ASTM D3525-04(2016)

(Test Method)Standard Test Method for Gasoline Diluent in Used Gasoline Engine Oils by Gas Chromatography

Standard Test Method for Gasoline Diluent in Used Gasoline Engine Oils by Gas Chromatography

SIGNIFICANCE AND USE

5.1 Some fuel dilution of the engine oil may take place during normal operation. However, excessive fuel dilution is of concern in terms of possible performance problems. This method provides a means to determine the magnitude of the fuel dilution, providing the user with the ability to predict performance problems and to take appropriate action.

SCOPE

1.1 This test method covers the use of gas chromatography to determine the amount of gasoline in used lubricating oils arising from their use in gasoline engines.

1.2 There is no limitation for the determination of the dilution range, provided that the amount of sample plus internal standard is within the linear range of the gas chromatograph detector.

1.3 This test method is limited to gas chromatographs equipped with flame ionization detectors and programmable ovens.

Note 1: The use of other detectors and instrumentation has been reported. However, the precision statement applies only when the instrumentation specified is employed.

1.4 The applicability of this method to gelled used engine oils has not been adequately investigated in order to ensure compliance with the indicated repeatability and reproducibility. Gelled oils are defined as oils that develop structure on standing, but that return to their original fluidity with light agitation.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3525 − 04 (Reapproved 2016)

Standard Test Method for

Gasoline Diluent in Used Gasoline Engine Oils by Gas

Chromatography

This standard is issued under the fixed designation D3525; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E355 Practice for Gas ChromatographyTerms and Relation-

ships

1.1 This test method covers the use of gas chromatography

E594 Practice for Testing Flame Ionization Detectors Used

to determine the amount of gasoline in used lubricating oils

in Gas or Supercritical Fluid Chromatography

arising from their use in gasoline engines.

E1510 Practice for Installing Fused Silica Open Tubular

1.2 There is no limitation for the determination of the

Capillary Columns in Gas Chromatographs

dilution range, provided that the amount of sample plus

internal standard is within the linear range of the gas chro-

3. Terminology

matograph detector.

3.1 Definitions:

1.3 This test method is limited to gas chromatographs

3.1.1 For definition of gas chromatography terms, refer to

equipped with flame ionization detectors and programmable

Practice E355.

ovens.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—The use of other detectors and instrumentation has been

3.2.1 fuel diluent, n—in used oil analysis, unburned fuel

reported. However, the precision statement applies only when the instru-

mentation specified is employed. components that enter the engine crankcase cause dilution of

the oil.

1.4 The applicability of this method to gelled used engine

3.2.1.1 Discussion—In this method, the fuel diluent compo-

oils has not been adequately investigated in order to ensure

nents being determined originate from gasoline.

compliancewiththeindicatedrepeatabilityandreproducibility.

Gelled oils are defined as oils that develop structure on

3.2.2 fuel dilution, n—the amount, expressed as a

standing, but that return to their original fluidity with light

percentage, of gasoline found in engine lubricating oil.

agitation.

3.2.2.1 Discussion—Fuel dilution may be the result of

engine wear or improper performance.

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.3 Abbreviations:

standard.

3.3.1 Acommonabbreviationofhydrocarboncompoundsis

1.6 This standard does not purport to address all of the

to designate the number of carbon atoms in the compound. A

safety concerns, if any, associated with its use. It is the

prefix is used to indicate the carbon chain form, while a

responsibility of the user of this standard to establish appro-

subscripted suffix denotes the number of carbon atoms.

priate safety and health practices and determine the applica-

Example:

bility of regulatory requirements prior to use.

normal decane n-C

iso-tetradecane i-C

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

E260 Practice for Packed Column Gas Chromatography

4.1 A gas chromatographic technique is used for analyzing

the samples, by adding a known percentage of n-tetradecane as

This test method is under the jurisdiction of ASTM Committee D02 on

an internal standard, in order to determine the weight percent

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

of gasoline fuel in the lubricating oil. A calibration curve is

Subcommittee D02.B0 on Automotive Lubricants.

previously constructed which plots the gasoline fuel to

Current edition approved April 1, 2016. Published May 2016. Originally

n-tetradecane response ratio versus the weight percent of

approved in 1976. Last previous edition approved in 2010 as D3525 – 04 (2010).

