ASTM A394-08(2015)

(Specification)Standard Specification for Steel Transmission Tower Bolts, Zinc-Coated and Bare

Standard Specification for Steel Transmission Tower Bolts, Zinc-Coated and Bare

ABSTRACT

This specification covers the chemical and mechanical requirements of hexagon and square-head zinc-coated steel bolts and atmospheric corrosion-resistant bolts for use in the construction of transmission towers, substations, and similar steel structures. The following types of bolts are: Type 0 includes hot-dip zinc-coated bolts made of low or medium carbon steel, Type 1 includes hot-dip zinc-coated bolts made of medium carbon steel, quenched and tempered, Type 2, and Type 3 includes bare, quenched, and tempered bolts made of weathering steel. Steel for the manufacture of bolts shall be made by any of the following processes: open-hearth, electric-furnace, or basic-oxygen. Type 1 bolts produced from medium carbon steel shall be quenched in a liquid medium from above the austenizing temperature. Type 1 bolts produced from medium carbon steel to which chromium, nickel, molybdenum, or boron were intentionally added shall be quenched only in oil from above the austenitizing temperature. Type 3 bolts shall be quenched only in oil from above the austenitizing temperature. Cold-headed Type 0 bolts shall be stress relief annealed before zinc coating to remove cold work effects such that the hardness measured anywhere on the surface or through the cross-section shall meet the requirement specified. Different tests shall be conducted in order to determine the following mechanical properties of bolts: hardness, tensile strength, and shear strength.

SCOPE

1.1 This specification covers the chemical and mechanical requirements of hexagon and square-head zinc-coated steel bolts and atmospheric corrosion-resistant bolts, in nominal thread diameters of 1/2 , 5/8 , 3/4 , 7/8 and 1 in. for use in the construction of transmission towers, substations, and similar steel structures. The various types of bolts covered in this specification are:

1.1.1 Type 0—Hot-dip zinc-coated bolts made of low or medium carbon steel.

1.1.2 Type 1—Hot-dip zinc-coated bolts made of medium carbon steel, quenched and tempered.

1.1.3 Type 2—Withdrawn in 2005.

1.1.4 Type 3—Bare (uncoated), quenched and tempered bolts made of weathering steel.

1.2 Annex A1 of this specification covers hot-dip zinc-coated steel ladder bolts, step bolts, and support-equipment bolts.

1.3 Nuts and washers that are supplied under this specification that are hot-dip zinc coated shall be in accordance with 4.4.

1.4 Terms used in this specification are defined in Terminology F1789.

1.5 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A394 − 08 (Reapproved 2015)

Standard Specification for

Steel Transmission Tower Bolts, Zinc-Coated and Bare

This standard is issued under the fixed designation A394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers the chemical and mechanical

A563 Specification for Carbon and Alloy Steel Nuts (Metric)

requirements of hexagon and square-head zinc-coated steel

A0563_A0563M

bolts and atmospheric corrosion-resistant bolts, in nominal

1 5 3 7

D3951 Practice for Commercial Packaging

thread diameters of ⁄2, ⁄8, ⁄4 , ⁄8 and 1 in. for use in the

F436 Specification for Hardened Steel Washers (Metric)

construction of transmission towers, substations, and similar

F0436_F0436M

steel structures. The various types of bolts covered in this

F606/F606M Test Methods for Determining the Mechanical

specification are:

Properties of Externally and Internally Threaded

1.1.1 Type 0—Hot-dip zinc-coated bolts made of low or

Fasteners, Washers, Direct Tension Indicators, and Rivets

medium carbon steel.

F788/F788M Specification for Surface Discontinuities of

1.1.2 Type 1—Hot-dip zinc-coated bolts made of medium

Bolts, Screws, Studs, and Rivets, Inch and Metric Series

carbon steel, quenched and tempered.

F1470 Practice for Fastener Sampling for Specified Me-

1.1.3 Type 2—Withdrawn in 2005.

chanical Properties and Performance Inspection

1.1.4 Type 3—Bare (uncoated), quenched and tempered

F1789 Terminology for F16 Mechanical Fasteners

bolts made of weathering steel.

F2329 Specification for Zinc Coating, Hot-Dip, Require-

1.2 Annex A1 of this specification covers hot-dip zinc-

ments for Application to Carbon and Alloy Steel Bolts,

coated steel ladder bolts, step bolts, and support-equipment

Screws, Washers, Nuts, and Special Threaded Fasteners

bolts.

G101 Guide for Estimating the Atmospheric Corrosion Re-

sistance of Low-Alloy Steels

1.3 Nuts and washers that are supplied under this specifica-

2.2 ASME Standards:

tion that are hot-dip zinc coated shall be in accordance with

B1.1 Unified Screw Threads

4.4.

B18.2.1 Square and Hex Bolts and Screws

1.4 Terms used in this specification are defined in Termi-

B18.24 Part Identifying Number (PIN) Code System Stan-

nology F1789.

dard for B18 Fastener Products

1.5 The values stated in inch-pound units are to be regarded

3. Ordering Information

as standard. No other units of measurement are included in this

standard.

3.1 Orders for products under this specification shall include

the following:

1.6 The following safety hazards caveat pertains only to the

3.1.1 Quantity (number of bolts and accessories).

test methods portion, Section 11, of this specification. This

3.1.2 Name of products, including accessories such as A563

standard does not purport to address all of the safety concerns,

nuts and F436 washers when desired.

if any, associated with its use. It is the responsibility of the user

3.1.3 Dimensions, including nominal bolt diameter and

of this standard to establish appropriate safety, health and

length. For bolts other than transmission-tower bolts, complete

environmental practices and determine the applicability of

dimensions are required (see Annex A1).

regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction of ASTM Committee F16 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Standards volume information, refer to the standard’s Document Summary page on

Studs and Nuts. the ASTM website.

Current edition approved June 15, 2015. Published June 2015. Originally Available from American Society of Mechanical Engineers (ASME), ASME

ε1

approved in 1955. Last previous edition approved in 2008 as A394 – 08 . DOI: International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

10.1520/A0394-08R15. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A394 − 08 (2015)

3.1.4 Type of bolt (for example, Type 0, 1, or 3). 4.2.3 Type 1 bolts, regardless of the steel used, and Type 3

3.1.4.1 When non-zinc-coated atmospheric corrosion- bolts shall be tempered by reheating to not less than 800°F.

resistant steel is required, Type 3 bolts shall be specified by the

4.2.4 Cold-headed Type 0 bolts shall be stress relief an-

purchaser.

nealed before zinc coating to remove cold work effects such

3.1.5 ASTM designation and year of issue. When year of

that the hardness measured anywhere on the surface or through

issue is not specified, bolts shall be furnished to the latest issue.

the cross-section shall meet the requirements in 6.1.

3.1.6 Additional requirements, if any, are to be specified on

4.3 Threads may be rolled or cut.

the purchase order:

4.4 Zinc Coatings, Hot Dip:

3.1.6.1 Shear-strength testing (see 6.2.1 and 6.2.2). Include

type of test required.

