ASTM D1439-15(2022)

(Test Method)Standard Test Methods for Sodium Carboxymethylcellulose

Standard Test Methods for Sodium Carboxymethylcellulose

SIGNIFICANCE AND USE

5.1 Moisture analysis (along with purity) is used to calculate the amount of active polymer in the material and must be considered when determining the amount of sodium carboxymethylcellulose to use in various formulations.

SCOPE

1.1 These test methods cover the testing of sodium carboxymethylcellulose.

1.2 The test procedures appear in the following order:

Sections

Moisture

4 – 9

Degree of Etherification:

Test Method A—Acid Wash

10 – 17

Test Method B—Nonaqueous Titration

10, 12, 18 – 23

Viscosity

24 – 29

Purity

30 – 37

Sodium Glycolate

38 – 46

Sodium Chloride

47 – 54

Density

55 – 61

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 15.1 and 20.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1439 − 15 (Reapproved 2022)

Standard Test Methods for

Sodium Carboxymethylcellulose

This standard is issued under the fixed designation D1439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1Specification for ASTM Liquid-in-Glass Thermometers

1.1 These test methods cover the testing of sodium car-

3. Purity of Reagents

boxymethylcellulose.

3.1 Reagent grade chemicals shall be used in all tests.

1.2 The test procedures appear in the following order:

Unlessotherwiseindicated,itisintendedthatallreagentsshall

Sections

conform to the specifications of the Committee on Analytical

Moisture 4–9

Reagents of the American Chemical Society, where such

Degree of Etherification:

Test Method A—Acid Wash 10–17

specifications are available. Other grades may be used, pro-

Test Method B—Nonaqueous Titration 10, 12, 18–23

vided it is first ascertained that the reagent is of sufficiently

Viscosity 24–29

Purity 30–37 high purity to permit its use without lessening the accuracy of

Sodium Glycolate 38–46

the determination.

Sodium Chloride 47–54

Density 55–61

3.2 Unless otherwise indicated, references to water shall be

understood to mean distilled water.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

MOISTURE

only.

1.4 This standard does not purport to address all of the

4. Scope

safety concerns, if any, associated with its use. It is the

4.1 Thistestmethodcoversthedeterminationofthevolatile

responsibility of the user of this standard to establish appro-

content of sodium carboxymethylcellulose.

priate safety, health, and environmental practices and deter-

4.2 The results of this test are used for calculating the total

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see 15.1 and 20. solids in the sample; and, by common usage, all materials

volatile at this test temperature are designated as moisture.

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Significance and Use

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.1 Moistureanalysis(alongwithpurity)isusedtocalculate

mendations issued by the World Trade Organization Technical

the amount of active polymer in the material and must be

Barriers to Trade (TBT) Committee.

consideredwhendeterminingtheamountofsodiumcarboxym-

ethylcellulose to use in various formulations.

2. Referenced Documents

2.1 ASTM Standards:

6. Apparatus

D1347 Test Methods for Methylcellulose (Withdrawn

6.1 Oven—Gravityconvectionoven,capableofmaintaining

2003)

a temperature of 105 6 3°C.

6.2 Weighing Bottles, low-form, 50-mm inside diameter by

These test methods are under the jurisdiction of ASTM Committee D01 on

30-mm height, or equivalent.

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.36 on Cellulose and Cellulose Derivatives. 6.3 Analytical Balance.

Current edition approved June 1, 2022. Published June 2022. Originally

approved in 1956. Last previous edition approved in 2015 as D1439–15. DOI:

10.1520/D1439-15R22.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ACS Reagent Chemicals, Specifications and Procedures for Reagents and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standard-Grade Reference Materials, American Chemical Society, Washington,

Standards volume information, refer to the standard’s Document Summary page on DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

the ASTM website. Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

The last approved version of this historical standard is referenced on U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

www.astm.org. copeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1439 − 15 (2022)

7. Procedure 13. Apparatus

7.1 Weigh3to5gofthe sample to the nearest 0.001 g in a 13.1 Stirrer, air-driven.

tared and covered weighing bottle.

13.2 Buchner Funnel, 75-mm, fitted with a 70-mm fine-

7.2 Place the bottle in an oven at 105°C for 2 h with the texture, heavy-duty filter paper. A 60-mm medium-porosity,

cover removed. Cool the bottle in a desiccator, replace the fritted glass funnel may also be used.

cover, and weigh.

