ASTM E2866-12(2016)

(Test Method)Standard Test Method for Determination of Diisopropyl Methylphosphonate, Ethyl Methylphosphonic Acid, Isopropyl Methylphosphonic Acid, Methylphosphonic Acid and Pinacolyl Methylphosphonic Acid in Soil by Pressurized Fluid Extraction and Analyzed by Liquid Chromatography/Tandem Mass Spectrometry

Standard Test Method for Determination of Diisopropyl Methylphosphonate, Ethyl Methylphosphonic Acid, Isopropyl Methylphosphonic Acid, Methylphosphonic Acid and Pinacolyl Methylphosphonic Acid in Soil by Pressurized Fluid Extraction and Analyzed by Liquid Chromatography/Tandem Mass Spectrometry

SIGNIFICANCE AND USE

5.1 This is a performance based method, and modifications are allowed to improve performance.

5.1.1 Due to the rapid development of newer instrumentation and column chemistries, changes to the analysis described in this standard are allowed as long as better or equivalent performance data result. Any modifications shall be documented and performance data generated. The user of the data generated by this Standard shall be made aware of these changes and given the performance data demonstrating better or equivalent performance.

5.2 Organophosphate pesticides affect the nervous system by disrupting the enzyme that regulates acetylcholine, a neurotransmitter. They were developed during the early 19th century, but their effects on insects, which were similar to their effects on humans, were discovered in 1932. Some are poisonous and were used as chemical weapon agents. Organophosphate pesticides are usually not persistent in the environment.7,8

5.3 This test method is for the analysis of selected organophosphorous based pesticide degradation products.

5.4 This method has been investigated for use with various soils.

SCOPE

1.1 This procedure covers the determination of Diisopropyl Methylphosphonate (DIMP), Ethyl Methylphosphonic Acid (EMPA), Isopropyl Methylphosphonic Acid (IMPA), Methylphosphonic Acid (MPA) and Pinacolyl Methylphosphonic Acid (PMPA), referred to collectively as organophosphonates (OPs) in this test method, in soil. This method is based upon solvent extraction of a soil by pressurized fluid extraction (PFE). The extract is filtered and analyzed by liquid chromatography/tandem mass spectrometry (LC/MS/MS). OPs are qualitatively and quantitatively determined by this method.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

