ASTM F2329-05(2011)

(Specification)Standard Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and Special Threaded Fasteners

Standard Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and Special Threaded Fasteners

ABSTRACT

This specification covers the requirements for hot-dip zinc coating applied to carbon steel and alloy steel bolts, screws, washers, nuts, and special threaded fasteners applied by the hot-dip coating process. The zinc used for the coating shall conform to the chemical composition required. The following tests shall be made to ensure that the zinc coating is being furnished in accordance with this specification: coating thickness; finish and appearance; embrittlement test; and adhesion test.

SCOPE

1.1 This specification covers the requirements for hot-dip zinc coating applied to carbon steel and alloy steel bolts, screws, washers, nuts, and special threaded fasteners applied by the hot-dip coating process. Nails and rivets are not included in this specification.

1.2 It is intended to be applicable to fasteners that are centrifuged or otherwise handled to remove excess galvanizing bath metal (free zinc).

1.3 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2329 – 05 (Reapproved 2011)

Standard Specification for

Zinc Coating, Hot-Dip, Requirements for Application to

Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and

Special Threaded Fasteners

This standard is issued under the fixed designation F2329; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F1470 Practice for Fastener Sampling for Specified Me-

chanical Properties and Performance Inspection

1.1 This specification covers the requirements for hot-dip

F1789 Terminology for F16 Mechanical Fasteners

zinc coating applied to carbon steel and alloy steel bolts,

screws, washers, nuts, and special threaded fasteners applied

3. Terminology

by the hot-dip coating process. Nails and rivets are not

3.1 Terms used in this specification are defined in Termi-

included in this specification.

nology F1789 unless otherwise defined in this specification.

1.2 It is intended to be applicable to fasteners that are

3.1.1 batchlot—quantity of identical parts cleaned, pickled,

centrifuged or otherwise handled to remove excess galvanizing

fluxed, and galvanized together at one time in a galvanizing

bath metal (free zinc).

basket.

1.3 The values stated in inch-pound units are to be regarded

3.1.2 galvanizing—hot-dip zinc coating.

as standard. No other units of measurement are included in this

3.1.3 high temperature galvanizing—galvanizing process

standard.

carried out in a ceramic vessel (kettle) at an approximate

1.4 This standard does not purport to address all of the

temperature ranging between 990 and 1040°F.

safety concerns, if any, associated with its use. It is the

3.1.4 hot-dip zinc coating of mechanical fasteners—process

responsibility of the user of this standard to establish appro-

whereby fasteners are zinc coated by immersion in a bath of

priate safety and health practices and determine the applica-

molten zinc, resulting in the formation of the iron/zinc alloy

bility of regulatory limitations prior to use.

coating and a zinc coating at the surface of the fastener. This

2. Referenced Documents process involves the removal of excess zinc by spinning the

2 parts in a centrifuge, or brushing the threaded portion, or

2.1 ASTM Standards:

handling otherwise to remove the excess zinc.

A153/A153M Specification for Zinc Coating (Hot-Dip) on

3.1.5 production lot—batches of parts originating from the

Iron and Steel Hardware

samemanufacturinglot,processedcontinuouslythroughclean-

A563 Specification for Carbon and Alloy Steel Nuts

ing, pickling, fluxing, dipping in molten zinc and spun in a

B487 Test Method for Measurement of Metal and Oxide

centrifuge, or other means, without any significant change in

CoatingThicknessbyMicroscopicalExaminationofCross

time, temperature, and concentration of the constituents of the

Section

process.

E376 Practice for Measuring Coating Thickness by

3.1.6 stress relief—process of heating parts for a definite

Magnetic-FieldorEddy-Current(Electromagnetic)Exami-

timeatagiventemperatureinordertorelievestressinducedby

nation Methods

work hardening.

F606 Test Methods for Determining the Mechanical Prop-

erties of Externally and Internally Threaded Fasteners,

4. Ordering Information

Washers, Direct Tension Indicators, and Rivets

4.1 Orders for zinc coating of fasteners to this specification

shall include the following:

This specification is under the jurisdiction of ASTM Committee F16 on

4.1.1 Name of product (that is bolt, stud, nut, washers, or

Fasteners and is the direct responsibility of Subcommittee F16.03 on Coatings on

other);

Fasteners.

