ASTM G176-03

(Test Method)Standard Test Method for Ranking Resistance of Plastics to Sliding Wear using Block-on-Ring Wear Test—Cumulative Wear Method

Standard Test Method for Ranking Resistance of Plastics to Sliding Wear using Block-on-Ring Wear Test—Cumulative Wear Method

SIGNIFICANCE AND USE

The significance of this test method in any overall measurement program directed toward a service application will depend on the relative match of test conditions to the conditions of the service application.

This test method prescribes the test procedure and method of calculating and reporting data for determining the sliding wear resistance of plastics, using cumulative volume loss.

The intended use of this test is for coarse screening of plastics in terms of their resistance to sliding wear.

SCOPE

1.1 This test method covers laboratory procedures for determining the resistance of plastics to sliding wear. The test utilizes a block-on-ring friction and wear testing machine to rank plastics according to their sliding wear characteristics against metals or other solids.

1.2 An important attribute of this test is that it is very flexible. Any material that can be fabricated into, or applied to, blocks and rings can be tested. Thus, the potential materials combinations are endless. In addition, the test can be run with different gaseous atmospheres and elevated temperatures, as desired, to simulate service conditions.

1.3 Wear test results are reported as the volume loss in cubic millimetres for the block and ring. Materials of higher wear resistance will have lower volume loss.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 176 – 03

Standard Test Method for

Ranking Resistance of Plastics to Sliding Wear Using

Block-on-Ring Wear Test—Cumulative Wear Method

This standard is issued under the fixed designation G176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G40 Terminology Relating to Wear and Erosion

G77 Test Method for Ranking Resistance of Materials to

1.1 This test method covers laboratory procedures for de-

Sliding Wear Using a Block-on-Ring Wear Test

termining the resistance of plastics to sliding wear. The test

G117 Guide for Calculating and Reporting Measures of

utilizes a block-on-ring friction and wear testing machine to

Precision Using Data from Interlaboratory Wear or Ero-

rank plastics according to their sliding wear characteristics

sion Tests

against metals or other solids.

1.2 An important attribute of this test is that it is very

3. Terminology

flexible.Anymaterialthatcanbefabricatedinto,orappliedto,

3.1 Definition:

blocks and rings can be tested. Thus, the potential materials

3.1.1 wear—damage to a solid surface, generally involving

combinations are endless. In addition, the test can be run with

progressive loss of material, due to relative motion between

different gaseous atmospheres and elevated temperatures, as

that surface and a contacting substance or substances. G40

desired, to simulate service conditions.

1.3 Weartestresultsarereportedasthevolumelossincubic

4. Summary of Test Method

millimetres for the block and ring. Materials of higher wear

4.1 A test plastic block is loaded against a metal test ring

resistance will have lower volume loss.

that rotates at a given speed for a given number of revolutions.

1.4 The values stated in SI units are to be regarded as the

Blockscarvolumeiscalculatedfromtheblockscarwidth.The

standard. The values given in parentheses are for information

friction force required to keep the block in place may be

only.

continuously measured during the test with a load cell. When

1.5 This standard does not purport to address all of the

this is done, the friction force data are combined with normal

safety concerns, if any, associated with its use. It is the

force data to obtain values for the coefficient of friction and

responsibility of the user of this standard to establish appro-

reported.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

5.1 The significance of this test method in any overall

2. Referenced Documents

measurement program directed toward a service application

2.1 ASTM Standards:

2 will depend on the relative match of test conditions to the

D618 Practice for Conditioning Plastics for Testing

conditions of the service application.

D2714 Test Method for Calibration and Operation of the

3 5.2 This test method prescribes the test procedure and

Falex Block-on-Ring Friction and Wear Testing Machine

method of calculating and reporting data for determining the

E122 Practice for Calculating Sample Size to Estimate,

sliding wear resistance of plastics, using cumulative volume

With a Specified Tolerable Error, the Average for Charac-

loss.

teristic of a Lot or Process

5.3 The intended use of this test is for coarse screening of

E177 Practice for Use of the Terms Precision and Bias in

4 plastics in terms of their resistance to sliding wear.