4.4.1 Type 0 and Type 1 bolts shall be hot-dip zinc-coated

3.1.6.2 Additional tests.

accordance with the requirements of Specification F2329,

3.1.6.3 Inspection (see 12.1 and 12.2).

except that the minimum average weight (thickness) of zinc

3.1.6.4 Certification (see 14.1). coating shall be 1.65 oz/ft (0.0028 in.) and the minimum

3.1.6.5 Test reports (see 14.1). weight of zinc coating on any one item shall be 1.50 oz/ft

(0.0025 in.).

3.1.6.6 Other finishes, specify other protective finish, if

required. 4.4.2 Bolt threads shall not be cut, rolled, or otherwise

finished after zinc coating.

NOTE 1—Examples of ordering description:

4.4.3 Hot-dip zinc-coated nuts furnished under Specifica-

(1) 1000 square-head transmission-tower bolts, ⁄2 by 2 in. Type 1, hot-dip

zinc coated, shear testing required, ASTM A394 – XX, with hot-dip

tion A563 shall be tapped after zinc coating.

zinc-coated hex nuts, Grade DH, ASTM A563 – XX,

4.4.4 Hot-dip zinc-coated nuts and washers supplied for use

(2) 1000 transmission tower bolts, ⁄2 by 2 in. Type 0, hot-dip zinc coated,

with bolts under this specification shall be zinc-coated in

ASTM A394 – XX, with hot-dip zinc-coated hex nuts, Grade A, ASTM

accordance with 4.4.1.

A563 – XX.

(3) 1000 transmission tower bolts, ⁄2 by 2 in. Type 3, ASTM A394 – XX,

4.5 Protection of Uncoated Surfaces—When hot-dip zinc-

with hex nuts, Grade DH3 weathering steel, ASTM A563 – XX and with

2 circular washers, Type 3, ASTM F436 – XX. coated nuts are ordered, the cutting oil or some other suitable

substance shall be left on the uncoated surface to inhibit rusting

3.1.7 For establishment of a part identifying system, see

during shipment and storage. It is recommended that the

ASME B18.24.

additional lubricant be clean and dry to the touch.

3.2 Recommended Nuts:

4.6 Secondary Processing:

3.2.1 Unless otherwise specified, all nuts on these bolts shall

4.6.1 If any processing which can affect the mechanical

be hex style and conform to the requirements of Specification

properties or performance of the bolts is performed after the

A563 as follows.

initial testing, the bolts shall be retested for all specified

Bolt Type Nut Grade Finish

mechanical properties and performance requirements affected

0 A hot-dip zinc-coated

1 DH hot-dip zinc-coated

by the reprocessing.

3 DH3 plain

4.6.2 When the secondary processing is heat treatment, the

3.3 Recommended Washers:

bolts shall be tested for all specified mechanical properties.

3.3.1 Suitable washers for use with Type 0 are hot-dip

Hot-dip zinc-coated bolts shall be tested for all specified

zinc-coated carbon-steel washers with dimensions that are in

mechanical properties.

accordance with Specification F436. Suitable washers for use

with Type 1 bolts are hot-dip zinc-coated Type 1 hardened-steel

5. Chemical Composition

washers that are in accordance with Specification F436. Suit-

5.1 Type 0 and Type 1 bolts shall conform to the chemical

able washers for use with Type 3 bolts are Type 3 hardened-

composition requirements specified in Table 1.

steel washers that are in accordance with Specification F436.

5.2 Type 3 bolts shall conform to one of the chemical

4. Materials and Manufacture

compositions specified in Table 2. The selection of the chemi-

cal composition A, B, C, D, E, or F shall be at the option of the

4.1 Steel for the manufacture of bolts shall be made by any

of the following processes: open-hearth, electric-furnace, or bolt manufacturer. See Guide G101 for methods of estimating

the atmospheric corrosion resistance of low alloy steels.

basic-oxygen.

4.2 Heat Treatment:

6. Mechanical Properties

4.2.1 Type 1 bolts produced from medium carbon steel shall

be quenched in a liquid medium from above the austenizing 6.1 Tension Test—Types 0, 1, and 3 bolts having a length

temperature. Type 1 bolts produced from medium carbon steel

equal to or more than 3 diameters shall be wedge tension tested

to which chromium, nickel, molybdenum, or boron were

as specified in 11.1 and shall conform to the tensile strength

intentionally added shall be quenched only in oil from above

requirements in Table 3. Zinc-coated bolts shall be tested after

the austenitizing temperature.

coating. Bolts too short for full size testing or for other reasons

4.2.2 Type 3 bolts shall be quenched only in oil from above not subject to tension tests, shall meet the following hardness

the austenitizing temperature. requirements:

A394 − 08 (2015)

