ASTM D5186-03(2009)

(Test Method)Standard Test Method for Determination of Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid Chromatography

Standard Test Method for Determination of Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid Chromatography

SIGNIFICANCE AND USE

The aromatic hydrocarbon content of motor diesel fuels is a factor that can affect their cetane number and exhaust emissions. The aromatic hydrocarbon content and the naphthalenes content of aviation turbine fuels affect their combustion characteristics and smoke-forming tendencies. These properties represent specifications for aviation turbine fuels (see Specification D 1655).

The United States Environmental Protection Agency (USEPA) regulates the aromatic content of diesel fuels. California Air Resources Board (CARB) regulations place limits on the total aromatics content and polynuclear aromatic hydrocarbon content of motor diesel fuel, thus requiring an appropriate analytical determination to ensure compliance with the regulations. Producers of diesel fuels will require similar determinations for process and quality control. This test method can be used to make such determinations.

This test method is applicable to materials in the boiling range of motor diesel fuels and is unaffected by fuel coloration. Test Method D 1319, which has been mandated by the USEPA for the determination of aromatics in motor diesel fuel, excludes materials with final boiling points greater than 315°C (600°F) from its scope. Test Method D 2425 is applicable to the determination of both total aromatics and polynuclear aromatic hydrocarbons in diesel fuel, but is much more costly and time-consuming to perform.

Results obtained by this test method have been shown to be statistically more precise than those obtained from Test Method D 1319 for typical diesel fuels, and this test method has a shorter analysis time. Cooperative study data have found this test method to be more precise than the published precision of Test Method D 1319 when applied to aviation turbine fuels and diesel fuels. Results from this test method for total polynuclear aromatic hydrocarbons are also expected to be at least as precise as those of Test Method D 2425.

SCOPE

1.1 This test method covers the determination of the total amounts of monoaromatic and polynuclear aromatic hydrocarbon compounds in motor diesel fuels, aviation turbine fuels, and blend stocks by supercritical fluid chromatography (SFC). The range of aromatics concentration to which this test method is applicable is from 1 to 75 mass %. The range of polynuclear aromatic hydrocarbon concentrations to which this test method is applicable is from 0.5 to 50 mass %.

1.2 The values stated in SI units are to be regarded as standard. The values stated in inch-pound units are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5186 − 03(Reapproved 2009)

Standard Test Method for

Determination of the Aromatic Content and Polynuclear

Aromatic Content of Diesel Fuels and Aviation Turbine Fuels

By Supercritical Fluid Chromatography

This standard is issued under the fixed designation D5186; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 critical pressure, n—that pressure needed to condense

a gas at the critical temperature.

1.1 This test method covers the determination of the total

amounts of monoaromatic and polynuclear aromatic hydrocar-

3.1.2 critical temperature, n—the highest temperature at

bon compounds in motor diesel fuels, aviation turbine fuels,

which a gaseous fluid may be converted to a liquid by means

and blend stocks by supercritical fluid chromatography (SFC).

of compression.

The range of aromatics concentration to which this test method

3.1.3 mononuclear aromatic hydrocarbons, n—hydro-

is applicable is from 1 to 75 mass %. The range of polynuclear

carbon compounds containing exactly one aromatic ring. This

aromatic hydrocarbon concentrations to which this test method

group includes benzene, alkyl-substituted benzenes, indans,

is applicable is from 0.5 to 50 mass %.

tetralins, alkyl-substituted indans, and alkyl-substituted tetra-

1.2 The values stated in SI units are to be regarded as

lins.

standard. The values stated in inch-pound units are for infor-

3.1.4 polynuclear aromatic hydrocarbons, n— all hydrocar-

mation only.

bon compounds containing two or more aromatic rings. These

1.3 This standard does not purport to address all of the

rings may be fused as in naphthalene and phenanthrene, or

safety concerns, if any, associated with its use. It is the

separate as in biphenyl.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.5 restrictor, n—a device, attached to the outlet of a

bility of regulatory limitations prior to use.

chromatographic column, to restrict the mobile phase flow

such that the mobile phase is maintained in the supercritical

2. Referenced Documents

state throughout the chromatographic column.

2.1 ASTM Standards:

3.1.6 supercritical fluid, n—a fluid maintained in a thermo-

D1319 Test Method for Hydrocarbon Types in Liquid Petro-

dynamic state above its critical temperature and critical pres-

leum Products by Fluorescent Indicator Adsorption

sure.

