ASTM D1364-02

(Test Method)Standard Test Method for Water in Volatile Solvents (Karl Fischer Reagent Titration Method)

Standard Test Method for Water in Volatile Solvents (Karl Fischer Reagent Titration Method)

SCOPE

1.1 This test method covers the determination of water in volatile solvents and chemical intermediates used in paint, varnish, lacquer, and related products.

1.2 This test method is not applicable in the presence of mercaptans, peroxides, or appreciable quantities of aldehydes or amines.

1.3 For purposes of determining conformance of an observed or a calculated value using this test method to relevant specifications, test result(s) shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 For hazard information and guidance, see the supplier's Material Safety Data sheet.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

Designation:D1364–02

Standard Test Method for

Water in Volatile Solvents (Karl Fischer Reagent Titration

1

Method)

This standard is issued under the fixed designation D 1364; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* addition of 0.05 mL of Karl Fischer reagent (6 mg of H O per

2

mL), causing a change of current flow of 10 to 20 µA that

1.1 This test method covers the determination of water in

persists for at least 30 s.

volatile solvents and chemical intermediates used in paint,

varnish, lacquer, and related products.

NOTE 1—Thisendpointissometimesincorrectlycalledthe“deadstop”

1.2 This test method is not applicable in the presence of which is the reverse of the above.

mercaptans, peroxides, or appreciable quantities of aldehydes

3.1.2 color end point—During the titration, the solution first

or amines.

turnsyellow,thenlaterdeepenstowardstheendofthetitration;

1.3 For purposes of determining conformance of an ob-

the end point is indicated by the change from yellow to

served or a calculated value using this test method to relevant

orange-red which is quite sharp and easily repeated. The

specifications, test result(s) shall be rounded off “to the nearest

orange-red color must persist for at least 30 s in order to

unit” in the last right-hand digit used in expressing the

indicate an end point.

specification limit, in accordance with the rounding-off method

NOTE 2—View the color by transmitted daylight or by transmitted light

of Practice E 29.

from an artificial daylight lamp, such as the one that complies with the

1.4 This standard does not purport to address all of the

specifications given in Test Method D 1500.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 This test method is based essentially upon the reduction

bility of regulatory limitations prior to use.

of iodine by sulfur dioxide in the presence of water. This

1.5 For hazard information and guidance, see the supplier’s

reaction can be used quantitatively only when pyridine and an

Material Safety Data sheet.

alcohol are present to react with the sulfur trioxide and

hydriodic acid produced according to the following reactions:

2. Referenced Documents

H O 1 I 1 SO 1 3C H N→ 2C H N·HI 1 C H N·SO

2 2 2 5 5 5 5 5 5 3

2.1 ASTM Standards:

C H N·SO 1 ROH→ C H N·HSO R

5 5 3 5 5 4

D 1500 Test Method for ASTM Color of Petroleum Prod-

(1)

2

ucts (ASTM Color Scale)

4.2 To determine water, Karl Fischer reagent (a solution of

E29 Practice for Using Significant Digits in Test Data to

3

iodine, pyridine, and sulfur dioxide, in the molar ratio of

Determine Conformance with Specifications

1 + 10 + 3) dissolved in anhydrous 2-methoxyethanol is added

3. Terminology

to a solution of the sample in anhydrous pyridine-ethylene

glycol (1 + 4) until all water present has been consumed. This

3.1 Definitions of Terms Specific to This Standard:

is evidenced by the persistence of the orange-red end-point

3.1.1 instrumental end point—that point in the titration

color; or alternatively by an indication on a galvanometer or

when two small platinum electrodes, upon which a potential of

similar current-indicating device which records the depolariza-

20 to 50 mV has been impressed, are depolarized by the

tion of a pair of noble-metal electrodes. The reagent is

standardized by titration of water.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

Current edition approved Dec. 10, 2002. Published February 2003. Originally

approved in 1955. Last previous edition approved in 1999 as D 1364 – 95 (1999).

2

Annual Book of ASTM Standards, Vol 05.01.

3

Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

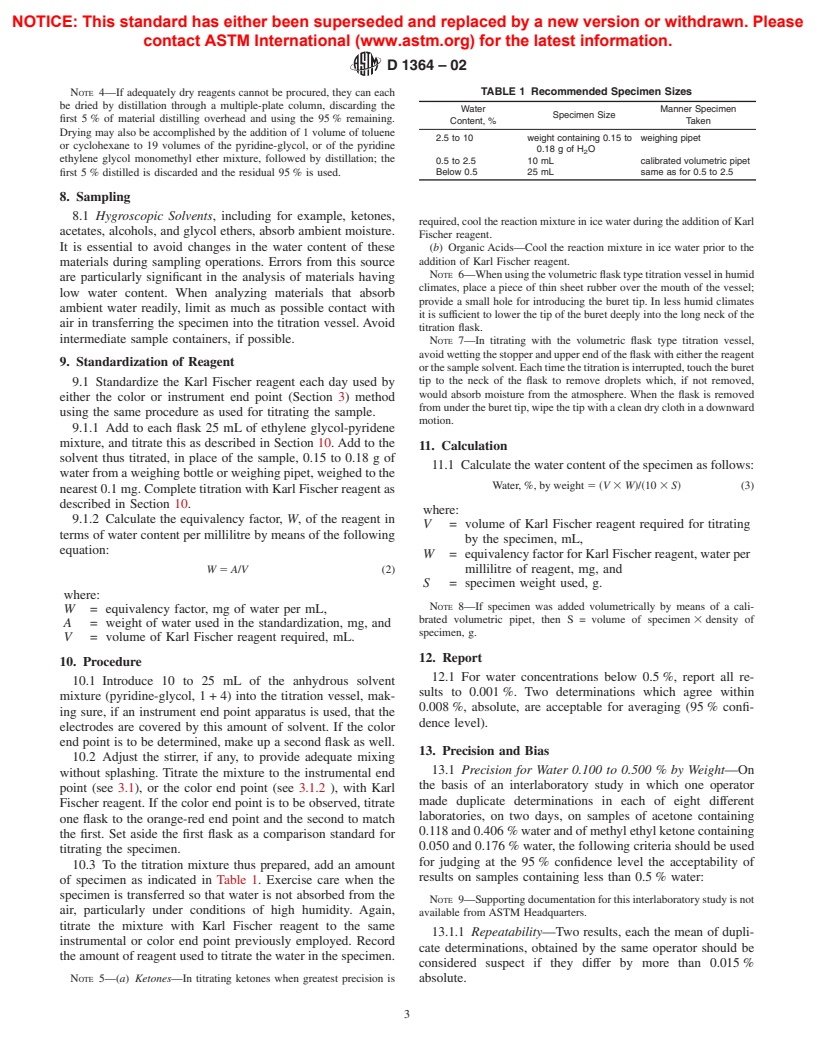

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Please

contact ASTM International (www.astm.org) for the latest information.

D1364–02

electrodes and capable of indicating a current flow of 10 to 20

5

µA by means of a galvanometer or radiotuning eye circuit.

6.4 BuretAssembly f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.