4.1.2 ASTM designation and year of issue, including fas-

Current edition approved May 1, 2011. Published June 2011. Originally

approved in 2005. Last previous edition approved in 2005 as F2329-05. DOI:

tener specification number;

10.1520/F2329-05R11.

4.1.3 Hydrogen embrittlement relief, as required by the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

purchaser see, 7.2.3;

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2329 – 05 (2011)

4.1.4 Quantity of fasteners to be hot-dip zinc coated; 5.5.1 When requested by the purchaser, treatments such as

4.1.5 Stress relief or tempering temperature to which the chromating or phosphating shall be applied to reduce the

fasteners where subjected, if applicable; possibility of wet storage staining (white corrosion) or to assist

4.1.6 Secondary processing such as chromating, phosphat- subsequent painting.

ing, or lubrication, if applicable; 5.5.2 When specified on the purchase order, the nuts, bolts,

4.1.7 Average galvanizing temperature to which fasteners or screws shall be lubricated to enhance assembly.

will be subjected, if required by the purchaser (see 7.2.2);

4.1.8 Specify baking if required (see 7.2.3); and 6. Chemical Composition of Zinc

4.1.9 Certification, if required (see 14.1).

6.1 Unless otherwise specified in the product standard, the

zinc used for the coating shall conform to the requirements of

5. Materials and Manufacture

the section on Zinc of Specification A153/A153M.

5.1 Condition of the As-Received Fasteners—The fasteners

as received by the galvanizer shall be free from contaminants

7. Safeguards Against Alteration of Fasteners Mechanical

that are not readily removed in the cleaning process and would

Properties

adversely affect the galvanizing.

7.1 Stress Relief—Fasteners subjected to severe work hard-

5.2 Process—Unless otherwise covered in this specifica-

ening shall be stress-relieved by the fastener manufacturer

tion, all processing parameters shall be in accordance with the

prior to hot-dip zinc coating (galvanizing).

requirements of Specification A153/A153M.

7.2 Hot-Dip Zinc Coating:

5.2.1 Process Control—Galvanized fasteners subjected to a

7.2.1 Effect of Temperature on Mechanical Properties:

process control plan based upon batch lot level shall comply

7.2.1.1 Galvanizing carried out at a temperature above

with the batch lot sampling plan in Table 1, and the sampling

800°F can adversely affect the final mechanical properties of

plan for production lot (prevention process) as determined in

the fasteners. Therefore, the supplier of the fasteners submit-

10.2.2 shall be applied.

ting the product to the galvanizer shall be aware of the

5.3 Spinning and Quenching:

tempering temperature of the fasteners relative to the tempera-

5.3.1 Parts shall be spun immediately following removal

ture of the galvanizing bath and the potential effect it may have

from the galvanizing bath and quenched in water. In addition,

on the product. When requested by the purchaser, the average

small parts shall be air cooled, as needed, in order to prevent

galvanizing temperature that the fasteners will be subjected to

the formation of zinc oxide.

shall be furnished.

5.3.2 Parts, which cannot be spun shall be brushed or

7.2.1.2 Unlessotherwiserequiredbytheproductstandardor

handled otherwise to remove the excess zinc.

by the purchaser, testing for mechanical properties is not

5.4 Alteration of Threaded Fasteners:

necessary if the galvanizing process is carried out at a lower

5.4.1 Fasteners that have been hot-dip galvanized shall not

temperature than the stress relief or tempering temperature of

be further altered (such as subjected to a cutting, rolling,

the fasteners. If the galvanizing process is carried out at a

finishing-tool operation) by the galvanizer unless specifically

higher temperature than the stress relief or the tempering

authorized in writing by the purchaser.

temperature of the fasteners, than the purchaser shall make

5.4.2 Hot-dip galvanizing of externally threaded fasteners

provision for mechanical testing.

shall meet the thread fitting requirements of the specified

7.2.1.3 Threaded fasteners made from carbon or alloy steel

product standard or specific allowance as determined by the

heat treated to a minimum specified hardness of 40 HRC, or

customer.

case hardened steel fasteners shall not be hot-dip zinc coated.

NOTE 1—The scope of this specification does not cover the require-

7.2.2 EffectofHydrogenontheMechanicalPropertiesafter

ments regarding the overtapping of galvanized nuts. These requirements

Galvanizing —Hydrogen has the potential of being introduced

are established by the applicable product standard, such as Specification

into the steel during acid pickling, prior to hot-dip galvanizing.

