ASTM A352/A352M-06

(Specification)Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-Temperature Service

Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-Temperature Service

ABSTRACT

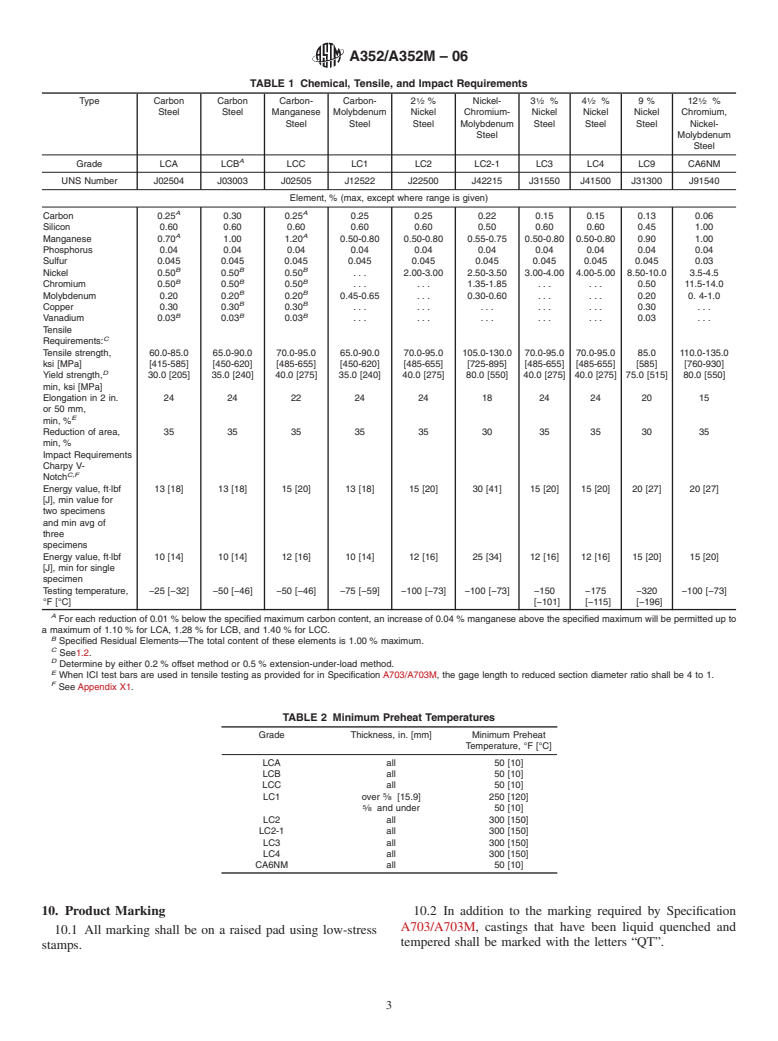

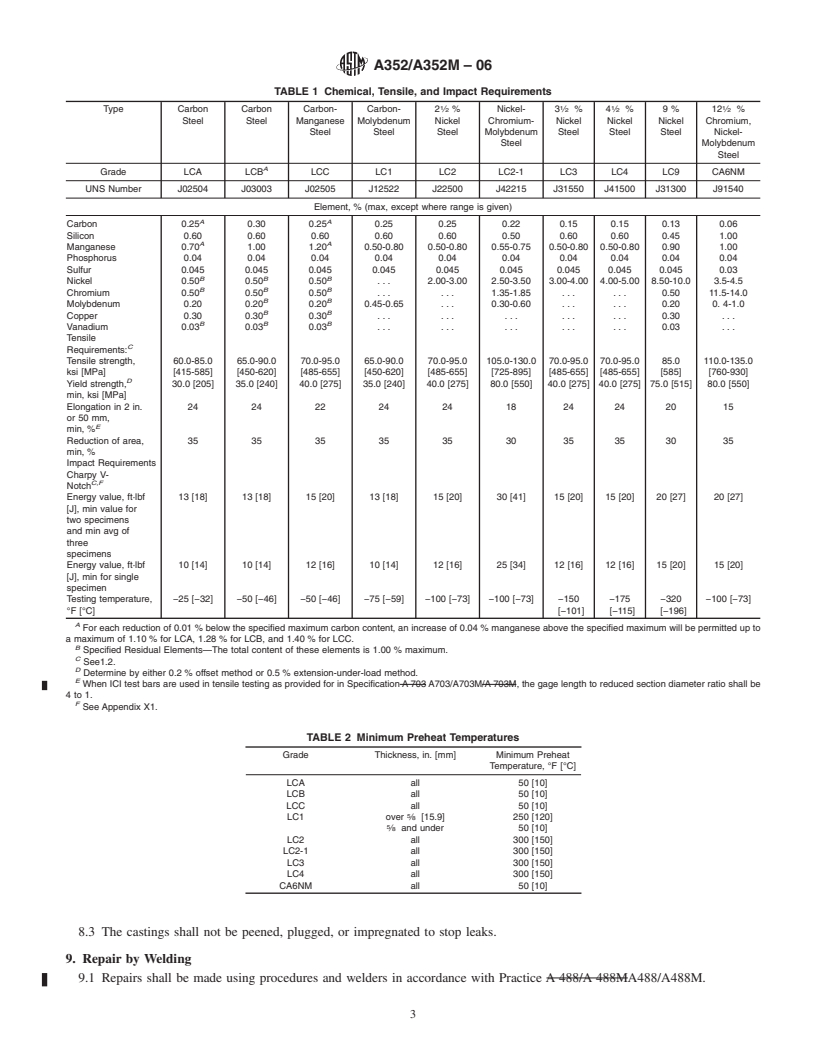

This specification covers steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for low-temperature service. Several grades of ferritic steels and one grade of martensitic steel are covered. All castings shall receive a heat treatment proper to their design and chemical composition. It should be recognized that liquid quenching of the ferritic grades is normally required to meet the mechanical properties of heavier sections. The steel shall conform to the requirements as to chemical composition specified. Tensile test and impact test shall be made to conform to the requirements specified.

SCOPE

1.1 This specification covers steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for low-temperature service.

1.2 Several grades of ferritic steels and one grade of martensitic steel are covered. Selection of analysis will depend on design and service conditions (Note). The temperature shown is the lowest temperature at which the material ordinarily is required to meet the impact requirements of this specification (see Supplementary Requirement S22, Impact Test Temperatures). Users should note that hardenability of some of the grades mentioned may restrict the maximum size at which the required mechanical properties are obtainable (see ).This specification covers the low-temperature requirements particularly pertinent for ferritic and martensitic steels. Certain of the grades of austenitic steel castings furnished in accordance with Specification A 351/A 351M have been found suitable for low-temperature service down to 300F [184C] and others down to 425F [254C]. These grades may be used when impact tested in accordance with Specification A 352/A 352M with energy levels and temperatures of test mutually agreed upon between the purchaser and the manufacturer. As a guide to the selection of energy levels and testing temperatures, should be consulted.