DOI: 10.1520/D3525-04R16.

gasoline fuel in lubricating oil mixtures containing a constant

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

amount of internal standard. Mass percent of gasoline fuel in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the samples is determined by interpolation from the calibration

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. curve.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3525 − 04 (2016)

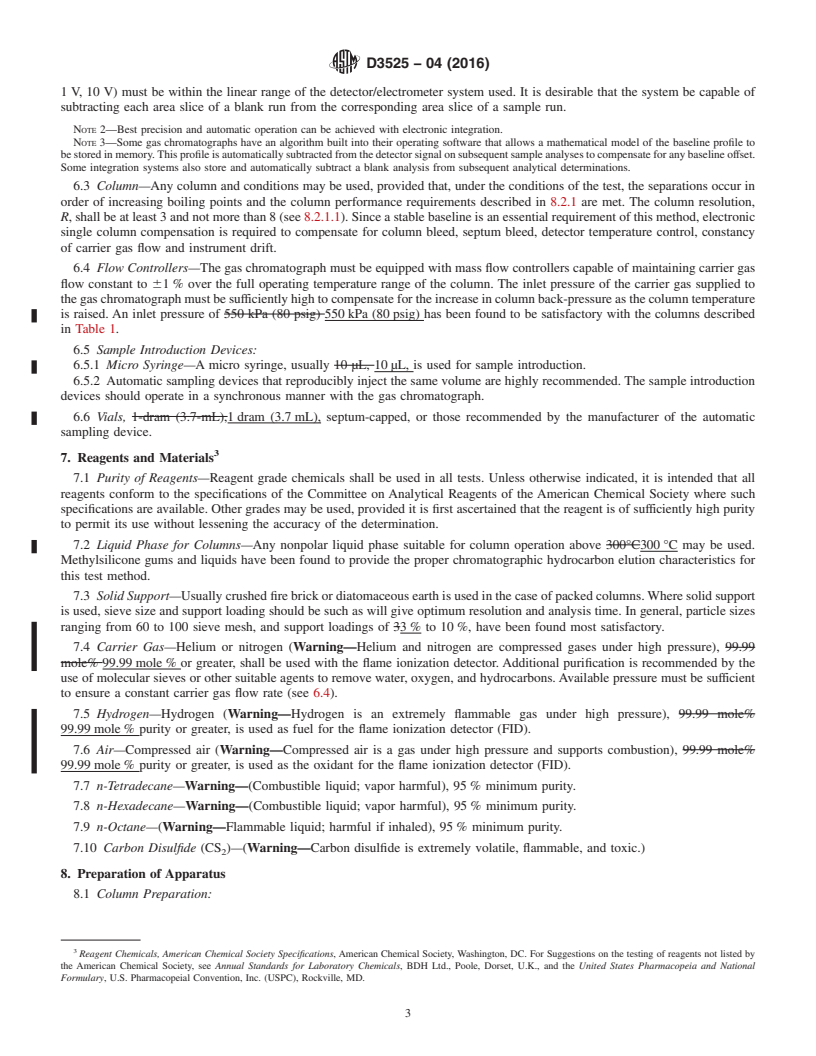

TABLE 1 Typical Operating Conditions

Packed Columns Open Tubular Columns

Column length, m (ft) 0.610 (2) 5 – 10

Column outside diameter, mm (in.) 3.2 (1/8) —

Column inner diameter, mm (in.) 2.36 ( 0.093) 0.53

Liquid phase methylsilicone gum or liquids cross-linked, bonded polydimethylsiloxane

