ASTM D7617/D7617M-11(2017)

(Test Method)Standard Test Method for Transverse Shear Strength of Fiber-reinforced Polymer Matrix Composite Bars

Standard Test Method for Transverse Shear Strength of Fiber-reinforced Polymer Matrix Composite Bars

SIGNIFICANCE AND USE

5.1 This test method for transverse shear strength is intended for use in laboratory tests in which the principal variable is the size or type of FRP bars. The test may be used for smooth round rods or on bars with a textured or undulating surface added to promote bond of the bars to Portland cement concrete. This test method establishes values of transverse shear strength for material specifications, quality control, quality assurance, research and development, and may also be used for structural design purposes.

5.2 Experience with this test method and the accompanying fixture is primarily with smooth rods and textured bars with diameters ranging from 6 mm to 25 mm [0.25 in. to 1 in.]. The method may be used for rods or bars of larger diameters, but the overall geometry of the test fixture may need to be increased.

SCOPE

1.1 This test method specifies the test requirements for (FRP) composite smooth round rods and textured bars for determining the transverse shear strength via a double shear fixture. FRP rods and bars are often loaded in transverse shear when these elements are used as dowels in concrete pavements, as stirrups in concrete beams, or as shear reinforcements in glued-laminated wood beams, for example.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7617/D7617M − 11 (Reapproved 2017)

Standard Test Method for

Transverse Shear Strength of Fiber-reinforced Polymer

Matrix Composite Bars

This standard is issued under the fixed designation D7617/D7617M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

1.1 This test method specifies the test requirements for

D5229/D5229M TestMethodforMoistureAbsorptionProp-

(FRP) composite smooth round rods and textured bars for

erties and Equilibrium Conditioning of Polymer Matrix

determining the transverse shear strength via a double shear

Composite Materials

fixture. FRP rods and bars are often loaded in transverse shear

D7205/D7205M Test Method for Tensile Properties of Fiber

whentheseelementsareusedasdowelsinconcretepavements,

Reinforced Polymer Matrix Composite Bars

as stirrups in concrete beams, or as shear reinforcements in

E4 Practices for Force Verification of Testing Machines

glued-laminated wood beams, for example.

E6 Terminology Relating to Methods of Mechanical Testing

1.2 The values stated in either SI units or inch-pound units

E122 Practice for Calculating Sample Size to Estimate,With

are to be regarded separately as standard. The values stated in

Specified Precision, the Average for a Characteristic of a

each system may not be exact equivalents; therefore, each

Lot or Process

system shall be used independently of the other. Combining

E456 Terminology Relating to Quality and Statistics

values from the two systems may result in non-conformance

with the standard.

3. Terminology

1.2.1 Within the text, the inch-pound units are shown in

brackets. 3.1 Terminology in D3878 defines terms relating to high-

modulus fibers and their composites. Terminology in D883

1.3 This standard does not purport to address all of the

defines terms relating to plastics. Terminology in E6 defines

safety concerns, if any, associated with its use. It is the

terms relating to mechanical testing. Terminology in E456

responsibility of the user of this standard to establish appro-

defines terms relating to statistics and the selection of sample

priate safety and health practices and determine the applica-

sizes. In the event of a conflict between terms, Terminology in

bility of regulatory limitations prior to use.

D3878 shall have precedence over the other terminology

1.4 This international standard was developed in accor-

standards.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 bar, n—a linear element, with a substantially round

mendations issued by the World Trade Organization Technical

cross section, often with surface undulations or a coating of

Barriers to Trade (TBT) Committee.

particles that promote mechanical interlock with concrete.

3.2.2 double shear fixture, n—atestfixturethatresultsinthe

2. Referenced Documents

desired shear force being applied to two distinct sections of the

2.1 ASTM Standards:

specimen.

A615/A615M SpecificationforDeformedandPlainCarbon-

3.2.3 failure, n—cleavage of the bar under test into three

Steel Bars for Concrete Reinforcement

pieces or into two pieces where the second non-cleaved shear

plane is highly damaged.