13.3 Drying Oven, maintained at 105°C.

7.3 Replace the sample in the oven for 30 min, cool, and

14. Reagents

reweigh.

14.1 Diphenylamine Reagent—Dissolve 0.5 g of diphe-

7.4 Continue this procedure to a mass loss of not more than

nylamine in 120 mL of sulfuric acid (H SO , 9+2). The

5 mg for 30 min drying time. 2 4

reagent should be essentially water-white. It will give a deep

8. Calculation

blue coloration with traces of nitrate or other oxidizing agents.

8.1 Calculate the percent moisture, M, as follows:

14.2 Ethyl Alcohol (95 volume %)—Denaturedethylalcohol

conformingtoeitherFormula2B,3A,or30oftheU.S.Bureau

M 5 A/B 3100 (1)

~ !

of Internal Revenue.

where:

14.3 Ethyl Alcohol (80 % by volume)—Dilute 840 mL of

A = mass loss on heating, g, and

Formula 2B, 3A, or 30 denatured alcohol to 1 L with water.

B = sample used, g.

14.4 Hydrochloric Acid, Standard (HCl, 0.3 to 0.5 N).

9. Precision and Bias

14.5 Methanol, anhydrous.

9.1 Precision—Statistical analysis of interlaboratory repro-

14.6 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

ducibilitytestresultsonsamplescontaining2to10%moisture

(HNO ).

indicates a precision of 60.2% absolute at the 95% confi-

14.7 Sodium Hydroxide, Standard Solution (0.3 to 0.5

dence level.

N)—Prepare and standardize a 0.3 to 0.5 N solution of sodium

9.2 Bias—No justifiable statement can be made on the bias

hydroxide (NaOH).

of the procedure for measuring moisture because no suitable

14.8 Sulfuric Acid (9 + 2)—Carefullymix9volumesH SO

reference material exists. 2 4

with 2 volumes of water.

DEGREE OF ETHERIFICATION

15. Procedure

10. Scope

15.1 Weigh approximately4gofthe sample into a 250-mL

10.1 These test methods cover the determination of the

beakerandadd75mLofethylalcohol(95%).Stirthemixture

degree of etherification (D.E.) of sodium carboxymethylcellu-

with an air–driven stirrer until a good slurry is obtained.Add 5

lose.

mLof HNO , while agitating, and continue agitation for 1 to 2

min. Heat the slurry and boil for 5 min. (Warning—Exercise

10.2 Two test methods are included as follows:

care to avoid fire.) Remove the heat and continue agitation for

10.2.1 Test Method A (Acid Wash), for crude grades of

10 to 15 min.

sodium carboxymethylcellulose with degrees of etherification

up to 0.85. Above 0.85 degree of etherification, slightly low

15.2 Decant the supernatant liquid through the filter and

results may be obtained.

transfer the precipitate to the filter with 50 to 100 mL of ethyl

10.2.2 Test Method B (Nonaqueous Titration), for purified

alcohol (95%).Wash the precipitate with ethyl alcohol (80%)

grades of sodium carboxymethylcellulose of all degrees of

that has been heated to 60°C, until all of the acid has been

etherification. It is not applicable to the crude grades.

removed.

15.3 Test for the removal of acid and salts (ash) by mixing

11. Significance and Use

adropoftheacidcarboxymethylcelluloseslurryfromthefilter

11.1 These test methods determine the amount of substitu-

with a drop of diphenylamine reagent on a white spot plate.A

ent groups added to the cellulose backbone. The level can

bluecolorindicatesthepresenceofnitrateandthenecessityfor

greatly affect solution properties, rheology, viscosity,

further washing. If the first drop of reagent does not produce a

hygroscopicity,salttolerance,andmanyotherpropertiesofthe

blue color, further drops should be added until an excess of

polymer.

reagentisknowntobepresent,notingthecoloraftereachdrop.

Four to six washings will usually suffice to give a negative test

Test Method A—Acid Wash

for nitrate.

