ASTM E1476-97

(Guide)Standard Guide for Metals Identification, Grade Verification, and Sorting

Standard Guide for Metals Identification, Grade Verification, and Sorting

SCOPE

1.1 This guide is intended for tutorial purposes only. It describes the general requirements, methods, and procedures for the nondestructive identification and sorting of metals.

1.2 It provides guidelines for the selection and use of methods suited to the requirements of particular metals sorting or identification problems.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1476 – 97

Standard Guide for

Metals Identification, Grade Verification, and Sorting

This standard is issued under the fixed designation E 1476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide is intended for tutorial purposes only. It 3.1 Definitions—Terms used in this guide are defined in the

describes the general requirements, methods, and procedures standards cited in Section 2 and in current technical literature

for the nondestructive identification and sorting of metals. or dictionaries; however, because a number of terms that are

1.2 It provides guidelines for the selection and use of used generally in nondestructive testing have meanings or

methods suited to the requirements of particular metals sorting carry implications unique to metal sorting, they appear with

or identification problems. explanation in Appendix X1.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1 A major concern of metals producers, warehousers, and

users is to establish and maintain the identity of metals from

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific melting to their final application. This involves the use of

standard quality assurance practices and procedures throughout

precautionary statements, see Section 10.

the various stages of manufacturing and processing, at ware-

2. Referenced Documents

houses and materials receiving, and during fabrication and final

2.1 ASTM Standards: installation of the product. These practices typically involve

E 158 Practice for Fundamental Calculations to Convert standard chemical analyses and physical tests to meet product

Intensities into Concentrations in Optical Emission Spec- acceptance standards, which are slow. Several pieces from a

trochemical Analysis production run are usually destroyed or rendered unusable

E 305 Practices for Establishing and Controlling Spectro- through mechanical and chemical testing, and the results are

chemical Analytical Curves used to assess the entire lot using statistical methods. Statistical

E 322 Method for X-Ray Emission Spectrometric Analysis quality assurance methods are usually effective; however,

of Low-Alloy Steels and Cast Irons mixed grades, off-chemistry, and nonstandard physical proper-

E 566 Practice for Electromagnetic (Eddy-Current) Sorting ties remain the primary causes for claims in the metals

of Ferrous Metals industry. A more comprehensive verification of product prop-

E 572 Test Method for X-Ray Emission Spectrometric erties is necessary. Nondestructive means are available to

Analysis of Stainless Steel supplement conventional metals grade verification techniques,

E 703 Practice for Electromagnetic (Eddy Current) Sorting and to monitor chemical and physical properties at selected

of Nonferrous Metals production stages, in order to assist in maintaining the identi-

E 977 Practice for Thermoelectric Sorting of Electrically ties of metals and their consistency in mechanical properties.

Conductive Materials 4.2 Nondestructive methods have the potential for monitor-

F 355 Test Method for Shock Absorbing Properties of ing grade during production on a continuous or statistical basis,

Playing Surface Systems and Materials for monitoring properties such as hardness and case depth, and

F 1156 Terminology Relating to Product Counterfeit Pro- for verifying the effectiveness of heat treatment, cold-working,

tection Systems and the like. They are quite often used in the field for solving

problems involving off-grade and mixed-grade materials.

4.3 The nondestructive methods covered in this guide pro-

This guide is under the jurisdiction of ASTM Committee E-7 on Nondestructive

vide both direct and indirect responses to the sample being

Testing and is the direct responsibility of Subcommittee E07.10 on Emerging NDT

evaluated. Spectrometric analysis instruments respond to the

Methods.

presence and percents of alloying constituents. The electro-

Current edition approved May 10, 1997. Published January 1998. Originally

published as E 1476 – 92. Last previous edition E 1476 – 95.

magnetic (eddy current) and thermoelectric methods, on the

Annual Book of ASTM Standards, Vol 03.05.

other hand, are among those that respond to properties in the

Annual Book of ASTM Standards, Vol 03.06.

sample that are affected by chemistry and processing, and they

Annual Book of ASTM Standards, Vol 03.03.

Annual Book of ASTM Standards, Vol 15.07.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1476–97

yield indirect information on composition and mechanical and yield; savings in time, labor, and material; and reduced

properties. In this guide, the spectrometric methods are classi- field failures and claims. This guide provides specific informa-

fied as quantitative, whereas the methods that yield indirect tion regarding nondestructive metals identification, grade veri-

readings are termed qualitative. fication, and sorting methods to assist in selecting the optimum

