ASTM D5543-94(2005)

(Test Method)Standard Test Methods for Low-Level Dissolved Oxygen in Water

Standard Test Methods for Low-Level Dissolved Oxygen in Water

SIGNIFICANCE AND USE

Dissolved oxygen is detrimental in certain boiler and steam cycles because it may accelerate corrosion. Concentrations above 10 μg/L are unacceptable in many high-pressure boiler systems. The efficiency of dissolved oxygen removal from boiler feedwater by chemical or mechanical means, or both, is determined by measuring the concentration before and after the process. The measurement is also made to check for air leakage into the boiler system.

The oxygen treatment method for boiler corrosion reduction requires injection of oxygen into the boiler feedwater. The resulting oxygen level is monitored for control purposes.

SCOPE

1.1 These test methods cover the determination of low-level (∧lt;100 [mu]g/L) dissolved oxygen in thermal-cycle steam condensate, deaerated boiler feedwater, boiler water, and deaerated deionized water. The following test methods are included: Range, mg/L Sections Test Method A--Color Comparator Test 0 to 100 8 to 17 Method Using Self-Filling Glass Ampoules Test Method B--Instrument Test Method 0 to 100 18 to 26 Using Self-Filling Glass Ampoules

1.2 These test methods may be applicable to electronic-grade, pharmaceutical-grade, and other high-purity waters, although these were not addressed in the collaborative study.

1.3 Test Method A is a colorimetric procedure applicable to dissolved oxygen in water in the range from 0 to 100 [mu]g/L.

1.4 Test Method B is an instrumented colorimetric procedure applicable to dissolved oxygen in water in the range from 0 to 100 [mu]g/L.

1.5 It is the user's responsibility to ensure the validity of these test methods for waters of untested matrices.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 5543–94 (Reapproved 2005)

Standard Test Methods for

1

Low-Level Dissolved Oxygen in Water

This standard is issued under the fixed designation D 5543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1192 Specification for Equipment for Sampling Water

3

and Steam in Closed Conduits

1.1 These test methods cover the determination of low-level

D 1193 Specification for Reagent Water

(<100µ g/L) dissolved oxygen in thermal-cycle steam conden-

D 2777 Practice for Determination of Precision and Bias of

sate, deaerated boiler feedwater, boiler water, and deaerated

Applicable Methods of Committee D19 on Water

deionized water. The following test methods are included:

D 3370 Practices for SamplingWater from Closed Conduits

Range, µg/L Sections

Test Method A—Color Comparator Test 0to100 8to17

3. Terminology

Method Using Self-Filling Glass

Ampoules

3.1 Definitions—For definitions of terms used in these test

Test Method B—Instrument Test Method 0 to 100 18 to 26

methods, refer to Terminology D 1129.

Using Self-Filling Glass Ampoules

1.2 These test methods may be applicable to electronic-

4. Significance and Use

grade, pharmaceutical-grade, and other high-purity waters,

4.1 Dissolved oxygen is detrimental in certain boiler and

although these were not addressed in the collaborative study.

steam cycles because it may accelerate corrosion. Concentra-

1.3 Test MethodAis a colorimetric procedure applicable to

tions above 10 µg/L are unacceptable in many high-pressure

dissolved oxygen in water in the range from 0 to 100 µg/L.

boiler systems. The efficiency of dissolved oxygen removal

1.4 Test Method B is an instrumented colorimetric proce-

from boiler feedwater by chemical or mechanical means, or

dure applicable to dissolved oxygen in water in the range from

both, is determined by measuring the concentration before and

0 to 100 µg/L.

after the process. The measurement is also made to check for

1.5 It is the user’s responsibility to ensure the validity of

air leakage into the boiler system.

these test methods for waters of untested matrices.

4.2 The oxygen treatment method for boiler corrosion

1.6 The values stated in SI units are to be regarded as the

reduction requires injection of oxygen into the boiler feedwa-

standard.

ter. The resulting oxygen level is monitored for control

1.7 This standard does not purport to address all of the

purposes.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Reagents

priate safety and health practices and determine the applica-

5.1 This test method does not require the preparation of any

bility of regulatory limitations prior to use.

reagents.All the necessary analytical reagents are provided by

the manufacturer in sealed ampoules.

