ASTM G76-02

(Test Method)Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets

Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets

SCOPE

1.1 This test method covers the determination of material loss by gas-entrained solid particle impingement erosion with jetnozzle type erosion equipment. This test method may be used in the laboratory to measure the solid particle erosion of different materials and has been used as a screening test for ranking solid particle erosion rates of materials in simulated service environments (1, 2). Actual erosion service involves particle sizes, velocities, attack angles, environments, etc., that will vary over a wide range (3-5). Hence, any single laboratory test may not be sufficient to evaluate expected service performance. This test method describes one well characterized procedure for solid particle impingement erosion measurement for which interlaboratory test results are available.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: G 76 – 02

Standard Test Method for

Conducting Erosion Tests by Solid Particle Impingement

1

Using Gas Jets

This standard is issued under the fixed designation G 76; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

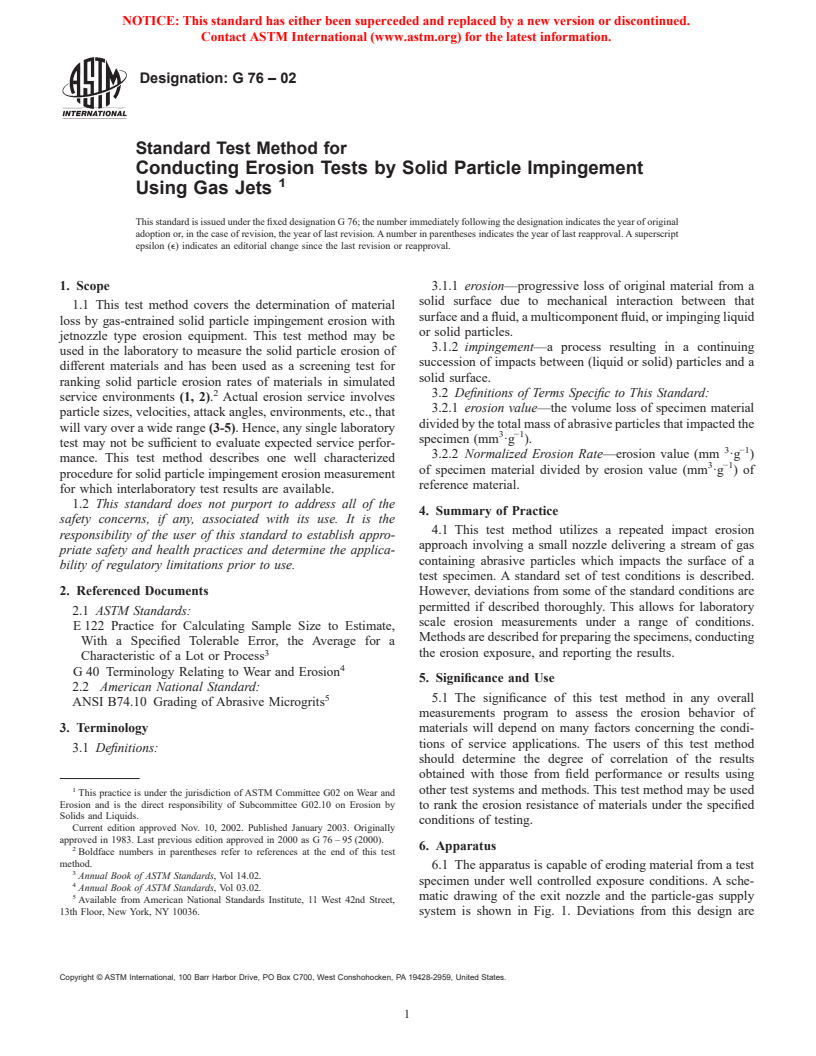

1. Scope 3.1.1 erosion—progressive loss of original material from a

solid surface due to mechanical interaction between that

1.1 This test method covers the determination of material

surface and a fluid, a multicomponent fluid, or impinging liquid

loss by gas-entrained solid particle impingement erosion with

or solid particles.

jetnozzle type erosion equipment. This test method may be

3.1.2 impingement—a process resulting in a continuing

used in the laboratory to measure the solid particle erosion of

succession of impacts between (liquid or solid) particles and a

different materials and has been used as a screening test for

solid surface.

ranking solid particle erosion rates of materials in simulated

2 3.2 Definitions of Terms Specific to This Standard:

service environments (1, 2). Actual erosion service involves

3.2.1 erosion value—the volume loss of specimen material

particle sizes, velocities, attack angles, environments, etc., that

divided by the total mass of abrasive particles that impacted the

will vary over a wide range (3-5). Hence, any single laboratory

3 −1

specimen (mm ·g ).

test may not be sufficient to evaluate expected service perfor-

3 −1

3.2.2 Normalized Erosion Rate—erosion value (mm ·g )

mance. This test method describes one well characterized

3 −1

of specimen material divided by erosion value (mm ·g )of

procedure for solid particle impingement erosion measurement

reference material.

for which interlaboratory test results are available.

1.2 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 This test method utilizes a repeated impact erosion

responsibility of the user of this standard to establish appro-

approach involving a small nozzle delivering a stream of gas

priate safety and health practices and determine the applica-

containing abrasive particles which impacts the surface of a

bility of regulatory limitations prior to use.

test specimen. A standard set of test conditions is described.

2. Referenced Documents However, deviations from some of the standard conditions are

permitted if described thoroughly. This allows for laboratory

2.1 ASTM Standards:

scale erosion measurements under a range of conditions.

E 122 Practice for Calculating Sample Size to Estimate,

Methods are described for preparing the specimens, conducting

With a Specified Tolerable Error, the Average for a

3

the erosion exposure, and reporting the results.

Characteristic of a Lot or Process

4

G 40 Terminology Relating to Wear and Erosion

5. Significance and Use

2.2 American National Standard:

5 5.1 The significance of this test method in any overall

ANSI B74.10 Grading of Abrasive Microgrits

measurements program to assess the erosion behavior of

3. Terminology materials will depend on many factors concerning the condi-

tions of service applications. The users of this test method

3.1 Definitions:

should determine the degree of correlation of the results

obtained with those from field performance or results using

1

other test systems and methods. This test method may be used

This practice is under the jurisdiction of ASTM Committee G02 on Wear and

Erosion and is the direct responsibility of Subcommittee G02.10 on Erosion by

to rank the erosion resistance of materials under the specified

Solids and Liquids.

conditions of testing.

Current edition approved Nov. 10, 2002. Published January 2003. Originally

approved in 1983. Last previous edition approved in 2000 as G 76 – 95 (2000).

6. Apparatus

2

Boldface numbers in parentheses refer to references at the end of this test

method.

6.1 The apparatus is capable of eroding material from a test

3

Annual Book of ASTM Standards, Vol 14.02.

specimen under well controlled exposure conditions. A sche-

4

Annual Book of ASTM Standards, Vol 03.02.

5 matic drawing of the exit nozzle and the particle-gas supply

Available from American National Standards Institute, 11 West 42nd Street,

13th Floor, New York, NY 10036. system is shown in Fig. 1. Deviations from this design are

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.