ASTM D5658-95(2006)

(Practice)Standard Practice for Sampling Unconsolidated Waste From Trucks

Standard Practice for Sampling Unconsolidated Waste From Trucks

SIGNIFICANCE AND USE

This practice is intended for use in the waste management industries to collect samples of unconsolidated waste from trucks. The sampling procedures described are general and should be used in conjunction with a site-specific work plan.

The purpose of collecting waste samples directly from a truck (rather than the waste source) is to verify (usually with screening analyses) that the waste contained in the truck is the same or similar material from a waste source that has been previously characterized and approved for treatment or disposal, or both.

SCOPE

1.1 This practice covers several methods for collecting waste samples from trucks. These methods are adapted specifically for sampling unconsolidated solid wastes in bulk loads using several types of sampling equipment.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 6 for specific precautionary statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5658 − 95(Reapproved 2006)

Standard Practice for

Sampling Unconsolidated Waste From Trucks

This standard is issued under the fixed designation D5658; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 unconsolidated—for solid material, the characteristic

of being uncemented or uncompacted, or both, and easily

1.1 This practice covers several methods for collecting

separated into smaller particles.

waste samples from trucks. These methods are adapted spe-

3.1.5 waste profile—specific information about the waste

cificallyforsamplingunconsolidatedsolidwastesinbulkloads

including its properties and composition, chemical

using several types of sampling equipment.

constituents, waste codes, transportation information, etc.

1.2 This standard does not purport to address all of the

3.1.6 work plan—a plan specific to a particular site, for

safety concerns, if any, associated with its use. It is the

conducting activities specified in the plan.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Practice

bility of regulatory limitations prior to use. See Section 6 for

4.1 The truck and its contents are inspected and appropriate

specific precautionary statements.

sampling equipment is selected. A clean sampling device is

2. Referenced Documents

then used to scoop, core, or auger into the waste material. The

2.1 ASTM Standards: sample or samples are collected and transferred to a sample

D4687 Guide for General Planning of Waste Sampling container. The sampling device is then cleaned and decontami-

D4700 Guide for Soil Sampling from the Vadose Zone nated or disposed of.

D5088 Practice for Decontamination of Field Equipment

5. Significance and Use

Used at Waste Sites

D5283 Practice for Generation of Environmental Data Re- 5.1 This practice is intended for use in the waste manage-

lated to Waste ManagementActivities: QualityAssurance ment industries to collect samples of unconsolidated waste

and Quality Control Planning and Implementation from trucks. The sampling procedures described are general

D5633 Practice for Sampling with a Scoop and should be used in conjunction with a site-specific work

plan.

3. Terminology

5.2 The purpose of collecting waste samples directly from a

3.1 Definitions of Terms Specific to This Standard:

truck (rather than the waste source) is to verify (usually with

3.1.1 authoritative sampling—a sample selected without

screening analyses) that the waste contained in the truck is the

regard to randomization.

same or similar material from a waste source that has been

3.1.2 paperwork—all required documentation, which may

previously characterized and approved for treatment or

includemanifests,wasteprofiles,samplelabels,siteforms,etc.

disposal, or both.

3.1.3 screening analysis—a preliminary qualitative or semi-

6. Safety Precautions

quantitative test that is designed to give the user rapid and

6.1 Safety precautions must always be observed when

specific information about a waste that will aid in determining

sampling waste. The work plan must include a Worker Health

waste identification, process compatibility, and safety in han-

and Safety section, because there are potential hazards associ-

dling.

ated with working around trucks as well as their potentially

hazardous contents.

This practice is under the jurisdiction of ASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.02 on

6.2 Truck sampling should be conducted from a properly

Sampling Techniques.

designed platform to allow the sampler to safely access the

Current edition approved Oct. 1, 2006. Published October 2006. Originally

truck bed with a minimum of difficulty.

approved in 1995. Last previous edition approved in 2001 as D5658 – 95(2001).

