ASTM C1220-98

(Test Method)Standard Test Method for Static Leaching of Monolithic Waste Forms for Disposal of Radioactive Waste

Standard Test Method for Static Leaching of Monolithic Waste Forms for Disposal of Radioactive Waste

SCOPE

1.1 This test method evaluates the relative chemical durability of simulated and radioactive monolithic waste forms such as glasses, ceramics, or cermets in various test solutions at temperatures

1.2 This test method can be used to distinguish differences in the leaching behavior of various simulated or radioactive waste forms under the specific conditions of the test based on analysis of the test solution. Data from this test are used to calculate the normalized elemental mass loss from specimens exposed to aqueous solutions at temperatures

1.3 Specimen surfaces may be altered during this test. These altered surfaces may be used to study the reaction of monolithic waste forms during static exposure to solutions.

1.4 This test method must be performed in accordance with all applicable quality assurance requirements for acceptance of the data.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see 7.3.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1220 – 98

Standard Test Method for

Static Leaching of Monolithic Waste Forms for Disposal of

Radioactive Waste

This standard is issued under the fixed designation C 1220; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1129 Terminology Relating to Water

D 1193 Specification for Reagent Water

1.1 This test method evaluates the relative chemical dura-

D 1293 Test Methods for pH of Water

bility of simulated and radioactive monolithic waste forms

E 177 Practice for Use of the Terms Precision and Bias in

such as glasses, ceramics, or cermets in various test solutions

ASTM Test Methods

at temperatures <100°C under low surface-area-to-volume

2.2 EPA Document:

(S/V) ratio conditions.

Test Methods for Evaluating Solid Waste, Physical/Chemical

1.2 This test method can be used to distinguish differences

Methods

in the leaching behavior of various simulated or radioactive

waste forms under the specific conditions of the test based on

3. Terminology

analysis of the test solution. Data from this test are used to

3.1 Definitions:

calculate the normalized elemental mass loss from specimens

3.1.1 accumulated dose—the sum of the absorbed doses

exposed to aqueous solutions at temperatures <100°C.

received by the system considered regardless of whether it is

1.3 Specimen surfaces may be altered during this test. These

exposed to radiation in a continuous or discontinuous fashion.

altered surfaces may be used to study the reaction of mono-

3.1.2 accuracy—the closeness of agreement between the

lithic waste forms during static exposure to solutions.

accepted reference value and individual results (Practice

1.4 This test method must be performed in accordance with

E 177).

all applicable quality assurance requirements for acceptance of

3.1.2.1 Discussion—In its usage in this test method, accu-

the data.

racy includes the effects of precision and bias. The term is

1.5 This standard does not purport to address all of the

applied to measurements wherein a specific standard reference

safety concerns, if any, associated with its use. It is the

is available such as NIST standard mass and reference solu-

responsibility of the user of this standard to establish appro-

tions traceable to a standards organization. The term “accurate

priate safety and health practices and determine the applica-

to within” a specified range means that individual measure-

bility of regulatory limitations prior to use. For a specific

ments on a reference standard are always within the specified

hazard statement, see 7.3.2.

range, for example, within 2°C of a certified NIST thermo-

2. Referenced Documents couple, within 0.5 mg of a NIST standard mass or within 10 %

of the value for a reference solution.

2.1 ASTM Standards:

3.1.3 actinide—any element with atomic number of 89 to

C 1109 Test Method for Analysis of Aqueous Leachates

103.

from Nuclear Waste Materials using Inductively Coupled

2 3.1.4 bias of a measurement process—a generic concept

Plasma-Atomic Emission Spectrometry

related to a consistent or systematic difference between a set of

C 1174 Practice for Prediction of the Long-Term Behavior

test results from the process and an accepted reference value of

of Waste Package Materials Including Waste Forms Used

the property being measured (Practice E 177).

in the Geologic Disposal of High-Level Nuclear Waste

3.1.5 chemical durability—the resistance of a glass, ce-

D 1125 Test Methods for Electrical Conductivity and Re-

ramic, or cermet test specimen to the release of its constituents

sistivity of Water

to an aqueous solution under the specific conditions of this test.