ASTM Test Methods

E691 Practice for Conducting an Inter-laboratory Study to

6. Apparatus and Test Specimens

Determine the Precision of a Test Method

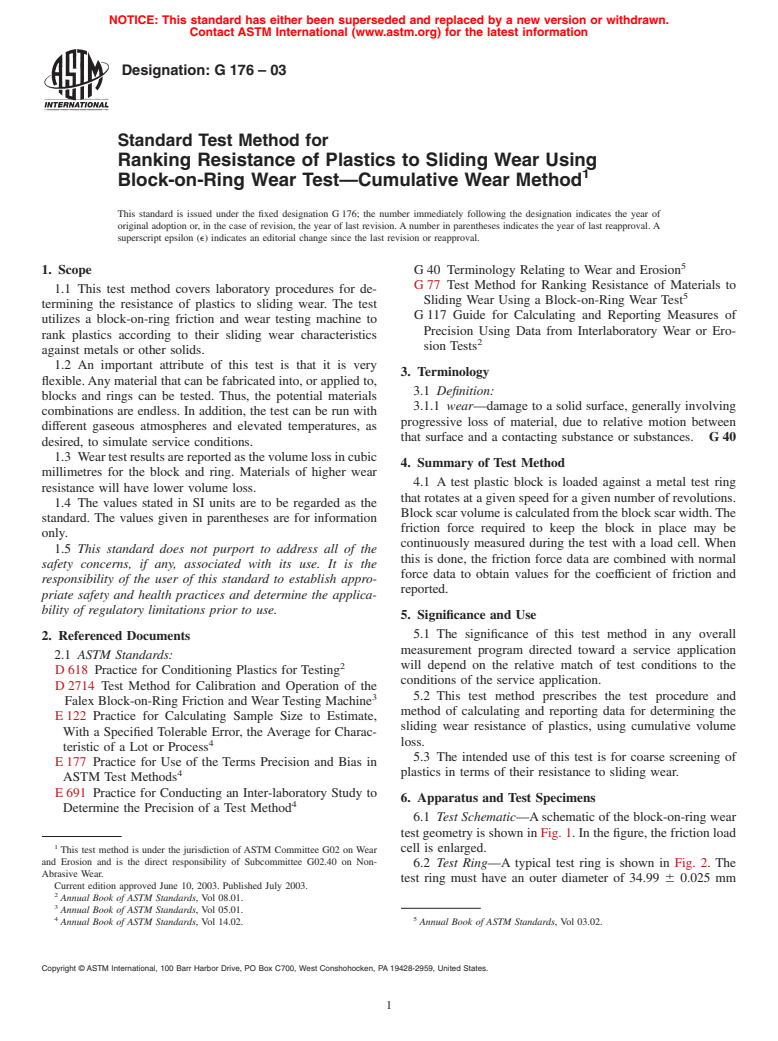

6.1 Test Schematic—Aschematic of the block-on-ring wear

testgeometryisshowninFig.1.Inthefigure,thefrictionload

cell is enlarged.