DOI: 10.1520/D5658-95R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Sampling Design

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Truck sampling can be conducted for many different

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. purposes. It is important that the purpose be integrated into the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5658 − 95 (2006)

sample design. If the purpose of sampling is to characterize the 8.3.7 Sample collection sheet.

waste, the sample should be collected from the waste source 8.3.8 Sample containers, with lids and liners.

duringtheloadingorunloadingofthetruck.Thisallowsaccess 8.3.9 Chain of custody forms.

to all portions of the material in the truck. If the purpose is to 8.3.10 Paperwork and site forms.

determine if the material in the truck conforms to a waste 8.3.11 Sample labels.

profile (that is, waste material that has previously been 8.3.12 Cloths or wipes.

characterized), then a less rigorous sampling approach can be

9. Sampling

used. Because of the difficulties of sampling the material in the

truck in situ, (authoritative) grab samples are usually collected

9.1 Basic Sampling Practices:

from the top portion of the material and subjected to screening 9.1.1 Access the truck by way of the sampling platform and

type analysis. This method will quickly demonstrate that the

collect the required number of samples using techniques in

sampled material (top portion) does or does not match the accordance with 9.2.

waste profile.

9.1.2 Place the collected material in a sample container.

9.1.3 Close the sample container.

7.2 Aworkplanshouldbeprepareddescribingthesampling

9.1.4 Wipe the outside of the sample container. Dispose of

locations, number of samples, depth of sampling and type of

the wipe cloth properly.

sampling equipment (see Practice D5283 and Guide D4687).

9.1.5 Note on site forms all relevant conditions and physical

NOTE 1—Because of limited access to the truck bed for sampling, the

characteristics associated with the collection of the sample.

samples collected are usually near-surface samples. There is a possibility

9.1.6 Fill out all required paperwork for each sample, as

that the material in the middle or on the bottom of the bed is different.

required by the work plan.

9.1.7 Completeandattachthelabeltothesideofthesample

8. Pre-Sampling

container after the sample has been collected.