3.1.5.1 Discussion—The response of glass, ceramics, or

1 cermets under other conditions is outside the scope of this test

This test method is under the jurisdiction of ASTM Committee C-26 on Nuclear

Fuel Cycle and is the direct responsibility of Subcommittee C26.07 on Waste method.

Materials.

Current edition approved July 10, 1998. Published October 1998. Originally

published as C 1220–92. Last previous edition C 1220–92. Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 12.01. SW846A, 3rd Ed., Revision 1, U.S. Environmental Protection Agency, Wash-

Annual Book of ASTM Standards, Vol 11.01. ington, DC, December 1987.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1220

3.1.6 closed system—a system that precludes the transport 4.1.1 Polytetrafluoroethylene (PTFE) test vessels and PTFE

of matter into or out of the system. specimen supports are used, provided the integrated dose to a

3.1.7 high-purity water—ASTM Type I or Type II water PTFE component from all radiation (alpha, beta, or gamma)

3 4

with a maximum total matter content of 0.1 g/m , a minimum does not exceed 10 rad (100 Gy), which has been shown to not

electrical resistivity of 16.67 MV·cm at 25°C, and no detect- damage PTFE. If the integrated dose to the test vessel and

able soluble silica (see Specification D 1193 and Terminology specimen support exceeds 10 rad, 304L stainless steel or fused

D 1129). silica vessels and specimen supports are to be used (in such

3.1.8 ion selective electrode (ISE)—a device for measuring tests involving brine leachants, fused silica vessels and com-

F-. ponents must be used because of the corrosion of stainless steel

3.1.9 leachant—a solution used, or intended for use, in by the brine) (see Note 1).

leaching.

NOTE 1—These modifications to the test method are required when

3.1.10 leachate—the solution resulting from a leach test.

using highly radioactive waste forms.

3.1.11 leaching—the action of removing soluble constitu-

4.2 Separate specimen and leachant volumes are required

ents from a solid into a solution.

for each data point. The test results are based on leachate

3.1.12 monolithic specimens—specimens that are physi-

analyses in all cases and include examination of the leached

cally one coherent piece, as opposed to powdered specimens

specimen surface after long-duration tests.

that consist of many small pieces of irregular configuration.

Monolithic specimens may consist of several individual

5. Significance and Use

phases, but they must be bound in a stable coherent configu-

5.1 This test method is intended principally to distinguish

ration.

differences in the leaching behavior of candidate monolithic,

3.1.13 nuclear waste forms—solid materials in which radio-

inorganic, radioactive waste forms under low surface-area-to-

active wastes have been immobilized.

volume (S/V) ratio conditions. The test method can be used to

3.1.14 open system—a system that permits the transport of

produce altered solid specimens to study the reaction of

matter into or out of the system, e.g., O and/or CO diffusion

2 2

monolithic waste forms during static exposure to solutions.

into or out of the system.

Data from this test may form part of the larger body of data that

3.1.15 polytetrafluoroethylene (PTFE)—a material pro-

is necessary in the logical approach to long-term prediction of

duced from various monomers that are polymerized into the

waste form behavior, as described in Practice C 1174. In

plastic.

particular, solution concentrations and characterization and

3.1.16 precision of a measurement process—a generic con-

altered surfaces may be used in the testing of geochemical

cept related to the closeness of agreement between test results

modelling codes. This test method excludes study of powdered

obtained under prescribed like conditions from the measure-

or organic materials. This test method can be used as either a

ment process being evaluated (Practice E 177). In this test

“characterization” or “accelerated” test under the protocol of

method, precision will be measured by either standard devia-

C 1174, mentioned above.

tion or relative standard deviation.

5.2 The total absorbed dose for each PTFE test vessel may

3.2 Abbreviations:

not exceed 10 rad (100 Gy) during the lifetime of the vessel.

3.2.1 EDX—energy-dispersive x-ray fluorescence instru-

Hence, a record of the absorbed dose each vessel receives must

ment (or analysis).

be maintained.

3.2.2 ICP—inductively coupled plasma.

5.2.1 More radiation-resistant materials are used when test-

3.2.3 PFA—perfluoroalkoxy.

ing in radiation fields where the accumulated absorbed dose

3.2.4 SEM—scanning electron microscope (or microscopy).

exceeds 10 rad (see Note 1).