12. Summary of Test Method

15.4 Finally, wash the precipitate with a small amount of

12.1 The water-soluble sodium carboxymethylcellulose is anhydrousmethanolanddrawairthroughituntilthealcoholis

converted to the insoluble acid form, purified by washing, completely removed. Transfer the precipitate to a glass or

dried, and then a weighed sample is reconverted to the sodium aluminum weighing dish provided with a cover. Heat the

salt with a measured excess of sodium hydroxide. uncovereddishonasteambathuntiltheodorofalcoholcanno

D1439 − 15 (2022)

longer be detected (in order to avoid fires due to methanol 19.1.1 Discard the aqueous potassium chloride solution,

fumes in the oven), then dry the dish and contents, uncovered then rinse and fill with the calomel electrode solution as

for3hat105°C. Place the cover on the dish and cool to room described in 20.2.

temperature in a desiccator.

19.1.2 Add a few crystals of potassium chloride and silver

chloride or silver oxide to the electrode.

15.5 The sulfate ash content of the sample at this point

should be less than 0.5% when determined on 0.5 g of the

19.2 Buret, micro, 10-mL capacity.

sample by the procedure given in theAsh as Sulfate section of

Test Methods D1347. If the ash content is greater than 0.5%,

20. Reagents

rewash the sample with ethyl alcohol (80%). If necessary,

20.1 Acetic Acid, glacial.

repeat the procedure described in 15.1 – 15.4.

15.6 Weigh, to the nearest 0.01 g, about 1 to 1.5 g of the 20.2 Calomel Electrode Solution—Add2gof potassium

chloride(KCl)and2gofsilverchloride(AgCl)orsilveroxide

dried acid carboxymethylcellulose (depending on the normal-

ity of the acid and base to be used) into a 500-mLErlenmeyer (Ag O) to 100 mL of methanol and shake thoroughly to

flask. Add 100 mL of water and 25.00 mL of 0.3 to 0.5 N saturate. Use the supernatant liquid.

NaOHsolution,whilestirring.Heatthesolutiontoboiling,and

20.3 1,4-Dioxane.

boil for 15 to 30 min.

20.4 Perchloric Acid (0.1 N)—Add 9 mL of concentrated

15.7 TitratetheexcessNaOH,whilethesolutionishot,with

perchloric acid (HClO , 70% to 1 L of dioxane, with stirring

the 0.3 to 0.5 N HCl to a phenolphthalein end point.

(Warning—The solution of perchloric acid in dioxane should

16. Calculation

never be heated or allowed to evaporate.). Store in an amber

glass bottle. Any slight discoloration that appears on standing

16.1 Calculate the degree of etherification, G, as follows:

may be disregarded.

A 5 ~BC 2 DE!/F (2)

20.4.1 Standardize the solution as follows: Dry potassium

G 5 0.162A/ 1 2 0.0584A (3)

~ !

acid phthalate for 2 h at 120°C. Weigh 2.5 g to the nearest

0.0001 g into a 250-mL volumetric flask. Add glacial acetic

where:

acid, shake to dissolve, and then make up to volume and mix

A = milliequivalents of acid consumed per gram of

thoroughly. Pipet 10 mLinto a 100-mLbeaker and add 50 mL

sample,

of acetic acid. Place on a magnetic stirrer and insert the

B = NaOH solution added, mL,

electrodes of the pH meter.Add nearly the required amount of

C = normality of the NaOH solution,

HClO from a buret, then decrease the increments to 0.05 mL

D = HCl required for titration of the excess NaOH, mL,

as the end point is approached. Record the millilitres of titrant

E = normality of the HCl,

versus millivolts, and continue the titration a few millilitres

F = acid carboxymethylcellulose used, g,

162 = gram molecular mass of the anhydroglucose unit of beyond the end point. Plot the titration curve and read the

cellulose, and volume of titrant at the inflection point. Calculate the

58 = netincreaseinmolecularmassofanhydroglucoseunit

normality, N, as follows:

for each carboxymethyl group substituted.

N 5 ~A 310 31000!/~B 3204.22 3250! (4)

17. Precision and Bias

where:

17.1 Precision—Statistical analysis of intralaboratory (re-

A = potassium acid phthalate used, g,

peatability) test results indicates a precision of 60.04 D.E.

B = HClO added, mL,

units at the 95% confidence level.

204.22 = gram molecular mass of potassium acid phthalate,

10 = potassium acid phthalate solution added, mL, and

17.2 Bias—Nojustifiablestatementcanbemadeonthebias

250 = glacial acetic acid used to dissolve potassium acid

oftheprocedureformeasuringdegreeofetherificationbecause

phthalate, mL.

no suitable reference material exists.

