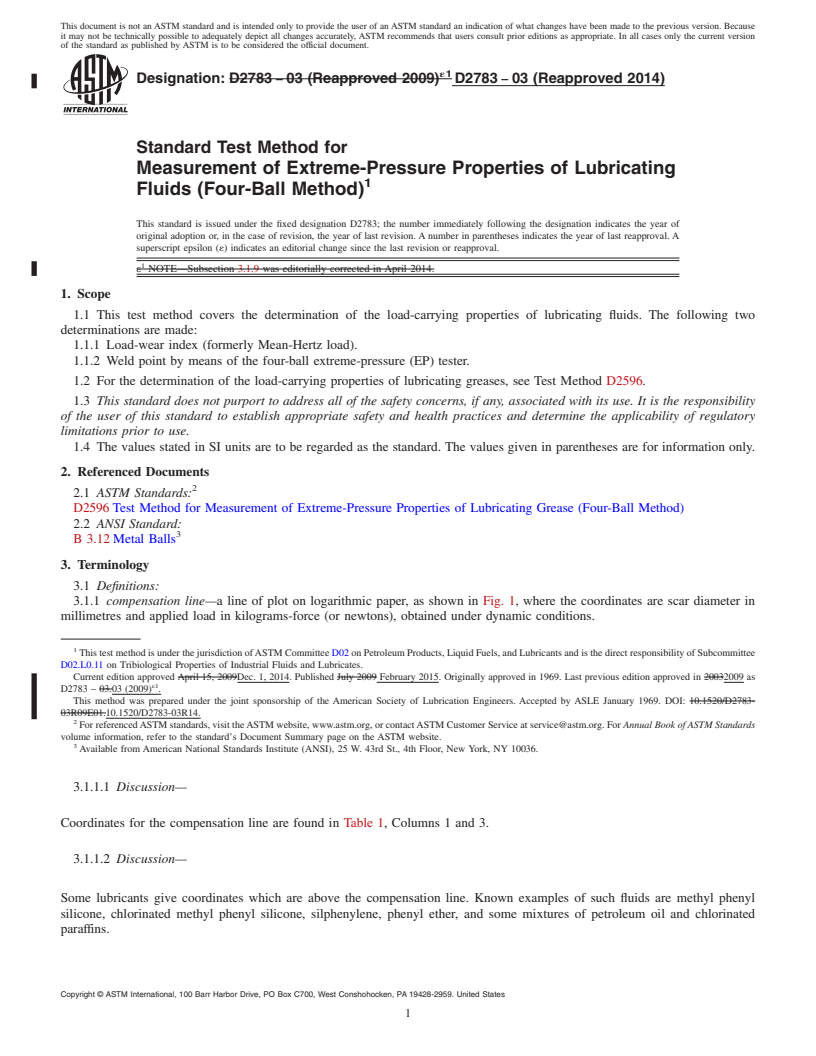

6.1 Four-Ball Extreme-Pressure Tester, illustrated in Figs.

2 and 3.

NOTE 1—It is important to distinguish between the four-ball EP tester

3.1.7 incipient seizure or initial seizure region—that region

andthefour-ballweartester.Thefour-ballEPtesterisdesignedfortesting

at which, with an applied load, there is a momentary break-

under more severe conditions and lacks the sensitivity necessary for the

down of the lubricating film. This breakdown is noted by a

four-ball wear test.

sudden increase in the measured scar diameter and a momen-

6.2 Microscope, equipped with a calibrated measuring scale

tary deflection of the indicating pen of the optional friction-

and readable to an accuracy of 0.01 mm.

measuring device. See Fig. 1.

6.3 Timer, graduated in tenths of a second.

3.1.8 last nonseizure load—the last load at which the

measured scar diameter is not more than 5 % above the

NOTE 2—Optional equipment with four-ball apparatus consists of a

friction-measuring device electrically driven and conveniently graduated

compensation line at the load. See Fig. 1.

in 10-s markings.