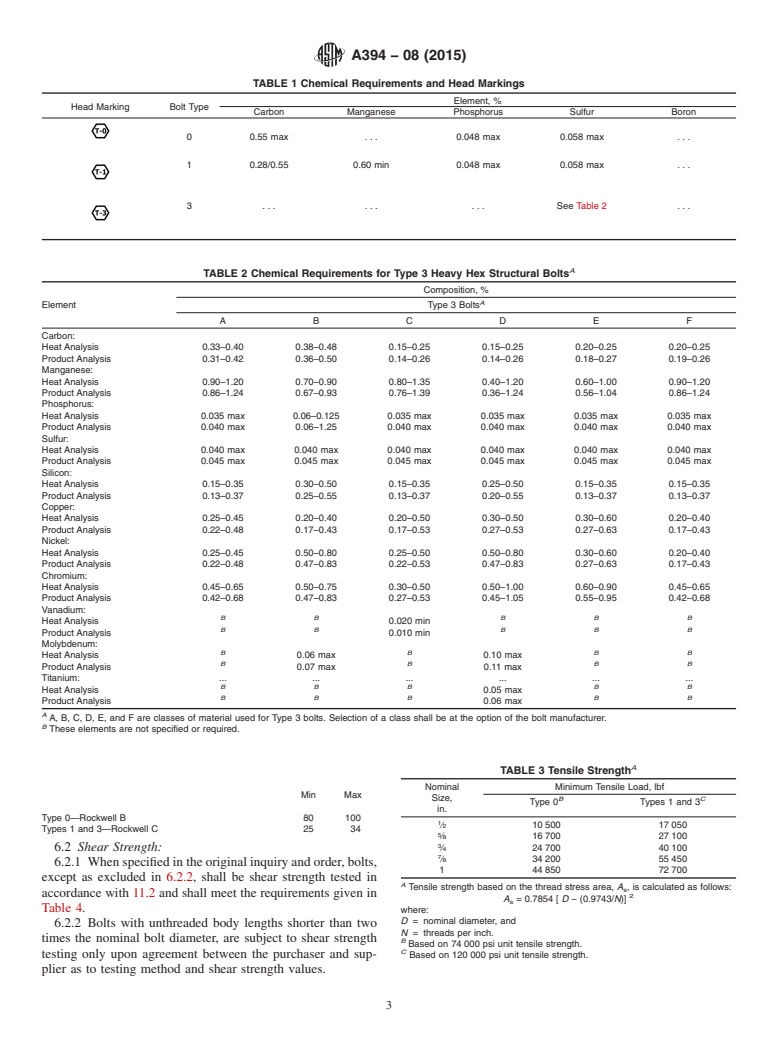

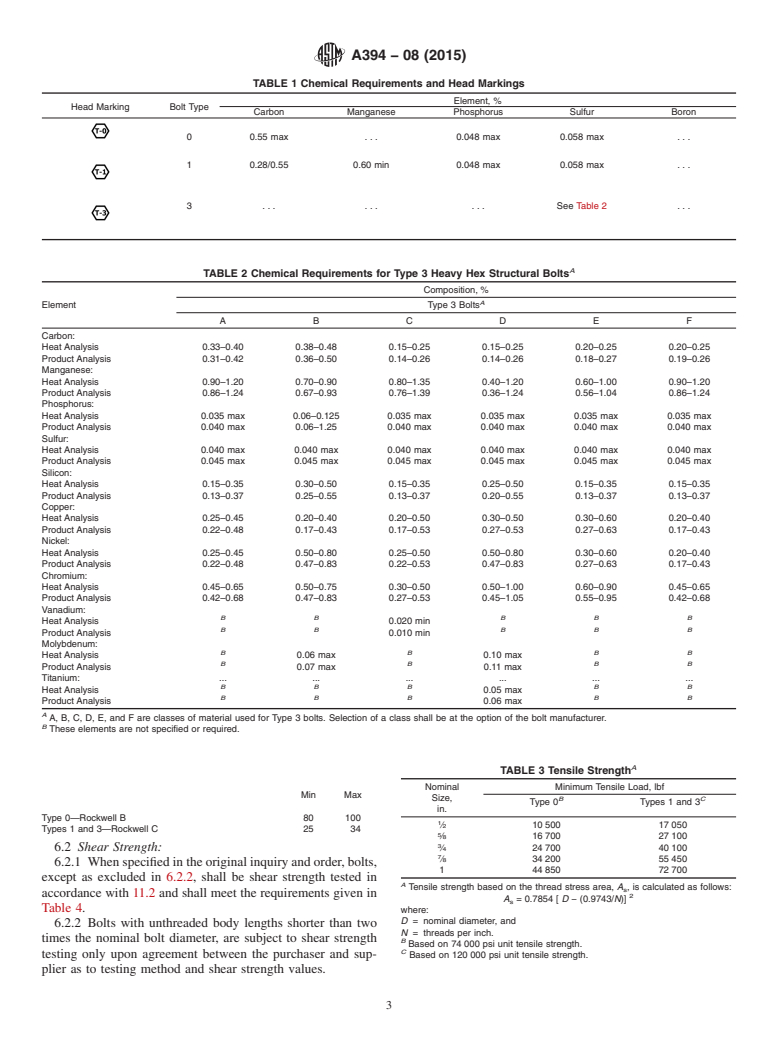

TABLE 1 Chemical Requirements and Head Markings

Element, %

Head Marking Bolt Type

Carbon Manganese Phosphorus Sulfur Boron

0 0.55 max . . . 0.048 max 0.058 max . . .

1 0.28/0.55 0.60 min 0.048 max 0.058 max . . .

3 . . . . . . . . . See Table 2 . . .

A

TABLE 2 Chemical Requirements for Type 3 Heavy Hex Structural Bolts

Composition, %

A

Element Type 3 Bolts

A B C D E F

Carbon:

Heat Analysis 0.33–0.40 0.38–0.48 0.15–0.25 0.15–0.25 0.20–0.25 0.20–0.25

Product Analysis 0.31–0.42 0.36–0.50 0.14–0.26 0.14–0.26 0.18–0.27 0.19–0.26

Manganese:

Heat Analysis 0.90–1.20 0.70–0.90 0.80–1.35 0.40–1.20 0.60–1.00 0.90–1.20

Product Analysis 0.86–1.24 0.67–0.93 0.76–1.39 0.36–1.24 0.56–1.04 0.86–1.24

Phosphorus:

Heat Analysis 0.035 max 0.06–0.125 0.035 max 0.035 max 0.035 max 0.035 max

Product Analysis 0.040 max 0.06–1.25 0.040 max 0.040 max 0.040 max 0.040 max

Sulfur:

Heat Analysis 0.040 max 0.040 max 0.040 max 0.040 max 0.040 max 0.040 max

Product Analysis 0.045 max 0.045 max 0.045 max 0.045 max 0.045 max 0.045 max

Silicon:

Heat Analysis 0.15–0.35 0.30–0.50 0.15–0.35 0.25–0.50 0.15–0.35 0.15–0.35

Product Analysis 0.13–0.37 0.25–0.55 0.13–0.37 0.20–0.55 0.13–0.37 0.13–0.37

Copper:

Heat Analysis 0.25–0.45 0.20–0.40 0.20–0.50 0.30–0.50 0.30–0.60 0.20–0.40

Product Analysis 0.22–0.48 0.17–0.43 0.17–0.53 0.27–0.53 0.27–0.63 0.17–0.43

Nickel:

Heat Analysis 0.25–0.45 0.50–0.80 0.25–0.50 0.50–0.80 0.30–0.60 0.20–0.40

Product Analysis 0.22–0.48 0.47–0.83 0.22–0.53 0.47–0.83 0.27–0.63 0.17–0.43

Chromium:

Heat Analysis 0.45–0.65 0.50–0.75 0.30–0.50 0.50–1.00 0.60–0.90 0.45–0.65

Product Analysis 0.42–0.68 0.47–0.83 0.27–0.53 0.45–1.05 0.55–0.95 0.42–0.68

Vanadium:

B B B B B

Heat Analysis 0.020 min

B B B B B

Product Analysis 0.010 min

Molybdenum:

B B B B

Heat Analysis 0.06 max 0.10 max

B B B B

Product Analysis 0.07 max 0.11 max

Titanium: . . . . . .

B B B B B

Heat Analysis 0.05 max

B B B B B

Product Analysis 0.06 max

A

A, B, C, D, E, and F are classes of material used for Type 3 bolts. Selection of a class shall be at the option of the bolt manufacturer.

B

These elements are not specified or required.

A

TABLE 3 Tensile Strength

Nominal Minimum Tensile Load, lbf

Min Max

Size, B C

Type 0 Types 1 and 3

in.

