ASTM C390-08

(Practice)Standard Practice for Sampling and Acceptance of Thermal Insulation Lots

Standard Practice for Sampling and Acceptance of Thermal Insulation Lots

SIGNIFICANCE AND USE

The sampling and inspection prescribed in this standard afford the purchaser a practical level of quality assurance on incoming material. They are based on cost/risk relationships considered typical for preformed thermal insulations offered for general use. In all cases, the purchaser should review this standard and determine its suitability in terms of his specific needs.

This procedure is intended primarily for the inspection of a continuing stream of lots, and there is not a high probability of rejecting occasional off lots. Consumer protection is based on economic pressure on the producer, through greater risk of lot rejection, to maintain the process average at 90 % conformance or better. Operating characteristic curves for the sampling plans employed can be found in Practice E 2234, Table X-C through Table X-F.

It is not the intent of this procedure to estimate lot quality, control the quality of production, relieve the supplier of responsibility for the quality of material offered, or determine the disposition of material found to be defective after receipt by the purchaser.

SCOPE

1.1 This standard provides criteria for establishing the acceptability of lots of shipments of preformed board, preformed block and pipe, and batts and blanket thermal insulation based on sampling and inspection.

1.2 This standard is intended for use in conjunction with appropriate ASTM material specifications that classify and describe the specific physical requirements for the product in terms of qualification requirements and inspection requirements. Determination of nonconformity shall be based on the tolerances for individual sample test values prescribed in the material specification.

1.3 This standard may require inspection substantially different from that performed in the normal course of production. If the purchaser requires sampling and acceptance inspection in accordance with this practice, he shall so specify in the order or contract.

1.4 The vales stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C390–08

Standard Practice for

1

Sampling and Acceptance of Thermal Insulation Lots

This standard is issued under the fixed designation C 390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 2234 Practice for Sampling a Stream of Product by

Attributes Indexed by AQL

1.1 This standard provides criteria for establishing the

acceptability of lots of shipments of preformed board, pre-

3. Terminology

formed block and pipe, and batts and blanket thermal insula-

3.1 Definitions:

tion based on sampling and inspection.

3.1.1 acceptable quality level (AQL)—when a continuous

1.2 This standard is intended for use in conjunction with

seriesoflotsisconsidered,thequalitylevelwhichforpurposes

appropriate ASTM material specifications that classify and

of sampling inspection is the limit of a satisfactory process

describe the specific physical requirements for the product in

average. The listedAQL (AQL=10%) is the maximum percent

terms of qualification requirements and inspection require-

defective level accepted 95% of the time by the sampling plan.

ments. Determination of nonconformity shall be based on the

3.1.2 acceptance number—the maximum number of the

tolerances for individual sample test values prescribed in the

nonconformitiesornonconformingunitsinthesamplethatwill

material specification.

permit acceptance of the inspected lot or batch.

1.3 This standard may require inspection substantially dif-

3.1.3 inspection—the process of measuring, examining,

ferent from that performed in the normal course of production.

testing, gaging, or otherwise comparing the unit with the

Ifthepurchaserrequiressamplingandacceptanceinspectionin

applicable requirements.

accordancewiththispractice,heshallsospecifyintheorderor

3.1.4 inspection lot—a collection of units of product from

contract.

which a sample is drawn and inspected to determine conform-

1.4 The vales stated in inch-pound units are to be regarded

ance with the acceptability criteria.

as standard. The values given in parentheses are mathematical

3.1.4.1 Discussion—An inspection lot may differ from a lot

conversions to SI units that are provided for information only

defined for other purposes.

and are not considered standard.

3.1.5 inspection, normal—inspection that is used in accor-

1.5 This standard does not purport to address all of the

dance with an acceptance sampling scheme when a process is

safety concerns, if any, associated with its use. It is the

considered to be operating at, or slightly better than, its

responsibility of the user of this standard to establish appro-

acceptable quality level.

priate safety and health practices and determine the applica-

3.1.6 inspection, tightened—a feature of a sampling scheme

bility of regulatory limitations prior to use.

using stricter acceptance criteria than those used in normal

2. Referenced Documents inspection. Tightened inspection is used in some sampling

2

schemes as a protective measure to increase the probability of

2.1 ASTM Standards:

rejecting lots when experience shows the level of submitted

C 168 Terminology Relating to Thermal Insulation

quality has deteriorated significantly.