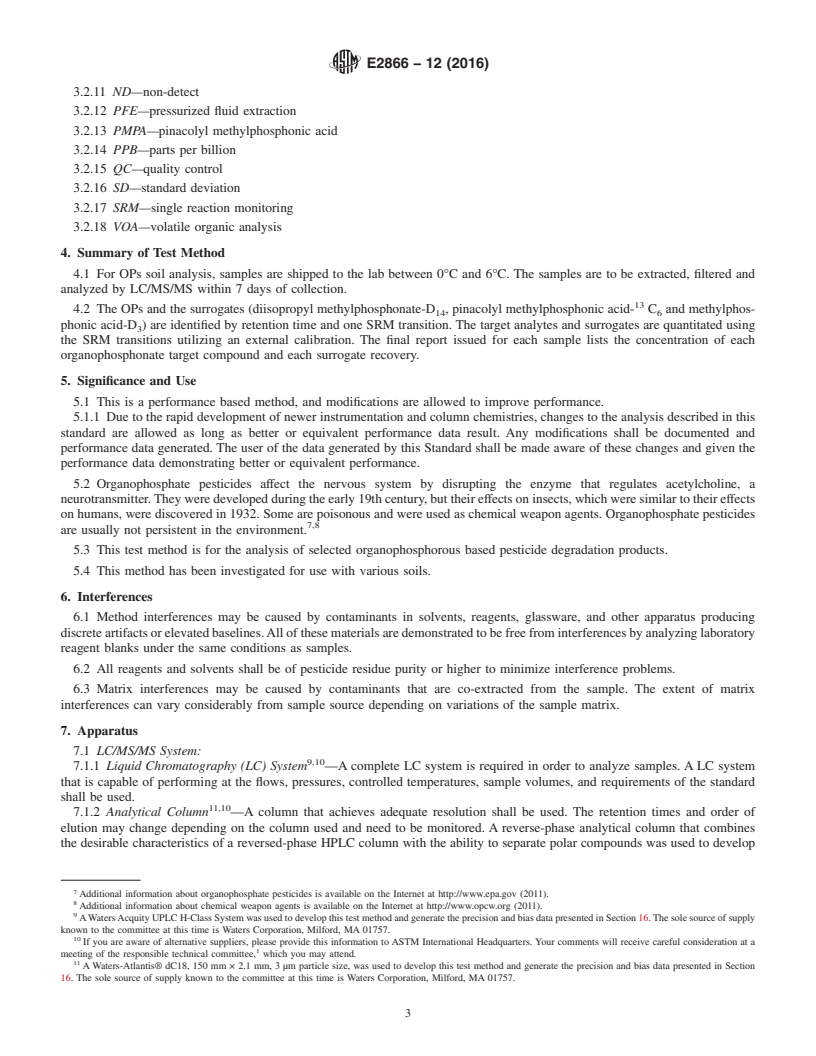

1.3 The Method Detection Limit2 (MDL), electrospray ionization (ESI) mode and Reporting Range3 for the OPs are listed in Table 1.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2866 − 12 (Reapproved 2016)

Standard Test Method for

Determination of Diisopropyl Methylphosphonate, Ethyl

Methylphosphonic Acid, Isopropyl Methylphosphonic Acid,

Methylphosphonic Acid and Pinacolyl Methylphosphonic

Acid in Soil by Pressurized Fluid Extraction and Analyzed

by Liquid Chromatography/Tandem Mass Spectrometry

This standard is issued under the fixed designation E2866; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This procedure covers the determination of Diisopropyl

ization established in the Decision on Principles for the

Methylphosphonate (DIMP), Ethyl Methylphosphonic Acid

Development of International Standards, Guides and Recom-

(EMPA), Isopropyl Methylphosphonic Acid (IMPA), Methyl-

mendations issued by the World Trade Organization Technical

phosphonicAcid(MPA)andPinacolylMethylphosphonicAcid

Barriers to Trade (TBT) Committee.

(PMPA), referred to collectively as organophosphonates (OPs)

in this test method, in soil. This method is based upon solvent

2. Referenced Documents

extraction of a soil by pressurized fluid extraction (PFE). The

2.1 ASTM Standards:

extract is filtered and analyzed by liquid chromatography/

D653Terminology Relating to Soil, Rock, and Contained

tandemmassspectrometry(LC/MS/MS).OPsarequalitatively

Fluids

and quantitatively determined by this method.

D1193Specification for Reagent Water

1.2 Units—The values stated in SI units are to be regarded D3694Practices for Preparation of Sample Containers and

asstandard.Nootherunitsofmeasurementareincludedinthis for Preservation of Organic Constituents

standard. D3740Practice for Minimum Requirements for Agencies

Engaged inTesting and/or Inspection of Soil and Rock as

1.3 The Method Detection Limit (MDL), electrospray

Used in Engineering Design and Construction

ionization (ESI) mode and Reporting Range for the OPs are

D3856Guide for Management Systems in Laboratories

listed in Table 1.

Engaged in Analysis of Water

1.4 This standard does not purport to address all of the

E2554Practice for Estimating and Monitoring the Uncer-

safety concerns, if any, associated with its use. It is the

tainty of Test Results of a Test Method Using Control

responsibility of the user of this standard to establish appro-

Chart Techniques

priate safety, health, and environmental practices and deter-

2.2 Other Documents:

mine the applicability of regulatory limitations prior to use.

EPApublication SW-846Test Methods for Evaluating Solid

Waste, Physical/Chemical Methods

40 CFR Part 136The Code of Federal Regulations,Appen-

dix B

This test method is under the jurisdiction ofASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.06 on

3. Terminology

Analytical Methods.

