ASTM D7176-06

(Specification)Standard Specification for Non-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried Applications

Standard Specification for Non-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried Applications

SCOPE

1.1 This specification covers polyvinyl chloride (PVC) flexible sheeting which is used for construction of concealed containment-membranes. Examples are ponds and lakes, canals, reservoirs, landfill liners, covers and closures or similar installations where the membrane is inaccessible once the construction is complete. Included are requirements for materials and sheeting, test methods, workmanship criteria and methods of marking. This Specification covers un-reinforced flexible sheet made from polyvinyl chloride (PVC) resin as the primary polymer intended for use in geomembranes. This specification covers PVC sheet 0.25 mm through 1.5 mm thickness (0.010 in. through 0.060 in.)-typically used for geomembrane linings.

1.2 Reworked materials may be used in this product in accordance with the requirements in Section .

1.3 The tests are intended to ensure quality and performance and are not intended for design purposes. Tests have been selected to be conducted primarily with liquids that simulate the environment to which the membrane will be subjected during actual use. The test and property limits used to characterize the sheet are values intended to ensure minimum quality for the intended purpose. In place design criteria such as material compatibility, chemical resistance, among others, are factors that shall be considered but are beyond the scope of this specification.

1.4 The values stated in metric units are to be regarded as the standard. The values stated in parentheses (English) are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7176 – 06

Standard Specification for

Non-Reinforced Polyvinyl Chloride (PVC) Geomembranes

Used in Buried Applications

This standard is issued under the fixed designation D7176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 Thisspecificationcoverspolyvinylchloride(PVC)flex-

ible sheeting which is used for construction of concealed

2. Referenced Documents

containment-membranes. Examples are ponds and lakes, ca-

2.1 ASTM Standards:

nals, reservoirs, landfill liners, covers and closures or similar

D751 Test Methods for Coated Fabrics

installations where the membrane is inaccessible once the

D792 Test Methods for Density and Specific Gravity (Rela-

construction is complete. Included are requirements for mate-

tive Density) of Plastics by Displacement

rials and sheeting, test methods, workmanship criteria and

D882 Test Method for Tensile Properties of Thin Plastic

methods of marking. This Specification covers un-reinforced

Sheeting

flexiblesheetmadefrompolyvinylchloride(PVC)resinasthe

D1004 Test Method for Tear Resistance (Graves Tear) of

primary polymer intended for use in geomembranes. This

Plastic Film and Sheeting

specification covers PVC sheet 0.25 mm through 1.5 mm

D1203 Test Methods for Volatile Loss From Plastics Using

thickness (0.010 in. through 0.060 in.)—typically used for

Activated Carbon Methods

geomembrane linings.

D1204 Test Method for Linear Dimensional Changes of

1.2 Reworked materials may be used in this product in

Nonrigid Thermoplastic Sheeting or Film at Elevated

accordance with the requirements in Section 5.

Temperature

1.3 Thetestsareintendedtoensurequalityandperformance

D1239 Test Method for Resistance of Plastic Films to

and are not intended for design purposes. Tests have been

Extraction by Chemicals

selected to be conducted primarily with liquids that simulate

D1243 Test Method for Dilute Solution Viscosity of Vinyl

the environment to which the membrane will be subjected

Chloride Polymers

during actual use. The test and property limits used to

D1790 Test Method for Brittleness Temperature of Plastic

characterize the sheet are values intended to ensure minimum

Sheeting by Impact

quality for the intended purpose. In place design criteria such

D2124 Test Method for Analysis of Components in Poly-

as material compatibility, chemical resistance, among others,

(Vinyl Chloride) Compounds Using an Infrared Spectro-

arefactorsthatshallbeconsideredbutarebeyondthescopeof

photometric Technique

this specification.

D4439 Terminology for Geosynthetics

1.4 The values stated in metric units are to be regarded as

D5033 Guide for Development of ASTM Standards Relat-

the standard.The values stated in parentheses (English) are for

ing to Recycling and Use of Recycled Plastics

information only.

D5199 Test Method for Measuring the Nominal Thickness

1.5 This standard does not purport to address all of the

of Geosynthetics

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction of ASTM Committee D35 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem- Standards volume information, refer to the standard’s Document Summary page on

branes. the ASTM website.