Percent liquid phase 10 —

Support material crushed fire brick or diatomaceous earth —

Treatment acid wash —

Support mesh size 80/100 —

Stationary phase thickness, microns — 0.88 – 2.65

Column temperature, initial °C 30 30

Column temperature, final °C 255 255

Programming rate, °C/min 6 6

Carrier gas helium or nitrogen helium or nitrogen

Carrier gas flow rate, mL/min 30 30

Detector flame ionization detector flame ionization detector

Detector temperature, °C 300 300

Injection port temperature, °C 255 255

Sample size, µL 0.7 0.1 – 0.2 (from 1/10 dilution in CS )

5. Significance and Use 6.2 Data Acquisition System—Means must be provided for

measuring the accumulated area under the chromatogram.This

5.1 Some fuel dilution of the engine oil may take place

can be done by means of an electronic integrator or computer

duringnormaloperation.However,excessivefueldilutionisof

based chromatography data system.

concern in terms of possible performance problems. This

6.2.1 Integrator/Computer System—The integrator/

method provides a means to determine the magnitude of the

computer system must have chromatographic software capable

fuel dilution, providing the user with the ability to predict

of measuring the retention times and areas of eluting peaks

performance problems and to take appropriate action.

(peak detection mode). The electronic range of the integrator/

computer (for example, 1 V, 10 V) must be within the linear

6. Apparatus

range of the detector/electrometer system used. It is desirable

6.1 Gas Chromatograph—Any gas chromatograph may be

that the system be capable of subtracting each area slice of a

used that has the following performance characteristics:

blank run from the corresponding area slice of a sample run.

6.1.1 Detector—Only a flame ionization detector can be

used in this method. The detector must have sufficient sensi-

NOTE 2—Best precision and automatic operation can be achieved with

tivity to detect 1.0 % n-tetradecane with a peak height of at electronic integration.

NOTE 3—Some gas chromatographs have an algorithm built into their

least 40 % of full scale on the data acquisition devise under the

operating software that allows a mathematical model of the baseline

conditions prescribed in this method. For further guidance on

profile to be stored in memory. This profile is automatically subtracted

testingflameionizationdetectors,refertoPracticeE594.When

from the detector signal on subsequent sample analyses to compensate for

operating at this sensitivity level, detector stability must be

any baseline offset. Some integration systems also store and automatically

such that a baseline drift of not more than 1 % full scale per subtract a blank analysis from subsequent analytical determinations.

hour is obtained. The detector must be capable of operating

6.3 Column—Any column and conditions may be used,

continuously at a temperature equivalent to the maximum

provided that, under the conditions of the test, the separations

column temperature employed. Connection of the column to

occur in order of increasing boiling points and the column

the detector must be such that no temperature zones exist

performance requirements described in 8.2.1 are met. The

below the column temperature (cold spots).

column resolution, R, shall be at least 3 and not more than 8

6.1.2 Column Temperature Programmer—The chromato-

(see8.2.1.1).Sinceastablebaselineisanessentialrequirement

graphmustbecapableoftemperatureprogramoperationofthe

of this method, electronic single column compensation is

oven over a range sufficient to establish a retention time of

required to compensate for column bleed, septum bleed,

0.25 min (15 s) for the initial peak and to elute the internal

detector temperature control, constancy of carrier gas flow and

standard totally.Aretention time repeatability of 0.3 min (18 s)

instrument drift.

must be achieved.

6.1.3 Sample Inlet System—The sample inlet system must 6.4 Flow Controllers—The gas chromatograph must be

be capable of operating continuously at a temperature equiva- equipped with mass flow controllers capable of maintaining

lent to the maximum column temperature employed. An carrier gas flow constant to 61 % over the full operating

on-column inlet with some means of programming the inlet temperature range of the column. The inlet pressure of the

temperature, including the point of sample introduction, up to carrier gas supplied to the gas chromatograph must be suffi-

the maximum temperature required can also be used. Connec- ciently high to compensate for the increase in column back-

tion of the column to the sample inlet system must be such that pressure as the column temperature is raised.An inlet pressure

notemperaturezonesexistbelowthecolumntemperature(cold of 550 kPa (80 psig) has been found to be satisfactory with the

spots). columns described in Table 1.