CurrenteditionapprovedJune1,2016.PublishedJuly2016.Originallyapproved

3.1 Definitions:

in 2012. Last previous edition approved in 2012 as E2866–12. DOI: 10.1520/

E2866-12R16.

2 4

The MDL is determined following the Code of Federal Regulations, 40 CFR For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Part136,AppendixButilizingsolventextractionofsoilbyPFE.Adetailedprocess contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

determining the MDLis explained in the reference and is beyond the scope of this Standardsvolumeinformation,refertothestandard’sDocumentSummarypageon

Standard to be explained here. the ASTM website.

3 5

Reporting range concentrations are calculated from Table 4 concentrations Available from National Technical Information Service (NTIS), U.S. Depart-

assuming a 100 µL injection of the lowest and highest level calibration standards ment of Commerce, 5285 Port Royal Road, Springfield, VA, 22161 or at http://

with a 40 mLfinal extract volume of a 10 gram soil sample.Volume variations will www.epa.gov/epawaste/hazard/testmethods/index.htm

change the reporting limit and ranges. The reporting limit (RL), lowest concentra- AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

tion of the reporting range, is calculated from the concentration of the Level 1 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

calibration standard as shown in Table 4. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2866 − 12 (2016)

–3

TABLE 1 Method Detection Limit and Reporting Range

3.2.6 mM—millimolar,1×10 moles/L

ESI MDL Reporting Range

3.2.7 MPA—methylphosphonic acid

Analyte

Mode (PPB) (PPB)

3.2.8 MRM—multiple reaction monitoring

Diisopropyl methylphosphonate Positive 2.7 40-2000

Ethyl methylphosphonic acid Negative 2.3 40-2000

3.2.9 MS—matrix spike

Ethyl methylphosphonic acid Positive 1.3 40-2000

Isopropyl methylphosphonic Negative 5.7 40-2000 3.2.10 NA—not applicable

acid

3.2.11 ND—non-detect

Isopropyl methylphosphonic Positive 2.8 40-2000

acid

3.2.12 PFE—pressurized fluid extraction

Methylphosphonic acid Positive 8.7 40-2000

Pinacolyl methylphosphonic Negative 5.3 40-2000

3.2.13 PMPA—pinacolyl methylphosphonic acid

acid

3.2.14 PPB—parts per billion

3.2.15 QC—quality control

3.2.16 SD—standard deviation

3.1.1 analytical column, n—the particles of the solid sta-

3.2.17 SRM—single reaction monitoring

tionary phase fill the whole inside volume of a tube (column)

that the mobile phase passes through using the pressure 3.2.18 VOA—volatile organic analysis

generated by the liquid chromatography system.

4. Summary of Test Method

3.1.2 filter unit, n—inthisstandard,afilterthatissupported

4.1 For OPs soil analysis, samples are shipped to the lab

with an inert housing to the solvents as described in Section 7

between0°Cand6°C.Thesamplesaretobeextracted,filtered

of this standard.

and analyzed by LC/MS/MS within 7 days of collection.

3.1.3 filtration device, n—a device used to remove particles

4.2 The OPs and the surrogates (diisopropyl

from the extract that may clog the liquid chromatography

methylphosphonate-D , pinacolyl methylphosphonic acid-

system. Described in section 7.3 of this standard. 14

C andmethylphosphonicacid-D )areidentifiedbyretention

6 3

3.1.4 glass fiber filter, n—Aporous glass fiber material onto

time and one SRM transition. The target analytes and surro-

which solid particles present in the extraction fluid, which

gates are quantitated using the SRM transitions utilizing an

flowsthroughit,arelargelycaughtandretained,thusremoving

external calibration. The final report issued for each sample

them from the extract.

lists the concentration of each organophosphonate target com-

3.1.5 hypodermic syringe, n—in this standard, a luer-lock-

pound and each surrogate recovery.

tipped glass syringe capable of holding a syringe-driven filter

5. Significance and Use

unit as described in section 7.3 of this standard.