8.1 Basic Pre-Sampling Practices:

9.2 Sampling with a Concentric Tube Thief:

8.1.1 Review all paperwork.

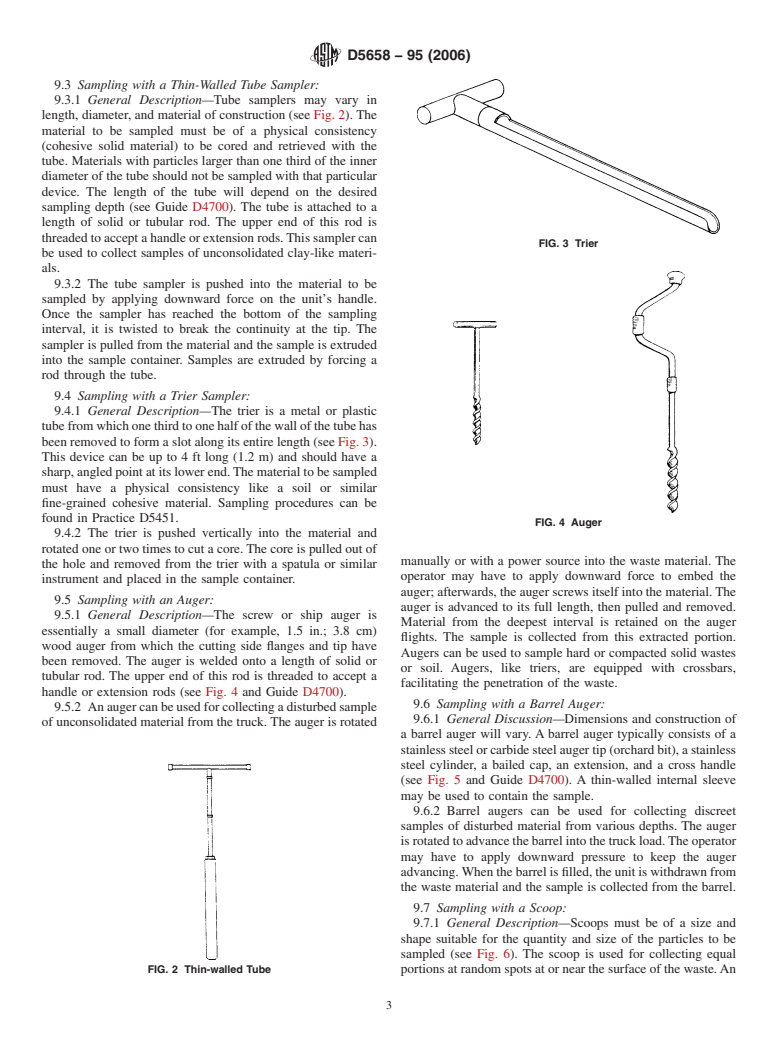

9.2.1 General Description—This device consists of two

8.1.2 Access the truck by way of the sampling platform so

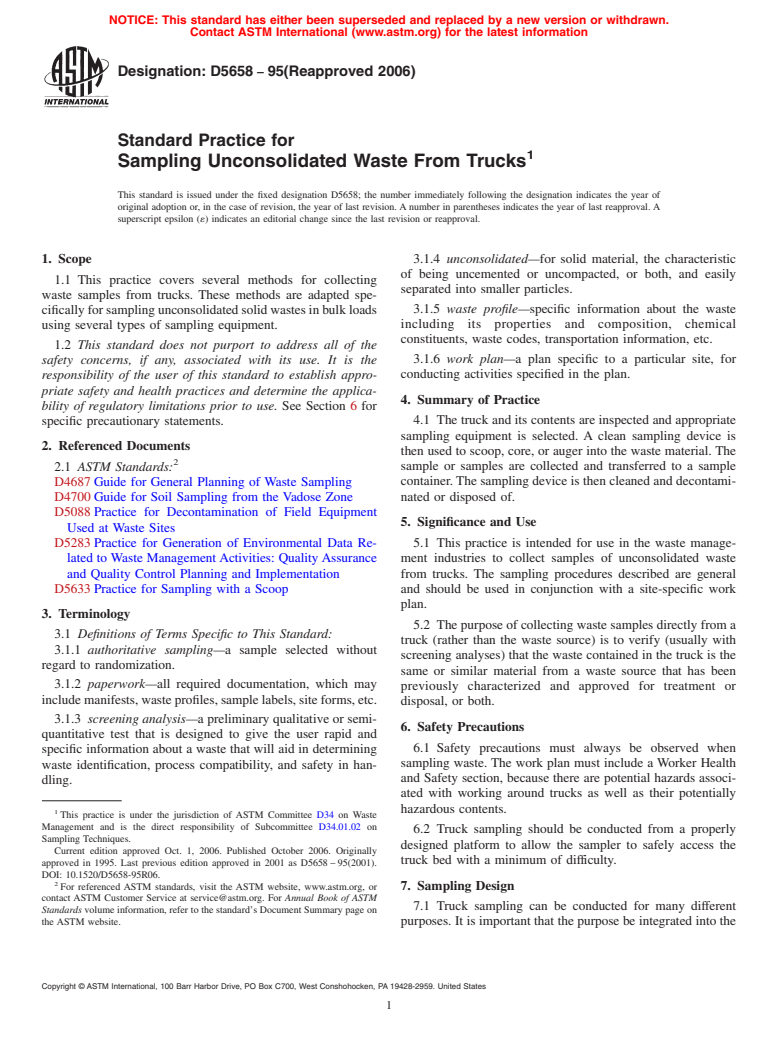

tubes, one fitting snugly inside the other (see Fig. 1). The

that the waste can be visually inspected to confirm agreement

bottomendoftheoutertubeisfittedwithapoint.Oblongholes

with the paperwork and identify any obvious discrepancies

are cut through both tubes. The holes are opened or closed by

(such as free liquids, etc.).

rotating the inner tube. Concentric tube samplers are commer-

8.2 Sampling Equipment:

cially available up to 6 ft (1.8 m) long and several inches

8.2.1 Selection:

(centimeters) in diameter.

8.2.1.1 Select the sampling equipment and sample contain-

9.2.2 Concentrictubesampleshavealimitedapplicationfor

ers appropriate for the waste in the truck, in accordance with

sampling trucks. Materials that are not free-flowing such as

the work plan or site-specific procedure. See Guide D4687 for

those that are hard packed, moist, or finely powdered will not

information on sample container selection.

enter this type of sampler under normal field conditions.

8.2.1.2 The sampling equipment, sample preparation

Sampling of materials containing granules or particles exceed-

equipment, sample containers, etc., must be clean, dry, and

ing one third of the slot width should not be attempted because

inert to the material being sampled. Before use, all equipment

bridging may occur.

including sample containers shall be inspected to ensure they

9.2.3 Insert

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.