D1655 Specification for Aviation Turbine Fuels

D2425 Test Method for Hydrocarbon Types in Middle Dis-

3.1.7 supercritical fluid chromatography, n— a class of

tillates by Mass Spectrometry

chromatography that employs supercritical fluids as mobile

D6299 Practice for Applying Statistical Quality Assurance

phases.

and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

4. Summary of Test Method

3. Terminology

4.1 A small aliquot of the fuel sample is injected onto a

packed silica adsorption column and eluted using supercritical

3.1 Definitions of Terms Specific to This Standard:

carbon dioxide mobile phase. Monoaromatics and polynuclear

aromatics in the sample are separated from nonaromatics and

This test method is under the jurisdiction of ASTM Committee D02 on

detected using a flame ionization detector.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.04.0C on Liquid Chromatography.

4.2 The detector response to hydrocarbons is recorded

Current edition approved April 15, 2009. Published July 2009. Originally

throughout the analysis time. The chromatographic areas

approved in 1991. Last previous edition approved in 2003 as D5186–03. DOI:

10.1520/D5186-03R09.

corresponding to the monoaromatic, polynuclear aromatic, and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

nonaromatic components are determined and the mass %

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

content of each of these groups in the fuel is calculated by area

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. normalization.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5186 − 03 (2009)

