ASTM D3524-90(1999)

(Test Method)Standard Test Method for Diesel Fuel Diluent in Used Diesel Engine Oils by Gas Chromatography

Standard Test Method for Diesel Fuel Diluent in Used Diesel Engine Oils by Gas Chromatography

SCOPE

1.1 This test method covers the determination of diesel fuel as a contaminant in used lubricating oil. The method is limited to SAE 30 oil. Note 1-This test method may be applicable to higher viscosity grade oils. However, such oils were not included in the program used to develop the precision statement.

1.2 There is some overlap of the boiling ranges of diesel fuel and SAE 30 engine oils. Moreover, the boiling range of SAE 30 oils from various sources can vary appreciably. As a result, the calibration can be altered by as much as 2%, in terms of fuel dilution. When testing unknown or mixed brands of used engine oil, it should be realized that the precision of the method may be poorer than the precision obtained when calibrating with a new oil representative of the used oil being tested.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3524–90(Reapproved 1999)

Standard Test Method for

Diesel Fuel Diluent in Used Diesel Engine Oils by Gas

Chromatography

This standard is issued under the fixed designation D 3524; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

For example: normal decane n–C

iso-tetradecane i–C

1.1 This test method covers the determination of diesel fuel

as a contaminant in used lubricating oil. The method is limited

3. Summary of Test Method

to SAE 30 oil.

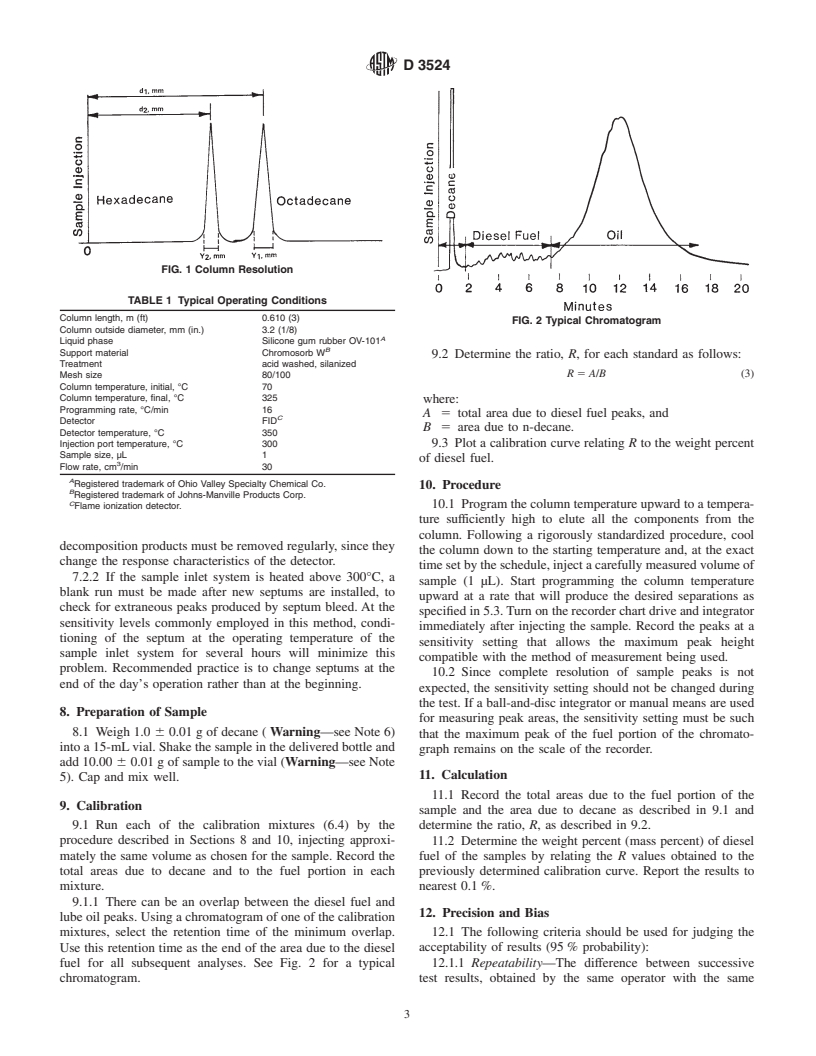

3.1 A mixture of n-decane and used lubricating oil is

introduced into a gas chromatographic column which separates

NOTE 1—This test method may be applicable to higher viscosity grade

oils. However, such oils were not included in the program used to develop

hydrocarbonsinboilingpointorder.Thecolumntemperatureis

the precision statement.

raised at a reproducible rate and the resulting chromatogram is

interpreted for diesel fuel dilution.