5.1 This is a performance based method, and modifications

3.1.6 liquid chromatography (LC) system, n—in this

are allowed to improve performance.

standard, a separation system using liquid as the mobile phase

5.1.1 Due to the rapid development of newer instrumenta-

and a stationary phase packed into a column.The use of small

tionandcolumnchemistries,changestotheanalysisdescribed

particles packed inside a column and a high inlet pressure

in this standard are allowed as long as better or equivalent

enables the separation of components in a mixture.

performance data result. Any modifications shall be docu-

3.1.7 organophosphonates (OPs), n—in this test method,

mented and performance data generated. The user of the data

Diisopropyl Methylphosphonate (DIMP), Ethyl Methylphos-

generated by this Standard shall be made aware of these

phonic Acid (EMPA), Isopropyl Methylphosphonic Acid

changes and given the performance data demonstrating better

(IMPA), Methylphosphonic Acid (MPA) and Pinacolyl Meth-

or equivalent performance.

ylphosphonic Acid (PMPA) collectively.

5.2 Organophosphate pesticides affect the nervous system

3.1.8 pressurized fluid extraction, n—the process of trans-

by disrupting the enzyme that regulates acetylcholine, a neu-

ferringtheanalytesofinterestfromthesolidmatrix,asoil,into

rotransmitter. They were developed during the early 19th

theextractionsolventusingpressureandelevatedtemperature.

century,buttheireffectsoninsects,whichweresimilartotheir

3.1.9 reporting range, n—the quantitative concentration

effects on humans, were discovered in 1932. Some are poison-

range for an analyte in this standard.

ous and were used as chemical weapon agents. Organophos-

3.1.10 tandem mass spectrometer, n—an arrangement in

phate pesticides are usually not persistent in the

7,8

which ions are subjected to two sequential stages of analysis

environment.

according to the quotient mass/charge.

5.3 This test method is for the analysis of selected organo-

3.2 Abbreviations:

phosphorous based pesticide degradation products.

3.2.1 DIMP—diisopropyl methylphosphonate

5.4 This method has been investigated for use with various

3.2.2 EMPA—ethyl methylphosphonic acid

soils.

3.2.3 IMPA—isopropyl methylphosphonic acid

Additional information about organophosphate pesticides is available on the

3.2.4 LC—liquid chromatography

Internet at http://www.epa.gov (2011).

3.2.5 LCS/LCSD—laboratory control spike/laboratory con-

Additional information about chemical weapon agents is available on the

trol spike duplicate Internet at http://www.opcw.org (2011).

E2866 − 12 (2016)

6. Interferences capable of withstanding the pressure requirements (≥2000 psi)

necessary for this procedure. A pressurized fluid extraction

6.1 Methodinterferencesmaybecausedbycontaminantsin

device shall be used that can meet the necessary requirements

solvents, reagents, glassware, and other apparatus producing

in this test method.

discrete artifacts or elevated baselines. All of these materials

14,10

7.2.2 Glass Fiber Filters.

are demonstrated to be free from interferences by analyzing

7.2.3 Amber VOA Vials—40 mLfor sample extracts and 60

laboratory reagent blanks under the same conditions as

mL for PFE.

samples.

7.3 Filtration Device:

6.2 All reagents and solvents shall be of pesticide residue

7.3.1 Hypodermic Syringe—A luer-lock tip glass syringe

purity or higher to minimize interference problems.

capable of holding a syringe driven filter unit.

6.3 Matrix interferences may be caused by contaminants

7.3.1.1 A 50 mL Lock Tip Glass Syringe size is recom-

that are co-extracted from the sample. The extent of matrix

mended since a 40 mL sample extract may result.

15,10

interferences can vary considerably from sample source de-

7.3.2 Filter Unit —Filter units of polyvinylidene fluo-

pending on variations of the sample matrix.

ride (PVDF) were used to filter the PFE extracts.

7.3.2.1 Discussion—Afilterunitshallbeusedthatmeetsthe

7. Apparatus

requirements of the test method.