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A 352 and SI units for material ordered to Specification A 352M.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A352/A352M – 06

Standard Specification for

Steel Castings, Ferritic and Martensitic, for Pressure-

1

Containing Parts, Suitable for Low-Temperature Service

This standard is issued under the fixed designationA352/A352M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 1.3 The values stated in either inch-pound units or SI units

2 are to be regarded separately as standard. Within the text, the

1.1 This specification covers steel castings for valves,

SI units are shown in brackets. The values stated in each

flanges, fittings, and other pressure-containing parts intended

system are not exact equivalents; therefore, each system must

primarily for low-temperature service.

beusedindependentlyoftheother.Combiningvaluesfromthe

1.2 Several grades of ferritic steels and one grade of

two systems may result in nonconformance with the specifi-

martensiticsteelarecovered.Selectionofanalysiswilldepend

cation. Inch-pound units are applicable for material ordered to

on design and service conditions (Note). The temperature

Specification A352 and SI units for material ordered to

shown is the lowest temperature at which the material ordinar-

Specification A352M.

ily is required to meet the impact requirements of this

specification (see Supplementary Requirement S22, Impact

2. Referenced Documents

Test Temperatures). Users should note that hardenability of

3

2.1 ASTM Standards:

some of the grades mentioned may restrict the maximum size

A351/A351M Specification for Castings, Austenitic, for

atwhichtherequiredmechanicalpropertiesareobtainable(see

Pressure-Containing Parts

Appendix X1).

