ASTM F2795-11

(Test Method)Standard Test Method for Performance of Self-Contained Soft Serve and Shake Machines

Standard Test Method for Performance of Self-Contained Soft Serve and Shake Machines

SIGNIFICANCE AND USE

The freeze-down energy consumption and duration can be used to determine time and energy required for a machine to be ready to serve when loaded with mix.

The minimum dispensing interval determination is used to determine the rate at which the product will be dispensed during the Heavy-Use Energy Consumption and Production Capacity Test (10.4).

Heavy-use energy consumption can be used by an operator to determine energy consumption during peak usage when selecting a soft-serve machine.

Production capacity can be used by an operator in selecting a soft-serve machine that meets their production requirements.

Impact draw is used to determine the peak rate at which servable quality product (as defined in 10.2.2) can be dispensed from a soft-serve machine.

Idle energy rate is a precise indicator of a soft serve machine’s energy performance under a stabilized ready-to-serve operating condition. This information enables the food service operator to consider energy performance when selecting soft-serve equipment.

Stand-by (night mode) energy rate is a precise indicator of a soft-serve or shake machine’s energy performance under a simulated overnight operating condition. This information enables the food service operator to consider energy performance when selecting soft-serve or shake equipment.

Heat Treat cycle energy consumption is a precise indicator of a soft serve or shake machine’s energy performance when operated in a heat treatment cycle. This information can be used by an operator to consider the energy requirement of using a heat treat cycle, if applicable.

SCOPE

1.1 This test method evaluates the energy consumption and performance of soft serve ice cream and shake machines. The food service operator can use this test to evaluate and select an appropriate soft serve or shake machine and understand its energy consumption and production capabilities.

1.2 This test method applies to the following types of soft serve and shake machines: (any of which may or may not have a reservoir for liquid mix). Included in these test methods are conventional and heat-treatment freezers. The unit may include separate refrigeration systems for the frozen product and fresh mix and may be either air-cooled or water-cooled.

1.3 The soft serve/shake machines will be tested for the following (where applicable):

1.3.1 Maximum power input, or maximum current draw,

1.3.2 Initial freeze-down energy consumption and duration,

1.3.3 Heavy-use energy consumption,

1.3.4 Production capacity,

1.3.5 Overrun,

1.3.6 Impact performance,

1.3.7 Idle energy rate, and

1.3.8 Heat treat cycle energy consumption (if applicable).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2795 − 11 AnAmerican National Standard

Standard Test Method for

Performance of Self-Contained Soft Serve and Shake

Machines

This standard is issued under the fixed designation F2795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Code of Federal Regulations:

21 CFR 135.110 Ice cream and frozen custard

1.1 This test method evaluates the energy consumption and

2.3 NSF/ANSI Standard:

performance of soft serve ice cream and shake machines. The

food service operator can use this test to evaluate and select an NSF/ANSI 6 Dispensing freezers

appropriate soft serve or shake machine and understand its

3. Terminology

energy consumption and production capabilities.

3.1 Definitions:

1.2 This test method applies to the following types of soft

3.1.1 air cooled unit, n—a unit which uses air passing over

serve and shake machines: (any of which may or may not have

a main condenser in the freezer cylinder refrigeration system.

a reservoir for liquid mix). Included in these test methods are

conventionalandheat-treatmentfreezers.Theunitmayinclude

3.1.2 combination unit, n—a unit employing two main

separate refrigeration systems for the frozen product and fresh

compressors and two main condensers with one or two

mix and may be either air-cooled or water-cooled.

condenser fan motors and two separate freezer doors (that is,

one for soft serve and another for shake), designed to dispense

1.3 The soft serve/shake machines will be tested for the

shake and soft serve product in the same footprint.

following (where applicable):

1.3.1 Maximum power input, or maximum current draw, 3.1.3 freeze-down energy, n—amount of energy consumed

1.3.2 Initial freeze-down energy consumption and duration,

(kWh) by the soft serve machine while cooling the product to

1.3.3 Heavy-use energy consumption, a servable temperature.

1.3.4 Production capacity,

3.1.4 freeze-down time, n—time required for the soft serve

1.3.5 Overrun,

machine while cooling the product to a servable temperature.