3.1.9 load-wear index (or the load-carrying property of a

lubricant), n—an index of the ability of a lubricant to minimize

wear at applied loads.

Further details applicable to this method may be found in: Sayles, F. S., et al.,

“The Four-Ball E. P. Tester, An ASTM Method of Test,” National Lubricating

3.1.9.1 Discussion—Under the conditions of this test, spe-

Grease Institute, NLGIA, Vol 32, No. 5, August 1968, pp. 162–167.

cific loadings in kilograms-force (or Newtons) having intervals

SatisfactorysourcesofsupplyforthisinstrumentareFalexCorp.,1020Airpark

of approximately 0.1 logarithmic units, are applied to the three

Dr., Sugar Grove, IL 60554–9585 and Stanhope-Seta Ltd., Park Close, Egham,

stationary balls for ten runs prior to welding. The load-wear Englefield Green, Surrey, England TW20 OXD.

D2783 − 03 (2014)

FIG. 2 Sectional View of Four-Ball Tester

FIG. 3 Four-Ball EP Test Machine

machine parts. Reagent Grade Stoddard solvent is an example of a solvent

7. Materials

that has been found suitable.

7.1 Cleaning Solvent, safe, non-film forming, nonchlori-

7.2 Rinse Solvent, same as in 7.1, but with higher volatility.

nated. (Warning— Flammable. Harmful if inhaled. See A1.1.)

ASTM n-Heptane is an example of one such rinse solvent that

NOTE 3—Certain petroleum distillates, formerly used as solvents, have

has been found suitable. (Warning—Flammable. Harmful if

been eliminated due to possible toxic effects. Each user should select a

inhaled. See A1.2.)

solvent that can meet applicable safety requirements and thoroughly clean

D2783 − 03 (2014)

NOTE 8—The time for the apparatus to “coast” to a stop is not

7.3 Test Balls —Test balls shall be chrome alloy steel, made

considered.

from AISI standard steel No. E-52100, with diameter of 12.7

mm (0.5 in.), Grade 25 EP (Extra Polish). Such balls are 9.7 Remove the test-lubricant cup assembly; remove the

described in B3.12, for Metal Balls. The Extra-Polish finish is chuck and discard the ball.

not described in that specification. The Rockwell C hardness

9.8 Measure the scar diameter of test balls as follows:

shall be 64 to 66, a closer limit than is found in the ANSI

9.8.1 Option A—Remove the test balls. Clean the balls with

requirement.

cleaning solvent (see 7.1) and then rinse solvent (see 7.2).

Wipe dry with a soft cloth. Place the individual balls on a

8. Preparation of Apparatus

suitable holder and by means of a microscope, measure to the

nearest 0.01 mm the scar diameters both parallel (horizontal)

8.1 Thoroughly clean four new test balls, test-lubricant cup,

and chuck assemblies by first washing with cleaning solvent and normal (vertical) to the striations in the scar surface of one

of the three test balls (Note 9).

(see 7.1) and then rinse solvent (see 7.2).

9.8.2 Option B—Leave the balls clamped in the cup. Pour

NOTE 4—Do not use solvents such as carbon tetrachloride or other

out the lubricating fluid. Wash the ball surfaces with cleaning

solvents that may inherently possess load-carrying properties which may

solvent (see 7.1) and then the rinse solvent (see 7.2). Using a

affect the results.

microscope,measuretothenearest0.01mmthescardiameters

8.2 Lower the crosshead by raising the lever arm. Lock the

both parallel (horizontal) and normal (vertical) to the striations

lever arm in the raised position by means of a locking

in the scar surface of one of the three test balls (Note 9).

arrangement for that purpose.

9.8.3 Measurements by microscope of the scar diameters on

all three balls, rather than one ball as outlined in Options A or

9. Procedure

B, may be made if the operator so desires.