A370 Test Methods and Definitions for Mechanical Testing

Grade Usual Minimum Testing

of Steel Products

Temperatures, °F [°C]

LCA −25 [–32]

A488/A488M Practice for Steel Castings, Welding, Quali-

LCB −50 [–46]

fications of Procedures and Personnel

LCC −50 [–46]

A703/A703M Specification for Steel Castings, General Re-

LC1 −75 [–59]

LC2 −100 [–73]

quirements, for Pressure-Containing Parts

LC2–1 −100 [–73]

E165 PracticeforLiquidPenetrantExaminationforGeneral

LC3 −150 [–101]

Industry

LC4 −175 [–115]

LC9 −320 [–196]

E709 Guide for Magnetic Particle Testing

CA6NM −100 [−73]

2.2 Manufacturers’ Standardization Society of the Valve

NOTE 1—This specification covers the low-temperature requirements

and Fittings Industry Standard:

particularly pertinent for ferritic and martensitic steels. Certain of the

SP-55 Quality Standard for Steel Castings for Valves,

grades of austenitic steel castings furnished in accordance with Specifi-

Flanges, and Fittings and Other Piping Components (Vi-

cationA351/A351Mhavebeenfoundsuitableforlow-temperatureservice

4

sual Method)

down to −300°F [−184°C] and others down to −425°F [−254°C]. These

grades may be used when impact tested in accordance with Specification

3. General Conditions for Delivery

A352/A352Mwithenergylevelsandtemperaturesoftestmutuallyagreed

upon between the purchaser and the manufacturer. As a guide to the 3.1 Material furnished to this specification shall conform to

selection of energy levels and testing temperatures, Appendix X1 should

the requirements of Specification A703/A703M including any

be consulted.

supplementary requirements that are indicated in the purchase

order. Failure to comply with the general requirements of

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

3

A01.18 on Castings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2006. Published March 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1952. Last previous edition approved in 2003 as A352/A352M-03. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0352_A0352M-06. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

cation SA-352, in Section II of that Code. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A352/A352M – 06

Specification A703/A703M constitutes nonconformance with one value permitted below the average minimum sp

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 352/A 352M–03 Designation: A352/A352M – 06

Standard Specification for

Steel Castings, Ferritic and Martensitic, for Pressure-

1

Containing Parts, Suitable for Low-Temperature Service

This standard is issued under the fixed designationA352/A352M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification covers steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily

for low-temperature service.

1.2 Several grades of ferritic steels and one grade of martensitic steel are covered. Selection of analysis will depend on design

andserviceconditions(Note).Thetemperatureshownisthelowesttemperatureatwhichthematerialordinarilyisrequiredtomeet

the impact requirements of this specification (see Supplementary Requirement S22, ImpactTestTemperatures). Users should note

that hardenability of some of the grades mentioned may restrict the maximum size at which the required mechanical properties

are obtainable (see Appendix X1).

Grade Usual Minimum Testing

Temperatures, °F [°C]

LCA −25 [–32]

LCB −50 [–46]

LCC −50 [–46]

LC1 −75 [–59]

LC2 −100 [–73]

LC2–1 −100 [–73]

LC3 −150 [–101]

LC4 −175 [–115]

LC9 −320 [–196]

CA6NM −100 [−73]

NOTE 1—This specification covers the low-temperature requirements particularly pertinent for ferritic and martensitic steels. Certain of the grades of

austenitic steel castings furnished in accordance with Specification A 351/A 351MA351/A351M have been found suitable for low-temperature service

down to −300°F [−184°C] and others down to −425°F [−254°C]. These grades may be used when impact tested in accordance with Specification

A352/A352M with energy levels and temperatures of test mutually agreed upon between the purchaser and the manufacturer.As a guide to the selection

of energy levels and testing temperatures, Appendix X1 should be consulted.

1.3 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

Inch-pound units are applicable for material ordered to Specification A352 and SI units for material ordered to Specification

A352M.

2. Referenced Documents

3

2.1 ASTM Standards:

A351/A351M Specification for Castings,Austenitic,Austenitic–Ferritic (Duplex), for Pressure–Containing Parts Specification

for Castings, Austenitic, for Pressure-Containing Parts

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteel,andRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.18

on Castings.

Current edition approved May 10, 2003. Published May 2003. Originally approved in 1952. Last previous edition approved in 1998 as A 352/A 352M-93 (1998).

Current edition approved March 1, 2006. Published March 2006. Originally approved in 1952. Last previous edition approved in 2003 as A352/A352M-03. DOI:

10.1520/A0352_A0352M-06.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-352, in Section II of that Code.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A352/A352M – 06

E165 Test Method for Liquid Penetrant Examination Practice for Liquid Penetrant Examination for General Industry

E709 Guide for Magnetic Particle ExaminationTesting

2.2 Manufacturers’ Standardization Society of the Valve and Fittings Industry Standard:

4

SP-55 Quality Standard for Steel Castings for Valve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.