ASTM A510-00

(Specification)Standard Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel

Standard Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel

SCOPE

1.1 This specification covers general requirements for carbon steel wire rods and uncoated coarse round wire in coils or straightened and cut lengths.

1.2 In case of conflict, the requirements in the purchase order, on the drawing, in the individual specification, and in this general specification shall prevail in the sequence named.

Note 1—A complete metric companion to Specification A 510 has been developed-Specification A 510M; therefore, no metric equivalents are presented in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: A 510 – 00

Standard Specification for

General Requirements for Wire Rods and Coarse Round

Wire, Carbon Steel

This standard is issued under the fixed designation A 510; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers general requirements for car- 3.1 Definitions of Terms Specific to This Standard:

bon steel wire rods and uncoated coarse round wire in coils or 3.1.1 carbon steel—steel in which no minimum content is

straightened and cut lengths. specified or required for aluminum, chromium, cobalt, colum-

1.2 In case of conflict, the requirements in the purchase bium, molybdenum, nickel, titanium, tungsten, vanadium, or

order, on the drawing, in the individual specification, and in zirconium, or any other element added to obtain a desired

this general specification shall prevail in the sequence named. alloying effect; when the specified minimum for copper does

not exceed 0.40 %; or when the maximum content specified for

NOTE 1—A complete metric companion to Specification A 510 has

any of the following elements does not exceed these percent-

been developed—Specification A 510M; therefore, no metric equivalents

ages: manganese 1.65, silicon 0.60, or copper 0.60.

are presented in this specification.

3.1.2 Discussion—In all carbon steels small quantities of

2. Referenced Documents

certain residual elements unavoidably retained from raw ma-

terials are sometimes found which are not specified or required,

2.1 ASTM Standards:

such as copper, nickel, molybdenum, chromium, etc. These

A 370 Test Methods and Definitions for Mechanical Testing

elements are considered as incidental and are not formally

of Steel Products

determined or reported.

A 700 Practices for Packaging, Marking, and Loading

—Elements may be specified to improve machinability of

Methods for Steel Products for Domestic Shipment

carbon steels such as sulfur and lead.

E 29 Practice for Using Significant Digits in Test Data to

3.1.4 coarse round wire—from 0.035 to 0.999 in. in diam-

Determine Conformance with Specifications

eter, inclusive, wire which is produced from hot-rolled wire

E 30 Test Methods for Chemical Analysis of Steel, Cast

rods or hot-rolled coiled bars by one or more cold reductions

Iron, Open-Hearth Iron, and Wrought Iron

primarily for the purpose of obtaining a desired size with

E 112 Test Methods for Determining Average Grain Size

dimensional accuracy, surface finish, and mechanical proper-

E 527 Practice for Numbering Metals and Alloys (UNS)

ties. By varying the amount of cold reduction and other wire

2.2 SAE Standard:

mill practices, including thermal treatment, a wide diversity of

J 1086 Numbering Metals and Alloy

mechanical properties and finishes are made available.

2.3 AIAG Standard:

3.1.5 Discussion— Coarse round wire is designated by

AIAGB-5 02.00 Primary Metals Identification Tag Applica-

Steel Wire Gage numbers, common fractions, or decimal parts

tion Standard

of an inch. The Steel Wire Gage system is shown in Table 1.

Since the many gage systems in use may cause confusion, the

purchaser is encouraged to specify wire diameters in inches or

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

decimal parts, or both.

A01.03 on Steel Rod and Wire.

3.1.6 straightened and cut wire—wire which is produced

Current edition approved March 10, 2000. Published May 2000. Originally

from coils of wire by means of special machinery which

published as A 510 – 64. Last previous edition A 510 – 94.

Annual Book of ASTM Standards, Vol 01.03. straightens the wire and cuts it to a specified length.

Annual Book of ASTM Standards, Vol 01.05.

3.1.7 Discussion—The straightening operation may alter

Annual Book of ASTM Standards, Vol 14.02.

the mechanical properties of the wire especially the tensile

Discontinued—See 1994 Annual Book of ASTM Standards, Vol 03.05.

strength. The straightening operation may also induce changes

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 01.01.

in the diameter of the wire. The extent of the changes in the

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

properties of the wire after cold straightening depends upon the

Warrendale, PA 15096.