1.3.6 Impact performance,

3.1.5 heat treat–cool phase, n—portion of the heat treat

1.3.7 Idle energy rate, and

cycle which involves cooling the product from ≥150°F

1.3.8 Heat treat cycle energy consumption (if applicable).

(≥65°C) to ≤41°F (≤5°C) within a period of 120 min or less.

1.4 This standard does not purport to address all of the

3.1.6 heat treat–heat phase, n—portion of the heat treat

safety concerns, if any, associated with its use. It is the

cycle which involves elevating product temperature from

responsibility of the user of this standard to establish appro-

≤41°F (5°C) to ≥150°F (66°C) within a period of 90 min.

priate safety and health practices and determine the applica-

3.1.7 heat treat–hold phase, n—portion of the heat treat

bility of regulatory limitations prior to use.

cycle which involves holding the product above a ≥150°F

(≥66°C) for a period of at least 30 min.

2. Referenced Documents

3.1.8 heat-treatment freezers, n—as defined in Specification

2.1 ASTM Standards:

F1604, operate as conventional freezers and heat all product to

F1604 Specification for Freezers, Ice Cream, Soft Serve,

150°F (66°C) minimum for at least 30 min daily to destroy

Shake

undesirable microorganisms.

3.1.9 ice cream or ice-cream (originally, iced cream), n—a

frozen dessert made from dairy products, such as milk and

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

Productivity and Energy Protocol.

Current edition approved Dec. 1, 2011. Published November 2012. DOI:

10.1520/F2795-11. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.access.gpo.gov.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2795 − 11

cream, combined with flavorings and sweeteners, such as 4.2 Power input is determined to confirm that the soft serve

sugar, and possible other ingredients. (21 CFR 135.110) machine is operating below maximum nameplate power rating.

3.1.10 idle energy rate, n—the rate of energy consumed 4.3 The hopper and barrel are loaded with 35 6 1°F (1.5 6

(kWh) by the soft serve or shake machine while holding or

0.5°C) mix. The time and energy required to freeze down the

maintaining the product in a ready-to-serve state without product to an acceptable serving condition is monitored (as

dispensing product.

defined in 10.2.2).

3.1.11 interval, n—length of time for one operator to draw a

4.4 Minimum Dispensing Interval Determination (as de-

portion of product from a soft serve machine.

fined in 10.3).

3.1.12 mix, n—a fluid that contains 4 to 6 % butterfat and is

4.5 Heavy-Use Power Rating, Energy Consumption and

a vanilla flavor.

Production Capacity Test (as defined in 10.4).

3.1.13 overrun, n—the increase in volume due to incorpo-

4.6 Impact Draw Test (as defined in 10.5).

ration of air while freezing soft serve and shake products under

4.7 Ready-to-Serve Idle Test (as defined in 10.6).

agitation, calculated by this formula:

4.8 Standby (Night Mode) Idle Test (as defined in 10.7).

~Weight of liquid mix 2 Weight of frozen product!

Overrun 5 (1)

Weight of frozen product 4.9 Heat Treat Cycle Energy Consumption Test (if appli-

cable) (as defined in 10.8).

3.1.14 product, n—mix that is frozen under agitation to

specific temperature without syrup that is ready to serve.

5. Significance and Use

3.1.15 shake, n—asweet,coldbeveragewhichismadefrom

5.1 The freeze-down energy consumption and duration can

milk, ice cream, and flavorings or sweeteners such as fruit

beusedtodeterminetimeandenergyrequiredforamachineto

syrup or chocolate sauce.

be ready to serve when loaded with mix.

3.1.16 spout adaptor, n—a device which is attached to the

5.2 The minimum dispensing interval determination is used

freezer door spout to assist in the filling of sampling container.

to determine the rate at which the product will be dispensed

3.1.17 standby idle energy, n—the rate of energy consumed

during the Heavy-Use Energy Consumption and Production

(kWh) by the soft serve machine while holding or maintaining

Capacity Test (10.4).

the product ≤41°F (≤5°C) without dispensing product. Also

5.3 Heavy-use energy consumption can be used by an

referred to as night mode in NSF/ANSI 6.

operator to determine energy consumption during peak usage

3.1.18 test method, n—a definitive procedure for the

when selecting a soft-serve machine.

identification, measurement, and evaluation of one or more

qualities, characteristics, or properties of a material, product,

5.4 Production capacity can be used by an operator in

system, or service that produces test results. selecting a soft-serve machine that meets their production

requirements.