2. Referenced Documents

5.2 Purity of Water—Unless otherwise indicated, references

2

2.1 ASTM Standards:

to water shall be understood to mean reagent water as defined

D 1066 Practice for Sampling Steam

by Type II of Specification D 1193.

D 1129 Terminology Relating to Water

6. Precautions

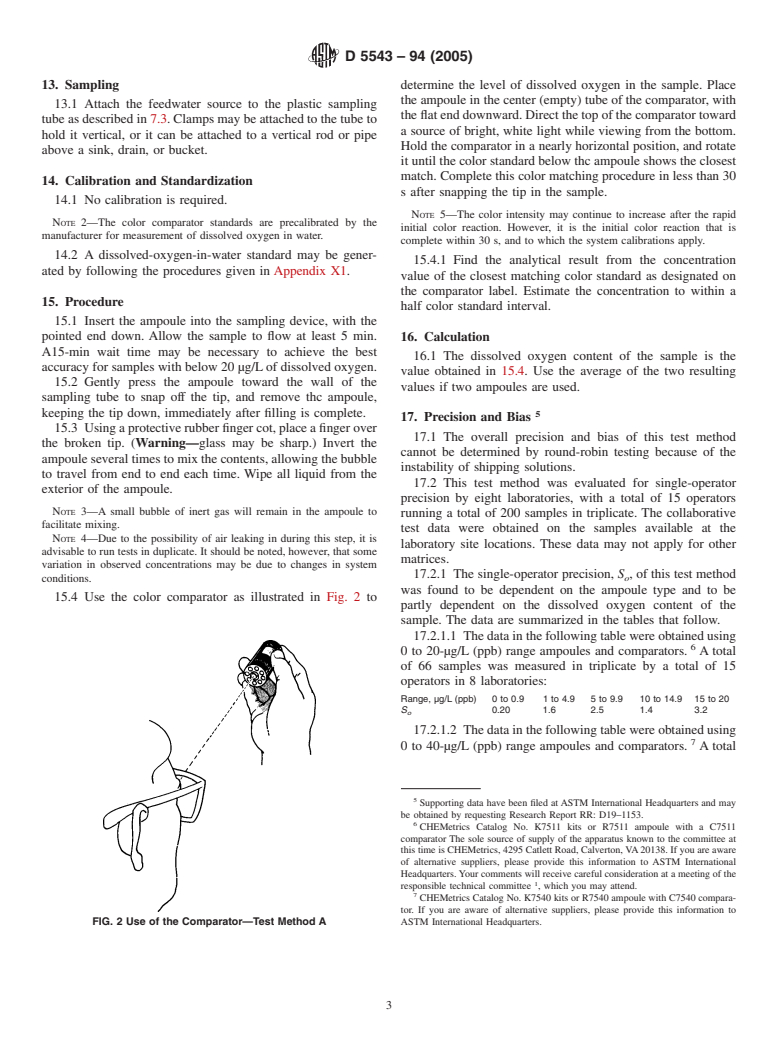

6.1 Users must exercise caution by using finger cots, in

1

These test methods are under the jurisdiction of ASTM Committee D19 on

accordance with the manufacturer’s instructions, when han-

Water and are the direct responsibility of Subcommittee D19.03 on Sampling of

Water and Water-Formed Deposits, Analysis of Water for Power Generation and

dling the mixing of sample and reagent in the glass ampoules.

Process Use, On-Line Water Analysis, and Surveillance of Water.

Current edition approved Jan. 1, 2005. Published January 2005.

7. Sampling

Originally approved in 1994. Last previous edition approved in 1999 as

e1

7.1 Sampling is the most critical part of any dissolved

D 5543 – 94 (1999) .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

oxygen test. The sample stream must be completely leak-free,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5543–94 (2005)

since even the smallest leak can elevate the oxygen level in the 10.4 The following interferences occur in the presence of

sample and cause large errors in the results. New or intermit- 2200 mg/L boron present as boric acid: (1) at pH levels below

tentlyusedsamplingsystemsmustbepurgedforaminimumo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.