7.1 LC/MS/MS System:

9,10

7.1.1 Liquid Chromatography (LC) System —Acomplete 8. Reagents and Materials

LC system is required in order to analyze samples. A LC

8.1 Purity of Reagents—HighPerformanceLiquidChroma-

system that is capable of performing at the flows, pressures,

tography (HPLC) pesticide residue analysis and spectropho-

controlled temperatures, sample volumes, and requirements of

tometry grade chemicals shall be used in all tests. Unless

the standard shall be used.

indicated otherwise, it is intended that all reagents shall

11,10

7.1.2 Analytical Column —A column that achieves ad-

conform to the Committee on Analytical Reagents of the

equate resolution shall be used. The retention times and order 16

American Chemical Society. Other reagent grades may be

ofelutionmaychangedependingonthecolumnusedandneed

used provided they are first determined to be of sufficiently

to be monitored. A reverse-phase analytical column that

highpuritytopermittheirusewithoutaffectingtheaccuracyof

combines the desirable characteristics of a reversed-phase

the measurements.

HPLC column with the ability to separate polar compounds

8.2 Purity of Water—Unless otherwise indicated, references

was used to develop this test method. MPAelutes early in the

to water shall mean reagent water conforming toASTM Type

chromatograph, at approximately 2 minutes, which is just

I of Specification D1193. It must be demonstrated that this

beyond the instrument void volume of 1.5 minutes.Acolumn

water does not contain contaminants at concentrations suffi-

is required that elutes MPA after the instrument void volume.

12,10

cient to interfere with the analysis.

7.1.3 Tandem Mass Spectrometer (MS/MS) System —A

MS/MS system capable of multiple reaction monitoring 8.3 Gases—Nitrogen (purity ≥97%) and Argon (purity

(MRM)analysisoranysystemthatiscapableofperformingat

≥99.999%).

the requirements in this standard shall be used.

8.4 Acetonitrile (CH CN, CAS # 75-05-8).

13,10

7.2 Pressurized Fluid Extraction Device (PFE):

8.5 2-Propanol (C H O, CAS # 67-63-0).

3 8

7.2.1 A PFE system was used for this test method with

8.6 Methanol (CH OH, CAS # 67-56-1).

appropriately-sized extraction cells. Cells are available that

will accommodate the 10 g sample sizes used in this test

8.7 Formic Acid (HCO H, ≥95%, CAS # 64-18-6).

method.Cellsshallbemadeofstainlesssteelorothermaterial

8.8 Diisopropyl Methylphosphonate (C H O P, DIMP,

7 17 3

CAS # 1445-75-6).

8.9 Ethyl Methylphosphonic Acid (C H O P, EMPA, CAS

3 9 3

AWatersAcquity UPLC H-Class System was used to develop this test method

# 1832-53-7).

andgeneratetheprecisionandbiasdatapresentedinSection16.Thesolesourceof

supply known to the committee at this time is Waters Corporation, Milford, MA

01757.

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider- Whatman Glass Fiber Filters 19.8 mm, Part # 047017, specially designed for

1 13

ation at a meeting of the responsible technical committee, which you may attend. the PFE system, were used to develop this test method and generate the precision

AWaters-Atlantis® dC18, 150 mm × 2.1 mm, 3 µm particle size, was used to and bias data presented in Section 16. The sole source of supply known to the

develop this test method and generate the precision and bias data presented in committee at this time is Dionex Corporation, Sunnyvale, CA 94088.

Section16.ThesolesourceofsupplyknowntothecommitteeatthistimeisWaters Millex®-GV Syringe Driven Filter Units PVDF 0.22 µm (Catalog #

Corporation

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2866 − 12 E2866 − 12 (Reapproved 2016)

Standard Test Method for

Determination of Diisopropyl Methylphosphonate, Ethyl

Methylphosphonic Acid, Isopropyl Methylphosphonic Acid,

Methylphosphonic Acid and Pinacolyl Methylphosphonic

Acid in Soil by Pressurized Fluid Extraction and Analyzed

by Liquid Chromatography/Tandem Mass Spectrometry

This standard is issued under the fixed designation E2866; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This procedure covers the determination of Diisopropyl Methylphosphonate (DIMP), Ethyl Methylphosphonic Acid

