ASTM D3973-85(2003)

(Test Method)Standard Test Method for Low-Molecular Weight Halogenated Hydrocarbons in Water

Standard Test Method for Low-Molecular Weight Halogenated Hydrocarbons in Water

SIGNIFICANCE AND USE

The incidental conversion of organic material to trihalomethanes and other volatile organohalides during chlorination of water is a possible health hazard and is the object of much research. This test method can be used as a rapid, simple means for determining many volatile organohalides in raw and processed water.

SCOPE

1.1 This test method covers the analysis of drinking water. It is also applicable to many environmental and waste waters when adequate validation is included.

1.2 This test method covers the determination of halomethanes, haloethanes, and some related extractable organohalides amenable to gas chromatographic measurement. The applicable concentration range for trihalomethanes is from 1 to 200 g/L. Detection limits depend on the compound, matrix, and on the characteristics of the gas chromatographic system.

1.3 For compounds not specifically included in the precision and bias section the analyst should validate the test method by collecting precision and bias data on actual samples.

1.4 Confirmation of component identities is obtained by observing retention times using gas chromatographic columns of different polarities. When concentrations are sufficiently high (>50 μg/L) confirmation with halogen specific detectors or gas chromatography/mass spectrometry (GC/MS) may be used. Confirmation of purgeable compounds at levels down to 1 μg/L can be obtained using Test Method D 3871 with GC/MS detection.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 3973–85 (Reapproved 2003)

Standard Test Method for

Low-Molecular Weight Halogenated Hydrocarbons in Water

This standard is issued under the fixed designation D 3973; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 355 Practice for Gas Chromatography Terms and Rela-

tionships

1.1 This test method covers the analysis of drinking water.

It is also applicable to many environmental and waste waters

3. Terminology

when adequate validation is included.

3.1 Definitions—For definitions of terms used in this test

1.2 This test method covers the determination of halometh-

method, refer to Terminology D 1129 and Practice E 355.

anes, haloethanes, and some related extractable organohalides

amenable to gas chromatographic measurement. The appli-

4. Summary of Test Method

cable concentration range for trihalomethanes is from 1 to 200

4.1 This test method employs liquid/liquid extraction to

µg/L.Detectionlimitsdependonthecompound,matrix,andon

isolate compounds of interest and provide a five-fold concen-

the characteristics of the gas chromatographic system.

5,6 ,7

trationenhancementpriortomeasurement. A5-mLaqueous

1.3 Forcompoundsnotspecificallyincludedintheprecision

sample is extracted once with 1 mL of solvent. -µL aliquot of

and bias section the analyst should validate the test method by

the extract is analyzed in a gas chromatograph equipped with

collecting precision and bias data on actual samples.

an electron-capture detector.

1.4 Confirmation of component identities is obtained by

4.2 Extraction efficiencies with the 1:5 solvent/sample ratio

observing retention times using gas chromatographic columns

for trihalomethanes average above 90 %. To compensate for

of different polarities. When concentrations are sufficiently

extraction losses, calibration standards are extracted and ana-

high (>50 µg/L) confirmation with halogen specific detectors

lyzed in an identical manner.

or gas chromatography/mass spectrometry (GC/MS) may be

4.3 The concentration of each component is calculated and

used. Confirmation of purgeable compounds at levels down to

reported in micrograms per litre.

1µg/LcanbeobtainedusingTestMethodD 3871withGC/MS

detection.

5. Significance and Use

1.5 This standard does not purport to address all of the

5.1 The incidental conversion of organic material to triha-

safety concerns, if any, associated with its use. It is the

lomethanes and other volatile organohalides during chlorina-

responsibility of the user of this standard to establish appro-

tion of water is a possible health hazard and is the object of

priate safety and health practices and determine the applica-

much research.This test method can be used as a rapid, simple

bility of regulatory limitations prior to use. Specific precau-

means for determining many volatile organohalides in raw and

tionary statements are given in Section 8.

processed water.

2. Referenced Documents

6. Interferences

2.1 ASTM Standards:

6.1 Volatile compounds that are extractable and responsive

D 1129 Terminology Relating to Water

to electron-capture detection may interfere with this test

D 1193 Specification for Reagent Water

method.

D 3871 Test Method for Purgeable Organic Compounds in

3 6.2 Impurities in the extracting solvent can be a source of

Water Using Headspace Sampling

interference. Solvent blanks should be analyzed daily and

before a new bottle of solvent is used for the first time.

This test method is under the jurisdiction of ASTM Committee D19 on Water

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor Annual Book of ASTM Standards, Vol 14.01.