Current edition approved May 1, 2006. Published May 2006. DOI: 10.1520/ Withdrawn. The last approved version of this historical standard is referenced

D7176-06. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7176 – 06

D5747 Practice for Tests to Evaluate the Chemical Resis- 5.2 The geomembrane sheet shall consist of polyvinyl

tance of Geomembranes to Liquids chloride (PVC) resin in amounts greater than 50% of the total

G160 Practice for Evaluating Microbial Susceptibility of weight suitably compounded with plasticizers, stabilizers,

Nonmetallic Materials By Laboratory Soil Burial additives, and pigments, to satisfy the physical property

requirements.

3. Terminology

5.3 A PVC resin with an inherent viscosity (logarithmic

3.1 Definitions—Definitions are in accordance with Termi-

viscosity number) of not less than 0.92 as determined by Test

nology D4439 unless otherwise indicated.

Method D1243.

3.2 Definitions of Terms Specific to This Standard:

5.4 Reworked materials, as defined in Guide D

3.2.1 fabricator, n—acompanythatconvertsgeomembrane

5033D5033, may be used in this product if all the require-

rolls into panels.

mentsinSections3,5,and6aremetbythereworkedmaterial.

3.2.2 homogeneous sheeting, n—sheeting that is of uniform

A maximum of up to 10% reworked material shall be

composition throughout its thickness.

permitted.

3.2.3 manufacture, n—a company that processes raw mate-

rials into geomembrane rolls.

6. Physical Properties and Requirements

3.2.4 panel, n—a series of geomembrane sheets fabricated

6.1 Thesheetingshallconformtothephysicalrequirements

together to make a larger unit, as supplied by a fabricator

prescribed in Tables 1 and 2.

usually folded onto a pallet or folded then rolled on a core.

6.2 Sheeting shall be compounded so that bonds between

3.2.5 roll, n—a quantity of geomembrane rolled up to form

sheets used in fabrication of large geomembrane panels can be

a single package as supplied from the manufacturer.

accomplished in the factory or field without reducing the

3.2.6 roll width, n—the width of a roll as supplied from the

overallresistanceofthemembranetopermeationorleakageor

manufacture, (typically 1.5 to 2.5 m) (60 to 96 in.).

significantly reducing the sheeting’s physical strength. The

3.2.7 sheet, n—a part of the manufactured geomembrane

manufacturer shall specify recommended bonding procedures

material cut from the roll.

in its product literature.

4. Classification 6.3 The sheeting shall be colored as agreed upon between

the purchaser and the seller as part of the purchase contract.

4.1 The sheeting will be subdivided by grades based on

6.4 The sheeting shall be monolithic and homogeneous.

thickness:

6.5 Metric values are converted from U.S. values and are

4.1.1 PVC10—0.254 mm (0.010 in.).

rounded to the available significant digits.

4.1.2 PVC20—0.508 mm (0.020 in.).

6.6 Manufacturing Certified Properties—Certified proper-

4.1.3 PVC30—0.762 mm (0.030 in.).

4.1.4 PVC40—1.016 mm (0.040 in.). ties are tested based on a quantity of material produced.

Certified properties are tested once per lot, or once every

4.1.5 PVC50—1.270 mm (0.050 in.).

4.1.6 PVC60—1.524 mm (0.060 in.). 18000 kg of material (40000 lb), whichever is more frequent.

The certification properties include thickness, tensile break

5. Materials and Manufacture

strength, elongation at break, modulus at 100% strain, tear

5.1 Thisspecificationcoverspolyvinylchloride(PVC)con- resistance, dimensional stability, and low temperature impact.

Thickness is to be tested once per roll unless automatic

tainment membrane formulated from PVC materials meeting

the following requirements: thickness measuring equipment is installed on the production

TABLE 1 Certified Properties

Certified Properties ASTM PVC 10 PVC 20 PVC 30 PVC 40 PVC 50 PVC 60

Thickness 6 D5199 0.254 6 0.013 mm 0.508 6 0.030 mm 0.762 6 0.040 mm 1.016 6 0.050 mm 1.270 6 0.060 mm 1.524 6 0.080 mm

(0.010 6 0.0005 in.) (0.020 6 0.0010 in.) (0.030 6 0.0015 in.) (0.040 6 0.0020 in.) (0.050 6 0.0025 in.) (0.060 6 0.0030 in.)