9.1 Place the three test balls in the test-lubricant cup. Place

NOTE9—ItisrecommendedthatpriortoselectionofOptionAorB,the

the lock ring over the test balls and screw down the nut

operator examines visually the test balls to ascertain no gross discrepancy

securely (Note 5). Pour the lubricating fluid to be tested over

in the wear scars formed on the test balls; if discrepancy is noted, then

the three test balls until they are covered.

wear scar measurements on all three test balls must be made.

NOTE 5—Subsequent independent investigations reported in 1971 by 9.9 Record (Table 1, Column 2) for the 784 N (80-kg) load

several laboratories indicate that optimum test repeatability is obtained

the average scar diameter by any one of the three techniques

when the force on the lock-down nut is maintained within the range 68 6

described in 9.8. Compare this average scar diameter with the

7 η· m (50 6 5 ft·lb), applied, and measured by means of a torque wrench.

compensation scar diameter (Table 1, Column 3).

Significantly lower weld points were obtained when the force applied was

approximately 136 N·m (100 ft·lb).

9.10 Make additional runs at consecutively higher test loads

(Table 1, Column 1), recording the measured scar diameter(s)

9.2 Bring the lubricant and cup to 18 to 35°C (65 to 95°F).

(Note 10) and discarding test balls, until welding occurs (Note

9.3 Pressoneballintotheballchuck(Note6)andmountthe

11). Make a check run at this point. If welding does not occur

chuck into the chuck-holder.

on the check run, repeat the test at the next higher load until

NOTE 6—Examine the chuck and top ball after each run. If the ball

welding is verified.

shows signs of movement in the chuck, even though welding of the

NOTE 10—Measuring the scar diameter(s) of test balls in the incipient

four-balls did not occur, the chuck should be replaced. When welding

and immediate seizure region is sometimes difficult due to the flow of

occursslippagebetweenballandchucknearlyalwaysoccurs.Ifthechuck

metal obliterating the full contact area formed by the rotating ball. In such

has metal from the top ball adhering to it, the metal must be removed or

casesthemetalflowcangenerallyberemovedorpeeledoffwithasuitable

the chuck replaced.

instrument. See Figs. 4 and 5. If the scar periphery is obscure or not well

9.4 Install the test-lubricant cup assembly on the test appa-

defined an estimate of the scar diameter is made. See Figs. 6 and 7.

ratus in contact with the fourth ball. Place the spacer between

NOTE 11—Shut off the motor immediately to prevent damage to the

tester. Excessive seizure between the ball and ball chuck may result if

cup and thrust bearing.

caution is not observed. Welding may be detected by any or all of the

9.5 Place the weight tray and sufficient weights on the

following: (1) If friction-measuring device is used, a sharp transverse

horizontalarmin

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D2783 − 03 (Reapproved 2009) D2783 − 03 (Reapproved 2014)

Standard Test Method for

Measurement of Extreme-Pressure Properties of Lubricating

Fluids (Four-Ball Method)

This standard is issued under the fixed designation D2783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Subsection 3.1.9 was editorially corrected in April 2014.

1. Scope

1.1 This test method covers the determination of the load-carrying properties of lubricating fluids. The following two

determinations are made:

1.1.1 Load-wear index (formerly Mean-Hertz load).

1.1.2 Weld point by means of the four-ball extreme-pressure (EP) tester.

1.2 For the determination of the load-carrying properties of lubricating greases, see Test Method D2596.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

2. Referenced Documents

2.1 ASTM Standards:

D2596 Test Method for Measurement of Extreme-Pressure Properties of Lubricating Grease (Four-Ball Method)

2.2 ANSI Standard:

B 3.12 Metal Balls

3. Terminology

3.1 Definitions:

3.1.1 compensation line—a line of plot on logarithmic paper, as shown in Fig. 1, where the coordinates are scar diameter in

millimetres and applied load in kilograms-force (or newtons), obtained under dynamic conditions.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.L0.11 on Tribiological Properties of Industrial Fluids and Lubricates.