This test method is under the jurisdiction of ASTM Committee D30 on

3.2.4 nominal cross sectional area, n—a measure of cross

Composite Materials and is the direct responsibility of Subcommittee D30.10 on

Composites for Civil Structures.

sectional area of a bar, determined over at least one represen-

Current edition approved Aug. 1, 2017. Published September 2017. Originally

tative length, used to calculate stress.

approved in 2011. Last previous edition approved as D7617/D7617M–11. DOI:

10.1520/D7617_D7617M-11R17.

3.2.5 projected outer diameter, n—the smallest diameter of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

a circle through which a bar, with its undulations or coatings,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

will pass. The bar may touch the circle but must pass through

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. without undue force.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7617/D7617M − 11 (2017)

3.2.6 rod, n—a bar with a smooth circular cross section and variable is the size or type of FRP bars. The test may be used

no texture or deformations. for smooth round rods or on bars with a textured or undulating

surface added to promote bond of the bars to Portland cement

3.2.7 standard cross sectional area, n—the cross sectional

concrete. This test method establishes values of transverse

area of a standard numbered steel concrete reinforcing bar as

shear strength for material specifications, quality control,

given in A615/A615M, Table 1.

quality assurance, research and development, and may also be

3.2.8 surface undulation, n—variation in the area,

used for structural design purposes.

orientation, or shape of cross section of a bar along its length,

5.2 Experience with this test method and the accompanying

intended to enhance mechanical interlock between a bar and

fixture is primarily with smooth rods and textured bars with

concrete, made by any of a number of processes such as, for

diameters ranging from 6 mm to 25 mm [0.25 in. to 1 in.]. The

example, indentation, addition of extra materials, and twisting.

method may be used for rods or bars of larger diameters, but

3.3 Symbols:

the overall geometry of the test fixture may need to be

3.3.1 A—nominalorstandardcrosssectionalareaofarodor

increased.

bar, see D7205/D7205M.

6. Interferences

3.3.2 P —maximum shear force carried by specimen N

S

6.1 Blade Alignment—The two lower and one upper blade

[lbf].

used for shearing the specimen are machined to fit the

3.3.3 τ —transverse shear strength, MPa [psi].

u

projectedouterdiameterofthebar.Theslotwidthanddiameter

4. Summary of Test Method

of the blades should be selected so that the bar fits snugly into

the fixture, but does not bind. The test results may be sensitive

4.1 Alength of fiber-reinforced polymer (FRP) rod or bar is

to the slot width for bars which have significant texture or

fittedintoadoubleshearfixturewithappropriatecuttingblades

deformations. See Fig. 1.

and clamped into place. The shear fixture is mounted into a

universal mechanical testing machine and monotonically 6.2 Surface Texture—The method has been used with tex-

loaded to failure while recording force and crosshead displace- tured bars with surface roughness amplitudes of up to 6 5%

ment. variation in diameter relative to the average bar diameter as

measured with a dial caliper. Use on bars with greater variation

5. Significance and Use

in surface roughness or regions with substantially-reduced

5.1 This test method for transverse shear strength is in- cross-sections may lead to increased scatter in test results or

tended for use in laboratory tests in which the principal failure of the specimens away from the two shearing planes.

NOTE 1—The blades should fit snugly around the bar without binding.

FIG. 1 Potential Interference for Undulating or Textured Bar

D7617/D7617M − 11 (2017)