Tensile Properties D882

Strength at Break Min 4.2 kN/m 8.4 kN/m 12.8 kN/m 17.0 kN/m 20.3 kN/m 24.0 kN/m

(24 lb/in.) (48 lb/in.) (73 lb/in.) (97 lb/in.) (116 lb/in.) (137 lb/in.)

Elongation Min 250 % 360 % 380 % 430 % 430 % 450 %

Modulus at 100 % Min 1.8 kN/m 3.6 kN/m 5.4 kN/m 7.2 kN/m 9.0 kN/m 10.8 kN/m

(10 lb/in.) (20 lb/in.) (30 lb/in.) (40 lb/in.) (50 lb/in.) (60 lb/in.)

Tear Strength D1004 11 N 27 N 35 N 44 N 58 N 67 N

Min (2.5 lb) (6 lb) (8 lb) (10 lb) (13 lb) (15 lb)

Dimensional Stability D1204 4% 4% 3% 3% 3% 3%

Max

Change

Low Temperature D1790 -23°C -26°C -29°C -29°C -29°C -29°C

Impact Pass (-10°F) (-15°F) (-20°F) (-20°F) (-20°F) (-20°F)

D7176 – 06

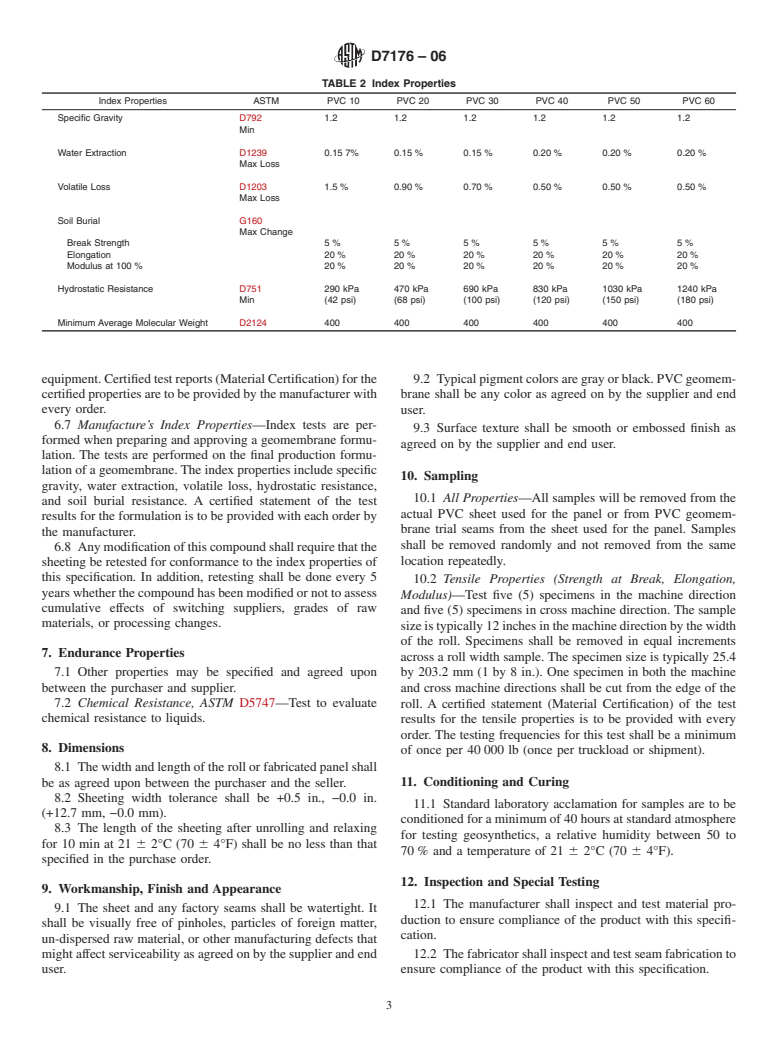

TABLE 2 Index Properties

Index Properties ASTM PVC 10 PVC 20 PVC 30 PVC 40 PVC 50 PVC 60

Specific Gravity D792 1.2 1.2 1.2 1.2 1.2 1.2

Min

Water Extraction D1239 0.15 7% 0.15 % 0.15 % 0.20 % 0.20 % 0.20 %

Max Loss

Volatile Loss D1203 1.5 % 0.90 % 0.70 % 0.50 % 0.50 % 0.50 %

Max Loss

Soil Burial G160

Max Change

Break Strength 5 % 5 % 5 % 5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.