9 kind of wire and also on the normal variations in the adjust-

Available from the Automotive Industry Action Group, 26200 Lahser, Suite

ments of the straightening equipment. It is therefore not

200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 510

A A

TABLE 1 Steel Wire Gage TABLE 2 Sizes of Wire Rods

Decimal Decimal Inch Decimal Inch Decimal

Gage No. Equivalent, Gage No. Equivalent, Fraction Equivalent, Fraction Equivalent,

in. in. in. in.

7 31

7/0 0.490 9 0.148* ⁄32 0.219 ⁄64 0.484

1 15 1

6/0 0.462* 9 ⁄2 0.142 ⁄64 0.234 ⁄2 0.500

1 33

5/0 0.430* 10 0.135 ⁄4 0.250 ⁄64 0.516

4/0 0.394* 10 ⁄2 0.128

17 17

3/0 0.362* 11 0.120* ⁄64 0.266 ⁄32 0.531

1 9 35

2/0 0.331 11 ⁄2 0.113 ⁄32 0.281 ⁄64 0.547

19 9

1/0 0.306 12 0.106* ⁄64 0.297 ⁄16 0.562

1 0.283 12 ⁄2 0.099

1 5 37

1 ⁄2 0.272 13 0.092* ⁄16 0.312 ⁄64 0.578

1 21 19

2 0.262* 13 ⁄2 0.086 ⁄64 0.328 ⁄32 0.594

1 11 39

2 ⁄2 0.253 14 0.080 ⁄32 0.344 ⁄64 0.609

3 0.244* 14 ⁄2 0.076

1 23 5

3 ⁄2 0.234 15 0.072 ⁄64 0.359 ⁄8 0.625

1 3 41

4 0.225* 15 ⁄2 0.067 ⁄8 0.375 ⁄64 0.641

1 25 21

4 ⁄2 0.216 16 0.062* ⁄64 0.391 ⁄32 0.656

5 0.207 16 ⁄2 0.058

1 13 43

5 ⁄2 0.200 17 0.054 ⁄32 0.406 ⁄64 0.672

1 27 11

6 0.192 17 ⁄2 0.051 ⁄64 0.422 ⁄16 0.688

1 7 45

6 ⁄2 0.184 18 0.048* ⁄16 0.438 ⁄64 0.703

7 0.177 18 ⁄2 0.044

1 29 23

7 ⁄2 0.170 19 0.041 ⁄64 0.453 ⁄32 0.719

1 15 47

8 0.162 19 ⁄2 0.038 ⁄32 0.469 ⁄64 0.734

8 ⁄2 0.155 20 0.035*

A

Rounded off to 3 decimal places in decimal equivalents in accordance with

A

The steel wire gage outlined in this table has been taken from the original procedures outlined in Practice E 29.

Washburn and Moen Gage chart. In 20 gage and coarser, sizes originally quoted

to 4 decimal equivalent places have been rounded to 3 decimal places in

4.2.2 Name of material (uncoated carbon steel wire),

accordance with rounding procedures of Practice E 29. All rounded U.S. custom-

4.2.3 Diameter (see 3.1.5),

ary values are indicated by an asterisk.

4.2.4 Length (straightened and cut only),

4.2.5 Chemical composition (Table 3, Table 4, Table 5, and

Table 6),

possible to forecast the properties of straightened and cut wire

4.2.6 Packaging,

and each kind of wire needs individual consideration. In most

4.2.7 ASTM designation and date of issue, and

cases, the end use of straightened and cut wire is not seriously

4.2.8 Special requirements, if any.

influenced by these changes.