(EMPA), Isopropyl Methylphosphonic Acid (IMPA), Methylphosphonic Acid (MPA) and Pinacolyl Methylphosphonic Acid

(PMPA), referred to collectively as organophosphonates (OPs) in this test method, in soil. This method is based upon solvent

extraction of a soil by pressurized fluid extraction (PFE). The extract is filtered and analyzed by liquid chromatography/tandem

mass spectrometry (LC/MS/MS). OPs are qualitatively and quantitatively determined by this method.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

2 3

1.3 The Method Detection Limit (MDL), electrospray ionization (ESI) mode and Reporting Range for the OPs are listed in

Table 1.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This test method is under the jurisdiction of ASTM Committee E54 on Homeland Security Applications and is the direct responsibility of Subcommittee E54.03 on

Decontamination.

Current edition approved Feb. 1, 2012June 1, 2016. Published March 2012July 2016. Originally approved in 2012. Last previous edition approved in 2012 as E2866 – 12.

DOI: 10.1520/E2866-12.10.1520/E2866-12R16.

The MDL is determined following the Code of Federal Regulations, 40 CFR Part 136, Appendix B utilizing solvent extraction of soil by PFE. A detailed process

determining the MDL is explained in the reference and is beyond the scope of this Standard to be explained here.

Reporting range concentrations are calculated from Table 4 concentrations assuming a 100 μL injection of the lowest and highest level calibration standards with a 40

mL final extract volume of a 10 gram soil sample. Volume variations will change the reporting limit and ranges. The reporting limit (RL), lowest concentration of the reporting

range, is calculated from the concentration of the Level 1 calibration standard as shown in Table 4.

TABLE 1 Method Detection Limit and Reporting Range

ESI MDL Reporting Range

Analyte

Mode (PPB) (PPB)

Diisopropyl methylphosphonate Positive 2.7 40-2000

Ethyl methylphosphonic acid Negative 2.3 40-2000

Ethyl methylphosphonic acid Positive 1.3 40-2000

Isopropyl methylphosphonic Negative 5.7 40-2000

acid

Isopropyl methylphosphonic Positive 2.8 40-2000

acid

Methylphosphonic acid Positive 8.7 40-2000

Pinacolyl methylphosphonic Negative 5.3 40-2000

acid

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2866 − 12 (2016)

2. Referenced Documents

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D1193 Specification for Reagent Water

D3694 Practices for Preparation of Sample Containers and for Preservation of Organic Constituents

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

D3856 Guide for Management Systems in Laboratories Engaged in Analysis of Water

E2554 Practice for Estimating and Monitoring the Uncertainty of Test Results of a Test Method Using Control Chart Techniques

2.2 Other Documents:

EPA publication SW-846 Test Methods for Evaluating Solid Waste, Physical/Chemical Methods

40 CFR Part 136 The Code of Federal Regulations, Appendix B

3. Terminology

3.1 Definitions:

3.1.1 analytical column, n—the particles of the solid stationary phase fill the whole inside volume of a tube (column) that the

mobile phase passes through using the pressure generated by the liquid chromatography system.

3.1.2 filter unit, n—in this standard, a filter that is supported with an inert housing to the solvents as described in Section 7 of

this standard.

3.1.3 filtration device, n—a device used to remove particles from the extract that may clog the liquid chromatography system.

Described in section 7.3 of this standard.

3.1.4 glass fiber filter, n—A porous glass fiber material onto which solid particles present in the extraction fluid, which flows

through it, are largely caught and retained , retained, thus removing them from the extract.

3.1.5 hypodermic syringe, n—in this standard, a luer-lock-tipped glass syringe capable of holding a syringe-driven filter unit as

described in section 7.3 of this standard.

3.1.6 liquid chromatography (LC) system, n—in this standard, a separation system using liquid as the mobile phase and a

stationary phase packed into a column. The use of small particles packed inside a column and a high inlet pressure enables the

separation of components in a mixture.