Organic Substances in Water. Mieure, J. P., “A Rapid and Sensitive Method for Determining Volatile

Current edition approved Jan. 10, 2003. Published January 2003. Originally Organohalides in Water,” Journal AWWA, Vol 69, 1977, p. 60.

e1 6

approved in 1980. Last previous edition approved in 1995 as D 3973 – 85 (1995) Richard, J. J., and Junk, G. A., “Liquid Extraction for Rapid Determination of

. Halomethanes in Water,” Journal AWWA , Vol 69, 1977, p. 62.

2 7

Annual Book of ASTM Standards, Vol 11.01. “TheAnalysis of Trihalomethanes in Drinking Water by Liquid/Liquid Extrac-

Annual Book of ASTM Standards, Vol 11.02. tion,”U.S.EnvironmentalProtectionAgency,EMSL,Cincinnati,OH,Sept.9,1977.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3973–85 (2003)

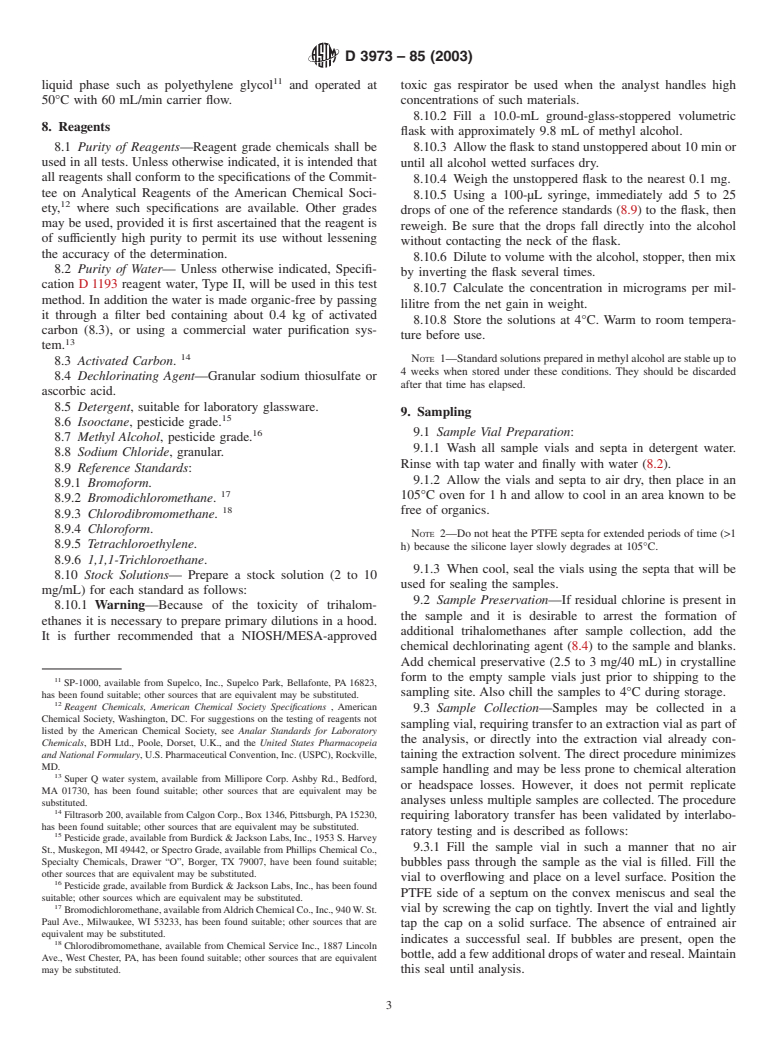

FIG. 1 Chromatograms of Standards

Whenever interfering compounds are traced to the solvent, a 7.5 Glass-Stoppered Volumetric Flasks, 10 and 100-mL.

new source of solvent should be obtained. Alternatively, 7.6 Gas Chromatograph, with electron-capture detector.

impurities may be removed by distillation, column chromatog- 7.7 Columns, either of the following columns have been

raphy or purging with high-purity nitrogen or helium. This found suitable for this analysis. See Fig. 1 for chromatograms.

procedure is quantitative as long as solvent interference con- If other column conditions are used, it is up to the analyst to

tributes less than 10 % to the component concentration in the demonstrate the precision and bias statements are met by

sample. collecting precision, bias, and recovery data.

7.7.1 Nonpolar, 3-mm inside diameter by 2-m long boro-

7. Apparatus

silicate glass packed with 100/120 mesh support coated with

a methyl silicone liquid phase and operated at 60°C with 45

7.1 Extraction Vessel, 9-mL (2-dram) vial with aluminum

foil or PTFE-lined caps. mL/min carrier flow.