This test method is under the jurisdiction of ASTM Committee G02 on Wear

and Erosion and is the direct responsibility of Subcommittee G02.40 on Non-

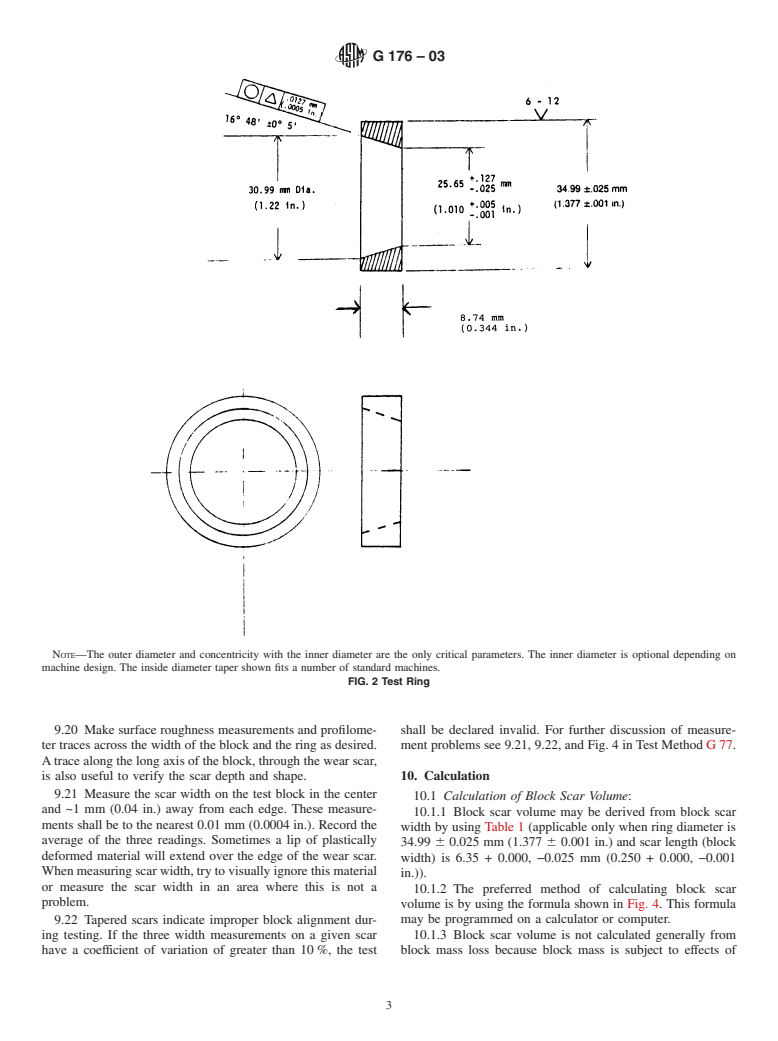

6.2 Test Ring—A typical test ring is shown in Fig. 2. The

Abrasive Wear.

test ring must have an outer diameter of 34.99 6 0.025 mm

Current edition approved June 10, 2003. Published July 2003.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 05.01.

4 5

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G176–03

9.4 For the plastic block, the following cleaning procedure

isrecommended:Cleantheplasticblockwithmethanol.Allow

the blocks to dry completely.After cleaning, handle the block

with clean, lint-free cotton gloves. Other procedures may be

used provided they do not affect the plastic. If an application

understudyusesaplasticinthemoldedcondition,itisadvised

to test a block with the test surface in the molded condition.

The wear of a molded surface may be different from the wear

of a machined surface.

FIG. 1 Test Schematic 9.5 Make surface texture and surface roughness measure-

ments across the width of the ring, as necessary. Note that a

surface profile does not completely describe a surface topol-

(1.377 6 0.001 in.) with an eccentricity between the inner and

ogy.Scanningelectronmicrographsmaybeused,asdesired,to

outer surfaces of no greater than 0.00125 mm (0.0005 in.). For

augment the description of the wear surfaces. Clean the ring

couples where surface condition is not under study, it is

again, if necessary, as in 9.3.

recommended that the outer diameter be a ground surface with

9.6 Demagnetize the ring and ferrous assembly.

a roughness of 0.152 to 0.305 µm (6 to 12 µin.) rms or center

9.7 Measure the block width and ring diameter to the

line average (CLA), in the direction of motion. However,

nearest 0.025 mm (0.001 in.).

alternate surface conditions may be evaluated in the test, as

9.8 Clean the self-aligning block holder, ring shaft, and

desired. It should be kept in mind that surface condition can

surrounding fixtures with solvent.

have an effect on sliding wear results.

9.9 Put the self-aligning block holder on the block.Apply a

NOTE 1—Acommonly used test ring is a carburized 4620 steel having

thin layer of lubricant to the self-aligning holder. Use of a

a hardness of 60 HRC or higher.

non-migrating product is suggested.