Type 0—Rockwell B 80 100

⁄2 10 500 17 050

Types 1 and 3—Rockwell C 25 34

⁄8 16 700 27 100

6.2 Shear Strength: ⁄4 24 700 40 100

⁄8 34 200 55 450

6.2.1 When specified in the original inquiry and order, bolts,

1 44 850 72 700

except as excluded in 6.2.2, shall be shear strength tested in

A

Tensile strength based on the thread stress area, A , is calculated as follows:

s

accordance with 11.2 and shall meet the requirements given in

A = 0.7854 [ D − (0.9743/N)]

s

Table 4.

where:

D = nominal diameter, and

6.2.2 Bolts with unthreaded body lengths shorter than two

N = threads per inch.

times the nominal bolt diameter, are subject to shear strength

B

Based on 74 000 psi unit tensile strength.

C

testing only upon agreement between the purchaser and sup- Based on 120 000 psi unit tensile strength.

plier as to testing method and shear strength values.

A394 − 08 (2015)

A

Hot-dip zinc-coated nuts are tapped oversize after coating.

TABLE 4 Shear Strengths

Minimum Load, lbf

7.3.3 The gaging limit for bolts shall be verified during

Type 0 Types 1 and 3

manufacture. In case of dispute, a calibrated thread ring gage of

Single Shear Single Shear Single Shear Single Shear

Nominal Size,

the same size as the oversize limit in 7.3.2 (Class X tolerance,

Strength Strength Strength Strength

in.

Through Through Through Through

gage tolerance plus) shall be used to verify compliance. The

Threads, Body, Threads, Body,

gage shall assemble with hand effort following application of

A B C D

lbf lbf lbf lbf

light machine oil to prevent galling and damage to the gage.

⁄2 6 950 9 000 9 350 14 600

5 These inspections, when performed to resolve controversy,

⁄8 11 150 14 100 15 050 22 850

⁄4 16 650 20 250 22 450 32 850

shall be conducted at the frequency specified in the quality

⁄8 23 150 27 600 31 150 44 750

assurance provisions of ASME B18.2.1.

1 30 400 36 050 41 000 58 450

A

Based on 55 200 psi unit shear strength across the area at root of threads.

B

8. Workmanship

Based on 45 880 psi unit shear strength across the nominal area.

C

Based on 74 400 psi unit shear strength across the area at root of threads.

D 8.1 Surface discontinuity limits of Types 1 and 3 shall be in

Based on 74 400 psi unit shear strength across the nominal area.

accordance with Specification F788/F788M.

9. Sampling

7. Dimensions

9.1 Testing Responsibility:

7.1 Bolt threads, before zinc coating, shall be the unified

9.1.1 Each lot shall b

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A394 − 08 (Reapproved 2015)

Standard Specification for

Steel Transmission Tower Bolts, Zinc-Coated and Bare

This standard is issued under the fixed designation A394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers the chemical and mechanical

A563 Specification for Carbon and Alloy Steel Nuts (Metric)

requirements of hexagon and square-head zinc-coated steel

A0563_A0563M

bolts and atmospheric corrosion-resistant bolts, in nominal

1 5 3 7

D3951 Practice for Commercial Packaging

thread diameters of ⁄2, ⁄8, ⁄4 , ⁄8 and 1 in. for use in the

F436 Specification for Hardened Steel Washers (Metric)

construction of transmission towers, substations, and similar

F0436_F0436M

steel structures. The various types of bolts covered in this

F606/F606M Test Methods for Determining the Mechanical

specification are:

Properties of Externally and Internally Threaded

1.1.1 Type 0—Hot-dip zinc-coated bolts made of low or

Fasteners, Washers, Direct Tension Indicators, and Rivets

medium carbon steel.

F788/F788M Specification for Surface Discontinuities of

1.1.2 Type 1—Hot-dip zinc-coated bolts made of medium

Bolts, Screws, Studs, and Rivets, Inch and Metric Series

carbon steel, quenched and tempered.

F1470 Practice for Fastener Sampling for Specified Me-

1.1.3 Type 2—Withdrawn in 2005.

chanical Properties and Performance Inspection

1.1.4 Type 3—Bare (uncoated), quenched and tempered

F1789 Terminology for F16 Mechanical Fasteners

bolts made of weathering steel.

F2329 Specification for Zinc Coating, Hot-Dip, Require-

1.2 Annex A1 of this specification covers hot-dip zinc-

ments for Application to Carbon and Alloy Steel Bolts,

coated steel ladder bolts, step bolts, and support-equipment

Screws, Washers, Nuts, and Special Threaded Fasteners

bolts.

G101 Guide for Estimating the Atmospheric Corrosion Re-

sistance of Low-Alloy Steels

1.3 Nuts and washers that are supplied under this specifica-

2.2 ASME Standards:

tion that are hot-dip zinc coated shall be in accordance with

B1.1 Unified Screw Threads

4.4.

B18.2.1 Square and Hex Bolts and Screws

1.4 Terms used in this specification are defined in Termi-

B18.24 Part Identifying Number (PIN) Code System Stan-

nology F1789.

dard for B18 Fastener Products

1.5 The values stated in inch-pound units are to be regarded

3. Ordering Information

as standard. No other units of measurement are included in this

standard.

3.1 Orders for products under this specification shall include

the following:

1.6 The following safety hazards caveat pertains only to the

3.1.1 Quantity (number of bolts and accessories).

test methods portion, Section 11, of this specification. This

3.1.2 Name of products, including accessories such as A563

standard does not purport to address all of the safety concerns,

nuts and F436 washers when desired.

if any, associated with its use. It is the responsibility of the user

3.1.3 Dimensions, including nominal bolt diameter and

of this standard to establish appropriate safety, health and

length. For bolts other than transmission-tower bolts, complete

environmental practices and determine the applicability of

dimensions are required (see Annex A1).

regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction of ASTM Committee F16 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Standards volume information, refer to the standard’s Document Summary page on

Studs and Nuts. the ASTM website.

Current edition approved June 15, 2015. Published June 2015. Originally Available from American Society of Mechanical Engineers (ASME), ASME

ε1

approved in 1955. Last previous edition approved in 2008 as A394 – 08 . DOI: International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

10.1520/A0394-08R15. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A394 − 08 (2015)

3.1.4 Type of bolt (for example, Type 0, 1, or 3). 4.2.3 Type 1 bolts, regardless of the steel used, and Type 3

bolts shall be tempered by reheating to not less than 800°F.

3.1.4.1 When non-zinc-coated atmospheric corrosion-

resistant steel is required, Type 3 bolts shall be specified by the

4.2.4 Cold-headed Type 0 bolts shall be stress relief an-

purchaser.

nealed before zinc coating to remove cold work effects such

3.1.5 ASTM designation and year of issue. When year of

that the hardness measured anywhere on the surface or through

issue is not specified, bolts shall be furnished to the latest issue.

the cross-section shall meet the requirements in 6.1.

3.1.6 Additional requirements, if any, are to be specified on

4.3 Threads may be rolled or cut.

the purchase order:

3.1.6.1 Shear-strength testing (see 6.2.1 and 6.2.2). Include 4.4 Zinc Coatings, Hot Dip:

type of test required.