Current edition approved April 15, 2009Dec. 1, 2014. Published July 2009 February 2015. Originally approved in 1969. Last previous edition approved in 20032009 as

ε1

D2783 – 03.03 (2009) .

This method was prepared under the joint sponsorship of the American Society of Lubrication Engineers. Accepted by ASLE January 1969. DOI: 10.1520/D2783-

03R09E01.10.1520/D2783-03R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

3.1.1.1 Discussion—

Coordinates for the compensation line are found in Table 1, Columns 1 and 3.

3.1.1.2 Discussion—

Some lubricants give coordinates which are above the compensation line. Known examples of such fluids are methyl phenyl

silicone, chlorinated methyl phenyl silicone, silphenylene, phenyl ether, and some mixtures of petroleum oil and chlorinated

paraffins.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2783 − 03 (2014)

ABE—Compensation line.

B—Point of last nonseizure load.

BC—Region of incipient seizure.

CD—Region of immediate seizure.

D—Weld point.

FIG. 1 Schematic Plot of Scar Diameter Versus Applied Load

TABLE 1 Suggested Form for Recording Test Results

Column 2 Column 3 Column 5

Column 1

Column4

Applied Average Scar Compensation Corrected

LD

h

A

Diameter, Scar Diameter, Load,

Load, kg

Factor

A

(L)

mm (X) mm kg (LD /X)

h

6 0.95

8 1.40

10 0.21 1.88

13 0.23 2.67

16 0.25 3.52

20 0.27 4.74

24 0.28 6.05

32 0.31 8.87

40 0.33 11.96

50 0.36 16.10

63 0.39 21.86

80 0.42 30.08

100 0.46 40.5

126 0.50 55.2

160 0.54 75.8

200 0.59 102.2

250 137.5

315 187.1

400 258

500 347

620 462

800 649

A

To convert from kilograms-force to newtons, multiply by 9.806.

3.1.2 compensation scar diameter—the average diameter, in millimetres, of the wear scar on the stationary balls caused by the

rotating ball under an applied load in the presence of a lubricant, but without causing either seizure or welding.

3.1.2.1 Discussion—

The wear scar obtained shall be within 5 % of the values noted in Table 1, Column 3.

3.1.3 corrected load—the load in kilograms-force (or newtons) for each run obtained by multiplying the applied load by the ratio

of the Hertz scar diameter to the measured scar diameter at that load.

3.1.4 Hertz line—a line of plot on logarithmic paper, as shown in Fig. 1, where the coordinates are scar diameter in millimetres

and applied load in kilograms-force (or newtons), obtained under static conditions.

3.1.5 Hertz scar diameter—the average diameter, in millimetres, of an indentation caused by the deformation of the balls under

static load (prior to test). It may be calculated from the equation

22 1/3

D 5 8.73 310 P (1)

~ !

h

D2783 − 03 (2014)

where:

D = Hertz diameter of the contact area, and

h

P = the static applied load.

3.1.6 immediate seizure region—that region of the scar-load curve characterized by seizure or welding at the startup or by large

wear scars. Initial deflection of indicating pen on the optional friction-measuring device is larger than with nonseizure loads. See

Fig. 1.

3.1.7 incipient seizure or initial seizure region—that region at which, with an applied load, there is a momentary breakdown of

the lubricating film. This breakdown is noted by a sudden increase in the measured scar diameter and a momentary deflection of

the indicating pen of the optional friction-measuring device. See Fig. 1.

3.1.8 last nonseizure load—the last load at which the measured scar diameter is not more than 5 % above the compensation line

at the load. See Fig. 1.

3.1.9 load-wear index (or the load-carrying property of a lubricant), n—an index of the ability of a lubricant to minimize wear

at applied loads.