D3525 − 04 (2016)

6.5 Sample Introduction Devices: 7.9 n-Octane—(Warning—Flammable liquid; harmful if

6.5.1 Micro Syringe—A micro syringe, usually 10 µL, is inhaled), 95 % minimum purity.

used for sample introduction.

7.10 CarbonDisulfide(CS )—(Warning—Carbondisulfide

6.5.2 Automatic sampling devices that reproducibly inject

is extremely volatile, flammable, and toxic.)

the same volume are highly recommended. The sample intro-

duction devices should operate in a synchronous manner with

8. Preparation of Apparatus

the gas chromatograph.

8.1 Column Preparation:

6.6 Vials, 1 dram (3.7 mL), septum-capped, or those recom-

8.1.1 Packed Columns—Any satisfactory method used in

mended by the manufacturer of the automatic sampling device.

the practice of gas chromatography (see Practice E260) that

will produce a column meeting the requirements of 6.3 may be

7. Reagents and Materials

used. The column must be conditioned at the maximum

7.1 Purity of Reagents—Reagent grade chemicals shall be

operating temperature until baseline drift due to column

used in all tests. Unless otherwise indicated, it is intended that

bleeding has been reduced to less than 1 % per hour.

all reagents conform to the specifications of the Committee on

8.1.1.1 The packed column can be conditioned very rapidly

Analytical Reagents of the American Chemical Society where

and effectively using the following procedure: Connect the

such specifications are available. Other grades may be used,

column to the inlet but leave the detector end free. Purge the

provided it is first ascertained that the reagent is of sufficiently

column thoroughly at ambient temperature with carrier gas.

high purity to permit its use without lessening the accuracy of

Turn off the carrier gas and allow the column to depressurize

the determination.

completely. Seal off the open end (detector end) of the column

7.2 Liquid Phase for Columns—Any nonpolar liquid phase

withanappropriatefitting.Raisethecolumntemperaturetothe

suitable for column operation above 300 °C may be used.

maximum operating temperature and hold at this temperature

Methylsilicone gums and liquids have been found to provide

for at least 1 h with no flow through the column. Cool the

the proper chromatographic hydrocarbon elution characteris-

column to ambient temperature. Then remove the cap from the

tics for this test method.

detector end of the column and turn the carrier gas back on.

Program the column temperature up to the maximum several

7.3 Solid Support—Usually crushed fire brick or diatoma-

times with normal carrier gas flow. Connect the free end of the

ceous earth is used in the case of packed columns.Where solid

column to the detector.

support is used, sieve size and support loading should be such

as will give optimum resolution and analysis time. In general,

NOTE 4—Difficulty in achieving the baseline drift requirement may

particle sizes ranging from 60 to 100 sieve mesh, and support

indicate column bleed due to insufficient conditioning.

loadings of 3 % to 10 %, have been found most satisfactory.

NOTE 5—An alternative method of column conditioning, which has

been found effective for packed columns with an initial loading of 10 %

7.4 Carrier Gas—Helium or nitrogen (Warning—Helium

liquid phase, consists of purging the column with carrier gas at the normal

and nitrogen are compressed gases under high pressure),

flowratewhileholdingthecolumnatmaximumoperatingtemperaturefor

99.99 mole % or greater, shall be used with the flame ioniza-

12 h to 16 h, while detached from the detector.

tion detector. Additional purification is recommended by the

8.1.2 Open Tubular Columns—Open tubular columns with

use of molecular sieves or other suitable agents to remove

cross-linked and bonded non-polar stationary phases are avail-

water, oxygen, and hydrocarbons. Available pressure must be

able from many manufacturers and are usually pre-

sufficient to ensure a constant carrier gas flow rate (see 6.4).

conditioned. These columns have much lower column bleed

7.5 Hydrogen—Hydrogen (Warning—Hydrogen is an ex- than packed columns. Column conditioning is still necessary

tremely flammable gas under high pressure), 99.99 mole %

(see Practice E1510). The column can be conditioned very

purity or greater, is used as fuel for the flame ionization

rapidly and effectively using the following procedure.

detector (FID).