4.4.1 Type 0 and Type 1 bolts shall be hot-dip zinc-coated

3.1.6.2 Additional tests.

accordance with the requirements of Specification F2329,

3.1.6.3 Inspection (see 12.1 and 12.2). except that the minimum average weight (thickness) of zinc

3.1.6.4 Certification (see 14.1). coating shall be 1.65 oz/ft (0.0028 in.) and the minimum

weight of zinc coating on any one item shall be 1.50 oz/ft

3.1.6.5 Test reports (see 14.1).

(0.0025 in.).

3.1.6.6 Other finishes, specify other protective finish, if

required.

4.4.2 Bolt threads shall not be cut, rolled, or otherwise

finished after zinc coating.

NOTE 1—Examples of ordering description:

4.4.3 Hot-dip zinc-coated nuts furnished under Specifica-

(1) 1000 square-head transmission-tower bolts, ⁄2 by 2 in. Type 1, hot-dip

zinc coated, shear testing required, ASTM A394 – XX, with hot-dip

tion A563 shall be tapped after zinc coating.

zinc-coated hex nuts, Grade DH, ASTM A563 – XX,

4.4.4 Hot-dip zinc-coated nuts and washers supplied for use

(2) 1000 transmission tower bolts, ⁄2 by 2 in. Type 0, hot-dip zinc coated,

with bolts under this specification shall be zinc-coated in

ASTM A394 – XX, with hot-dip zinc-coated hex nuts, Grade A, ASTM

accordance with 4.4.1.

A563 – XX.

(3) 1000 transmission tower bolts, ⁄2 by 2 in. Type 3, ASTM A394 – XX,

4.5 Protection of Uncoated Surfaces—When hot-dip zinc-

with hex nuts, Grade DH3 weathering steel, ASTM A563 – XX and with

coated nuts are ordered, the cutting oil or some other suitable

2 circular washers, Type 3, ASTM F436 – XX.

substance shall be left on the uncoated surface to inhibit rusting

3.1.7 For establishment of a part identifying system, see

during shipment and storage. It is recommended that the

ASME B18.24.

additional lubricant be clean and dry to the touch.

3.2 Recommended Nuts:

4.6 Secondary Processing:

3.2.1 Unless otherwise specified, all nuts on these bolts shall

4.6.1 If any processing which can affect the mechanical

be hex style and conform to the requirements of Specification

properties or performance of the bolts is performed after the

A563 as follows.

initial testing, the bolts shall be retested for all specified

Bolt Type Nut Grade Finish

0 A hot-dip zinc-coated mechanical properties and performance requirements affected

1 DH hot-dip zinc-coated

by the reprocessing.

3 DH3 plain

4.6.2 When the secondary processing is heat treatment, the

3.3 Recommended Washers:

bolts shall be tested for all specified mechanical properties.

3.3.1 Suitable washers for use with Type 0 are hot-dip

Hot-dip zinc-coated bolts shall be tested for all specified

zinc-coated carbon-steel washers with dimensions that are in

mechanical properties.

accordance with Specification F436. Suitable washers for use

with Type 1 bolts are hot-dip zinc-coated Type 1 hardened-steel

5. Chemical Composition

washers that are in accordance with Specification F436. Suit-

5.1 Type 0 and Type 1 bolts shall conform to the chemical

able washers for use with Type 3 bolts are Type 3 hardened-

composition requirements specified in Table 1.

steel washers that are in accordance with Specification F436.

5.2 Type 3 bolts shall conform to one of the chemical

4. Materials and Manufacture

compositions specified in Table 2. The selection of the chemi-

4.1 Steel for the manufacture of bolts shall be made by any cal composition A, B, C, D, E, or F shall be at the option of the

bolt manufacturer. See Guide G101 for methods of estimating

of the following processes: open-hearth, electric-furnace, or

basic-oxygen. the atmospheric corrosion resistance of low alloy steels.

4.2 Heat Treatment:

6. Mechanical Properties

4.2.1 Type 1 bolts produced from medium carbon steel shall

be quenched in a liquid medium from above the austenizing

6.1 Tension Test—Types 0, 1, and 3 bolts having a length

temperature. Type 1 bolts produced from medium carbon steel

equal to or more than 3 diameters shall be wedge tension tested

to which chromium, nickel, molybdenum, or boron were

as specified in 11.1 and shall conform to the tensile strength

intentionally added shall be quenched only in oil from above

requirements in Table 3. Zinc-coated bolts shall be tested after

the austenitizing temperature.

coating. Bolts too short for full size testing or for other reasons

4.2.2 Type 3 bolts shall be quenched only in oil from above not subject to tension tests, shall meet the following hardness

the austenitizing temperature. requirements:

A394 − 08 (2015)

TABLE 1 Chemical Requirements and Head Markings

Element, %

Head Marking Bolt Type

Carbon Manganese Phosphorus Sulfur Boron

0 0.55 max . . . 0.048 max 0.058 max . . .

1 0.28/0.55 0.60 min 0.048 max 0.058 max . . .

3 . . . . . . . . . See Table 2 . . .

A

TABLE 2 Chemical Requirements for Type 3 Heavy Hex Structural Bolts

Composition, %

A

Element Type 3 Bolts

A B C D E F

Carbon:

Heat Analysis 0.33–0.40 0.38–0.48 0.15–0.25 0.15–0.25 0.20–0.25 0.20–0.25

Product Analysis 0.31–0.42 0.36–0.50 0.14–0.26 0.14–0.26 0.18–0.27 0.19–0.26

Manganese:

Heat Analysis 0.90–1.20 0.70–0.90 0.80–1.35 0.40–1.20 0.60–1.00 0.90–1.20

Product Analysis 0.86–1.24 0.67–0.93 0.76–1.39 0.36–1.24 0.56–1.04 0.86–1.24

Phosphorus:

Heat Analysis 0.035 max 0.06–0.125 0.035 max 0.035 max 0.035 max 0.035 max

Product Analysis 0.040 max 0.06–1.25 0.040 max 0.040 max 0.040 max 0.040 max

Sulfur:

Heat Analysis 0.040 max 0.040 max 0.040 max 0.040 max 0.040 max 0.040 max

Product Analysis 0.045 max 0.045 max 0.045 max 0.045 max 0.045 max 0.045 max

Silicon:

Heat Analysis 0.15–0.35 0.30–0.50 0.15–0.35 0.25–0.50 0.15–0.35 0.15–0.35

Product Analysis 0.13–0.37 0.25–0.55 0.13–0.37 0.20–0.55 0.13–0.37 0.13–0.37

Copper:

Heat Analysis 0.25–0.45 0.20–0.40 0.20–0.50 0.30–0.50 0.30–0.60 0.20–0.40

Product Analysis 0.22–0.48 0.17–0.43 0.17–0.53 0.27–0.53 0.27–0.63 0.17–0.43

Nickel:

Heat Analysis 0.25–0.45 0.50–0.80 0.25–0.50 0.50–0.80 0.30–0.60 0.20–0.40

Product Analysis 0.22–0.48 0.47–0.83 0.22–0.53 0.47–0.83 0.27–0.63 0.17–0.43

Chromium:

Heat Analysis 0.45–0.65 0.50–0.75 0.30–0.50 0.50–1.00 0.60–0.90 0.45–0.65

Product Analysis 0.42–0.68 0.47–0.83 0.27–0.53 0.45–1.05 0.55–0.95 0.42–0.68

Vanadium:

B B B B B

Heat Analysis 0.020 min

B B B B B

Product Analysis 0.010 min

Molybdenum:

B B B B

Heat Analysis 0.06 max 0.10 max

B B B B

Product Analysis 0.07 max 0.11 max

Titanium: . . . . . .