6.3 Test Block—AtestblockisshowninFig.3.Blockwidth

9.10 Place the block in position on the machine and, while

is 6.35 + 0.000, −0.025 mm (0.250 + 0.000, −0.001 in.).

holding the block in position, place the ring on the shaft and

6.4 Optical Device (or equivalent), with metric or English

lock the ring in place, using a method in accordance with the

unit calibration, is also necessary so that scar width can be

requirements of the specific machine design.

measured with a precision of 0.01 mm (0.0004 in.) or equiva-

9.11 Center the block on the ring while placing a light

lent.

manual pressure on the lever arm to bring the block and ring

into contact. Be sure the edge of the block is parallel to the

7. Reagents

edge of the ring and that the mating surfaces are perfectly

7.1 Reagents may include the following: aligned. This is accomplished by making sure the specimen

holder is free during mounting so that the quarter segment can

NOTE 2—Organic cleaners should be used with caution as they may

properly seat itself. Release the pressure on the lever arm.

react with the plastic being tested.

9.12 Place the required weights on the load bale and adjust

7.1.1 Methanol.

the lever arm in accordance with the requirements of the

7.1.2 Eye Glass Cleaner.

specific machine design to provide a load of 44.3 N (10 lbf) at

the block/ring interface. Then remove the load by raising the

8. Preparation and Calibration of Apparatus

weights.

8.1 Run the calibration procedure that is in Test Method

9.13 Set the revolution counter to zero.

D2714 to ensure good mechanical operation of the test

9.14 Gently lower the weights to apply the required load.

equipment.

9.15 If using a variable speed machine, turn on the machine

and slowly increase the power to the drive motor until the ring

9. Procedure

starts to rotate, and record the “static” friction force. Continue

9.1 Condition the test specimens at 23 6 2°C (73.4 6

to increase the rate of rotation to 200 rpm. If using a fixed

3.6°F) and 50 6 5% relative humidity for not less than 40 h

speed machine, simply turn on the machine.

prior to testing in accordance with Procedure A of Practice

9.16 During the test, record the friction force.

D618 for those samples where conditioning is required.

9.17 Stop the test manually or automatically after 240000

9.2 The recommended test conditions are the standard

revolutions (20 h).

laboratory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6

9.18 A final “static” friction force may be measured with a

5% relative humidity.

variablespeedmachine.Leavingonthefullload,wait3min 6

9.3 Clean the ring using a procedure that will remove any

10 s, then turn on the machine and slowly increase the power

scale, oil film, or residue without damaging the surface. The

to the drive motor until the ring starts to rotate, recording the

following procedure is recommended: clean the ring in a

final “static” friction force. Then turn off the motor.

suitable solvent, ultrasonically, if possible; a methanol rinse

maybeusedtoremoveanytracesofsolventresidue.Allowthe 9.19 Remove the block and ring and clean. For metals, use

rings to dry completely. Handle the ring with clean, lint-free a suitable solvent. For plastics, remove loose debris with a dry

cotton gloves from this point on. soft brush.

G176–03

NOTE—The outer diameter and concentricity with the inner diameter are the only critical parameters. The inner diameter is optional depending on

machine design. The inside diameter taper shown fits a number of standard machines.

FIG. 2 Test Ring

9.20 Make surface roughness measurements and profilome- shall be declared invalid. For further discussion of measure-

ter traces across the width of the block and the ring as desired. ment problems see 9.21, 9.22, and Fig. 4 inTest MethodG77.

Atrace along the long axis of the block, through the wear scar,

is also useful to verify the scar depth and shape. 10. Calculation

9.21 Measure the scar width on the test block in the center

10.1 Calculation of Block Scar Volume:

and ~1 mm (0.04 in.) away from each edge. These measure-

10.1.1 Block scar volume may be derived from block scar

ments shall be to the nearest 0.01 mm (0.0004 in.). Record the

width by using Table 1 (applicable only when ring diameter is

average of the three readings. Sometimes a lip of plastically

34.99 6 0.025 mm (1.377 6 0.001 in.) and scar length (block

deformed material will extend over the edge of the wear scar.