3.1.19 twin single spout freezer, n—a machine employing

either of the above configurations (Twin Twist machine “A” or

5.5 Impact draw is used to determine the peak rate at which

“B”) but with two single spout doors which can only dispense

servablequalityproduct(asdefinedin10.2.2)canbedispensed

from one Freezer Cylinder.

from a soft-serve machine.

3.1.20 twin twist freezer “A”, n—a machine using two main

5.6 Idle energy rate is a precise indicator of a soft serve

compressors and two main condensers with one or two

machine’s energy performance under a stabilized ready-to-

condenser fan motors and a freezer door (3 spout) which the

serve operating condition. This information enables the food

center spout draws from both freezer cylinders.

service operator to consider energy performance when select-

ing soft-serve equipment.

3.1.21 twin twist freezer “B”, n—a machine with single

main compressor, single main condenser fan motor, with a

5.7 Stand-by (night mode) energy rate is a precise indicator

freezer door (3 spout) which the center spout draws product

of a soft-serve or shake machine’s energy performance under a

from both freezer cylinders.

simulated overnight operating condition. This information

enables the food service operator to consider energy perfor-

3.1.22 uncertainty, n—a measure of systematic and preci-

sion errors in specified instrumentation or measure of repeat- mance when selecting soft-serve or shake equipment.

ability of a recorded test result.

5.8 Heat Treat cycle energy consumption is a precise

3.1.23 water cooled unit, n—a unit which uses water pass-

indicator of a soft serve or shake machine’s energy perfor-

ing through a twin tube condenser in the freezer cylinder mance when operated in a heat treatment cycle. This informa-

refrigeration system.

tion can be used by an operator to consider the energy

requirement of using a heat treat cycle, if applicable.

4. Summary of Test Method

6. Apparatus

4.1 This test method is designed to address machines which

have self contained refrigeration system(s) for the main freez- 6.1 Analytical Balance Scale, for measuring weights up to

ing cylinder(s) and may or may not contain a mix storage 25 lb (11.33 kg), with a resolution of 0.01 lb (0.004 kg) and an

system as part of the unit. uncertainty of 0.01 lb (0.004 kg).

F2795 − 11

6.2 Stop Watch, with at least 1-s resolution. 7.2 Small Container, for testing soft serve machines with

less than 10 gal/h (37.8 L/h) capacity.

6.3 Thermocouple Probe, calibrated industry standard type

T or type K thermocouples capable of immersion with a range 7.3 Medium Container, for testing soft serve machines with

of 0 to 250°F (–17.7 to 121°C) and an uncertainty of 61°F greater than 10 gal/h (37.8 L/h) capacity and shake machines

(60.6°C). rated ≤20 gal/h (≤75.7 L/h).

6.4 Watt-Hour Meter, for measuring the electrical energy 7.4 Large Container, for impact testing of shake machines

consumption, shall have a resolution of at least 10 Wh and a rated more than 20 gal/h (75.7 L/h).

maximum uncertainty no greater than 1.5 % of the measured

value for any demand greater than 100W. For any demand less 8. Sampling, Test Units

than 100 W, the meter shall have a resolution of at least 10 Wh

8.1 Soft Serve or Shake Machine—Select a representative

and a maximum uncertainty no greater than 10 %.

production model for performance testing.