1.2 There is some overlap of the boiling ranges of diesel

fuel and SAE 30 engine oils. Moreover, the boiling range of

4. Significance and Use

SAE 30 oils from various sources can vary appreciably. As a

4.1 Some fuel dilution of the engine oil may take place

result, the calibration can be altered by as much as 2 %, in

duringnormaloperation.However,excessivefueldilutionisof

terms of fuel dilution. When testing unknown or mixed brands

concern in terms of possible performance problems.

ofusedengineoil,itshouldberealizedthattheprecisionofthe

method may be poorer than the precision obtained when

5. Apparatus

calibrating with a new oil representative of the used oil being

5.1 Gas Chromatograph—Any gas chromatograph can be

tested.

used that has the following performance characteristics:

1.3 The values stated in SI units are to be regarded as the

5.1.1 Detector—Either a thermal conductivity or flame

standard. The values stated in inch-pound units are for infor-

ionization detector can be used. The detector must have

mation only.

sufficient sensitivity to detect 1.0 % decane with a peak height

1.4 This standard does not purport to address all of the

of at least 10 % of full scale on the recorder under the

safety concerns, if any, associated with its use. It is the

conditions prescribed in this method, and without loss of

responsibility of the user of this standard to establish appro-

resolution as defined in 7.1.3. The detector also must be

priate safety and health practices and determine the applica-

capable of operating continuously at a temperature equivalent

bility of regulatory limitations prior to use.

to the maximum column temperature employed, and it must be

2. Terminology

connected to the column so as to avoid any cold spots. Under

the conditions described for the method, the drift should not be

2.1 Definitions of Terms Specific to This Standard:

more than 1 % of full scale per hour.

2.1.1 fuel dilution—the amount, expressed as a percentage,

5.1.2 Column Temperature Programmer— The chromato-

of engine fuel found in engine lubricating oil. This may be the

graph must be capable of program temperature operation over

result of engine wear or improper performance.

a range sufficient to establish a retention time of at least 1 min

2.2 Abbreviations:

for the initial peak(s) and to elute the entire sample. The

2.2.1 Acommon abbreviation of hydrocarbon compounds is

programming rate must be sufficiently reproducible to obtain

to designate the number of carbon atoms in the compound. A

retention time repeatability of 0.1 min for each component in

prefix is used to indicate the carbon chain form, while a

the calibration mixture (6.4).

subscripted suffix denotes the number of carbon atoms.

5.1.3 Sample Inlet System—The sample inlet system must

be capable of operating continuously at a temperature equiva-

This test method is under the jurisdiction of ASTM Committe D-2 on

lenttothemaximumcolumntemperatureemployed,orprovide

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

on-column injection with some means of programming the

D02.04.0H on Chromatographic Methods.

entire column, including point of sample introduction up to the

Current edition approved Oct. 26, 1990. Published December 1990. Originally

published as D 3524 – 76. Last previous edition D 3524 – 86.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3524

maximum temperature required. The sample inlet system must 6.4 Calibration Mixtures—Aminimum of three mixtures of

beconnectedtothechromatographiccolumnsoastoavoidany diesel fuel and lubricating oil (Warning—See Note 5.) of a

cold spots. similar type to that being analyzed are prepared to cover the

5.2 Recorder—A recording potentiometer with a full-scale range from 0 to 12 weight% (mass%) diesel fuel, calculated as

response time of2sor less must be used. If a manual method follows:

of area measurement, such as a planimeter, is employed, the

Diesel fuel, wt% ~mass %!

chart speed must be at least 152 cm/h (60 in./h) to minimize

errors in peak area measurements. This requirement is waived weight ~mass! of fuel

5 3 100

weight ~mass! of fuel and oil

if a ball-and-disc integrator or an electronic integrator is

(1)

employed.