width) is 6.35 + 0.000, −0.025 mm (0.250 + 0.000, −0.001

Whenmeasuringscarwidth,trytovisuallyignorethismaterial

in.)).

or measure the scar width in an area where this is not a

10.1.2 The preferred method of calculating block scar

problem.

volume is by using the formula shown in Fig. 4. This formula

9.22 Tapered scars indicate improper block alignment dur- may be programmed on a calculator or computer.

ing testing. If the three width measurements on a given scar 10.1.3 Block scar volume is not calculated generally from

have a coefficient of variation of greater than 10%, the test block mass loss because block mass is subject to effects of

G176–03

materialtransfer.Keepingthisinmind,blockmasslossmaybe shutoff at a preset frictional load). If the machine malfunctions

interpreted semi-quantitatively in a comparative evaluation of oratestblockhasataperedscar,thedatashallnotbeused,and

variousmaterialcouples.Iftheblockscarcannotbeaccurately the test shall be rerun.

measured following 9.21, a scar volume should not be calcu- 11.2 Report the following:

lated, but a notation made of the problem, for example, 11.2.1 Test Parameters:

material transfer, plastic deformation, and so forth. 11.2.1.1 Block material,

10.2 Calculate coefficient of friction values from friction 11.2.1.2 Ring material and hardness (whenever applicable),

force values as follows: 11.2.1.3 Ring and block initial surface roughness, and

11.2.1.4 Number of replicates.

F

ƒ 5 (1)

11.2.2 Results—Report the average and the coefficient of

W

variation of the following (the coefficient of variation is the

where:

standard deviation divided by the average; it is expressed as a

ƒ = coefficient of friction,

percent).

F = measured friction force, N (lbf), and

11.2.2.1 Block scar width, mm,

W = applied load, 44.3 N (10 lbf). 3

11.2.2.2 Block scar volume, mm , calculated from scar

10.3 Calculate ring volume loss as follows:

width, and

ringmassloss 11.2.2.3 Ambient conditions, if other than normal labora-

volumeloss 5 (2)

ringdensity

tory conditions.

11.2.3 Reporting Optional:

10.3.1 Iftheringgainsmassduringthetest,thevolumeloss

11.2.3.1 Final surface roughness of block and ring,

is reported as zero with a notation that weight gain occurred.

11.2.3.2 Ring heat treatment, and

Ring mass loss can be affected by transfer of the plastic to the

11.2.3.3 Initial “static” and dynamic coefficients of friction

metal surface. If plastic transfer to the ring is obvious, then a

and final “static” and dynamic coefficients of friction.

ringscarvolumeshouldnotbecalculatedfromtheweightloss

measurement, but a notation should be made that plastic

12. Precision and Bias

transfer occurred. If there are obvious signs of abrasion of the

12.1 The precision and bias of the measurements obtained

ring surface, such as scratches or grooving, this should also be

noted. In this case profilometry may be used to measure with this test procedure will depend upon strict adherence to

the stated test procedure.

material loss.

12.2 The consistency of agreement in repeated tests on the

11. Report

same material will depend upon material consistency, machine

11.1 Report any unusual event or an overload shutoff of the and material interaction, and close observation of the test by a

machine(onsomemachinesitispossibletohaveanautomatic competent machine operator.

G176–03

TABLE 1 Block Scar Widths and Volumes for Blocks 6.35-mm Wide Mated Against Rings 34.99 mm in Diameter

Block Scar Block Scar

Volume Width Volume Width Volume Volume Width Volume Width Volume

Width Width

3 3 3 3 3 3

(mm ) (mm) (mm ) (mm) (mm ) (mm ) (mm) (mm ) (mm) (mm )

(mm) (mm)

0.30 0.0008 1.01 0.0312 1.72 0.1541 2.42 0.4295 3.12 0.9212 3.83 1.7062

0.31 0.0009 1.02 0.0321 1.73 0.1568 2.43 0.4348 3.13 0.9301 3.84 1.7196

0.32 0.0010 1.03 0.0331 1.74 0.1595 2.44 0.4402 3.14 0.9391

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.