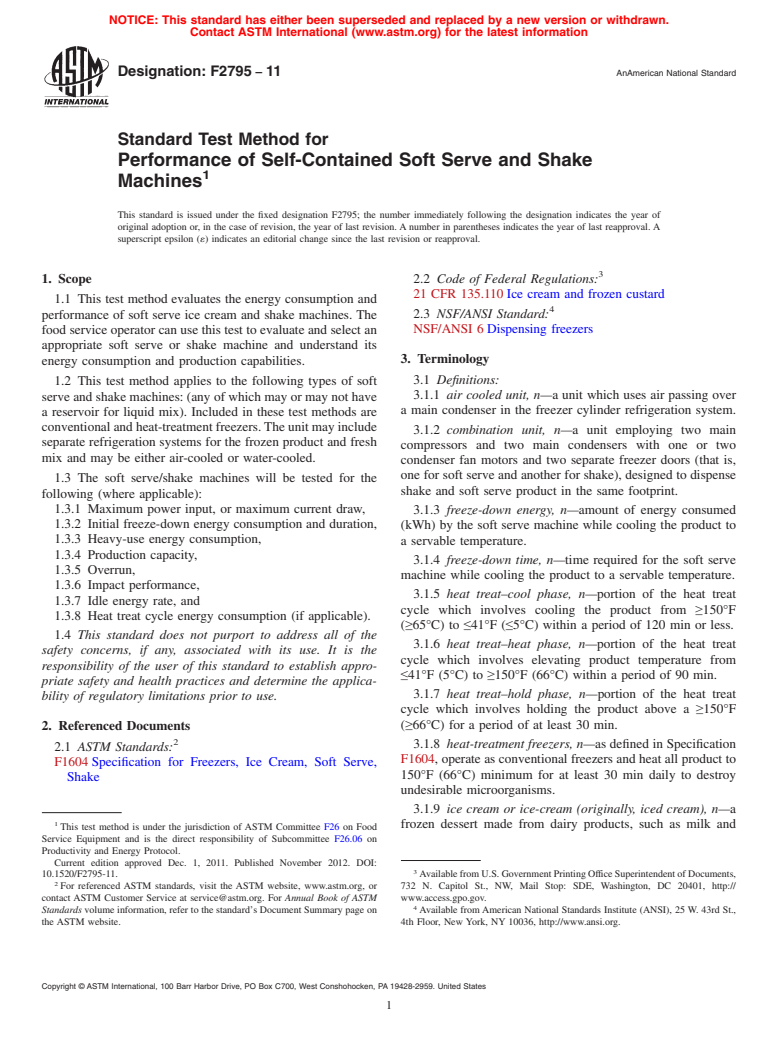

6.5 Spout Adapter, to facilitate measuring product tempera-

ture and filling container during the test which is made from an 9. Preparation of Apparatus

Acetal (POM) material and has a ID surface finish of 32√ .

