ASTM D3294-97

(Specification)Standard Specification for PTFE Resin Molded Sheet and Molded Basic Shapes

Standard Specification for PTFE Resin Molded Sheet and Molded Basic Shapes

SCOPE

1.1 This specification establishes requirements and methods of test for the material, dimensions, and workmanship, and the physical and electrical properties of molded sheet in minimum thicknesses of 0.794 mm ( 1/32 in.) manufactured from PTFE resin molding materials.

1.2 This specification also establishes requirements for molded basic shapes made from resin molding and extrusion materials. This specification is for products 0.3 mm (12 in.) or less in a dimension parallel to and 12.7 mm (0.5 in.) or greater in the dimension perpendicular to the direction of the applied molding pressure.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Special attention is called to sections 13.2, 13.3, 13.6, 13.8, and A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3294 – 97

Standard Specification for

Polytetrafluoroethylene (PTFE) Resin Molded Sheet and

Molded Basic Shapes

This standard is issued under the fixed designation D 3294; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * and Density of Plastics by Displacement

D 883 Terminology Relating to Plastics

1.1 This specification establishes requirements and methods

D 1505 Test Method for Density of Plastics by the Density-

of test for the material, dimensions, and workmanship, and the

Gradient Technique

physical and electrical properties of molded sheet in minimum

1 D 1600 Terminology for Abbreviated Terms Relating to

thicknesses of 0.794 mm ( ⁄32 in.) manufactured from PTFE

Plastics

resin molding materials.

D 1708 Test Method for Tensile Properties of Plastics by

1.2 This specification also establishes requirements for

Use of Microtensile Specimens

molded basic shapes made from resin molding and extrusion

D 1898 Practice for Sampling of Plastics

materials. This specification is for products 300 mm (12 in.) or

D 3293 Specification for PTFE Resin Molded Sheet

less in a dimension parallel to and 12.7 mm (0.5 in.) or greater

D 3892 Practice for Packaging/Packing of Plastics

in the dimension perpendicular to the direction of the applied

D 4591 Test Method for Determining Temperatures and

molding pressure.

Heats of Transitions of Fluoropolymers by Differential

1.3 The values stated in SI units are to be regarded as the

Scanning Calorimetry

standard.

E 94 Guide for Radiographic Testing

1.4 The following precautionary caveat pertains only to the

test method portion, Section 7, of this specification. This

3. Terminology

standard does not purport to address all of the safety concerns,

3.1 Definitions:

if any, associated with its use. It is the responsibility of the user

3.1.1 Definitions are in accordance with Terminology D 883

of this standard to establish appropriate safety and health

unless otherwise specified.

practices and determine the applicability of regulatory limita-

3.1.2 lot, n—one continuous production run or a uniform

tions prior to use. Special attention is called to 13.2, 13.3, 13.6,

blend of two or more production runs of one size sheet or

13.8, and A1.

molded basic shape.

NOTE 1—There is no similar or equivalent ISO standard.

3.2 Abbreviations:

3.2.1 Abbreviations are in accordance with Terminology

2. Referenced Documents

D 1600. PTFE is the abbreviation for polytetrafluoroethylene.

2.1 ASTM Standards:

D 149 Test Method for Dielectric Breakdown Voltage and 4. Classification

Dielectric Strength of Solid Electrical Insulating Materials

4.1 This specification covers the following three types of

at Commercial Power Frequencies

molded basic sheets and shapes:

D 618 Practice for Conditioning Plastics and Electrical

4.1.1 Type I—Premium; normally used for exacting electri-

Insulating Materials for Testing

cal, mechanical, or chemical applications.

D 638 Test Method for Tensile Properties of Plastics

4.1.2 Type II—General purpose; for electrical, mechanical,

D 792 Test Methods for Specific Gravity (Relative Density)

and chemical applications not requiring premium material.

4.1.3 Type III—Mechanical Grade; for noncritical chemical,

electrical, and mechanical applications.

This specification is under the jurisdiction of ASTM Committee D-20 on

4.1.4 Type IV—Utility; having no electrical requirements

Plastics, and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

and with mechanical properties at a lower level.

Materials (Section D20.15.12).