4.4 This guide describes a variety of qualitative and quan- approach to solving specific needs.

titative methods. It summarizes the operating principles of each 5.3 Spectrometric methods are capable of directly indicating

method, provides guidance on where and how each may be the presence and percent of many of the elements that

applied, gives (when applicable) the precision and bias that characterize a metal grade. The spectrometric and thermoelec-

may be expected, and assists the investigator in selecting the tric techniques examine only the outermost surfaces of the

best candidates for specific grade verification or sorting prob- sample or material. As a result, for grade verification purposes,

lems. it may be necessary to grind sufficiently deep to ensure testing

4.5 For the purposes of this guide, the term “nondestruc- of the base metal for accurate readings. However, grinding may

tive” includes techniques that may require the removal of small affect the thermoelectric response. The spectrometric methods

amounts of metal during the examination, without affecting the require physical contact and often some surface preparation.

serviceability of the product. The electromagnetic method, however, does not require con-

4.6 The nondestructive methods covered in this guide pro- tact and very often is suited for on-line, automatic operation.

vide quantitative and qualitative information on metals prop- The thermoelectric method, although requiring contact, re-

erties; they are listed as follows: sponds to many of the same parameters that influence the

4.6.1 Quantitative: electromagnetic responses. Both respond to chemical compo-

4.6.1.1 X-ray fluorescence spectrometry, and sition, processing, and treatments that affect the physical and

4.6.1.2 Optical emission spectrometry. mechanical properties of the product. Nondestructive methods

4.6.2 Qualitative: for indicating the mechanical properties of a metal are beyond

4.6.2.1 Electromagnetic (eddy current), the scope of this guide.

4.6.2.2 Conductivity/resistivity, 5.4 Each method has particular advantages and disadvan-

4.6.2.3 Thermoelectric, tages. The selection of suitable candidates for a specific grade

4.6.2.4 Chemical spot checks, verification or sorting application requires an understanding of

4.6.2.5 Triboelectric, and the technical operating features of each method. These include

4.6.2.6 Spark testing (special case). the precision and bias necessary for the application and

practical considerations such as product configuration, surface

5. Background

condition, product and ambient temperatures, environmental

5.1 The standard quality assurance procedures for verifying

constraints, etc.

the composition and physical properties of a metal at a

6. General Procedures

producing facility are through chemical analysis and mechani-

cal testing. These required tests result in the sacrifice of a 6.1 Standardization/Calibration:

certain amount of production for the preparation of samples, 6.1.1 Of primary concern in any materials identification or

are costly and time-consuming, and may not provide timely sorting program is delineation of the pertinent product charac-

information regarding changes in product quality. In a market teristics (such as chemical composition, processing, configu-

in which a single failure can result in heavy litigation and ration, and physical properties) and the assignment of accep-

damage costs, the manufacturer requires assurance that his tance limits to each. Often prescribed by materials

production will meet the customer’s acceptance standards. specifications, they also may result from quality assurance

Nondestructive grade verification provides one means of moni- procedures or by agreement between the producer and the user.

toring production to ensure that the product will meet accep- 6.1.2 Of equal importance is the selection of reference

tance requirements. standards. Quantitative methods employ coupon standards that

5.2 Nondestructive methods may be used in conjunction are representative of the metals or alloy compositions to be

with the accepted standard product quality tests to provide verified, and the analytical instrumentation is calibrated against

continuous verification that current production lies within the them. The indirect methods, particularly those that respond to

agreed upon acceptance limits specified. In-line electromag- physical properties as well as composition, require reference

netic tests may be used to indicate the consistency of produc- standards that will represent the material specified in compo-

tion. Any deviation from the norms set for the acceptance band sition, mechanical and physical properties, and processing, as

will result in automatic alarms, kick-out, or other means of well as cover the means and extremes of the acceptance band.

alerting production personnel of a problem. Thus alerted, the Coupon reference standards or product reference standards, or

mill can determine the cause for the alarm and take corrective both, may be selected as required.

action. Portable optical emission spectrometry units may be 6.1.2.1 Coupon Reference Standards—These are small, eas-

used to determine the concentrations of critical elements ily handled metal panels made to specified chemical composi-

without having to resort to slow physical and chemical tions. They are available commercially in sets, singly, or to

analyses. A quality assurance program combining conventional specification. They are useful for instrument calibration, deter-

measurements with suitable nondestructive methods can pro- mining separability among metals, and field use with portable

vide effective and timely information on product composition equipment. They are not intended to reflect the effects of

and physical properties. This will result in improved quality processing or heat treatment on the acceptability of a product.

E1476–97

6.1.2.2 Product Reference Standards—These must repre- typical examples. On instruments with digital or cathode ray

sent the product specified in composition and mechanical and tube displays, it is common practice to show the position and

physical properties. Ideally, three or more product reference extent of adjustable gates for the setting of automatic alarm

standards covering the mean, plus two or more covering the circuits.

extremes, should be obtained, suitably catalogued, and marked 6.3.2 Automatic alarm gates may be positioned and adjusted

for proper identification. to be triggered by the presence or absence of a signal of a given

amplitude and location. Both of these are adjustable. They are

6.1.3 Calibration procedures for each method must be

designed for use in automatic or operator-assisted systems to

followed as specified by the instrument manufacturer. Coupon

indicate when a product falls outside the acceptance limits, as

reference standards are used to calibrate and set up quantitative

well as to indicate whether it falls on the high or the low side.