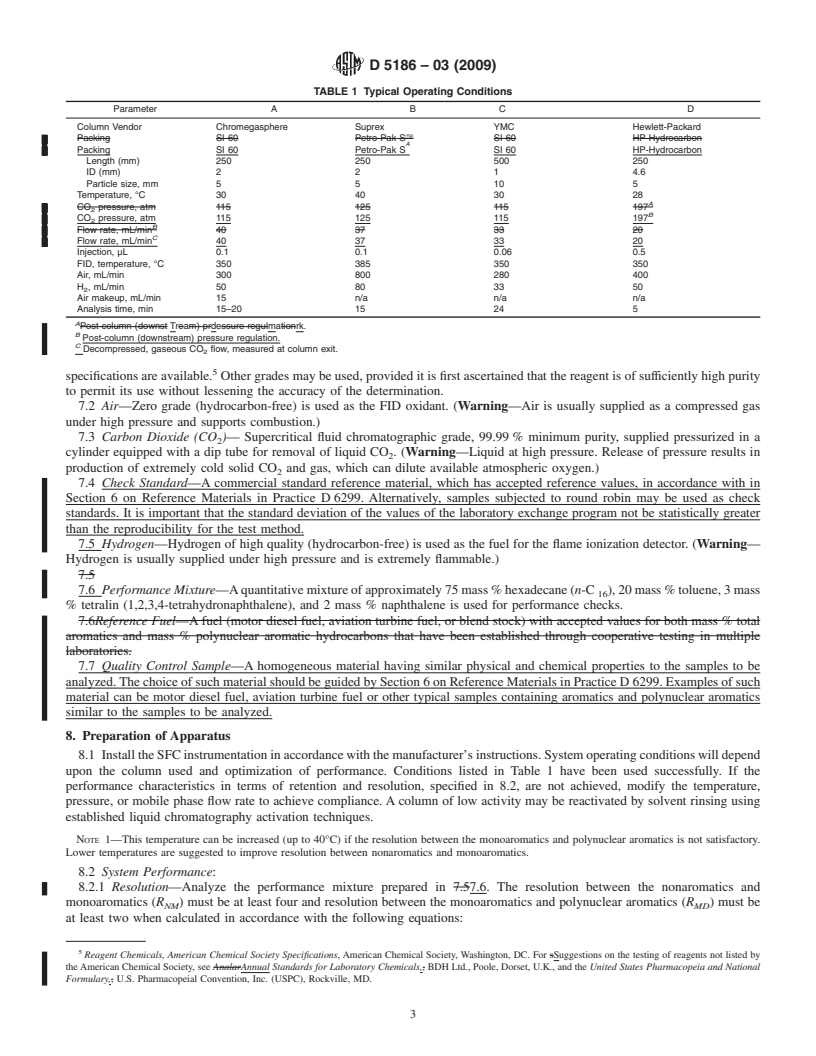

TABLE 1 Typical Operating Conditions

Parameter A B C D

Column Vendor Chromegasphere Suprex YMC Hewlett-Packard

A

Packing SI 60 Petro-Pak S SI 60 HP-Hydrocarbon

Length (mm) 250 250 500 250

ID (mm) 2 2 1 4.6

Particle size, mm 5 5 10 5

Temperature, °C 30 40 30 28

B

CO pressure, atm 115 125 115 197

C

Flow rate, mL/min 40 37 33 20

Injection, µL 0.1 0.1 0.06 0.5

FID, temperature, °C 350 385 350 350

Air, mL/min 300 800 280 400

H , mL/min 50 80 33 50

Air makeup, mL/min 15 n/a n/a n/a

Analysis time, min 15–20 15 24 5

A

Trademark.

B

Post-column (downstream) pressure regulation.

C

Decompressed, gaseous CO flow, measured at column exit.

5. Significance and Use polynuclear aromatic hydrocarbons are also expected to be at

least as precise as those of Test Method D2425.

5.1 The aromatic hydrocarbon content of motor diesel fuels

is a factor that can affect their cetane number and exhaust

6. Apparatus

emissions. The aromatic hydrocarbon content and the naphtha-

lenes content of aviation turbine fuels affect their combustion

6.1 Supercritical Fluid Chromatograph (SFC)—Any SFC

characteristics and smoke-forming tendencies. These proper-

instrumentation can be used that has the following capabilities

ties represent specifications for aviation turbine fuels (see

and meets the performance requirements in Section 8.

Specification D1655).

6.1.1 Pump—The SFC instrumentation must include a

pump capable of delivering supercritical carbon dioxide to the

5.2 The United States Environmental Protection Agency

(USEPA) regulates the aromatic content of diesel fuels. Cali- column without pressure fluctuations and at constant flow. The

pump is typically a single-stroke-type (syringe) pump or a

forniaAirResourcesBoard(CARB)regulationsplacelimitson

the total aromatics content and polynuclear aromatic hydrocar- highly dampened reciprocating pump with pressure fluctua-

tions not exceeding 60.3 % of the operating pressure.

bon content of motor diesel fuel, thus requiring an appropriate

analytical determination to ensure compliance with the regu-

6.1.2 Detector—This test method is limited to the use of the

lations. Producers of diesel fuels will require similar determi-

flame ionization detector (FID). The detector must have

nationsforprocessandqualitycontrol.Thistestmethodcanbe

sufficient sensitivity to detect 0.1 mass % toluene in hexade-

used to make such determinations.

caneunderinstrumentconditionsemployedinthistestmethod.

6.1.3 Column Temperature Control—The chromatograph

5.3 This test method is applicable to materials in the boiling

must be capable of column temperature control of at least

rangeofmotordieselfuelsandisunaffectedbyfuelcoloration.

60.5°C (1°F) at the operating temperature.

Test Method D1319, which has been mandated by the USEPA

for the determination of aromatics in motor diesel fuel, 6.1.4 Sample Inlet System—A liquid sample injection valve

excludes materials with final boiling points greater than 315°C is required, capable of reproducibly introducing samples in the

(600°F) from its scope.Test Method D2425 is applicable to the 0.05 to 0.50-µL liquid volume range. The inlet system should

determination of both total aromatics and polynuclear aromatic be operated at between 25 and 30°C. The sample inlet system

hydrocarbons in diesel fuel, but is much more costly and must be connected to the chromatographic column so that loss

time-consuming to perform. of chromatographic efficiency is avoided.

6.1.5 Post-column Restrictor—A device capable of main-

5.4 Resultsobtainedbythistestmethodhavebeenshownto

taining mobile phase supercritical conditions within the col-

be statistically more precise than those obtained from Test

umn and up to the detector inlet must be connected to the end

MethodD1319fortypicaldieselfuels,andthistestmethodhas

3 4

of the column.

a shorter analysis time. Cooperative study data have found

thistestmethodtobemoreprecisethanthepublishedprecision 6.1.6 Column—Any liquid or supercritical fluid chromato-

graphic column may be used that provides separation of

of Test Method D1319 when applied to aviation turbine fuels

and diesel fuels. Results from this test method for total nonaromatic, monoaromatic, and polynuclear aromatic hydro-

carbons and meets the performance requirements of Section 8.