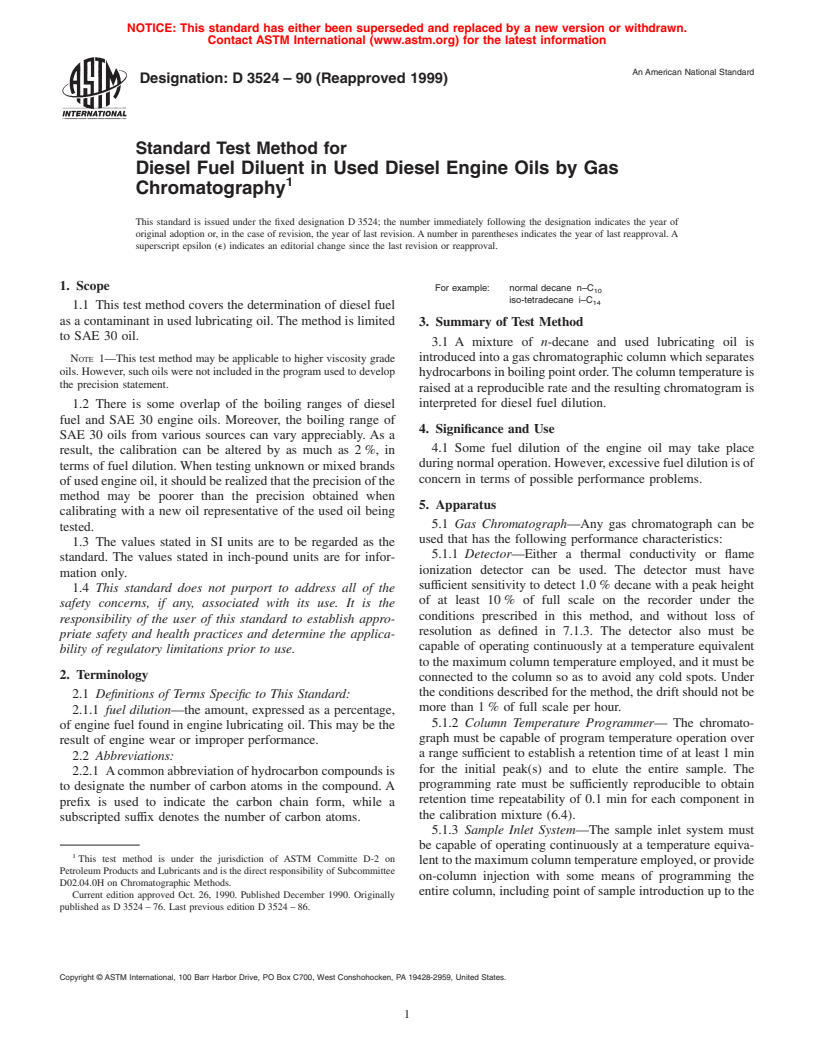

5.3 Column—Any column and conditions may be used,

NOTE 3—Warning: Argon, helium, and nitrogen are compressed gases

provided, under the conditions of the test, separations are in under pressure.

NOTE 4—Warning: Hydrogen is an extremely flammable gas under

order of boiling points and the column resolution, R, is at least

pressure.

3 and not more than 5 (7.1.3). Since a stable baseline is an

NOTE 5—Warning: Combustible liquid.

essential requirement of this method, matching dual columns

are required to compensate for column bleed, which cannot be 6.5 n-Decane, 99 % pure. (Warning—See Note 6.)

eliminated completely by conditioning alone.

NOTE 6—Warning: Combustible, vapor harmful.

5.4 Integrator—Means must be provided for determining

the accumulated area under the chromatogram. This can be 7. Preparation of Apparatus

done manually by means of a polar planimeter. Mechanical

7.1 Column Preparation—Any satisfactory method used in

means, such as the disc integrator, may be used also. However,

the practice of the gas chromatography that will produce a

best precision and automatic operation can be achieved with

column meeting the requirements of 5.3 may be used. The

electronic integration.

column must be conditioned at the maximum operating tem-

5.5 Flow Controllers—Chromatographs using thermal con-

perature until baseline shift due to column bleeding has been

ductivity detectors also must be equipped with constant-flow

reduced to a minimum.

controllers capable of holding carrier gas flow constant to

7.1.1 The column can be conditioned very rapidly and

61 % over the full operating temperature range.

effectively by the following procedure:

5.6 Sample Device:

7.1.1.1 Disconnect the column from the detector.

5.6.1 Micro Syringe—A micro syringe, usually 10 µL, is

7.1.1.2 Purgethecolumnthoroughlyatambienttemperature

used for sample introduction.

with carrier gas.

5.6.2 Automatic sampling devices or other sampling means,

7.1.1.3 Turn off the carrier gas and allow the column to

such as indium encapsulation, may be used, provided the

depressurize completely.

system can be operated at a temperature sufficiently high to

7.1.1.4 Raise the column temperature to the maximum

vaporize completely hydrocarbons with an atmospheric boiling

operating temperature and hold at this temperature for at least

pointof538°C(1000°F),andthesamplingsystemisconnected

1 h with no flow through the column.

to the chro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.