3.1.7 organophosphonates (OPs), n—in this test method, Diisopropyl Methylphosphonate (DIMP), Ethyl Methylphosphonic

Acid (EMPA), Isopropyl Methylphosphonic Acid (IMPA), Methylphosphonic Acid (MPA) and Pinacolyl Methylphosphonic Acid

(PMPA) collectively.

3.1.8 pressurized fluid extraction, n—the process of transferring the analytes of interest from the solid matrix, a soil, into the

extraction solvent using pressure and elevated temperature.

3.1.9 reporting range, n—the quantitative concentration range for an analyte in this standard.

3.1.10 tandem mass spectrometer, n—an arrangement in which ions are subjected to two sequential stages of analysis according

to the quotient mass/charge.

3.2 Abbreviations:

3.2.1 DIMP—diisopropyl methylphosphonate

3.2.2 EMPA—ethyl methylphosphonic acid

3.2.3 IMPA—isopropyl methylphosphonic acid

3.2.4 LC—liquid chromatography

3.2.5 LCS/LCSD—laboratory control spike/laboratory control spike duplicate

-3

3.2.6 mM—millimolar, 1 × 10 moles/L

3.2.7 MPA—methylphosphonic acid

3.2.8 MRM—multiple reaction monitoring

3.2.9 MS—matrix spike

3.2.10 NA—not applicable

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from National Technical Information Service (NTIS), U.S. Department of Commerce, 5285 Port Royal Road, Springfield, VA, 22161 or at http://www.epa.gov/

epawaste/hazard/testmethods/index.htm

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

E2866 − 12 (2016)

3.2.11 ND—non-detect

3.2.12 PFE—pressurized fluid extraction

3.2.13 PMPA—pinacolyl methylphosphonic acid

3.2.14 PPB—parts per billion

3.2.15 QC—quality control

3.2.16 SD—standard deviation

3.2.17 SRM—single reaction monitoring

3.2.18 VOA—volatile organic analysis

4. Summary of Test Method

4.1 For OPs soil analysis, samples are shipped to the lab between 0°C and 6°C. The samples are to be extracted, filtered and

analyzed by LC/MS/MS within 7 days of collection.

4.2 The OPs and the surrogates (diisopropyl methylphosphonate-D , pinacolyl methylphosphonic acid- C and methylphos-

14 6

phonic acid-D ) are identified by retention time and one SRM transition. The target analytes and surrogates are quantitated using

the SRM transitions utilizing an external calibration. The final report issued for each sample lists the concentration of each

organophosphonate target compound and each surrogate recovery.

5. Significance and Use

5.1 This is a performance based method, and modifications are allowed to improve performance.

5.1.1 Due to the rapid development of newer instrumentation and column chemistries, changes to the analysis described in this

standard are allowed as long as better or equivalent performance data result. Any modifications shall be documented and

performance data generated. The user of the data generated by this Standard shall be made aware of these changes and given the

performance data demonstrating better or equivalent performance.

5.2 Organophosphate pesticides affect the nervous system by disrupting the enzyme that regulates acetylcholine, a

neurotransmitter. They were developed during the early 19th century, but their effects on insects, which were similar to their effects

on humans, were discovered in 1932. Some are poisonous and were used as chemical weapon agents. Organophosphate pesticides

7,8

are usually not persistent in the environment.

5.3 This test method is for the analysis of selected organophosphorous based pesticide degradation products.

5.4 This method has been investigated for use with various soils.

6. Interferences

6.1 Method interferences may be caused by contaminants in solvents, reagents, glassware, and other apparatus producing

discrete artifacts or elevated baselines. All of these materials are demonstrated to be free from interferences by analyzing laboratory

reagent blanks under the same conditions as samples.

6.2 All reagents and solvents shall be of pesticide residue purity or higher to minimize interference problems.

6.3 Matrix interferences may be caused by contaminants that are co-extracted from the sample. The extent of matrix

interferences can vary considerably from sample source depending on variations of the sample matrix.