Some columns and conditions that have been used successfully

Supporting data (obtained in a comparison study of Test Methods D1319 and are shown in Table 1.

D5186) have been filed at ASTM International Headquarters and may be obtained

6.1.7 Integrator—Means must be provided for the determi-

by requesting Research Report RR:D02-1276.

nation of both discrete chromatographic peak areas and the

Supporting data have been filed at ASTM International Headquarters and may

be obtained by requesting Research Report RR:D02-1388. accumulated area under the chromatogram. This can be done

D5186 − 03 (2009)

by means of a computer or electronic integrator. The computer fully. If the performance characteristics in terms of retention

or integrator must have the capability of correcting for baseline and resolution, specified in 8.2, are not achieved, modify the

shifts during the run.

temperature, pressure, or mobile phase flow rate to achieve

compliance. A column of low activity may be reactivated by

7. Reagents and Materials

solvent rinsing using established liquid chromatography acti-

7.1 Purity of Reagents—Reagent grade chemicals shall be vation techniques.

used in all tests. Unless otherwise indicated, it is intended that

NOTE 1—This temperature can be increased (up to 40°C) if the

all reagents conform to the specifications of the Committee on

resolution between the monoaromatics and polynuclear aromatics is not

Analytical Reagents of the American Chemical Society where

satisfactory. Lower temperatures are suggested to improve resolution

such specifications are available. Other grades may be used,

between nonaromatics and monoaromatics.

provided it is first ascertained that the reagent is of sufficiently

8.2 System Performance:

high purity to permit its use without lessening the accuracy of

8.2.1 Resolution—Analyze the performance mixture pre-

the determination.

pared in 7.6. The resolution between the nonaromatics and

7.2 Air—Zero grade (hydrocarbon-free) is used as the FID

monoaromatics (R ) must be at least four and resolution

NM

oxidant. (Warning—Air is usually supplied as a compressed

between the monoaromatics and polynuclear aromatics (R )

MD

gas under high pressure and supports combustion.)

must be at least two when calculated in accordance with the

7.3 Carbon Dioxide (CO )— Supercritical fluid chromato-

following equations:

graphic grade, 99.99 % minimum purity, supplied pressurized

2 3 t 2 t

~ !

2 1

in a cylinder equipped with a dip tube for removal of liquid

R 5 (1)

NM

1.699 3 y 1y

~ !

2 1

CO.(Warning—Liquid at high pressure. Release of pressure

results in production of extremely cold solid CO and gas,

2 3 t 2 t

2 ~ !

4 3

R 5 (2)

MD

which can dilute available atmospheric oxygen.)

1.699 3 y 1y

~ !

4 3

7.4 Check Standard—Acommercial standard reference ma-

where:

terial, which has accepted reference values, in accordance with

t = time for the n-C peak apex, s,

1 16

in Section 6 on Reference Materials in Practice D6299.

t = time for the toluene peak apex, s,

Alternatively, samples subjected to round robin may be used as

t = time for the tetralin peak apex, s,

check standards. It is important that the standard deviation of

t = time for the naphthalene peak apex, s,

the values of the laboratory exchange program not be statisti-

y = peak width at half height of n-C peak, s,

1 16

cally greater than the reproducibility for the test method.

y = peak width at half height of toluene, s,

y = peak width at half height of tetralin, s, and

7.5 Hydrogen—Hydrogen of high quality (hydrocarbon-

y = peak width at half height of naphthalene, s.

free) is used as the fuel for the flame ionization detector.

(Warning—Hydrogen is usually supplied under high pressure

8.2.2 Retention Time Reproducibility —Repeated injections

and is extremely flammable.)

of the performance mixture must show a retention time

7.6 Performance Mixture—A quantitative mixture of ap- repeatability (maximum difference between duplicate runs) of

proximately 75 mass % hexadecane (n-C ), 20 mass % not more than 0.5 % for n-C and toluene peaks.