3.1.6.1 Discussion—It is expected that the higher rate of

rejections inherent with tightened inspection will lead the

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

supplier to improve the quality of the submitted product. The

Insulation and is the direct responsibility of Subcommittee C16.31 on Chemical and

criteria for determining when quality has deteriorated signifi-

Physical Properties.

cantly must be defined in objective terms for any given

Current edition approved April 15, 2008. Published May 2008. Originally

approved in 1957. Last previous edition approved 2003 as C 390 – 03.

sampling scheme.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.7 lot (batch)—a definite quantity of some product

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

manufactured under conditions of production that are consid-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ered uniform.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

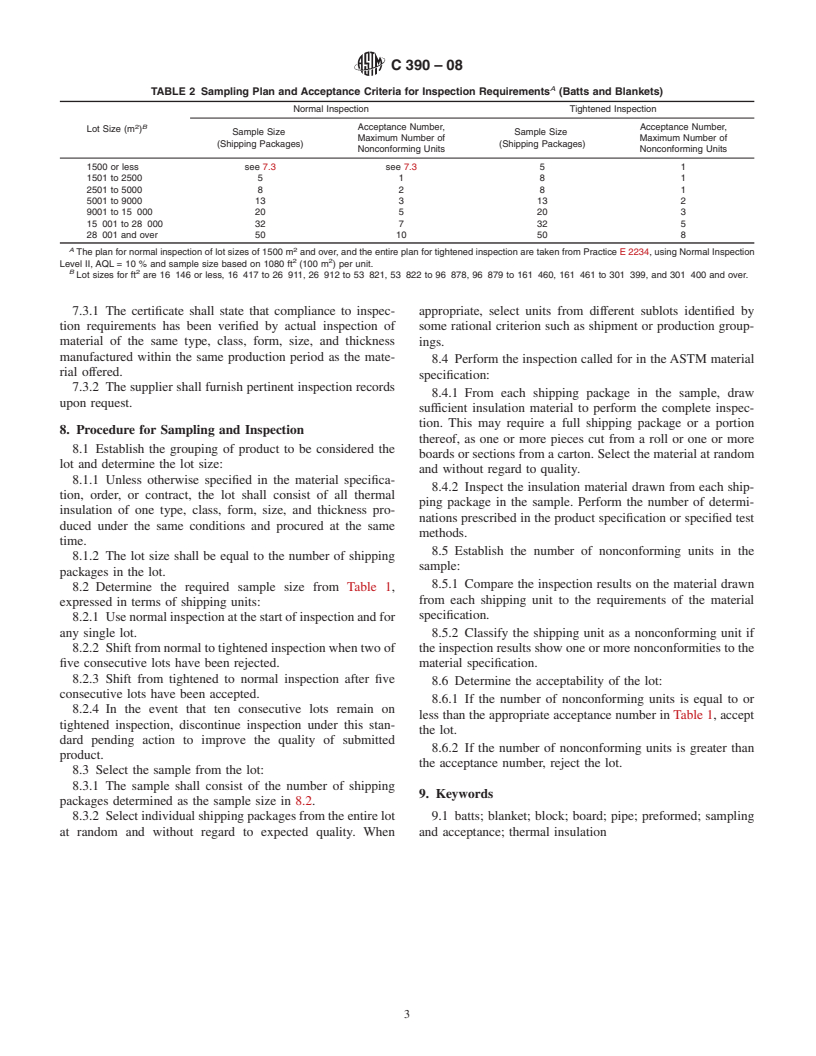

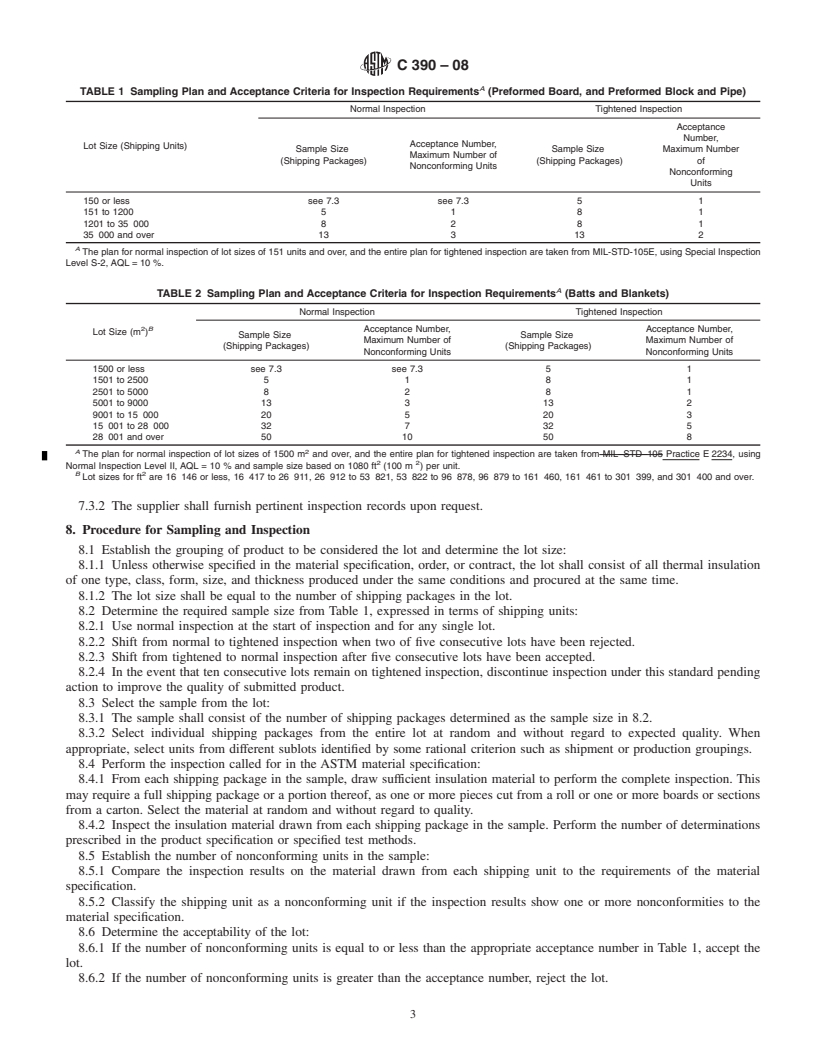

C390–08

3.1.8 lot size—the number of units in a lot or inspection lot. 5. Classification of Requirements

3.1.9 nonconforming unit—a unit of product or service

5.1 ASTM material

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C390–03 Designation: C 390 – 08

Standard Practice for

1

Sampling and Acceptance of Thermal Insulation Lots

This standard is issued under the fixed designation C 390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This standard provides criteria for establishing the acceptability of lots of shipments of preformed board, preformed block

and pipe, and batts and blanket thermal insulation based on sampling and inspection.

1.2 This standard is intended for use in conjunction with appropriate ASTM material specifications that classify and describe

the specific physical requirements for the product in terms of qualification requirements and inspection requirements.

Determination of nonconformity shall be based on the tolerances for individual sample test values prescribed in the material

specification.

1.3 This standard may require inspection substantially different from that performed in the normal course of production. If the

purchaser requires sampling and acceptance inspection in accordance with this practice, he shall so specify in the order or contract.