B B B B B

Heat Analysis 0.05 max

B B B B B

Product Analysis 0.06 max

A

A, B, C, D, E, and F are classes of material used for Type 3 bolts. Selection of a class shall be at the option of the bolt manufacturer.

B

These elements are not specified or required.

A

TABLE 3 Tensile Strength

Nominal Minimum Tensile Load, lbf

Min Max

Size,

B C

Type 0 Types 1 and 3

in.

Type 0—Rockwell B 80 100

⁄2 10 500 17 050

Types 1 and 3—Rockwell C 25 34

⁄8 16 700 27 100

6.2 Shear Strength: ⁄4 24 700 40 100

⁄8 34 200 55 450

6.2.1 When specified in the original inquiry and order, bolts,

1 44 850 72 700

except as excluded in 6.2.2, shall be shear strength tested in

A

Tensile strength based on the thread stress area, A , is calculated as follows:

s

accordance with 11.2 and shall meet the requirements given in

A = 0.7854 [ D − (0.9743/N)]

s

Table 4. where:

D = nominal diameter, and

6.2.2 Bolts with unthreaded body lengths shorter than two

N = threads per inch.

times the nominal bolt diameter, are subject to shear strength B

Based on 74 000 psi unit tensile strength.

C

testing only upon agreement between the purchaser and sup- Based on 120 000 psi unit tensile strength.

plier as to testing method and shear strength values.

A394 − 08 (2015)

A

TABLE 4 Shear Strengths Hot-dip zinc-coated nuts are tapped oversize after coating.

Minimum Load, lbf

7.3.3 The gaging limit for bolts shall be verified during

Type 0 Types 1 and 3

manufacture. In case of dispute, a calibrated thread ring gage of

Single Shear Single Shear Single Shear Single Shear

Nominal Size,

the same size as the oversize limit in 7.3.2 (Class X tolerance,

Strength Strength Strength Strength

in.

Through Through Through Through

gage tolerance plus) shall be used to verify compliance. The

Threads, Body, Threads, Body,

gage shall assemble with hand effort following application of

A B C D

lbf lbf lbf lbf

light machine oil to prevent galling and damage to the gage.

⁄2 6 950 9 000 9 350 14 600

5 These inspections, when performed to resolve controversy,

⁄8 11 150 14 100 15 050 22 850

⁄4 16 650 20 250 22 450 32 850

shall be conducted at the frequency specified in the quality

⁄8 23 150 27 600 31 150 44 750

assurance provisions of ASME B18.2.1.

1 30 400 36 050 41 000 58 450

A

Based on 55 200 psi unit shear strength across the area at root of threads.

B 8. Workmanship

Based on 45 880 psi unit shear strength across the nominal area.

C

Based on 74 400 psi unit shear strength across the area at root of threads.

D 8.1 Surface discontinuity limits of Types 1 and 3 shall be in

Based on 74 400 psi unit shear strength across the nominal area.

accordance with Specification F788/F788M.

9. Sampling

7. Dimensions

9.1 Testing Responsibility:

7.1 Bolt threads, before zinc coating, shall be the unified

9.1.1 Each lot shall be tested by the manufacturer prior to

coarse thread series and Class 2A tolerance as defined in the

shipment in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A394 − 08 A394 − 08 (Reapproved 2015)

Standard Specification for

Steel Transmission Tower Bolts, Zinc-Coated and Bare

This standard is issued under the fixed designation A394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Table 1 was editorially revised in November 2011.

1. Scope*

1.1 This specification covers the chemical and mechanical requirements of hexagon and square-head zinc-coated steel bolts and

1 5 3 7

atmospheric corrosion-resistant bolts, in nominal thread diameters of ⁄2, ⁄8, ⁄4 , ⁄8 and 1 in. for use in the construction of

transmission towers, substations, and similar steel structures. The various types of bolts covered in this specification are:

1.1.1 Type 0—Hot-dip zinc-coated bolts made of low or medium carbon steel.

1.1.2 Type 1—Hot-dip zinc-coated bolts made of medium carbon steel, quenched and tempered.

1.1.3 Type 2—Withdrawn in 2005.

1.1.4 Type 3—Bare (uncoated), quenched and tempered bolts made of weathering steel.

1.2 Annex A1 of this specification covers hot-dip zinc-coated steel ladder bolts, step bolts, and support-equipment bolts.

1.3 Nuts and washers that are supplied under this specification that are hot-dip zinc coated shall be in accordance with 4.4.

1.4 Terms used in this specification are defined in Terminology F1789.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only. standard. No other units of measurement are included in this standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A563 Specification for Carbon and Alloy Steel Nuts

D3951 Practice for Commercial Packaging

F436 Specification for Hardened Steel Washers

F606F606/F606M Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners,

Washers, and Rivets (Metric) F0606_F0606M Direct Tension Indicators, and Rivets

F788/F788M Specification for Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric Series

F1470 Practice for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

F1789 Terminology for F16 Mechanical Fasteners

F2329 Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws, Washers,

Nuts, and Special Threaded Fasteners

G101 Guide for Estimating the Atmospheric Corrosion Resistance of Low-Alloy Steels

2.2 ASME Standards:

B1.1 Unified Screw Threads

B18.2.1 Square and Hex Bolts and Screws

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Nuts, Rivets

and Washers.

Current edition approved Dec. 1, 2008June 15, 2015. Published January 2009June 2015. Originally approved in 1955. Last previous edition approved in 20072008 as

ε1

A394 – 07.A394 – 08 . DOI: 10.1520/A0394-08E01.10.1520/A0394-08R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, ThreeTwo Park Ave., New York, NY 10016-5990,

http://www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A394 − 08 (2015)

B18.24 Part Identifying Number (PIN) Code System Standard for B18 Fastener Products

3. Ordering Information

3.1 Orders for products under this specification shall include the following:

3.1.1 Quantity (number of bolts and accessories).

3.1.2 Name of products, including accessories such as A563 nuts and F436 washers when desired.

3.1.3 Dimensions, including nominal bolt diameter and length. For bolts other than transmission-tower bolts, complete

dimensions are required (see Annex A1).

3.1.4 Type of bolt (for example, Type 0, 1, or 3).

3.1.4.1 When non-zinc-coated atmospheric corrosion-resistant steel is required, Type 3 bolts shall be specified by the purchaser.