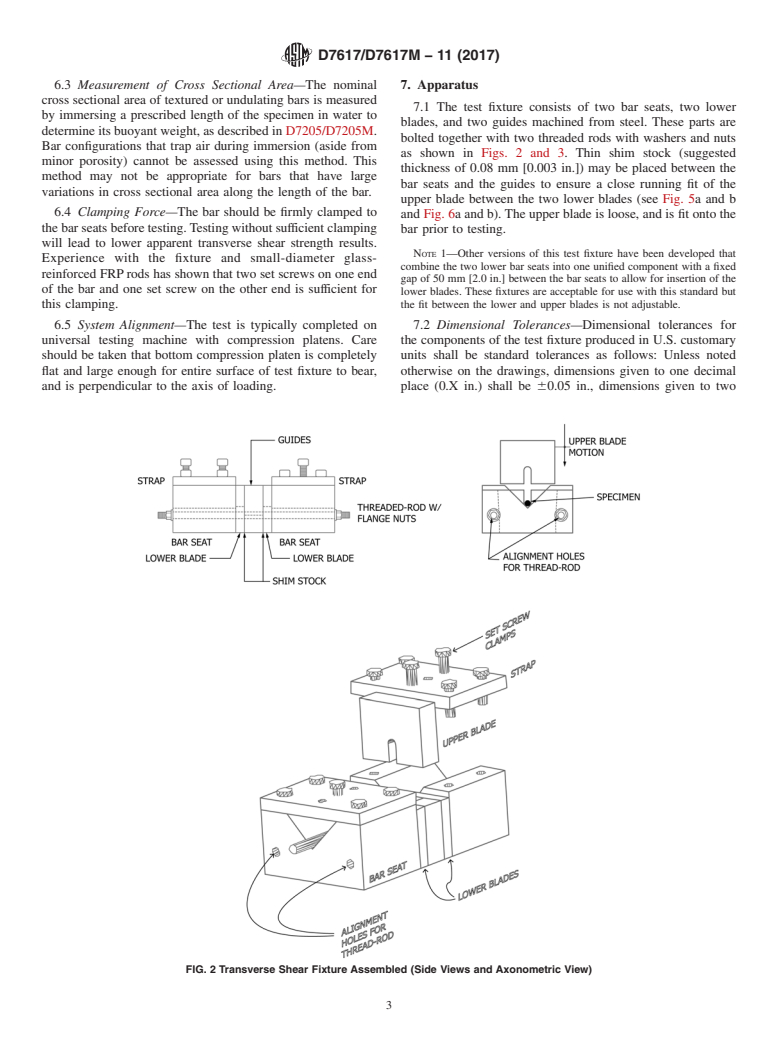

6.3 Measurement of Cross Sectional Area—The nominal 7. Apparatus

cross sectional area of textured or undulating bars is measured

7.1 The test fixture consists of two bar seats, two lower

by immersing a prescribed length of the specimen in water to

blades, and two guides machined from steel. These parts are

determine its buoyant weight, as described in D7205/D7205M.

bolted together with two threaded rods with washers and nuts

Bar configurations that trap air during immersion (aside from

as shown in Figs. 2 and 3. Thin shim stock (suggested

minor porosity) cannot be assessed using this method. This

thickness of 0.08 mm [0.003 in.]) may be placed between the

method may not be appropriate for bars that have large

bar seats and the guides to ensure a close running fit of the

variations in cross sectional area along the length of the bar.

upper blade between the two lower blades (see Fig. 5a and b

6.4 Clamping Force—The bar should be firmly clamped to

and Fig. 6a and b). The upper blade is loose, and is fit onto the

the bar seats before testing.Testing without sufficient clamping

bar prior to testing.

will lead to lower apparent transverse shear strength results.

NOTE 1—Other versions of this test fixture have been developed that

Experience with the fixture and small-diameter glass-

combine the two lower bar seats into one unified component with a fixed

reinforced FRProds has shown that two set screws on one end

gap of 50 mm [2.0 in.] between the bar seats to allow for insertion of the

of the bar and one set screw on the other end is sufficient for

lower blades. These fixtures are acceptable for use with this standard but

this clamping. the fit between the lower and upper blades is not adjustable.

6.5 System Alignment—The test is typically completed on 7.2 Dimensional Tolerances—Dimensional tolerances for

universal testing machine with compression platens. Care the components of the test fixture produced in U.S. customary

should be taken that bottom compression platen is completely units shall be standard tolerances as follows: Unless noted

flat and large enough for entire surface of test fixture to bear, otherwise on the drawings, dimensions given to one decimal

and is perpendicular to the axis of loading. place (0.X in.) shall be 60.05 in., dimensions given to two

FIG. 2 Transverse Shear Fixture Assembled (Side Views and Axonometric View)

D7617/D7617M − 11 (2017)

NOTE 1—(1) Assembled fixture with sheared specimen and (2) main body of fixture disassembled (note presence of shim stock on guides).