20.5 Potassium Acid Phthalate, primary standard, National

Test Method B—Nonaqueous Titration

Institute of Standards and Technology Standard Sample No.

18. Summary of Test Methods

84.

18.1 This measurement is based upon a nonaqueous acid-

21. Procedure

base titration. The sample is refluxed with glacial acetic acid,

and the resulting sodium acetate is titrated with a standard

21.1 Weigh0.2gofthesample,tothenearest0.0001g,into

solution of perchloric acid in dioxane, to a potentiometric end

a 250-mL Erlenmeyer flask with ground-glass joint. Add 75

point. Impurities containing alkaline sodium will also be

mL of acetic acid, connect to a water-cooled condenser, and

titrated under these conditions. Sodium chloride does not

reflux gently on a hot plate for 2 h.

interfere.

21.2 Cool,andtransferthesolutiontoa250-mLbeakerwith

19. Apparatus

the aid of 50 mL of acetic acid. Place on the magnetic stirrer

19.1 pH Meter,equippedwithastandardglasselectrodeand and titrate to a potentiometric end point with 0.1 N HClO in

a calomel electrode modified as follows: accordance with 20.4.

D1439 − 15 (2022)

TABLE 1 Rotational Elements and Speeds

22. Calculation

Rotational Element Selection

22.1 Calculate the degree of etherification, H, as follows

(see Fig. 1)

(Note 1):

Viscosity Range, Length Diameter Speed Torque Scale

(mPa·s) (mm) (mm) (r/min) Multiplier

M 5 AN 3100 / G 3 100 2 B (5)

~ ! ~ ~ !!

10 to 100 19 65 60 1

H 5 0.162 M/ 1.000 2 0.080 M (6)

~ ~ !!

100 to 200 19 65 30 2

200 to 1000 10 54 30 10

where:

1000 to 4000 5.9 43 30 40

4000 to 10000 3.2 31 30 200

M = milliequivalents of acid consumed per gram of

sample,

A = HClO added, mL,

25. Significance and Use

N = normality of HClO ,

G = sample used, g,

25.1 This test method determines the relative ability of the

B = percent moisture, determined on a separate sample, in

polymer to thicken water. This is the primary function of

accordance with Sections4–7,

sodium carboxymethylcellulose.

162 = gram molecular mass of an anhydroglucose unit of

cellulose, and

26. Apparatus

80 = net increase in molecu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1439 − 15 D1439 − 15 (Reapproved 2022)

Standard Test Methods for

Sodium Carboxymethylcellulose

This standard is issued under the fixed designation D1439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 These test methods cover the testing of sodium carboxymethylcellulose.

1.2 The test procedures appear in the following order:

Sections

Moisture 4 – 9

Degree of Etherification:

Test Method A—Acid Wash 10 – 17

Test Method B—Nonaqueous Titration 10, 12, 18 – 23

Viscosity 24 – 29

Purity 30 – 37

Sodium Glycolate 38 – 46

Sodium Chloride 47 – 54

Density 55 – 61

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific hazard statements, see 15.1 and 20.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1347 Test Methods for Methylcellulose (Withdrawn 2003)

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Purity of Reagents

3.1 Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents shall conform

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved Dec. 1, 2015June 1, 2022. Published January 2016June 2022. Originally approved in 1956. Last previous edition approved in 20082015 as

ɛ1

D1439 – 03 (2008)D1439 – 15. . DOI: 10.1520/D1439-15.10.1520/D1439-15R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1439 − 15 (2022)

to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where such specifications are

available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use

without lessening the accuracy of the determination.

3.2 Unless otherwise indicated, references to water shall be understood to mean distilled water.

MOISTURE

4. Scope

4.1 This test method covers the determination of the volatile content of sodium carboxymethylcellulose.

4.2 The results of this test are used for calculating the total solids in the sample; and, by common usage, all materials volatile at

this test temperature are designated as moisture.

4. Scope

4.1 This test method covers the determination of the volatile content of sodium carboxymethylcellulose.

4.2 The results of this test are used for calculating the total solids in the sample; and, by common usage, all materials volatile at

this test temperature are designated as moisture.

5. Significance and Use

5.1 Moisture analysis (along with purity) is used to calculate the amount of active polymer in the material and must be considered

when determining the amount of sodium carboxymethylcellulose to use in various formulations.