7. Apparatus

7.1 LC/MS/MS System:

9,10

7.1.1 Liquid Chromatography (LC) System —A complete LC system is required in order to analyze samples. A LC system

that is capable of performing at the flows, pressures, controlled temperatures, sample volumes, and requirements of the standard

shall be used.

11,10

7.1.2 Analytical Column —A column that achieves adequate resolution shall be used. The retention times and order of

elution may change depending on the column used and need to be monitored. A reverse-phase analytical column that combines

the desirable characteristics of a reversed-phase HPLC column with the ability to separate polar compounds was used to develop

Additional information about organophosphate pesticides is available on the Internet at http://www.epa.gov (2011).

Additional information about chemical weapon agents is available on the Internet at http://www.opcw.org (2011).

A Waters Acquity UPLC H-Class System was used to develop this test method and generate the precision and bias data presented in Section 16. The sole source of supply

known to the committee at this time is Waters Corporation, Milford, MA 01757.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend.

A Waters-Atlantis® dC18, 150 mm × 2.1 mm, 3 μm particle size, was used to develop this test method and generate the precision and bias data presented in Section

16. The sole source of supply known to the committee at this time is Waters Corporation, Milford, MA 01757.

E2866 − 12 (2016)

this test method. MPA elutes early in the chromatograph, at approximately 2 minutes, which is just beyond the instrument void

volume of 1.5 minutes. A column is required that elutes MPA after the instrument void volume.

12,10

7.1.3 Tandem Mass Spectrometer (MS/MS) System —A MS/MS system capable of multiple reaction monitoring (MRM)

analysis or any system that is capable of performing at the requirements in this standard shall be used.

13,10

7.2 Pressurized Fluid Extraction Device (PFE) :

7.2.1 A PFE system was used for this test method with appropriately-sized extraction cells. Cells are available that will

accommodate the 10 g sample sizes used in this test method. Cells shall be made of stainless steel or other material capable of

withstanding the pressure requirements (≥2000 psi) necessary for this procedure. A pressurized fluid extraction device shall be used

that can meet the necessary requirements in this test method.

14,10

7.2.2 Glass Fiber Filters.

7.2.3 Amber VOA Vials—40 mL for sample extracts and 60 mL for PFE.

7.3 Filtration Device:

7.3.1 Hypodermic Syringe—A luer-lock tip glass syringe capable of holding a syringe driven filter unit.

7.3.1.1 A 50 mL Lock Tip Glass Syringe size is recommended since a 40 mL sample extract may result.

15,10

7.3.2 Filter Unit —Filter units of polyvinylidene fluoride (PVDF) were used to filter the PFE extracts.

7.3.2.1 Discussion—A filter unit shall be used that meets the requirements of the test method.

8. Reagents and Materials

8.1 Purity of Reagents—High Performance Liquid Chromatography (HPLC) pesticide residue analysis and spectrophotometry

grade chemicals shall be used in all tests. Unless indicated otherwise, it is intended that all reagents shall conform to the Committee

on Analytical Reagents of the American Chemical Society. Other reagent grades may be used provided they are first determined

to be of sufficiently high purity to permit their use without affecting the accuracy of the measurements.

8.2 Purity of Water—Unless otherwise indicated, references to water shall mean reagent water conforming to ASTM Type I of

Specification D1193. It must be demonstrated that this water does not contain contaminants at concentrations sufficient to interfere

with the analysis.

8.3 Gases—Nitrogen (purity ≥97%) and Argon (purity ≥99.999%).

8.4 Acetonitrile (CH CN, CAS # 75-05-8).

8.5 2-Propanol (C H O, CAS # 67-63-0).

3 8

8.6 Methanol (CH OH, CAS # 67-56-1).

8.7 Formic Acid (HCO H, ≥95%, CAS # 64-18-6).

8.8 Diisopropyl Methylphosphonate (C H O P, DIMP, CAS # 1445-75-6).

7 17 3

8.9 Ethyl Methylphosphonic Acid (C H O P, EMPA, CAS # 1832-53-7).

3 9 3

8.10 Isopropyl Methylphosphonic Acid (C H O P, IMPA, CAS # 1832-54-8).

4 11

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.