3.1.9.1 Discussion—

Under the conditions of this test, specific loadings in kilograms-force (or Newtons) having intervals of approximately 0.1

logarithmic units, are applied to the three stationary balls for ten runs prior to welding. The load-wear index is the average of the

sum of the corrected loads determined for the ten applied loads immediately preceding the weld point.

3.1.10 weld point—under the conditions of this test, the lowest applied load in kilograms at which the rotating ball welds to the

three stationary balls, indicating the extreme-pressure level of the lubricants-force (or newtons) has been exceeded.

3.1.10.1 Discussion—

Some lubricants do not allow true welding, and extreme scoring of the three stationary balls results. In such cases, the applied load

which produces a maximum scar diameter of 4 mm is reported as the weld point.

4. Summary of Test Method

4.1 The tester is operated with one steel ball under load rotating against three steel balls held stationary in the form of a cradle.

Test lubricant covers the lower three balls. The rotating speed is 1760 6 40 rpm. The machine and test lubricant are brought to

18 to 35°C (65 to 95°F) and then a series of tests of 10-s duration are made at increasing loads until welding occurs. Ten tests are

made below the welding point. If ten loads have not been run when welding occurs and the scars at loads below seizure are within

5 % of the compensation line (AB Fig. 1) no further runs are necessary. The total can be brought to ten by assuming that loads

below the last nonseizure load will produce wear scars equal to the “compensation scar diameter.” Values of these “assumed” scars

are given in Table 1. For clarification of “last nonseizure load” and “weld point” see Fig. 1.

5. Significance and Use

5.1 This test method, used for specification purposes, differentiates between lubricating fluids having low, medium, and high

level of extreme-pressure properties. The user of this method should determine to his own satisfaction whether results of this test

procedure correlate with field performance or other bench test machines.

6. Apparatus

6.1 Four-Ball Extreme-Pressure Tester, illustrated in Figs. 2 and 3.

NOTE 1—It is important to distinguish between the four-ball EP tester and the four-ball wear tester. The four-ball EP tester is designed for testing under

more severe conditions and lacks the sensitivity necessary for the four-ball wear test.

6.2 Microscope, equipped with a calibrated measuring scale and readable to an accuracy of 0.01 mm.

6.3 Timer, graduated in tenths of a second.

NOTE 2—Optional equipment with four-ball apparatus consists of a friction-measuring device electrically driven and conveniently graduated in 10-s

markings.

Further details applicable to this method may be found in: Sayles, F. S., et al., “The Four-Ball E. P. Tester, An ASTM Method of Test,” National Lubricating Grease

Institute, NLGIA, Vol 32, No. 5, August 1968, pp. 162–167.

Satisfactory sources of supply for this instrument are Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554–9585 and Stanhope-Seta Ltd., Park Close, Egham, Englefield

Green, Surrey, England TW20 OXD.

D2783 − 03 (2014)

FIG. 2 Sectional View of Four-Ball Tester

FIG. 3 Four-Ball EP Test Machine

7. Materials

7.1 Cleaning Solvent, safe, non-film forming, nonchlorinated. (Warning— Flammable. Harmful if inhaled. See A1.1.)

NOTE 3—Certain petroleum distillates, formerly used as solvents, have been eliminated due to possible toxic effects. Each user should select a solvent

that can meet applicable safety requirements and thoroughly clean machine parts. Reagent Grade Stoddard solvent is an example of a solvent that has

been found suitable.

D2783 − 03 (2014)

7.2 Rinse Solvent, same as in 7.1, but with higher volatility. ASTM n-Heptane is an example of one such rinse solvent that has

been found suitable. (Warning—Flammable. Harmful if inhaled. See A1.2.)

7.3 Test Balls —Test balls shall be chrome alloy steel, made from AISI standard steel No. E-52100, with diameter of 12.7 mm

(0.5 in.), Grade 25 EP (Extra Polish). Such balls are described in B3.12, for Metal Balls. The Extra-Polish finish is not described

in that specification. The Rockwell C hardness shall be 64 to 66, a closer limit than is found in the ANSI requirement.