A563 (or others), or in writing by the purchaser, if needed.

For high strength fasteners (having a specified minimum

5.5 Secondary Processing:

product hardness of 33 HRC), there is a risk of internal

hydrogen embrittlement. If required by the product standard or

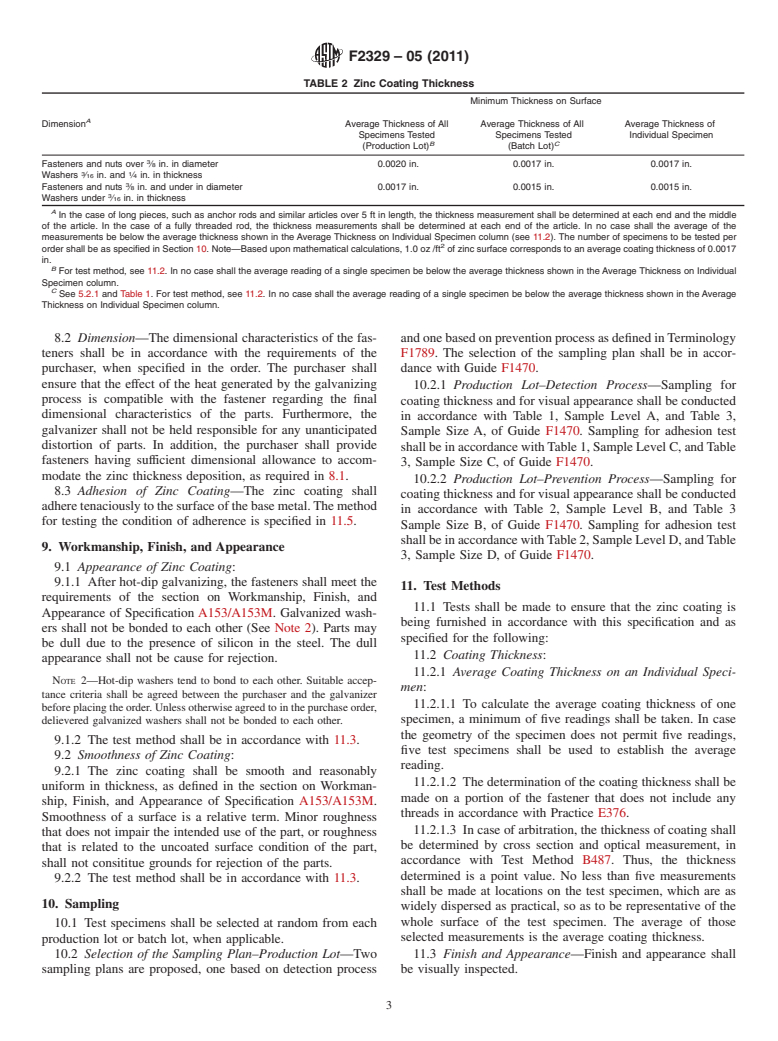

A

TABLE 1 Process Control of Batch Lot

by the purchaser, mechanical descaling (with or without flash

Sampling Plan

pickling) or baking shall be conducted to reduce the risk of

B

Sample Size

internal hydrogen embrittlement. Baking shall be conducted

after pickling and prior to hot-dip galvanizing.

D

Batch Lot Size Average Coating Adhesion Appearance

C

7.2.3 Effect of the Galvanizing Temperature—Externally

Thickness

threaded ferrous fasteners over 1.00 in. diameter with a

5to25 1 1 1

26 to 50 1 1 2 specifiedminimumhardnessofHRC33andhighershallnotbe

51 to 150 2 1 2

hot-dip zinc coated at high temperature (see definition in 3.1.3)

151 and over 2 2 2

in order to avoid microcracks.

A

The acceptance criterion in all cases is zero defects.

B

The sample size is the number of specimen(s) required to be tested/inspected

8. Coating and Dimensional Requirements

to the applicable criteria.

C

Coating thickness frequency of measurements: one set of specimen(s) for

8.1 Coating Thickness—The zinc coating thickness shall

every five batch lots. For test method, see 11.1.

D

Visual inspection for conformance. meet the requirements of Table 2.

F2329 – 05 (2011)

TABLE 2 Zinc Coating Thickness

Minimum Thickness on Surface

A

Dimension Average Thickness of A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.