3.2.5 TEM—transmission electron microscope (or micros-

5.3 Both aerated and deaerated solutions may be used in this

copy).

test method. However, when testing highly radioactive speci-

3.2.6 XRD—x-ray diffractometer (or diffraction).

mens, tests with deaerated solutions are mandatory to minimize

radiolysis effects of nitrogen (see Note 1). Control of the

4. Summary of Test Method

oxygen fugacity is not part of this test method. Such control

4.1 Specimens of known volume and geometric surface area

and measurement may be required for specific uses of leaching

are immersed in the reference leachants without agitation for

data but are beyond the scope of this test method. Preparation

defined time periods at defined temperatures. The surface-area-

−1

of deaerated leachants is covered in 7.2.2.

to-volume ratio (S/V) is held constant within 0.5 of 10.0 m .

5.4 The use of PTFE test vessels may result in some F−

Three reference temperatures, 40°, 70°, and 90°C, and a

release from the vessel to the solution. For PTFE vessels that

number of specific time periods are identified in a series of test

meet the qualification requirements of this test method (see

matrices established to meet objectives that include evaluation

6.4), the amount of release at low radiation levels, < 10 rad, is

of waste forms for comparative purposes. In the test method,

not significant. Fluoride, at the concentrations encountered in

three reference leachants are used: high-purity water and two

tests where the radiation dose is limited to less than 10 rad and

solutions (silicate/bicarbonate and brine) that approximate

fluids that the waste form may encounter in a geologic

repository. In addition to the reference leachants, others may be

Strachan, D. M., “Effect of Gamma Irradiation on Simulated Waste Glass

used. The test is for application to simulated waste forms and

Leaching and on the Leach Vessel,” Journal of the American Ceramic Society 66[9],

to radioactive specimens. C-158-C-160, 1983.

C 1220

qualified PTFE is used, has not been demonstrated to have an generally be between 20 mL and 1 L. The vessels shall be

effect on leaching behavior. The primary reason for limiting sufficiently impervious and have a tight-fitting lid to limit

the integrated dose to PTFE vessels and specimen supports to

leachant loss during the test to less than 10 % of the original

10 rad and requiring that the PTFE vessels be qualified is to volume. The specimen support shall be constructed of the same

ensure that excessive fluoride releases do not occur (see Note

material as the vessel or of equally inert material and designed

1). In order to monitor fluoride releases, which could have an

to maintain the specimen near the centroid of the leach volume

influence on test results, analysis for F− concentration is a test

but must not contact more than 5 % of the specimen surface

requirement.

area.