1.4

1.4 The vales stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 168Terminology Relating to Thermal Insulation

2.2 U.S. Military Standard:

2

MIL-STD-105ESampling Procedures and Tables for Inspection by Attributes

C 168 Test Methods for Determining Average Grain Size

E 2234 Test Methods for Determining Average Grain Size

3. Terminology

3.1 Definitions:

3.1.1 acceptable quality level (AQL)—when a continuous series of lots is considered, the quality level which for purposes of

sampling inspection is the limit of a satisfactory process average. The listedAQL (AQL=10%) is the maximum percent defective

level accepted 95% of the time by the sampling plan.

3.1.2 acceptance number—the maximum number of the nonconformities or nonconforming units in the sample that will permit

acceptance of the inspected lot or batch.

3.1.3 inspection—the process of measuring, examining, testing, gaging, or otherwise comparing the unit with the applicable

requirements.

3.1.4 inspection lot—a collection of units of product from which a sample is drawn and inspected to determine conformance

with the acceptability criteria.

3.1.4.1 Discussion—An inspection lot may differ from a lot defined for other purposes.

3.1.5 inspection, normal—inspection that is used in accordance with an acceptance sampling scheme when a process is

considered to be operating at, or slightly better than, its acceptable quality level.

1

This practice is under the jurisdiction ofASTM Committee C16 onThermal Insulation and is the direct responsibility of Subcommittee C16.31 on Chemical and Physical

Properties.

Current edition approved April 10, 2003.15, 2008. Published May 2003.2008. Originally approved in 1957. Last previous edition approved 2002 as C 390 –02.

2

Annual Book of ASTM Standards, Vol 04.06.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C390–08

3.1.6 inspection, tightened—a feature of a sampling scheme using stricter acceptance criteria than those used in normal

inspection. Tightened inspection is used in some sampling schemes as a protective measure to increase the probability of rejecting

lots when experience shows the level of submitted quality has deteriorated significantly.

3.1.6.1 Discussion—It is expected that the higher rate of rejections inherent with tightened inspection

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.