6. Apparatus

6.1 Oven—Gravity convection oven, capable of maintaining a temperature of 105 6 3°C.3 °C.

6.2 Weighing Bottles, low-form, 50-mm inside diameter by 30-mm height, or equivalent.

6.3 Analytical Balance.

7. Procedure

7.1 Weigh 3 to 5 g of the sample to the nearest 0.001 g in a tared and covered weighing bottle.

7.2 Place the bottle in an oven at 105°C105 °C for 2 h with the cover removed. Cool the bottle in a desiccator, replace the cover,

and weigh.

7.3 Replace the sample in the oven for 30 min, cool, and reweigh.

7.4 Continue this procedure to a mass loss of not more than 5 mg for 30 min drying time.

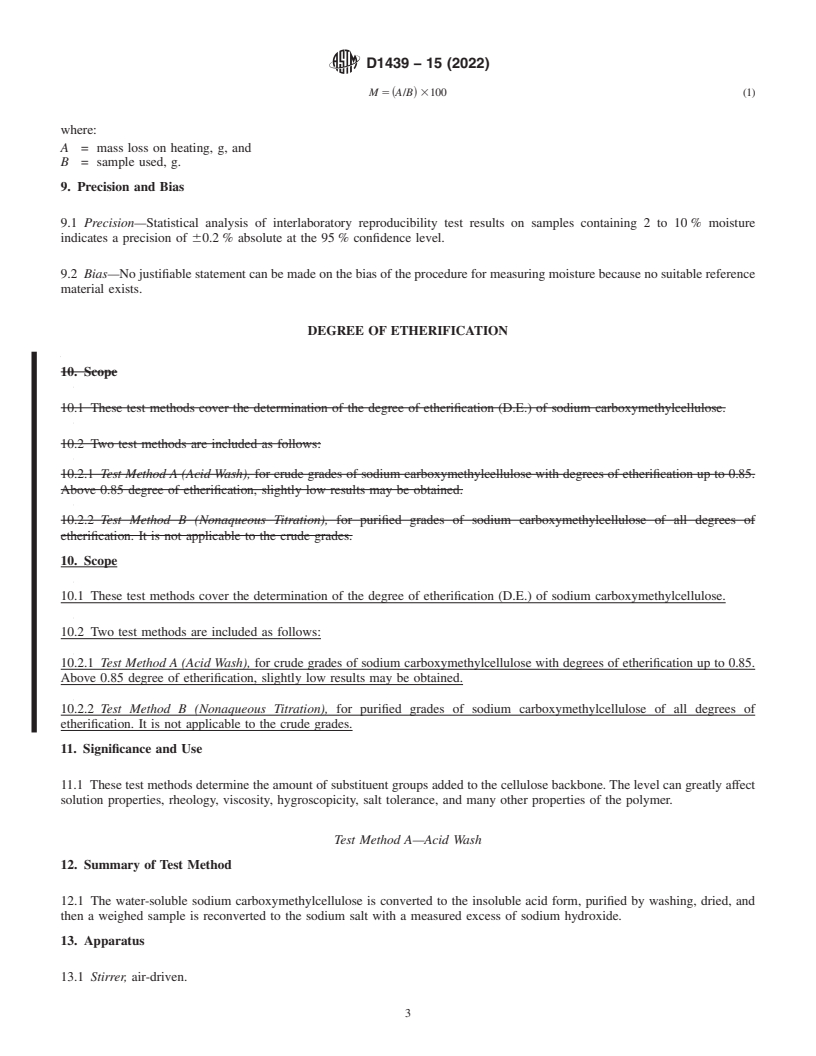

8. Calculation

8.1 Calculate the percent moisture, M, as follows:

Reagent Chemicals, American Chemical Society Specifications,ACS Reagent Chemicals, Specifications and Procedures for Reagents and Standard-Grade Reference

Materials, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for

Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC),

Rockville, MD.

D1439 − 15 (2022)

M 5 A/B 3100 (1)

~ !

where:

A = mass loss on heating, g, and

B = sample used, g.

9. Precision and Bias

9.1 Precision—Statistical analysis of interlaboratory reproducibility test results on samples containing 2 to 10 % moisture

indicates a precision of 60.2 % absolute at the 95 % confidence level.

9.2 Bias—No justifiable statement can be made on the bias of the procedure for measuring moisture because no suitable reference

material exists.