8.1.2.1 Once the open tubular column has been properly

installed into the gas chromatograph inlet and tested to be leak

7.6 Air—Compressed air (Warning—Compressed air is a

free, set the column and detector gas flows. Before heating the

gas under high pressure and supports combustion),

column, allow the system to purge with carrier gas at ambient

99.99 mole % purity or greater, is used as the oxidant for the

temperature for at least 30 min.

flame ionization detector (FID).

8.1.2.2 Increase the oven temperature about 5 °C to 10 °C

7.7 n-Tetradecane—Warning—(Combustible liquid; vapor

perminutetothefinaloperatingtemperatureandholdforabout

harmful), 95 % minimum purity.

30 min or until a stable baseline is observed.

7.8 n-Hexadecane—Warning—(Combustible liquid; vap

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3525 − 04 (Reapproved 2010) D3525 − 04 (Reapproved 2016)

Standard Test Method for

Gasoline Diluent in Used Gasoline Engine Oils by Gas

Chromatography

This standard is issued under the fixed designation D3525; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the use of gas chromatography to determine the amount of gasoline in used lubricating oils arising

from their use in gasoline engines.

1.2 There is no limitation for the determination of the dilution range, provided that the amount of sample plus internal standard

is within the linear range of the gas chromatograph detector.

1.3 This test method is limited to gas chromatographs equipped with flame ionization detectors and programmable ovens.

NOTE 1—The use of other detectors and instrumentation has been reported. However, the precision statement applies only when the instrumentation

specified is employed.

1.4 The applicability of this method to gelled used engine oils has not been adequately investigated in order to ensure

compliance with the indicated repeatability and reproducibility. Gelled oils are defined as oils that develop structure on standing,

but that return to their original fluidity with light agitation.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E260 Practice for Packed Column Gas Chromatography

E355 Practice for Gas Chromatography Terms and Relationships

E594 Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

E1510 Practice for Installing Fused Silica Open Tubular Capillary Columns in Gas Chromatographs

3. Terminology

3.1 Definitions:

3.1.1 For definition of gas chromatography terms, refer to Practice E355.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 fuel diluent, n—in used oil analysis, unburned fuel components that enter the engine crankcase cause dilution of the oil.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.B0 on Automotive Lubricants.

Current edition approved Oct. 1, 2010April 1, 2016. Published November 2010May 2016. Originally approved in 1976. Last previous edition approved in 20042010 as

D35325D3525 – 04 (2010).–04. DOI: 10.1520/D3525-04R10.10.1520/D3525-04R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.2.1.1 Discussion—

In this method, the fuel diluent components being determined originate from gasoline.

3.2.2 fuel dilution, n—the amount, expressed as a percentage, of gasoline found in engine lubricating oil.

3.2.2.1 Discussion—

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3525 − 04 (2016)

Fuel dilution may be the result of engine wear or improper performance.

3.3 Abbreviations:

3.3.1 A common abbreviation of hydrocarbon compounds is to designate the number of carbon atoms in the compound. A prefix

is used to indicate the carbon chain form, while a subscripted suffix denotes the number of carbon atoms.

Example:

normal decane n-C

iso-tetradecane i-C

4. Summary of Test Method

4.1 A gas chromatographic technique is used for analyzing the samples, by adding a known percentage of n-tetradecane as an

internal standard, in order to determine the weight percent of gasoline fuel in the lubricating oil. A calibration curve is previously

constructed which plots the gasoline fuel to n-tetradecane response ratio versus the weight percent of gasoline fuel in lubricating

oil mixtures containing a constant amount of internal standard. Mass percent of gasoline fuel in the samples is determined by

interpolation from the calibration curve.

5. Significance and Use

5.1 Some fuel dilution of the engine oil may take place during normal operation. However, excessive fuel dilution is of concern

in terms of possible performance problems. This method provides a means to determine the magnitude of the fuel dilution,

providing the user with the ability to predict performance problems and to take appropriate action.