NOTE 3—A typical ordering description is as follows: 40 000 lb

3.1.8 wire rods—rods which are hot rolled from billets to an

Uncoated Carbon Steel Wire, 0.148 in. (9 ga.) diameter, Grade 1008 in

approximate round cross section into coils of one continuous

500 lb Coils on Tubular Carriers to ASTM A 510-XX, or

length. Rods are not comparable to hot-rolled bars in accuracy

2500 Pieces, Carbon Steel Wire, 0.375 in. diameter, Straightened and

of cross section or surface finish and as a semifinished product

Cut 29 ⁄2 in., Grade 1015, in 25 Piece Bundles on Pallets to ASTM A

are intended primarily for the manufacture of wire.

510-XX.

7 47

3.1.9 Discussion—Rod sizes from ⁄32 to ⁄64in. in diameter,

5. Manufacture

inclusive, are designated by fractions or decimal parts of an

5.1 The steel shall be made by the open-hearth, electric-

inch as shown in Table 2.

furnace, or basic-oxygen process. The steel may be either ingot

4. Ordering Information

cast or strand cast.

4.1 Orders for hot-rolled wire rods under this specification

6. Chemical Composition

should include the following information:

6.1 The chemical composition for steel under this specifi-

4.1.1 Quantity (pounds),

cation shall conform to the requirements set forth in the

4.1.2 Name of material (wire rods),

purchase order. Chemical compositions are specified by ranges

4.1.3 Diameter (Table 2),

or limits for carbon and other elements. The grades commonly

4.1.4 Chemical composition grade no. (Table 3, Table 4,

specified for carbon steel wire rods and coarse round wire are

Table 5, and Table 6),

shown in Table 3, Table 4, Table 5, and Table 6.

4.1.5 Packaging,

6.2 Cast or Heat Analysis (Formerly Ladle Analysis)—An

4.1.6 ASTM designation and date of issue, and

analysis of each cast or heat shall be made by the producer to

4.1.7 Special requirements, if any.

determine the percentage of the elements specified. The analy-

NOTE 2—A typical ordering description is as follows: 100 000 lb Wire

sis shall be made from a test sample, preferably taken during

Rods, ⁄32 in., Grade 1010 in approximately 1000 lb Coils to ASTM A 510

the pouring of the cast or heat. The chemical composition thus

dated .

determined shall be reported, if required, to the purchaser, or

4.2 Orders for coarse round wire under this specification his representative.

should include the following information: 6.3 Product Analysis (Formerly Check Analysis)—A prod-