Current edition approved Sept. 10, 1997. Published April 1998. Originally 4.2 Types I, II, and III may be subdivided into two grades as

published as D 3294 – 74. Last previous edition D 3294 – 91a.

follows:

This revision combines Specification D 3293 and Specification D 3294. Speci-

fication D 3293 has been withdrawn. A complete summary of changes is given at the

end of the text. Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 10.02. Annual Book of ASTM Standards, Vol 08.03.

3 6

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 03.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3294

A

TABLE 1 Physical and Electrical Requirements for PTFE Sheets

4.2.1 Grade 1—made only from virgin resin.

4.2.2 Grade 2—may be made using reprocessed resin. Dielectric

Tensile Elonga-

B C

Strength Specific

A A D

4.3 The grades may be further subdivided into three classes

Types Strength tion (min) Porosity

(min) Volts Gravity

(min) psi Percent

as follows:

Per Mill

4.3.1 Class A—resistant to thermal dimensional change not

E

I 4500 300 600 2.15 to 2.18 Zero penetration

exceeding 0.5 %.

II 3000 225 500 2.14 to 2.19 Not required

III 2000 150 300 2.13 to 2.19 Not required

4.3.2 Class B—thermal dimensional change not exceeding

IV 1300 75 Not required 2.13 to 2.20 Not required

5.0 %.

A

See 13.2.

4.3.3 Class C—thermal dimensional change may exceed

B

See 13.3

5.0 %. C

See 13.4

D

See 13.6

4.4 A one-line system may be used to specify materials

E

PTFE sheet used for tank lining shall be Type I but shall have a specific gravity

covered by this specification. The system uses predefined cells

of 2.19 to 2.22.

to refer to specific aspects of this specification, as illustrated

below.

TABLE 2 Physical and Electrical Requirements for Basic Shapes

Specification

Dielectric

Tensile Strength Elongation %

Types Strength Volts Specific Gravity

Standard Number : Type : Grade : Class : Special

psi (min) (min)

Block : : : : Notes per mil (min)

:: : : : I 4800 325 1200 2.14 to 2.18

II 3200 240 850 2.14 to 2.19

III 1500 75 250 2.13 to 2.20

Example: Specification D 3294 – 97, I I A

For this example, the line callout would be Specification

D 3294 – 97,11A and would specify premium virgin form of

8. Dimensions

polytetrafluoroethylene that has all of the properties listed for

that Type, Grade, and Class in the appropriate specified

8.1 The size, shape, dimensional tolerances, and dimen-

properties, tables, or both, in the specification identified. A

sional stability shall be as specified in the contract or order.

comma is used as the separator between the standard Number

8.2 The tolerance on length and width shall be plus 6.3 mm

and the Type. Separators are not needed between the Type,

( ⁄4 in.), minus 0 mm (in.).

Grade, and Class. Provision for Special Notes is included so

that other information can be provided when required. An 9. Workmanship, Finish, and Appearance

example would be in Specification D 3295 where dimensions

9.1 Color—Type I shall be white to translucent, but may

and tolerances are specified for each AWG size within Type

have occasional spots. Types II, III, and IV are typically white,

and Class. When Special Notes are used, they should be

but may vary to light gray or light brown. For Types II, III, and

preceded by a comma.

IV occasional small gray, brown, or black spots shall not be

considered as cause for rejection.

5. Ordering Information

9.2 Finish—The material shall be as free as is commercially

5.1 The molded sheet or basic shapes covered in this

practical from surface blisters, wrinkles, cracks and other

specification shall be ordered stating the type, grade, and class

surface defects that might affect its serviceability. It shall also

and that they meet the requirements of this specification.

be commercially free of macroscopic voids, cracks, and foreign

inclusions.

6. Materials

9.3 Internal Defects—The moldings shall be as free as is

6.1 The sheet or molded basic shape from Types I, II, III, or

commercially practical of microscopic voids, cracks, and

IV shall be made from unpigmented PTFE as free of foreign

foreign inclusions.

matter as commercially practical.

10. Sampling

7. Requirements

10.1 For purposes of sampling, an inspection lot for exami-

7.1 The sheet covered by this specification shall meet the

nation and tests shall consist of all material of the same type,

physical and electrical requirements specified in Table 1 and

grade, and class and nominal size submitted for inspection at

paragraph 7.1.1 when tested by the methods given in Section

one time.

13.