6. Apparatus

6.1 Gas Chromatograph—Any gas chromatograph may be used that has the following performance characteristics:

6.1.1 Detector—Only a flame ionization detector can be used in this method. The detector must have sufficient sensitivity to

detect 1.0 % n-tetradecane with a peak height of at least 40 % of full scale on the data acquisition devise under the conditions

prescribed in this method. For further guidance on testing flame ionization detectors, refer to Practice E594. When operating at

this sensitivity level, detector stability must be such that a baseline drift of not more than 1 % full scale per hour is obtained. The

detector must be capable of operating continuously at a temperature equivalent to the maximum column temperature employed.

Connection of the column to the detector must be such that no temperature zones exist below the column temperature (cold spots).

6.1.2 Column Temperature Programmer—The chromatograph must be capable of temperature program operation of the oven

over a range sufficient to establish a retention time of 0.25 min (15 s) 0.25 min (15 s) for the initial peak and to elute the internal

standard totally. A retention time repeatability of 0.3 min (18 s) 0.3 min (18 s) must be achieved.

6.1.3 Sample Inlet System—The sample inlet system must be capable of operating continuously at a temperature equivalent to

the maximum column temperature employed. An on-column inlet with some means of programming the inlet temperature,

including the point of sample introduction, up to the maximum temperature required can also be used. Connection of the column

to the sample inlet system must be such that no temperature zones exist below the column temperature (cold spots).

6.2 Data Acquisition System—Means must be provided for measuring the accumulated area under the chromatogram. This can

be done by means of an electronic integrator or computer based chromatography data system.

6.2.1 Integrator/Computer System—The integrator/computer system must have chromatographic software capable of measuring

the retention times and areas of eluting peaks (peak detection mode). The electronic range of the integrator/computer (for example,

TABLE 1 Typical Operating Conditions

Packed Columns Open Tubular Columns

Column length, m (ft) 0.610 (2) 5 – 10

Column outside diameter, mm (in.) 3.2 (1/8) —

Column inner diameter, mm (in.) 2.36 ( 0.093) 0.53

Liquid phase methylsilicone gum or liquids cross-linked, bonded polydimethylsiloxane

Percent liquid phase 10 —

Support material crushed fire brick or diatomaceous earth —

Treatment acid wash —

Support mesh size 80/100 —

Stationary phase thickness, microns — 0.88 – 2.65

Column temperature, initial °C 30 30

Column temperature, final °C 255 255

Programming rate, °C/min 6 6

Carrier gas helium or nitrogen helium or nitrogen

Carrier gas flow rate, mL/min 30 30

Detector flame ionization detector flame ionization detector

Detector temperature, °C 300 300

Injection port temperature, °C 255 255

Sample size, μL 0.7 0.1 – 0.2 (from 1/10 dilution in CS )

D3525 − 04 (2016)

1 V, 10 V) must be within the linear range of the detector/electrometer system used. It is desirable that the system be capable of

subtracting each area slice of a blank run from the corresponding area slice of a sample run.

NOTE 2—Best precision and automatic operation can be achieved with electronic integration.

NOTE 3—Some gas chromatographs have an algorithm built into their operating software that allows a mathematical model of the baseline profile to

be stored in memory. This profile is automatically subtracted from the detector signal on subsequent sample analyses to compensate for any baseline offset.

Some integration systems also store and automatically subtract a blank analysis from subsequent analytical determinations.

6.3 Column—Any column and conditions may be used, provided that, under the conditions of the test, the separations occur in

order of increasing boiling points and the column performance requirements described in 8.2.1 are met. The column resolution,

R, shall be at least 3 and not more than 8 (see 8.2.1.1). Since a stable baseline is an essential requirement of this method, electronic

single column compensation is required to compensate for column bleed, septum bleed, detector temperature control, constancy

of carrier gas flow and instrument drift.