16 16

toluene, 3 mass % tetralin (1,2,3,4-tetrahydronaphthalene), and

8.2.3 Detector Accuracy Test—This test method assumes

2 mass % naphthalene is used for performance checks.

that the FID response approximates the theoretical unit carbon

response. To verify this assumption, analyze the performance

7.7 Quality Control Sample—Ahomogeneous material hav-

mixture and calculate the response factors, relative to hexade-

ing similar physical and chemical properties to the samples to

cane ( RRF), for each of the components in the performance

be analyzed. The choice of such material should be guided by

i

mix, using the following equations:

Section 6 on Reference Materials in Practice D6299. Examples

of such material can be motor diesel fuel, aviation turbine fuel

A

i

RF 5 (3)

or other typical samples containing aromatics and polynuclear i

M

i

aromatics similar to the samples to be analyzed.

RF

i

RRF 5 (4)

i

8. Preparation of Apparatus RF

C16

8.1 Install the SFC instrumentation in accordance with the

where:

manufacturer’s instructions. System operating conditions will

A = Component i in performance mix, area %,

i

depend upon the column used and optimization of perfor-

M = Component i in performance mix, known mass %,

i

mance. Conditions listed in Table 1 have been used success-

RF = response factor of Component i,

i

RF = response factor of hexadecane in performance mix,

C16

and

Reagent Chemicals, American Chemical Society Specifications, American

RRF = relative response factor of Component i.

i

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

These values can then be compared to the theoretical

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

response factor for each component in the performance mix as

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: D 5186 – 03 (Reapproved 2009)

Designation:D5186–99

Standard Test Method for

Determination of the Aromatic Content and Polynuclear

Aromatic Content of Diesel Fuels and Aviation Turbine Fuels

By Supercritical Fluid Chromatography

This standard is issued under the fixed designation D 5186; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the total amounts of monoaromatic and polynuclear aromatic hydrocarbon

compounds in motor diesel fuels, aviation turbine fuels, and blend stocks by supercritical fluid chromatography (SFC). The range

of aromatics concentration to which this test method is applicable is from 1 to 75 mass %. The range of polynuclear aromatic

hydrocarbon concentrations to which this test method is applicable is from 0.5 to 50 mass %.

1.2 The values stated in SI units are to be regarded as standard. The values stated in inch-pound units are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

D 1655 Specification for Aviation Turbine Fuels

D 2425 Test Method for Hydrocarbon Types in Middle Distillates by Mass Spectrometry Test Method for Hydrocarbon Types

in Middle Distillates by Mass Spectrometry

D 6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 critical pressure, n—that pressure needed to condense a gas at the critical temperature.

3.1.2 critical temperature, n—the highest temperature at which a gaseous fluid may be converted to a liquid by means of

compression.

3.1.3 mononuclear aromatic hydrocarbons, n—hydrocarbon compounds containing exactly one aromatic ring. This group

includes benzene, alkyl-substituted benzenes, indans, tetralins, alkyl-substituted indans, and alkyl-substituted tetralins.

3.1.4 polynuclear aromatic hydrocarbons, n— all hydrocarbon compounds containing two or more aromatic rings. These rings

may be fused as in naphthalene and phenanthrene, or separate as in biphenyl.

3.1.5 restrictor, n—a device, attached to the outlet of a chromatographic column, to restrict the mobile phase flow such that the

mobile phase is maintained in the supercritical state throughout the chromatographic column.

3.1.6 supercritical fluid, n—a fluid maintained in a thermodynamic state above its critical temperature and critical pressure.

3.1.7 supercritical fluid chromatography, n— a class of chromatography that employs supercritical fluids as mobile phases.

4. Summary of Test Method

4.1 Asmall aliquot of the fuel sample is injected onto a packed silica adsorption column and eluted using supercritical carbon

This test method is under the jurisdiction of ASTM Committee D-2 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04 on

Hydrocarbon Analysis.

Current edition approved April 10, 1999. Published June 1999. Originally published as D5186–91. Last previous edition D5186–96.D02 on Petroleum Products and

Lubricants and is the direct responsibility of Subcommittee D02.04.0C on Liquid Chromatography.

Current edition approved April 15, 2009. Published July 2009. Originally approved in 1991. Last previous edition approved in 2003 as D 5186–03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5186–03 (2009)

dioxide mobile phase. Monoaromatics and polynuclear aromatics in the sample are separated from nonaromatics and detected

using a flame ionization detector.

4.2 The detector response to hydrocarbons is recorded throughout the analysis time. The chromatographic areas corresponding

to the monoaromatic, polynuclear aromatic, and nonaromatic components are determined and the mass % content of each of these

groups in the fuel is calculated by area normalization.