3.1.5 ASTM designation and year of issue. When year of issue is not specified, bolts shall be furnished to the latest issue.

3.1.6 Additional requirements, if any, are to be specified on the purchase order:

3.1.6.1 Shear-strength testing (see 6.2.1 and 6.2.2). Include type of test required.

3.1.6.2 Additional tests.

3.1.6.3 Inspection (see 12.1 and 12.2).

3.1.6.4 Certification (see 14.1).

3.1.6.5 Test reports (see 14.1).

3.1.6.6 Other finishes, specify other protective finish, if required.

NOTE 1—Examples of ordering description:

(1) 1000 square-head transmission-tower bolts, ⁄2 by 2 in. Type 1, hot-dip zinc coated, shear testing required, ASTM A394 – XX, with hot-dip zinc-coated

hex nuts, Grade DH, ASTM A563 – XX,

(2) 1000 transmission tower bolts, ⁄2 by 2 in. Type 0, hot-dip zinc coated, ASTM A394 – XX, with hot-dip zinc-coated hex nuts, Grade A, ASTM

A563 – XX.

(3) 1000 transmission tower bolts, ⁄2 by 2 in. Type 3, ASTM A394 – XX, with hex nuts, Grade DH3 weathering steel, ASTM A563 – XX and with 2

circular washers, Type 3, ASTM F436 – XX.

3.1.7 For establishment of a part identifying system, see ASME B18.24.

3.2 Recommended Nuts:

3.2.1 Unless otherwise specified, all nuts on these bolts shall be hex style and conform to the requirements of Specification A563

as follows.

Bolt Type Nut Grade Finish

0 A hot-dip zinc-coated

1 DH hot-dip zinc-coated

3 DH3 plain

3.3 Recommended Washers:

3.3.1 Suitable washers for use with Type 0 are hot-dip zinc-coated carbon-steel washers with dimensions that are in accordance

with Specification F436. Suitable washers for use with Type 1 bolts are hot-dip zinc-coated Type 1 hardened-steel washers that

are in accordance with Specification F436. Suitable washers for use with Type 3 bolts are Type 3 hardened-steel washers that are

in accordance with Specification F436.

4. Materials and Manufacture

4.1 Steel for the manufacture of bolts shall be made by any of the following processes: open-hearth, electric-furnace, or

basic-oxygen.

4.2 Heat Treatment:

4.2.1 Type 1 bolts produced from medium carbon steel shall be quenched in a liquid medium from above the austenizing

temperature. Type 1 bolts produced from medium carbon steel to which chromium, nickel, molybdenum, or boron were

intentionally added shall be quenched only in oil from above the austenitizing temperature.

4.2.2 Type 3 bolts shall be quenched only in oil from above the austenitizing temperature.

4.2.3 Type 1 bolts, regardless of the steel used, and Type 3 bolts shall be tempered by reheating to not less than 800°F.

4.2.4 Cold-headed Type 0 bolts shall be stress relief annealed before zinc coating to remove cold work effects such that the

hardness measured anywhere on the surface or through the cross-section shall meet the requirements in 6.1.

4.3 Threads may be rolled or cut.

4.4 Zinc Coatings, Hot Dip:

4.4.1 Type 0 and Type 1 bolts shall be hot-dip zinc-coated accordance with the requirements of Specification F2329, except that

the minimum average weight (thickness) of zinc coating shall be 1.65 oz/ft (0.0028 in.) and the minimum weight of zinc coating

on any one item shall be 1.50 oz/ft (0.0025 in.).

4.4.2 Bolt threads shall not be cut, rolled, or otherwise finished after zinc coating.

4.4.3 Hot-dip zinc-coated nuts furnished under Specification A563 shall be tapped after zinc coating.

A394 − 08 (2015)

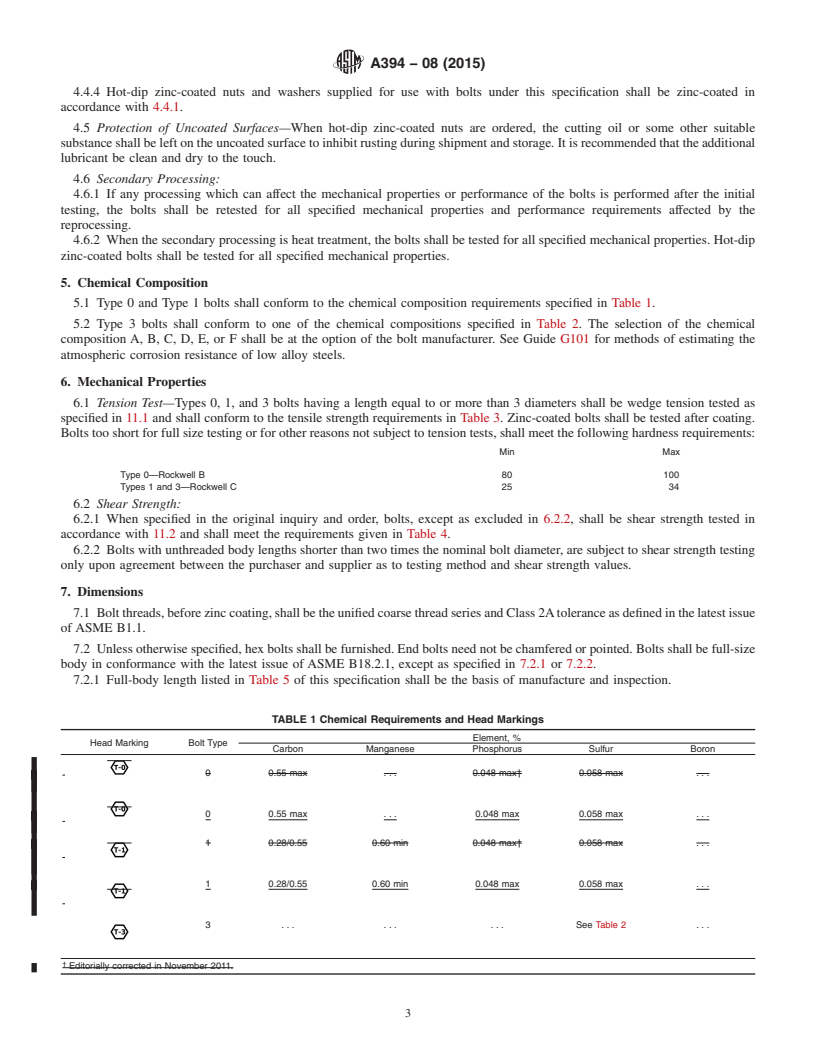

4.4.4 Hot-dip zinc-coated nuts and washers supplied for use with bolts under this specification shall be zinc-coated in

accordance with 4.4.1.

4.5 Protection of Uncoated Surfaces—When hot-dip zinc-coated nuts are ordered, the cutting oil or some other suitable

substance shall be left on the uncoated surface to inhibit rusting during shipment and storage. It is recommended that the additional

lubricant be clean and dry to the touch.