(spectrometric) or qualitative (thermoelectric and chemical

Similarly, instruments may be equipped with a computer buss

spot check, etc.) verifications, as well as for metals sorting

interface for electronic data processing.

checks on electromagnetic, electrical conductivity, and similar

6.3.3 As described in the calibration and setup procedure,

instruments. Rod, bar, wire, and tubular product reference

acceptance and rejection criteria should be established on the

standards are used almost exclusively for the qualitative

basis of specified product parameters. These may be a simple

methods, such as the electromagnetic, electrical conductivity,

go/no-go selection or a more complex classification based on

triboelectric, and spark tests. These are fabricated from the

special requirements. The decision as to how refined a sorting

product being manufactured, from samples with compositions

is possible is based on a number of product and measurement

and physical properties verified through analytical tests.

variables that are peculiar to the product, inspection method(s),

6.1.4 The known product reference standards used for the

and service requirements. Such decisions should be handled on

qualitative methods must be representative of the chemistry,

an individual basis.

processing, surface, and other physical and mechanical param-

eters that might affect readings. Product standard parameters

7. Survey of Nondestructive Metals Sorting/Grade

must be verifiable.

Verification Methods

6.1.5 Coupon reference standards are useful for initial

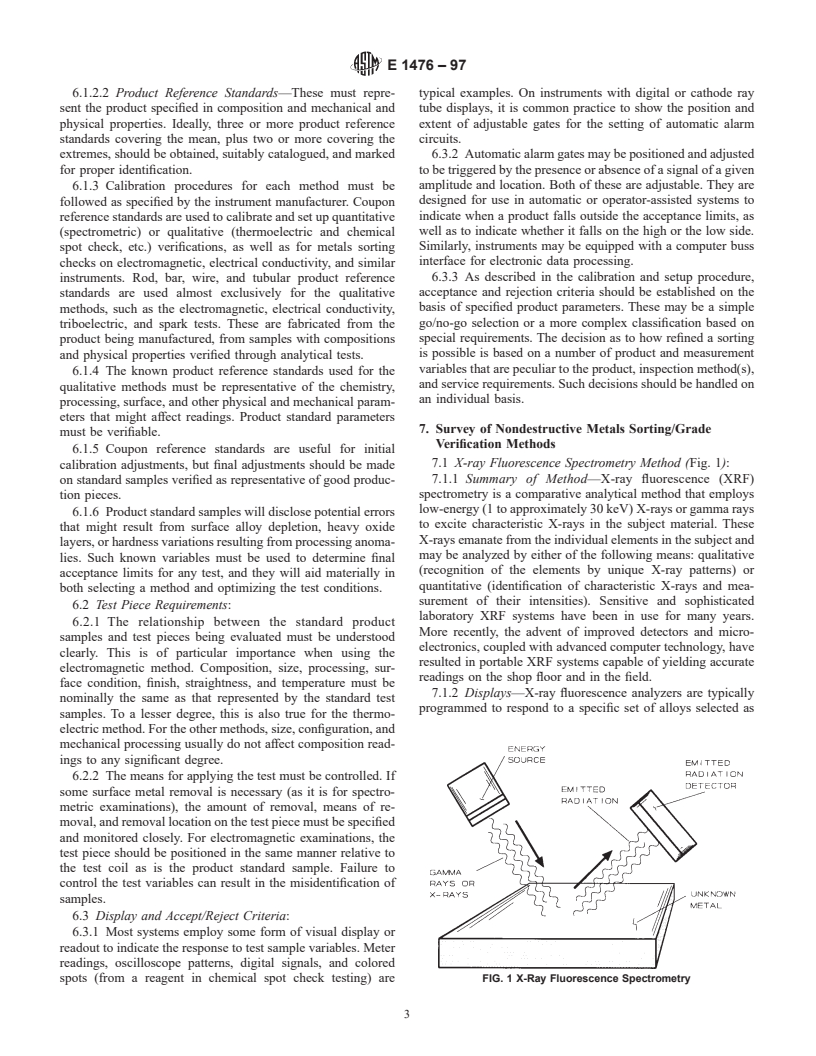

7.1 X-ray Fluorescence Spectrometry Method (Fig. 1):

calibration adjustments, but final adjustments should be made

7.1.1 Summary of Method—X-ray fluorescence (XRF)

on standard samples verified as representative of good produc-

spectrometry is a comparative analytical method that employs

tion pieces.

low-energy (1 to approximately 30 keV) X-rays or gamma rays

6.1.6 Product standard samples will disclose potential errors

to excite characteristic X-rays in the subject material. These

that might result from surface alloy depletion, heavy oxide

X-rays emanate from the individual elements in the subject and

layers, or hardness variations resulting from processing anoma-

may be analyzed by either of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.