DEGREE OF ETHERIFICATION

10. Scope

10.1 These test methods cover the determination of the degree of etherification (D.E.) of sodium carboxymethylcellulose.

10.2 Two test methods are included as follows:

10.2.1 Test Method A (Acid Wash), for crude grades of sodium carboxymethylcellulose with degrees of etherification up to 0.85.

Above 0.85 degree of etherification, slightly low results may be obtained.

10.2.2 Test Method B (Nonaqueous Titration), for purified grades of sodium carboxymethylcellulose of all degrees of

etherification. It is not applicable to the crude grades.

10. Scope

10.1 These test methods cover the determination of the degree of etherification (D.E.) of sodium carboxymethylcellulose.

10.2 Two test methods are included as follows:

10.2.1 Test Method A (Acid Wash), for crude grades of sodium carboxymethylcellulose with degrees of etherification up to 0.85.

Above 0.85 degree of etherification, slightly low results may be obtained.

10.2.2 Test Method B (Nonaqueous Titration), for purified grades of sodium carboxymethylcellulose of all degrees of

etherification. It is not applicable to the crude grades.

11. Significance and Use

11.1 These test methods determine the amount of substituent groups added to the cellulose backbone. The level can greatly affect

solution properties, rheology, viscosity, hygroscopicity, salt tolerance, and many other properties of the polymer.

Test Method A—Acid Wash

12. Summary of Test Method

12.1 The water-soluble sodium carboxymethylcellulose is converted to the insoluble acid form, purified by washing, dried, and

then a weighed sample is reconverted to the sodium salt with a measured excess of sodium hydroxide.

13. Apparatus

13.1 Stirrer, air-driven.

D1439 − 15 (2022)

13.2 Buchner Funnel, 75-mm, fitted with a 70-mm fine-texture, heavy-duty filter paper. A 60-mm medium-porosity, fritted glass

funnel may also be used.

13.3 Drying Oven, maintained at 105°C.105 °C.

14. Reagents

14.1 Diphenylamine Reagent—Dissolve 0.5 g of diphenylamine in 120 mL of sulfuric acid (H SO , 9 + 2). The reagent should be

2 4

essentially water-white. It will give a deep blue coloration with traces of nitrate or other oxidizing agents.

14.2 Ethyl Alcohol (95 volume %)—Denatured ethyl alcohol conforming to either Formula 2B, 3A, or 30 of the U. S. Bureau of

Internal Revenue.

14.3 Ethyl Alcohol (80 % by volume)—Dilute 840 mL of Formula 2B, 3A, or 30 denatured alcohol to 1 L with water.

14.4 Hydrochloric Acid, Standard (HCl, 0.3 to 0.5 N).

14.5 Methanol, anhydrous.

14.6 Nitric Acid (sp gr 1.42)—Concentrated nitric acid (HNO ).

14.7 Sodium Hydroxide, Standard Solution(0.3 Solution (0.3 to 0.5 N)—Prepare and standardize a 0.3 to 0.5 N solution of sodium

hydroxide (NaOH).

14.8 Sulfuric Acid (9 + 2)—Carefully mix 9 volumes H SO with 2 volumes of water.

2 4

15. Procedure

15.1 Weigh approximately 4 g of the sample into a 250-mL beaker and add 75 mL of ethyl alcohol (95 %). Stir the mixture with

an air–driven stirrer until a good slurry is obtained. Add 5 mL of HNO , while agitating, and continue agitation for 1 to 2 min.

Heat the slurry and boil for 5 min. (Warning—WarningExercise—Exercise care to avoid fire.) Remove the heat and continue

agitation for 10 to 15 min.

15.2 Decant the supernatant liquid through the filter and transfer the precipitate to the filter with 50 to 100 mL of ethyl alcohol

(95 %). Wash the precipitate with ethyl alcohol (80 %) that has been heated to 60°C,60 °C, until all of the acid has been removed.

15.3 Test for the removal of acid and salts (ash) by mixing a drop of the acid carboxymethylcellulose slurry from the filter with

a drop of diphenylamine reagent on a white spot plate. A blue color indicates the presence of nitrate and the necessity for further

washing. If the first drop of reagent does not produce a blue color, further drops should be added until an excess of reagent is known

to be present, noting the color after each drop. Four to six washings will usually suffice to give a negative test for nitrate.