4.6 Secondary Processing:

4.6.1 If any processing which can affect the mechanical properties or performance of the bolts is performed after the initial

testing, the bolts shall be retested for all specified mechanical properties and performance requirements affected by the

reprocessing.

4.6.2 When the secondary processing is heat treatment, the bolts shall be tested for all specified mechanical properties. Hot-dip

zinc-coated bolts shall be tested for all specified mechanical properties.

5. Chemical Composition

5.1 Type 0 and Type 1 bolts shall conform to the chemical composition requirements specified in Table 1.

5.2 Type 3 bolts shall conform to one of the chemical compositions specified in Table 2. The selection of the chemical

composition A, B, C, D, E, or F shall be at the option of the bolt manufacturer. See Guide G101 for methods of estimating the

atmospheric corrosion resistance of low alloy steels.

6. Mechanical Properties

6.1 Tension Test—Types 0, 1, and 3 bolts having a length equal to or more than 3 diameters shall be wedge tension tested as

specified in 11.1 and shall conform to the tensile strength requirements in Table 3. Zinc-coated bolts shall be tested after coating.

Bolts too short for full size testing or for other reasons not subject to tension tests, shall meet the following hardness requirements:

Min Max

Type 0—Rockwell B 80 100

Types 1 and 3—Rockwell C 25 34

6.2 Shear Strength:

6.2.1 When specified in the original inquiry and order, bolts, except as excluded in 6.2.2, shall be shear strength tested in

accordance with 11.2 and shall meet the requirements given in Table 4.

6.2.2 Bolts with unthreaded body lengths shorter than two times the nominal bolt diameter, are subject to shear strength testing

only upon agreement between the purchaser and supplier as to testing method and shear strength values.

7. Dimensions

7.1 Bolt threads, before zinc coating, shall be the unified coarse thread series and Class 2A tolerance as defined in the latest issue

of ASME B1.1.

7.2 Unless otherwise specified, hex bolts shall be furnished. End bolts need not be chamfered or pointed. Bolts shall be full-size

body in conformance with the latest issue of ASME B18.2.1, except as specified in 7.2.1 or 7.2.2.

7.2.1 Full-body length listed in Table 5 of this specification shall be the basis of manufacture and inspection.

TABLE 1 Chemical Requirements and Head Markings

Element, %

Head Marking Bolt Type

Carbon Manganese Phosphorus Sulfur Boron

0 0.55 max . . . 0.048 max† 0.058 max . . .

0 0.55 max . . . 0.048 max 0.058 max . . .

1 0.28/0.55 0.60 min 0.048 max† 0.058 max . . .

1 0.28/0.55 0.60 min 0.048 max 0.058 max . . .

3 . . . . . . . . . See Table 2 . . .

†

Editorially corrected in November 2011.

A394 − 08 (2015)

A

TABLE 2 Chemical Requirements for Type 3 Heavy Hex Structural Bolts

Composition, %

A

Element Type 3 Bolts

A B C D E F

Carbon:

Heat Analysis 0.33–0.40 0.38–0.48 0.15–0.25 0.15–0.25 0.20–0.25 0.20–0.25

Product Analysis 0.31–0.42 0.36–0.50 0.14–0.26 0.14–0.26 0.18–0.27 0.19–0.26

Manganese:

Heat Analysis 0.90–1.20 0.70–0.90 0.80–1.35 0.40–1.20 0.60–1.00 0.90–1.20

Product Analysis 0.86–1.24 0.67–0.93 0.76–1.39 0.36–1.24 0.56–1.04 0.86–1.24

Phosphorus:

Heat Analysis 0.035 max 0.06–0.125 0.035 max 0.035 max 0.035 max 0.035 max

Product Analysis 0.040 max 0.06–1.25 0.040 max 0.040 max 0.040 max 0.040 max

Sulfur:

Heat Analysis 0.040 max 0.040 max 0.040 max 0.040 max 0.040 max 0.040 max

Product Analysis 0.045 max 0.045 max 0.045 max 0.045 max 0.045 max 0.045 max

Silicon:

Heat Analysis 0.15–0.35 0.30–0.50 0.15–0.35 0.25–0.50 0.15–0.35 0.15–0.35

Product Analysis 0.13–0.37 0.25–0.55 0.13–0.37 0.20–0.55 0.13–0.37 0.13–0.37

Copper:

Heat Analysis 0.25–0.45 0.20–0.40 0.20–0.50 0.30–0.50 0.30–0.60 0.20–0.40

Product Analysis 0.22–0.48 0.17–0.43 0.17–0.53 0.27–0.53 0.27–0.63 0.17–0.43

Nickel:

Heat Analysis 0.25–0.45 0.50–0.80 0.25–0.50 0.50–0.80 0.30–0.60 0.20–0.40

Product Analysis 0.22–0.48 0.47–0.83 0.22–0.53 0.47–0.83 0.27–0.63 0.17–0.43

Chromium:

Heat Analysis 0.45–0.65 0.50–0.75 0.30–0.50 0.50–1.00 0.60–0.90 0.45–0.65

Product Analysis 0.42–0.68 0.47–0.83 0.27–0.53 0.45–1.05 0.55–0.95 0.42–0.68

Vanadium:

B B B B B

Heat Analysis 0.020 min

B B B B B

Product Analysis 0.010 min

Molybdenum:

B B B B

Heat Analysis 0.06 max 0.10 max

B B B B

Product Analysis 0.07 max 0.11 max

Titanium: . . . . . .

B B B B B

Heat Analysis 0.05 max

B B B B B

Product Analysis 0.06 max

A

A, B, C, D, E, and F are classes of material used for Type 3 bolts. Selection of a class shall be at the option of the bolt manufacturer.

B

These elements are not specified or required.

A

TABLE 3 Tensile Strength

Nominal Minimum Tensile Load, lbf

Size, B C

Type 0 Types 1 and 3

in.

⁄2 10 500 17 050

⁄8 16 700 27 100

⁄4 24 700 40 100

⁄8 34 200 55 450

1 44 850 72 700

A

Tensile strength based on the thread stress area, A , is calculated as follows:

s

A = 0.7854 [ D − (0.9743/N)]

s

where:

D = nominal diameter, and

N = threads per inch.

B

Based on 74 000 psi unit tensile strength.

C

Based on 120 000 psi unit tensile strength.

7.2.2 On rolled thread bolts, the distance from the top of the extrusion angle to be the first fully formed thread shall not exceed

3.5 thread pitches in length.

7.3 Threads:

7.3.1 Uncoated—There shall be the Unified Coarse Thread Series as specified in ASME B1.1, and shall have Class 2A

tolerances.

7.3.2 Coated—Unless otherwise specified, zinc-coated bolts to be used with zinc-coated nuts or tapped holes that are tapped

oversize, in accordance with Specification A563, shall have Class 2A threads before hot-dip zinc-coating. After zinc-coating, the

maximum limits of pitch and major diameter shall not exceed the Class 2A limit by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.