5. Significance and Use

5.1 Thearomatichydrocarboncontentofmotordieselfuelsisafactorthatcanaffecttheircetanenumberandexhaustemissions.

Thearomatichydrocarboncontentandthenaphthalenescontentofaviationturbinefuelsaffecttheircombustioncharacteristicsand

smoke-forming tendencies. These properties represent specifications for aviation turbine fuels (see Specification D 1655).

5.2 The United States Environmental ProtectionAgency (USEPA) regulates the aromatic content of diesel fuels. CaliforniaAir

Resources Board (CARB) regulations place limits on the total aromatics content and polynuclear aromatic hydrocarbon content

of motor diesel fuel, thus requiring an appropriate analytical determination to ensure compliance with the regulations. Producers

of diesel fuels will require similar determinations for process and quality control. This test method can be used to make such

determinations.

5.3 This test method is applicable to materials in the boiling range of motor diesel fuels and is unaffected by fuel coloration.

Test Method D 1319, which has been mandated by the USEPA for the determination of aromatics in motor diesel fuel, excludes

materials with final boiling points greater than 315°C (600°F) from its scope. Test Method D 2425 is applicable to the

determination of both total aromatics and polynuclear aromatic hydrocarbons in diesel fuel, but is much more costly and

time-consuming to perform.

5.4 Results obtained by this test method have been shown to be statistically more precise than those obtained fromTest Method

3 4

D 1319 for typical diesel fuels, and this test method has a shorter analysis time. Cooperative study data have found this test

method to be more precise than the published precision of Test Method D 1319 when applied to aviation turbine fuels and diesel

fuels. Results from this test method for total polynuclear aromatic hydrocarbons are also expected to be at least as precise as those

of Test Method D 2425.

6. Apparatus

6.1 Supercritical Fluid Chromatograph (SFC)—Any SFC instrumentation can be used that has the following capabilities and

meets the performance requirements in Section 8.

6.1.1 Pump—The SFC instrumentation must include a pump capable of delivering supercritical carbon dioxide to the column

withoutpressurefluctuationsandatconstantflow.Thepumpistypicallyasingle-stroke-type(syringe)pumporahighlydampened

reciprocating pump with pressure fluctuations not exceeding 60.3 % of the operating pressure.

6.1.2 Detector—This test method is limited to the use of the flame ionization detector (FID). The detector must have sufficient

sensitivity to detect 0.1 mass % toluene in hexadecane under instrument conditions employed in this test method.

6.1.3 Column Temperature Control—The chromatograph must be capable of column temperature control of at least 60.5°C

(1°F) at the operating temperature.

6.1.4 Sample Inlet System—Aliquid sample injection valve is required, capable of reproducibly introducing samples in the 0.05

to 0.50-µL liquid volume range. The inlet system should be operated at between 25 and 30°C. The sample inlet system must be

connected to the chromatographic column so that loss of chromatographic efficiency is avoided.

6.1.5 Post-column Restrictor—Adevice capable of maintaining mobile phase supercritical conditions within the column and up

to the detector inlet must be connected to the end of the column.

6.1.6 Column—Any liquid or supercritical fluid chromatographic column may be used that provides separation of nonaromatic,

monoaromatic, and polynuclear aromatic hydrocarbons and meets the performance requirements of Section 8. Some columns and

conditions that have been used successfully are shown in Table 1.

6.1.7 Integrator—Means must be provided for the determination of both discrete chromatographic peak areas and the

accumulated area under the chromatogram. This can be done by means of a computer or electronic integrator. The computer or

integrator must have the capability of correcting for baseline shifts during the run.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

Data obtained in a comparison study of Test Methods D1319 and D5186 are filed at ASTM Headquarters with Research Report RR: D02-1276.

Supporting data (obtained in a comparison study of Test Methods D 1319 and D 5186) have been filed at ASTM International Headquarters and may be obtained by

requesting Research Report RR: D02-1276.

Results are filed at ASTM Headquarters. Request Research Report: D02-1388.

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR: D02-1388.