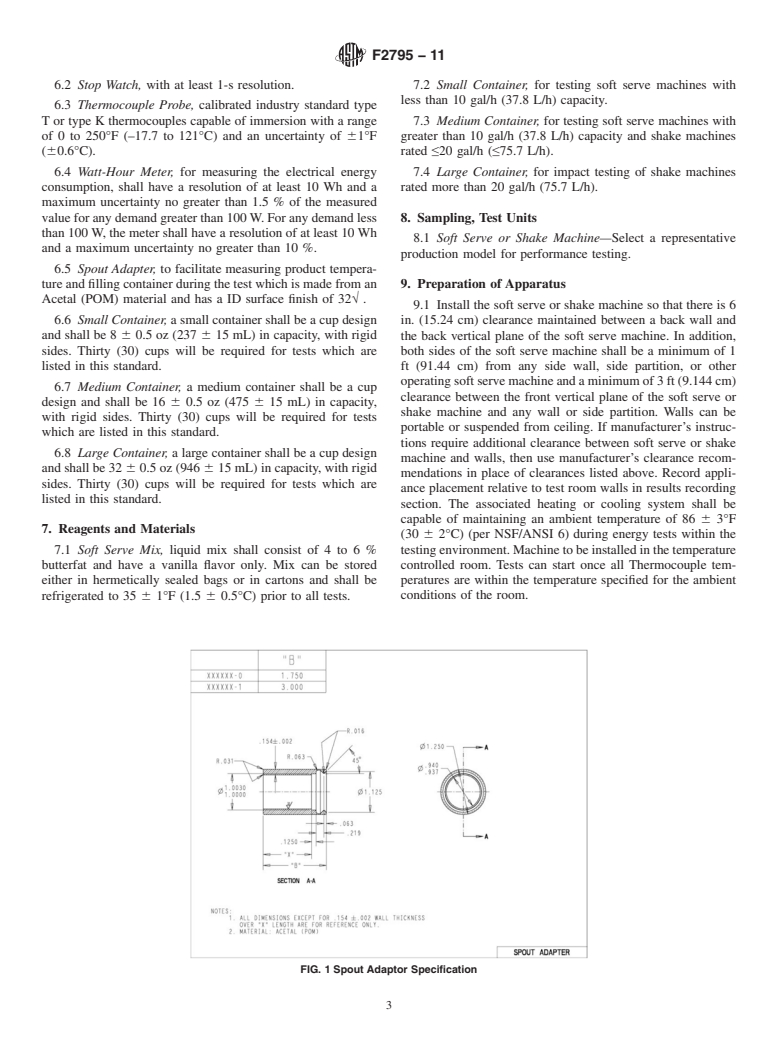

9.1 Install the soft serve or shake machine so that there is 6

6.6 Small Container, a small container shall be a cup design in. (15.24 cm) clearance maintained between a back wall and

and shall be 8 6 0.5 oz (237 6 15 mL) in capacity, with rigid

the back vertical plane of the soft serve machine. In addition,

sides. Thirty (30) cups will be required for tests which are both sides of the soft serve machine shall be a minimum of 1

listed in this standard.

ft (91.44 cm) from any side wall, side partition, or other

operatingsoftservemachineandaminimumof3ft(9.144cm)

6.7 Medium Container, a medium container shall be a cup

clearance between the front vertical plane of the soft serve or

design and shall be 16 6 0.5 oz (475 6 15 mL) in capacity,

shake machine and any wall or side partition. Walls can be

with rigid sides. Thirty (30) cups will be required for tests

portable or suspended from ceiling. If manufacturer’s instruc-

which are listed in this standard.

tions require additional clearance between soft serve or shake

6.8 Large Container, a large container shall be a cup design

machine and walls, then use manufacturer’s clearance recom-

and shall be 32 6 0.5 oz (946 6 15 mL) in capacity, with rigid

mendations in place of clearances listed above. Record appli-

sides. Thirty (30) cups will be required for tests which are

ance placement relative to test room walls in results recording

listed in this standard.

section. The associated heating or cooling system shall be

capable of maintaining an ambient temperature of 86 6 3°F

7. Reagents and Materials

(30 6 2°C) (per NSF/ANSI 6) during energy tests within the

7.1 Soft Serve Mix, liquid mix shall consist of 4 to 6 % testingenvironment.Machinetobeinstalledinthetemperature

butterfat and have a vanilla flavor only. Mix can be stored controlled room. Tests can start once all Thermocouple tem-

either in hermetically sealed bags or in cartons and shall be peratures are within the temperature specified for the ambient

refrigerated to 35 6 1°F (1.5 6 0.5°C) prior to all tests. conditions of the room.

FIG. 1 Spout Adaptor Specification

F2795 − 11

FIG. 2 Example of Appliance Placement

9.2 Connect the soft serve or shake machine to a Watt-Hour 10.1.1.2 Average air temperature over the complete test

meter. A voltage regulator may be required during tests if the period.

voltage supply is not within 62.5 % of the manufacturer’s

10.1.1.3 Average relative humidity over the complete test

nameplate voltage. period.

10.1.1.4 Water consumed (where applicable for water

9.3 Confirm (while the soft serve or shake machine com-

cooled machines).

pressor(s) is energized) that the supply voltage is within 62.5

10.1.1.5 Averageincomingwatertemperatureoverthecom-

% of the operating voltage specified by the manufacturer.

plete test period (where applicable for water cooled machines).

Record the test voltage for each test.

10.1.1.6 Average exit water temperature over the complete

NOTE 1—The purpose of the testing procedure is to evaluate the

performance of a soft serve or shake machine at its rated electric voltage.

test period (where applicable for water cooled machines).

If a soft serve or shake machine is rated dual voltage (that is, designed to

10.1.1.7 Temperature of mix.

operate at either 208 or 240Vwith no change in components), the voltage

10.1.1.8 Temperature of dispensed product.

selected by the manufacturer or tester, or both, shall be recorded. The

performance of a dual voltage soft serve or shake machine may differ at 10.1.1.9 Weight of frozen product in the cup, when appli-

the two voltages.

cable.

9.4 To facilitate monitoring product temperature during 10.1.2 For ea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.