15.4 Finally, wash the precipitate with a small amount of anhydrous methanol and draw air through it until the alcohol is

completely removed. Transfer the precipitate to a glass or aluminum weighing dish provided with a cover. Heat the uncovered dish

on a steam bath until the odor of alcohol can no longer be detected (in order to avoid fires due to methanol fumes in the oven),

then dry the dish and contents, uncovered for 3 h at 105°C.105 °C. Place the cover on the dish and cool to room temperature in

a desiccator.

15.5 The sulfate ash content of the sample at this point should be less than 0.5 % when determined on 0.5 g of the sample by the

procedure given in the Ash as Sulfate section of Test Methods D1347. If the ash content is greater than 0.5 %, rewash the sample

with ethyl alcohol (80 %). If necessary, repeat the procedure described in 15.1 – 15.4.

15.6 Weigh, to the nearest 0.01 g, about 1 to 1.5 g of the dried acid carboxymethylcellulose (depending on the normality of the

D1439 − 15 (2022)

acid and base to be used) into a 500-mL Erlenmeyer flask. Add 100 mL of water and 25.00 mL of 0.3 to 0.5 N NaOH solution,

while stirring. Heat the solution to boiling, and boil for 15 to 30 min.

15.7 Titrate the excess NaOH, while the solution is hot, with the 0.3 to 0.5 N HCl to a phenolphthalein end point.

16. Calculation

16.1 Calculate the degree of etherification, G, as follows:

A 5 BC 2 DE /F (2)

~ !

G 5 0.162A/~12 0.0584A! (3)

where:

A = milliequivalents of acid consumed per gram of sample,

B = NaOH solution added, mL,

C = normality of the NaOH solution,

D = HCl required for titration of the excess NaOH, mL,

E = normality of the HCl,

F = acid carboxymethylcellulose used, g,

162 = gram molecular mass of the anhydroglucose unit of cellulose, and

58 = net increase in molecular mass of anhydroglucose unit for each carboxymethyl group substituted.

17. Precision and Bias

17.1 Precision—Statistical analysis of intralaboratory (repeatability) test results indicates a precision of 60.04 D.E. units at the

95 % confidence level.

17.2 Bias—No justifiable statement can be made on the bias of the procedure for measuring degree of etherification because no

suitable reference material exists.

Test Method B—Nonaqueous Titration

18. Summary of Test Methods

18.1 This measurement is based upon a nonaqueous acid-base titration. The sample is refluxed with glacial acetic acid, and the

resulting sodium acetate is titrated with a standard solution of perchloric acid in dioxane, to a potentiometric end point. Impurities

containing alkaline sodium will also be titrated under these conditions. Sodium chloride does not interfere.

19. Apparatus

19.1 pH Meter, equipped with a standard glass electrode and a calomel electrode modified as follows:

19.1.1 Discard the aqueous potassium chloride solution, then rinse and fill with the calomel electrode solution as described in 20.2.

19.1.2 Add a few crystals of potassium chloride and silver chloride or silver oxide to the electrode.

19.2 Buret, micro, 10-mL capacity.

20. Reagents

20.1 Acetic Acid, glacial.

20.2 Calomel Electrode Solution—Add 2 g of potassium chloride (KCl) and 2 g of silver chloride (AgCl) or silver oxide (Ag O)

to 100 mL of methanol and shake thoroughly to saturate. Use the supernatant liquid.

20.3 1,4-Dioxane.

D1439 − 15 (2022)

20.4 Perchloric Acid (0.1 N)—Add 9 mL of concentrated perchloric acid (HClO , 70 % to 1 L of dioxane, with stirring

(Warning—WarningThe—The solution of perchloric acid in dioxane should never be heated or allowed to evaporate.). Store in

an amber glass bottle. Any slight discoloration that appears on standing may be disregarded.

20.4.1 Standardize the solution as follows: Dry potassium acid phthalate for 2 h at 120°C.120 °C. Weigh 2.5 g to the nearest

0.0001 g into a 250-mL volumetric flask. Add glacial acetic acid, shake to dissolve, and then make up to volume and mix

thoroughly. Pipet 10 mL into a 100-mL beaker and add 50 mL of acetic acid. Place on a magnetic stirrer and insert the electrodes

of the pH meter. Add nearly the required amount of HClO from a buret, then decrease the increments to 0.05 mL as the end point

is approached. Record the millilitres of titrant versus millivolts, and continue the titration a few millilitres beyond the end point.

Plot the titration curve and read the volume of titrant at the inflection point. Calculate the normality, N, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.