10.2 The total quantity of sheet or basic shapes to be taken

7.2 The molded basic shapes covered by this specification

from each lot shall be approximately twice that estimated to be

shall meet the physical and electrical requirements specified in

required for the tests that are to be made, in order to permit

Table 2 and 7.1.1 when tested by the test methods given in

repeat tests without resampling.

Section 13.

10.3 The sheet or basic shapes selected for sampling may be

7.2.1 Melting Point—the melting point of all types of sheet

chosen at random from each lot. If the shipment consists of

and molded basic shapes shall be 327 6 10°C when tested in

more than one lot or “run” of material, each lot shall be

accordance with paragraph 13.8.

sampled separately. The average result of the specimens tested

shall conform to the requirements specified in this specifica-

See the ASTM Form and Style Manual. Available from ASTM Headquarters. tion.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3294

11. Number of Tests surface and sample. Remove any tool marks resulting from

sample preparation which are not essentially parallel to the

11.1 Routine lot inspection tests shall consist of all the tests

long axis of the specimen by light sanding in a direction

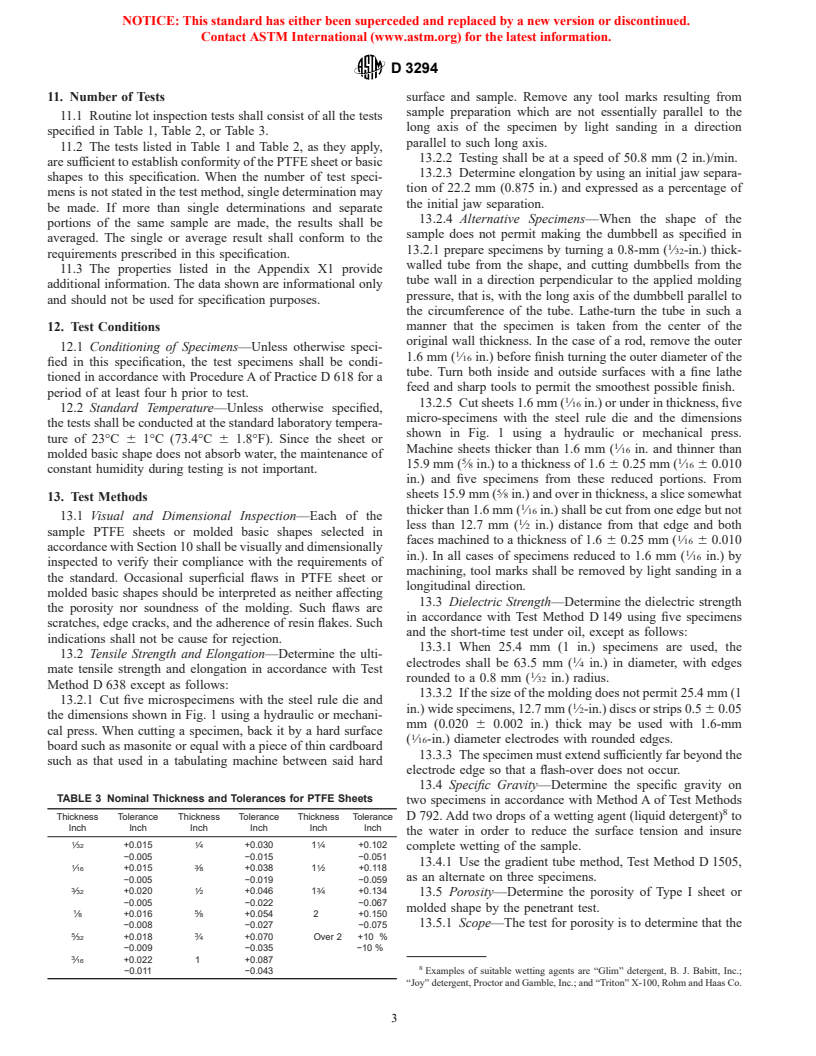

specified in Table 1, Table 2, or Table 3.

parallel to such long axis.