6.4 Identification of Vessels and Cleaning History—Vessel

6. Apparatus and Analytical Requirements

identification and the cleaning history of each vessel must be

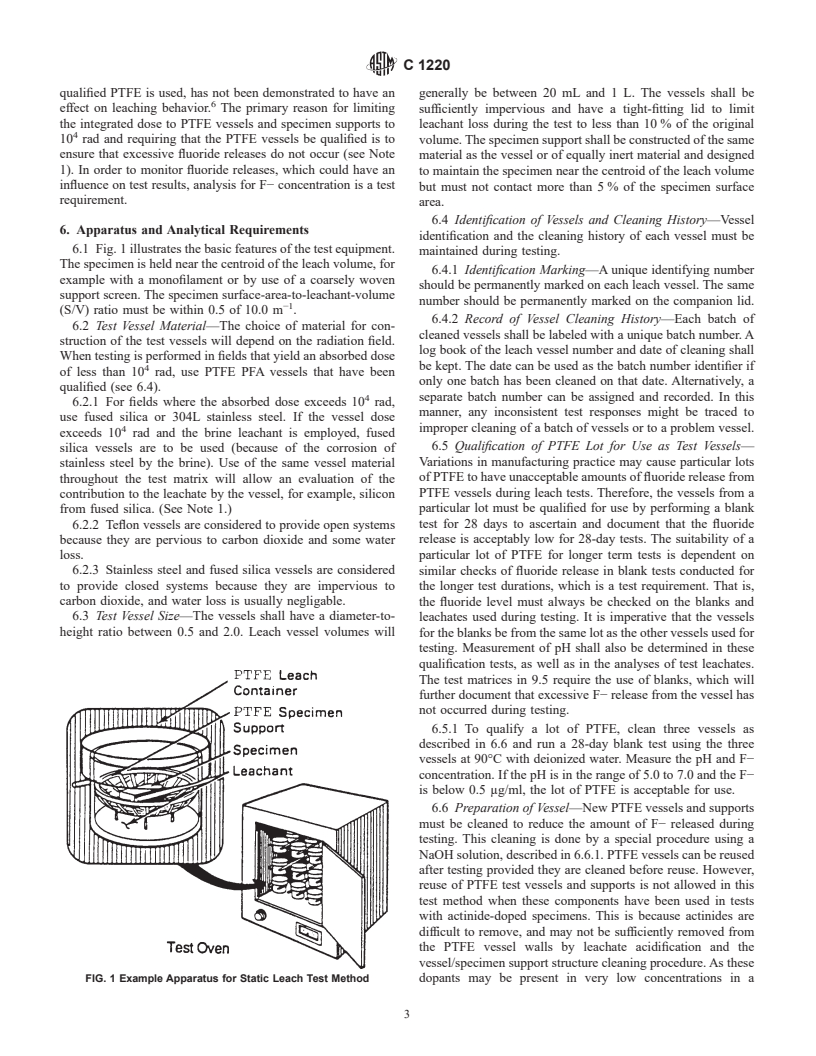

6.1 Fig. 1 illustrates the basic features of the test equipment.

maintained during testing.

The specimen is held near the centroid of the leach volume, for

6.4.1 Identification Marking—A unique identifying number

example with a monofilament or by use of a coarsely woven

should be permanently marked on each leach vessel. The same

support screen. The specimen surface-area-to-leachant-volume

number should be permanently marked on the companion lid.

−1

(S/V) ratio must be within 0.5 of 10.0 m .

6.4.2 Record of Vessel Cleaning History—Each batch of

6.2 Test Vessel Material—The choice of material for con-

cleaned vessels shall be labeled with a unique batch number. A

struction of the test vessels will depend on the radiation field.

log book of the leach vessel number and date of cleaning shall

When testing is performed in fields that yield an absorbed dose

4 be kept. The date can be used as the batch number identifier if

of less than 10 rad, use PTFE PFA vessels that have been

only one batch has been cleaned on that date. Alternatively, a

qualified (see 6.4).

4 separate batch number can be assigned and recorded. In this

6.2.1 For fields where the absorbed dose exceeds 10 rad,

manner, any inconsistent test responses might be traced to

use fused silica or 304L stainless steel. If the vessel dose

4 improper cleaning of a batch of vessels or to a problem vessel.

exceeds 10 rad and the brine leachant is employed, fused

6.5 Qualification of PTFE Lot for Use as Test Vessels—

silica vessels are to be used (because of the corrosion of

Variations in manufacturing practice may cause particular lots

stainless steel by the brine). Use of the same vessel material

of PTFE to have unacceptable amounts of fluoride release from

throughout the test matrix will allow an evaluation of the

PTFE vessels during leach tests. Therefore, the vessels from a

contribution to the leachate by the vessel, for example, silicon

from fused silica. (See Note 1.) particular lot must be qualified for use by performing a blank

test for 28 days to ascertain and document that the fluoride

6.2.2 Teflon vessels are considered to provide open systems

because they are pervious to carbon dioxide and some water release is acceptably low for 28-day tests. The suitability of a

loss. particular lot of PTFE for longer term tests is dependent on

6.2.3 Stainless steel and fused silica vessels are considered similar checks of fluoride release in blank tests conducted for

to provide closed systems because they are impervious to the longer test durations, which is a test requirement. That is,

carbon dioxide, and water loss is usually negligable.

the fluoride level must always be checked on the blanks and

6.3 Test Vessel Size—The vessels shall have a diameter-to- leachates used during testing. It is imperative that the vessels

height ratio between 0.5 and 2.0. Leach vessel volumes will

for the blanks be from the same lot as the other vessels used for

testing. Measurement of pH shall also be determined in these

qualification tests, as well as in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.