D5186–03 (2009)

TABLE 1 Typical Operating Conditions

Parameter A B C D

Column Vendor Chromegasphere Suprex YMC Hewlett-Packard

Packing SI 60 Petro-Pak SY SI 60 HP-Hydrocarbon

A

Packing SI 60 Petro-Pak S SI 60 HP-Hydrocarbon

Length (mm) 250 250 500 250

ID (mm) 2 2 1 4.6

Particle size, mm 5 5 10 5

Temperature, °C 30 40 30 28

A

CO pressure, atm 115 125 115 197

B

CO pressure, atm 115 125 115 197

B

Flow rate, mL/min 40 37 33 20

C

Flow rate, mL/min 40 37 33 20

Injection, µL 0.1 0.1 0.06 0.5

FID, temperature, °C 350 385 350 350

Air, mL/min 300 800 280 400

H , mL/min 50 80 33 50

Air makeup, mL/min 15 n/a n/a n/a

Analysis time, min 15–20 15 24 5

A

Post-column (downst Tream) prdessure regulmationrk.

B

Post-column (downstream) pressure regulation.

C

Decompressed, gaseous CO flow, measured at column exit.

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

7.2 Air—Zero grade (hydrocarbon-free) is used as the FID oxidant. (Warning—Air is usually supplied as a compressed gas

under high pressure and supports combustion.)

7.3 Carbon Dioxide (CO )— Supercritical fluid chromatographic grade, 99.99 % minimum purity, supplied pressurized in a

cylinder equipped with a dip tube for removal of liquid CO.(Warning—Liquid at high pressure. Release of pressure results in

production of extremely cold solid CO and gas, which can dilute available atmospheric oxygen.)

7.4 Check Standard—A commercial standard reference material, which has accepted reference values, in accordance with in

Section 6 on Reference Materials in Practice D 6299. Alternatively, samples subjected to round robin may be used as check

standards. It is important that the standard deviation of the values of the laboratory exchange program not be statistically greater

than the reproducibility for the test method.

7.5 Hydrogen—Hydrogen of high quality (hydrocarbon-free) is used as the fuel for the flame ionization detector. (Warning—

Hydrogen is usually supplied under high pressure and is extremely flammable.)

7.5

7.6 Performance Mixture—Aquantitativemixtureofapproximately75mass%hexadecane(n-C ),20mass%toluene,3mass

% tetralin (1,2,3,4-tetrahydronaphthalene), and 2 mass % naphthalene is used for performance checks.

7.6Reference Fuel—Afuel (motor diesel fuel, aviation turbine fuel, or blend stock) with accepted values for both mass % total

aromatics and mass % polynuclear aromatic hydrocarbons that have been established through cooperative testing in multiple

laboratories.

7.7 Quality Control Sample—A homogeneous material having similar physical and chemical properties to the samples to be

analyzed.The choice of such material should be guided by Section 6 on Reference Materials in Practice D 6299. Examples of such

material can be motor diesel fuel, aviation turbine fuel or other typical samples containing aromatics and polynuclear aromatics

similar to the samples to be analyzed.

8. Preparation of Apparatus

8.1 InstalltheSFCinstrumentationinaccordancewiththemanufacturer’sinstructions.Systemoperatingconditionswilldepend

upon the column used and optimization of performance. Conditions listed in Table 1 have been used successfully. If the

performance characteristics in terms of retention and resolution, specified in 8.2, are not achieved, modify the temperature,

pressure, or mobile phase flow rate to achieve compliance. A column of low activity may be reactivated by solvent rinsing using

established liquid chromatography activation techniques.

NOTE 1—This temperature can be increased (up to 40°C) if the resolution between the monoaromatics and polynuclear aromatics is not satisfactory.

Lower temperatures are suggested to improve resolution between nonaromatics and monoaromatics.

8.2 System Performance:

8.2.1 Resolution—Analyze the performance mixture prepared in 7.57.6. The resolution between the nonaromatics and

monoaromatics (R ) must be at least four and resolution between the monoaromatics and polynuclear aromatics (R ) must be

NM MD

at least two when calculated in accordance with the following equations:

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For sSuggestions on the testing of reagents not listed by

theAmerican Chemical Society, see AnalarAnnual Standards for Laboratory Chemicals,, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary,, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D5186–03 (2009)

2 3 ~t 2 t !

2 1

R 5 (1)

NM

1.699 3 ~y 1 y !

2 1

2 3 ~t 2 t !

4 3

R 5 (2)

MD

1.699 3 ~y 1 y !

4 3

where:

t = time for the n-C peak apex, s,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.