FIG. 3 Photographs of Test Fixture

decimal places (0.0X in.) shall be 60.01 in., and dimensions 0.10 mm [0.004 in.] wider than the measured diameter of the

given to three decimal places (0.00X in.) shall be 60.005 in. rods. For textured or undulating bars the slot shall be equal to

For components produced in SI units, standard tolerances for

the projected outer diameter from the roughly circular bar. The

dimensions given to zero decimal places (X mm) shall be 60.1

depth of the semi-circle at the bottom of the slot shall be

mm, dimensions given to one decimal place (0.X mm) shall be

established so that the diameter of the semi-circle is tangent

60.25 mm, dimension given to two decimal places (0.0X mm)

with the angled side of the bar seat (see Fig. 1 and Fig. 5).

shall be 60.10 mm.

7.4.2 Upper Blade—The upper blade is machined from 25

7.3 Bar Seats—The two bar seats are identical and have a

mm [1.000 in.] thick steel having a precision ground finish of

v-shaped bed for supporting the ends of the bars (see Fig. 4a

0.80 µm [32 µin.] or better. The upper blade has the same

and b).

machined slot and diameter as the two lower blades (see Fig.

7.4 Blades—The lower blades and upper blade should be 7a and b).

machined from tool steel, hardened to 55 to 58 HRC.

NOTE2—Thisstandarddoesnotgivespecificdimensionalrequirements

7.4.1 Lower Blades—The two lower blades are machined

for the slots and diameters of the lower and upper blades, as a wide range

from 12 mm [0.500 in.] thick steel having a precision ground

of textured bars and smooth rods, produced under both SI and US

finish of 0.80 µm [32 µin.] or better. The slots in the lower

Customary standards, may be tested using this method. Fig. 5 and Fig. 7

blades are machined based on the diameter of the bars to be

depict the dimensions of lower and upper blades for a 3/8 in. and a 10 mm

tested. For smooth round rods, the width of the slot shall be smooth rod. In U.S. practice, blades for the apparatus are typically made

D7617/D7617M − 11 (2017)

FIG. 4 a Bar Seat (U.S. Customary Units)

for smooth and textured rods in diameters that range between 6 mm (0.25

7.7.1 Testing Machine Heads—The testing machine shall

in.) to 25 mm (1 in.).

have both an essentially stationary head and a movable head.

The movable head shall be equipped with a deflection measur-

7.5 Guides—The guides are machined from the same steel

ing device.

as the upper blade.The two guides are of equal thickness to the

7.7.2 Drive Mechanism—The testing machine drive mecha-

upper blade and may be tapered to facilitate insertion of the

upper blade into the fixture. The holes in the guides align with nism shall be capable of imparting to the movable head a

controlled velocity with respect to the stationary head. The

the holes in the lower blades and in the bar seats so that the

entire assembly can be bolted together (see Fig. 6a and b). velocity of the movable head shall be capable of being

regulated as specified in 11.4.

7.6 Strap—Straps, nominally 12 mm [0.5 in.] thick, and

7.7.3 Force Indicator—The testing machine force-sensing

mounted at the top of both bar seats, are used to clamp the bar

device shall be capable of indicating the total force being

or rod firmly into the bar seats during testing. Socket-head cap

carried by the test specimen. This device shall be essentially

screws pass through threads in the straps and clamp the

free from inertia lag at the specified rate of testing and shall

specimens onto the bar seats. (see Fig. 8a and b).

indicate the force with an accuracy over the force range(s) of

7.7 Testing Machine—The testing machine shall be in con- interest of within 6 1 % of the indicated value. The force

formance with Practices E4 and shall satisfy the following

range(s) of interest may be fairly low for modulus evaluation,

requirements: much higher for strength evaluation, or both, as required.

D7617/D7617M − 11 (2017)

FIG. 4 b Bar Seat (SI Units) (continued)

8. Sampling and Test Specimens be determined by measuring the average diameter of the rod to

a precision of 0.02 mm [0.001 in.] and calculating the area of

8.1 Specimens shall be representative of the lot or batch

the rod assuming that it is circular.

being tested. In the test section of the specimen, no postpro-

duction

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.