6.4 Flow Controllers—The gas chromatograph must be equipped with mass flow controllers capable of maintaining carrier gas

flow constant to 61 % over the full operating temperature range of the column. The inlet pressure of the carrier gas supplied to

the gas chromatograph must be sufficiently high to compensate for the increase in column back-pressure as the column temperature

is raised. An inlet pressure of 550 kPa (80 psig) 550 kPa (80 psig) has been found to be satisfactory with the columns described

in Table 1.

6.5 Sample Introduction Devices:

6.5.1 Micro Syringe—A micro syringe, usually 10 μL, 10 μL, is used for sample introduction.

6.5.2 Automatic sampling devices that reproducibly inject the same volume are highly recommended. The sample introduction

devices should operate in a synchronous manner with the gas chromatograph.

6.6 Vials, 1-dram (3.7-mL),1 dram (3.7 mL), septum-capped, or those recommended by the manufacturer of the automatic

sampling device.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

7.2 Liquid Phase for Columns—Any nonpolar liquid phase suitable for column operation above 300°C300 °C may be used.

Methylsilicone gums and liquids have been found to provide the proper chromatographic hydrocarbon elution characteristics for

this test method.

7.3 Solid Support—Usually crushed fire brick or diatomaceous earth is used in the case of packed columns. Where solid support

is used, sieve size and support loading should be such as will give optimum resolution and analysis time. In general, particle sizes

ranging from 60 to 100 sieve mesh, and support loadings of 33 % to 10 %, have been found most satisfactory.

7.4 Carrier Gas—Helium or nitrogen (Warning—Helium and nitrogen are compressed gases under high pressure), 99.99

mole% 99.99 mole % or greater, shall be used with the flame ionization detector. Additional purification is recommended by the

use of molecular sieves or other suitable agents to remove water, oxygen, and hydrocarbons. Available pressure must be sufficient

to ensure a constant carrier gas flow rate (see 6.4).

7.5 Hydrogen—Hydrogen (Warning—Hydrogen is an extremely flammable gas under high pressure), 99.99 mole%

99.99 mole % purity or greater, is used as fuel for the flame ionization detector (FID).

7.6 Air—Compressed air (Warning—Compressed air is a gas under high pressure and supports combustion), 99.99 mole%

99.99 mole % purity or greater, is used as the oxidant for the flame ionization detector (FID).

7.7 n-Tetradecane—Warning—(Combustible liquid; vapor harmful), 95 % minimum purity.

7.8 n-Hexadecane—Warning—(Combustible liquid; vapor harmful), 95 % minimum purity.

7.9 n-Octane—(Warning—Flammable liquid; harmful if inhaled), 95 % minimum purity.

7.10 Carbon Disulfide (CS )—(Warning—Carbon disulfide is extremely volatile, flammable, and toxic.)

8. Preparation of Apparatus

8.1 Column Preparation:

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D3525 − 04 (2016)

8.1.1 Packed Columns—Any satisfactory method used in the practice of gas chromatography (see Practice E260) that will

produce a column meeting the requirements of 6.3 may be used. The column must be conditioned at the maximum operating

temperature until baseline drift due to column bleeding has been reduced to less than 1 % per hour.

8.1.1.1 The packed column can be conditioned very rapidly and effectively using the following procedure: Connect the column

to the inlet but leave the detector end free. Purge the column thoroughly at ambient temperature with carrier gas. Turn off the carrier

gas and allow the column to depressurize completely. Seal off the open end (detector end) of the column with an appropriate fitting.

Raise the column temperature to the maximum operating temperature and hold at this temperature for at least 1 h with no flow

through the column. Cool the column to ambient temperature. Then remove the cap from the detector end of the column and turn

the carrier gas back on. Program the column temperature up to the maximum several times with normal carrier gas flow. Connect

the free end of the column to the detector.

NOTE 4—Difficulty in achieving the baseline drift requirement may indicate column bleed due to insufficient conditioning.

NOTE 5—An alternative method of column conditioning, which has been found effective for packed columns with an initial loading of 10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.