4.2.1 Quantity (pounds or pieces), uct analysis may be made by the purchaser. The analysis is not

A 510

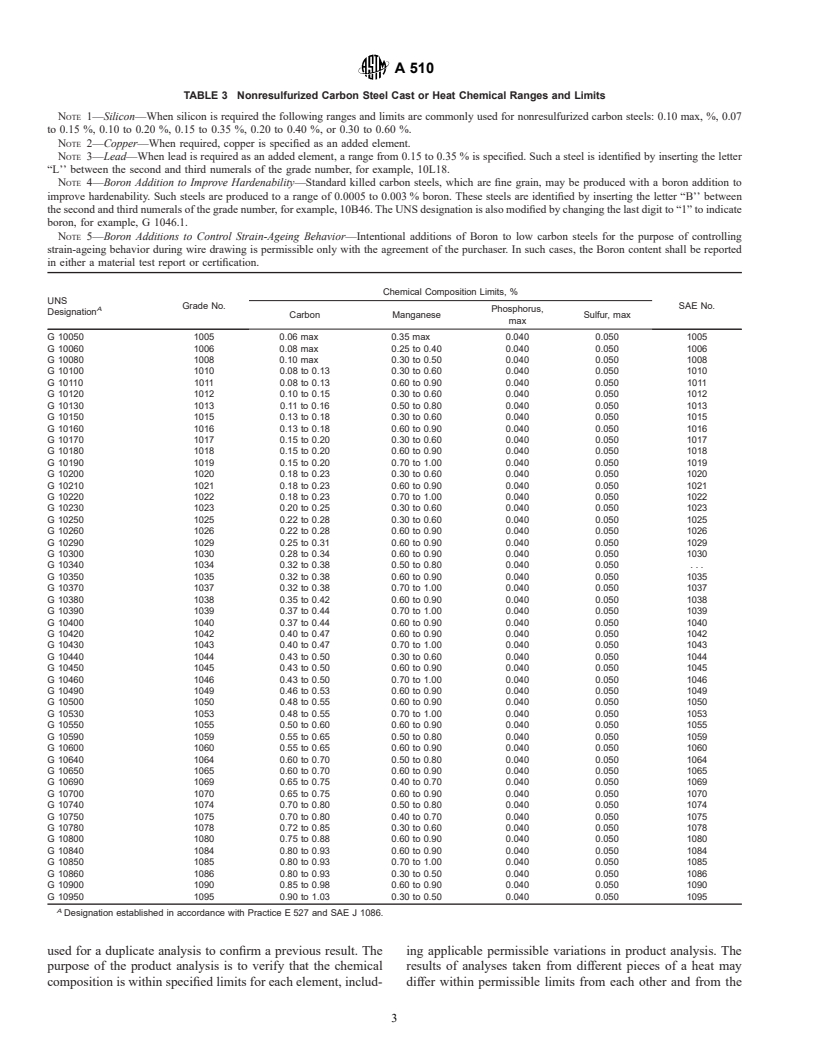

TABLE 3 Nonresulfurized Carbon Steel Cast or Heat Chemical Ranges and Limits

NOTE 1—Silicon—When silicon is required the following ranges and limits are commonly used for nonresulfurized carbon steels: 0.10 max, %, 0.07

to 0.15 %, 0.10 to 0.20 %, 0.15 to 0.35 %, 0.20 to 0.40 %, or 0.30 to 0.60 %.

NOTE 2—Copper—When required, copper is specified as an added element.

NOTE 3—Lead—When lead is required as an added element, a range from 0.15 to 0.35 % is specified. Such a steel is identified by inserting the letter

“L’’ between the second and third numerals of the grade number, for example, 10L18.

NOTE 4—Boron Addition to Improve Hardenability—Standard killed carbon steels, which are fine grain, may be produced with a boron addition to

improve hardenability. Such steels are produced to a range of 0.0005 to 0.003 % boron. These steels are identified by inserting the letter “B’’ between

the second and third numerals of the grade number, for example, 10B46. The UNS designation is also modified by changing the last digit to “1” to indicate

boron, for example, G 1046.1.

NOTE 5—Boron Additions to Control Strain-Ageing Behavior—Intentional additions of Boron to low carbon steels for the purpose of controlling

strain-ageing behavior during wire drawing is permissible only with the agreement of the purchaser. In such cases, the Boron content shall be reported

in either a material test report or certification.

Chemical Composition Limits, %

UNS

Grade No. SAE No.