11.2 The tests listed in Table 1 and Table 2, as they apply,

13.2.2 Testing shall be at a speed of 50.8 mm (2 in.)/min.

are sufficient to establish conformity of the PTFE sheet or basic

13.2.3 Determine elongation by using an initial jaw separa-

shapes to this specification. When the number of test speci-

tion of 22.2 mm (0.875 in.) and expressed as a percentage of

mens is not stated in the test method, single determination may

the initial jaw separation.

be made. If more than single determinations and separate

13.2.4 Alternative Specimens—When the shape of the

portions of the same sample are made, the results shall be

sample does not permit making the dumbbell as specified in

averaged. The single or average result shall conform to the

13.2.1 prepare specimens by turning a 0.8-mm ( ⁄32-in.) thick-

requirements prescribed in this specification.

walled tube from the shape, and cutting dumbbells from the

11.3 The properties listed in the Appendix X1 provide

tube wall in a direction perpendicular to the applied molding

additional information. The data shown are informational only

pressure, that is, with the long axis of the dumbbell parallel to

and should not be used for specification purposes.

the circumference of the tube. Lathe-turn the tube in such a

manner that the specimen is taken from the center of the

12. Test Conditions

original wall thickness. In the case of a rod, remove the outer

12.1 Conditioning of Specimens—Unless otherwise speci-

1.6 mm ( ⁄16 in.) before finish turning the outer diameter of the

fied in this specification, the test specimens shall be condi-

tube. Turn both inside and outside surfaces with a fine lathe

tioned in accordance with Procedure A of Practice D 618 for a

feed and sharp tools to permit the smoothest possible finish.

period of at least four h prior to test.

13.2.5 Cut sheets 1.6 mm ( ⁄16 in.) or under in thickness, five

12.2 Standard Temperature—Unless otherwise specified,

micro-specimens with the steel rule die and the dimensions

the tests shall be conducted at the standard laboratory tempera-

shown in Fig. 1 using a hydraulic or mechanical press.

ture of 23°C 6 1°C (73.4°C 6 1.8°F). Since the sheet or

Machine sheets thicker than 1.6 mm ( ⁄16 in. and thinner than

molded basic shape does not absorb water, the maintenance of

5 1

15.9 mm ( ⁄8 in.) to a thickness of 1.6 6 0.25 mm ( ⁄16 6 0.010

constant humidity during testing is not important.

in.) and five specimens from these reduced portions. From

sheets 15.9 mm ( ⁄8 in.) and over in thickness, a slice somewhat

13. Test Methods

thicker than 1.6 mm ( ⁄16 in.) shall be cut from one edge but not

13.1 Visual and Dimensional Inspection—Each of the

less than 12.7 mm ( ⁄2 in.) distance from that edge and both

sample PTFE sheets or molded basic shapes selected in

faces machined to a thickness of 1.6 6 0.25 mm ( ⁄16 6 0.010

accordance with Section 10 shall be visually and dimensionally

in.). In all cases of specimens reduced to 1.6 mm ( ⁄16 in.) by

inspected to verify their compliance with the requirements of

machining, tool marks shall be removed by light sanding in a

the standard. Occasional superficial flaws in PTFE sheet or

longitudinal direction.

molded basic shapes should be interpreted as neither affecting

13.3 Dielectric Strength—Determine the dielectric strength

the porosity nor soundness of the molding. Such flaws are

in accordance with Test Method D 149 using five specimens

scratches, edge cracks, and the adherence of resin flakes. Such

and the short-time test under oil, except as follows:

indications shall not be cause for rejection.

13.3.1 When 25.4 mm (1 in.) specimens are used, the

13.2 Tensile Strength and Elongation—Determine the ulti-

electrodes shall be 63.5 mm ( ⁄4 in.) in diameter, with edges

mate tensile strength and elongation in accordance with Test

rounded to a 0.8 mm ( ⁄32 in.) radius.

Method D 638 except as follows:

13.3.2 If the size of the molding does not permit 25.4 mm (1

13.2.1 Cut five microspecimens with the steel rule die and

in.) wide specimens, 12.7 mm ( ⁄2-in.) discs or strips 0.5 6 0.05

the dimensions shown in Fig. 1 using a hydraulic or mechani-

mm (0.020 6 0.002 in.) thick may be used with 1.6-mm

cal press. When cutting a specimen, back it by a hard surface

( ⁄16-in.) diameter electrodes with rounded edges.

board such as masonite or equal with a piece of thin cardboard

13.3.3 The specimen must extend sufficiently far beyond the

such as that used in a tabulating machine between said hard

electrode edge so that a flash-over does not occur.

13.4 Specific Gravity—Determine the spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.