7.7.2 Polar, 3-mm inside diameter by 2-m long borosilicate

7.2 Sample Containers, 40-mL screw cap vials sealed with

glass packed with 100/120 mesh support coated with a polar

PTFE-faced silicone septa.

7.3 Micro Syringes, 10, 100-µL.

7.4 Pipets, 1.0 and 5.0-mL transfer.

Gas-Chrom Q, available fromApplied Science Laboratory, Inc., P.O. Box 440,

State College, PA16801, has been found suitable; other sources that are equivalent

may be substituted.

8 10

13075 vials and 12722 septa, available from Pierce Chemical Co., P.O. Box OV-101, available from Ohio Valley Specialty Chemical, Inc., Route 6,

117,Rockford,IL61105,havebeenfoundsuitable;othersourcesthatareequivalent Marietta, OH 45750, has been found suitable; other sources that are equivalent may

may be substituted. be substituted.

D 3973–85 (2003)

liquid phase such as polyethylene glycol and operated at toxic gas respirator be used when the analyst handles high

50°C with 60 mL/min carrier flow. concentrations of such materials.

8.10.2 Fill a 10.0-mL ground-glass-stoppered volumetric

8. Reagents

flask with approximately 9.8 mL of methyl alcohol.

8.1 Purity of Reagents—Reagent grade chemicals shall be 8.10.3 Allow the flask to stand unstoppered about 10 min or

used in all tests. Unless otherwise indicated, it is intended that

until all alcohol wetted surfaces dry.

all reagents shall conform to the specifications of the Commit-

8.10.4 Weigh the unstoppered flask to the nearest 0.1 mg.

tee on Analytical Reagents of the American Chemical Soci-

8.10.5 Using a 100-µL syringe, immediately add 5 to 25

ety, where such specifications are available. Other grades

drops of one of the reference standards (8.9) to the flask, then

may be used, provided it is first ascertained that the reagent is

reweigh. Be sure that the drops fall directly into the alcohol

of sufficiently high purity to permit its use without lessening

without contacting the neck of the flask.

the accuracy of the determination.

8.10.6 Dilute to volume with the alcohol, stopper, then mix

8.2 Purity of Water— Unless otherwise indicated, Specifi-

by inverting the flask several times.

cation D 1193 reagent water, Type II, will be used in this test

8.10.7 Calculate the concentration in micrograms per mil-

method. In addition the water is made organic-free by passing

lilitre from the net gain in weight.

it through a filter bed containing about 0.4 kg of activated

8.10.8 Store the solutions at 4°C. Warm to room tempera-

carbon (8.3), or using a commercial water purification sys-

ture before use.

tem.

NOTE 1—Standard solutions prepared in methyl alcohol are stable up to

8.3 Activated Carbon.

4 weeks when stored under these conditions. They should be discarded

8.4 Dechlorinating Agent—Granular sodium thiosulfate or

after that time has elapsed.

ascorbic acid.

8.5 Detergent, suitable for laboratory glassware.

9. Sampling

8.6 Isooctane, pesticide grade.

16 9.1 Sample Vial Preparation:

8.7 Methyl Alcohol, pesticide grade.

9.1.1 Wash all sample vials and septa in detergent water.

8.8 Sodium Chloride, granular.

Rinse with tap water and finally with water (8.2).

8.9 Reference Standards:

9.1.2 Allow the vials and septa to air dry, then place in an

8.9.1 Bromoform.

105°C oven for 1 h and allow to cool in an area known to be

8.9.2 Bromodichloromethane.

free of organics.

8.9.3 Chlorodibromomethane.

8.9.4 Chloroform.

NOTE 2—Do not heat the PTFE septa for extended periods of time (>1

8.9.5 Tetrachloroethylene.

h) because the silicone layer slowly degrades at 105°C.

8.9.6 1,1,1-Trichloroethane.

9.1.3 When cool, seal the vials using the septa that will be

8.10 Stock Solutions— Prepare a stock solution (2 to 10

used for sealing the samples.

mg/mL) for each standard as follows:

9.2 Sample Preservation—If residual chlorine is present in

8.10.1 Warning—Because of the toxicity of trihalom-

the sample and it is desirable to arrest the formation of

ethanes it is necessary to prepare primary dilutions in a hood.

additional trihalomethanes after sample collection, add the

It is further recommended that a NIOSH/MESA-approved

chemical dechlorinating agent (8.4) to the sample and blanks.

Add chemical preservativ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.