8. Preparation of Apparatus

8.1 Thoroughly clean four new test balls, test-lubricant cup, and chuck assemblies by first washing with cleaning solvent (see

7.1) and then rinse solvent (see 7.2).

NOTE 4—Do not use solvents such as carbon tetrachloride or other solvents that may inherently possess load-carrying properties which may affect the

results.

8.2 Lower the crosshead by raising the lever arm. Lock the lever arm in the raised position by means of a locking arrangement

for that purpose.

9. Procedure

9.1 Place the three test balls in the test-lubricant cup. Place the lock ring over the test balls and screw down the nut securely

(Note 5). Pour the lubricating fluid to be tested over the three test balls until they are covered.

NOTE 5—Subsequent independent investigations reported in 1971 by several laboratories indicate that optimum test repeatability is obtained when the

force on the lock-down nut is maintained within the range 68 6 7 η· m (50 6 5 ft·lb), applied, and measured by means of a torque wrench. Significantly

lower weld points were obtained when the force applied was approximately 136 N·m (100 ft·lb).

9.2 Bring the lubricant and cup to 18 to 35°C (65 to 95°F).

9.3 Press one ball into the ball chuck (Note 6) and mount the chuck into the chuck-holder.

NOTE 6—Examine the chuck and top ball after each run. If the ball shows signs of movement in the chuck, even though welding of the four-balls did

not occur, the chuck should be replaced. When welding occurs slippage between ball and chuck nearly always occurs. If the chuck has metal from the

top ball adhering to it, the metal must be removed or the chuck replaced.

9.4 Install the test-lubricant cup assembly on the test apparatus in contact with the fourth ball. Place the spacer between cup

and thrust bearing.

9.5 Place the weight tray and sufficient weights on the horizontal arm in the correct notch for a base test load of 784 N (80 kg).

Release the lever arm and gently apply (Note 7) the test load to the balls, making certain the cup assembly and spacer are centered.

If the optional friction-measuring device is used, connect the calibrated arm on the test-lubricant cup to the indicator spring by

means of the clip and wire.

NOTE 7—Shock-loading should be avoided as it may deform the balls permanently.

9.6 Start the motor and run for 10 6 0.2 s.

NOTE 8—The time for the apparatus to “coast” to a stop is not considered.

9.7 Remove the test-lubricant cup assembly; remove the chuck and discard the ball.

9.8 Measure the scar diameter of test balls as follows:

9.8.1 Option A—Remove the test balls. Clean the balls with cleaning solvent (see 7.1) and then rinse solvent (see 7.2). Wipe

dry with a soft cloth. Place the individual balls on a suitable holder and by means of a microscope, measure to the nearest 0.01

mm the scar diameters both parallel (horizontal) and normal (vertical) to the striations in the scar surface of one of the three test

balls (Note 9).

9.8.2 Option B—Leave the balls clamped in the cup. Pour out the lubricating fluid. Wash the ball surfaces with cleaning solvent

(see 7.1) and then the rinse solvent (see 7.2). Using a microscope, measure to the nearest 0.01 mm the scar diameters both parallel

(horizontal) and normal (vertical) to the striations in the scar surface of one of the three test balls (Note 9).

9.8.3 Measurements by microscope of the scar diameters on all three balls, rather than one ball as outlined in Options A or B,

may be made if the operator so desires.

NOTE 9—It is recommended that prior to selection of Option A or B, the operator examines visually the test balls to ascertain no gross discrepancy

in the wear scars formed on the test balls; if discrepancy is noted, then wear scar measurements on all three test balls must be made.

9.9 Record (Table 1, Column 2) for the 784 N (80-kg) load the average scar diameter by any one of the three techniques

described in 9.8. Compare this average scar diameter with the compensation scar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.