A

Phosphorus,

Designation

Carbon Manganese Sulfur, max

max

G 10050 1005 0.06 max 0.35 max 0.040 0.050 1005

G 10060 1006 0.08 max 0.25 to 0.40 0.040 0.050 1006

G 10080 1008 0.10 max 0.30 to 0.50 0.040 0.050 1008

G 10100 1010 0.08 to 0.13 0.30 to 0.60 0.040 0.050 1010

G 10110 1011 0.08 to 0.13 0.60 to 0.90 0.040 0.050 1011

G 10120 1012 0.10 to 0.15 0.30 to 0.60 0.040 0.050 1012

G 10130 1013 0.11 to 0.16 0.50 to 0.80 0.040 0.050 1013

G 10150 1015 0.13 to 0.18 0.30 to 0.60 0.040 0.050 1015

G 10160 1016 0.13 to 0.18 0.60 to 0.90 0.040 0.050 1016

G 10170 1017 0.15 to 0.20 0.30 to 0.60 0.040 0.050 1017

G 10180 1018 0.15 to 0.20 0.60 to 0.90 0.040 0.050 1018

G 10190 1019 0.15 to 0.20 0.70 to 1.00 0.040 0.050 1019

G 10200 1020 0.18 to 0.23 0.30 to 0.60 0.040 0.050 1020

G 10210 1021 0.18 to 0.23 0.60 to 0.90 0.040 0.050 1021

G 10220 1022 0.18 to 0.23 0.70 to 1.00 0.040 0.050 1022

G 10230 1023 0.20 to 0.25 0.30 to 0.60 0.040 0.050 1023

G 10250 1025 0.22 to 0.28 0.30 to 0.60 0.040 0.050 1025

G 10260 1026 0.22 to 0.28 0.60 to 0.90 0.040 0.050 1026

G 10290 1029 0.25 to 0.31 0.60 to 0.90 0.040 0.050 1029

G 10300 1030 0.28 to 0.34 0.60 to 0.90 0.040 0.050 1030

G 10340 1034 0.32 to 0.38 0.50 to 0.80 0.040 0.050 . . .

G 10350 1035 0.32 to 0.38 0.60 to 0.90 0.040 0.050 1035

G 10370 1037 0.32 to 0.38 0.70 to 1.00 0.040 0.050 1037

G 10380 1038 0.35 to 0.42 0.60 to 0.90 0.040 0.050 1038

G 10390 1039 0.37 to 0.44 0.70 to 1.00 0.040 0.050 1039

G 10400 1040 0.37 to 0.44 0.60 to 0.90 0.040 0.050 1040

G 10420 1042 0.40 to 0.47 0.60 to 0.90 0.040 0.050 1042

G 10430 1043 0.40 to 0.47 0.70 to 1.00 0.040 0.050 1043

G 10440 1044 0.43 to 0.50 0.30 to 0.60 0.040 0.050 1044

G 10450 1045 0.43 to 0.50 0.60 to 0.90 0.040 0.050 1045

G 10460 1046 0.43 to 0.50 0.70 to 1.00 0.040 0.050 1046

G 10490 1049 0.46 to 0.53 0.60 to 0.90 0.040 0.050 1049

G 10500 1050 0.48 to 0.55 0.60 to 0.90 0.040 0.050 1050

G 10530 1053 0.48 to 0.55 0.70 to 1.00 0.040 0.050 1053

G 10550 1055 0.50 to 0.60 0.60 to 0.90 0.040 0.050 1055

G 10590 1059 0.55 to 0.65 0.50 to 0.80 0.040 0.050 1059

G 10600 1060 0.55 to 0.65 0.60 to 0.90 0.040 0.050 1060

G 10640 1064 0.60 to 0.70 0.50 to 0.80 0.040 0.050 1064

G 10650 1065 0.60 to 0.70 0.60 to 0.90 0.040 0.050 1065

G 10690 1069 0.65 to 0.75 0.40 to 0.70 0.040 0.050 1069

G 10700 1070 0.65 to 0.75 0.60 to 0.90 0.040 0.050 1070

G 10740 1074 0.70 to 0.80 0.50 to 0.80 0.040 0.050 1074

G 10750 1075 0.70 to 0.80 0.40 to 0.70 0.040 0.050 1075

G 10780 1078 0.72 to 0.85 0.30 to 0.60 0.040 0.050 1078

G 10800 1080 0.75 to 0.88 0.60 to 0.90 0.040 0.050 1080

G 10840 1084 0.80 to 0.93 0.60 to 0.90 0.040 0.050 1084

G 10850 1085 0.80 to 0.93 0.70 to 1.00 0.040 0.050 1085

G 10860 1086 0.80 to 0.93 0.30 to 0.50 0.040 0.050 1086

G 10900 1090 0.85 to 0.98 0.60 to 0.90 0.040 0.050 1090

G 10950 1095 0.90 to 1.03 0.30 to 0.50 0.040 0.050 1095

A

Designation established in accordance with Practice E 527 and SAE J 1086.

used for a duplicate analysis to confirm a previous result. The ing applicable permissible variations in product analysis. The

purpose of the product analysis is to verify that the chemical results of analyses taken from different pieces of a heat may

composition is within specified limits for each element, includ- differ within permissible limits from each other and from the

A 510

TABLE 4 Nonresulfurized Carbon Steel, High Manganese, Cast or Heat Chemical Ranges and Limits

NOTE 1—Silicon—When silicon is required the following ranges and limits are commonly used for nonresulfurized carbon steels: 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.