ASTM D7402-09

(Practice)Standard Practice for Identifying Cationic Emulsified Asphalts

Standard Practice for Identifying Cationic Emulsified Asphalts

SIGNIFICANCE AND USE

Cationic emulsified asphalts are identified by the migration of the particles to a negatively charged electrode (cathode) by means of a direct current. Aggregates and sands used in conjunction with emulsified asphalts are often predominantly either negatively or positively charged. Emulsified asphalts should be selected to be compatible with the available aggregate or sand. This practice will aid in identifying a cationic type of emulsified asphalt as defined by Specification D 2397.

SCOPE

1.1 This practice is used to identify cationic emulsified asphalts. Positively charged particles are classified as cationic. Emulsified asphalts that don’t register a positive charge may also be classified as cotionic slow-setting if they coat a specific type of negatively charged silica sand.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7402 −09

Standard Practice for

Identifying Cationic Emulsified Asphalts

This standard is issued under the fixed designation D7402; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope gateorsand.Thispracticewillaidinidentifyingacationictype

of emulsified asphalt as defined by Specification D2397.

1.1 This practice is used to identify cationic emulsified

asphalts. Positively charged particles are classified as cationic.

4. Sample Conditioning for Testing

Emulsified asphalts that don’t register a positive charge may

4.1 All emulsified asphalts shall be properly stirred to

also be classified as cotionic slow-setting if they coat a specific

achieve homogeneity before testing.

type of negatively charged silica sand.

4.2 All emulsified asphalts with viscosity testing require-

1.2 The values stated in SI units are to be regarded as

ments of 50°C shall be heated to 50 6 3°C in the original

standard. No other units of measurement are included in this

sample container in a water bath or oven.The container should

standard.

be vented to relieve pressure. After the sample reaches 50 6

1.3 This standard does not purport to address all of the

3°C, stir the sample to achieve homogeneity.

safety concerns, if any, associated with its use. It is the

4.3 Emulsified asphalts with viscosity testing requirements

responsibility of the user of this standard to establish appro-

of 25°C should be mixed or stirred at 25 6 3°C in the original

priate safety and health practices and determine the applica-

sample container to achieve homogeneity.

bility of regulatory limitations prior to use.

NOTE 1—Emulsified asphalts with viscosity testing requirements of

1.4 This international standard was developed in accor-

25°C may be heated and stirred as specified in 4.2 if necessary. In the

dance with internationally recognized principles on standard-

event the 4.2 method is used, the sample should be cooled to 25 6 3°C

ization established in the Decision on Principles for the

before testing.

Development of International Standards, Guides and Recom-

METHOD A

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Apparatus

2. Referenced Documents

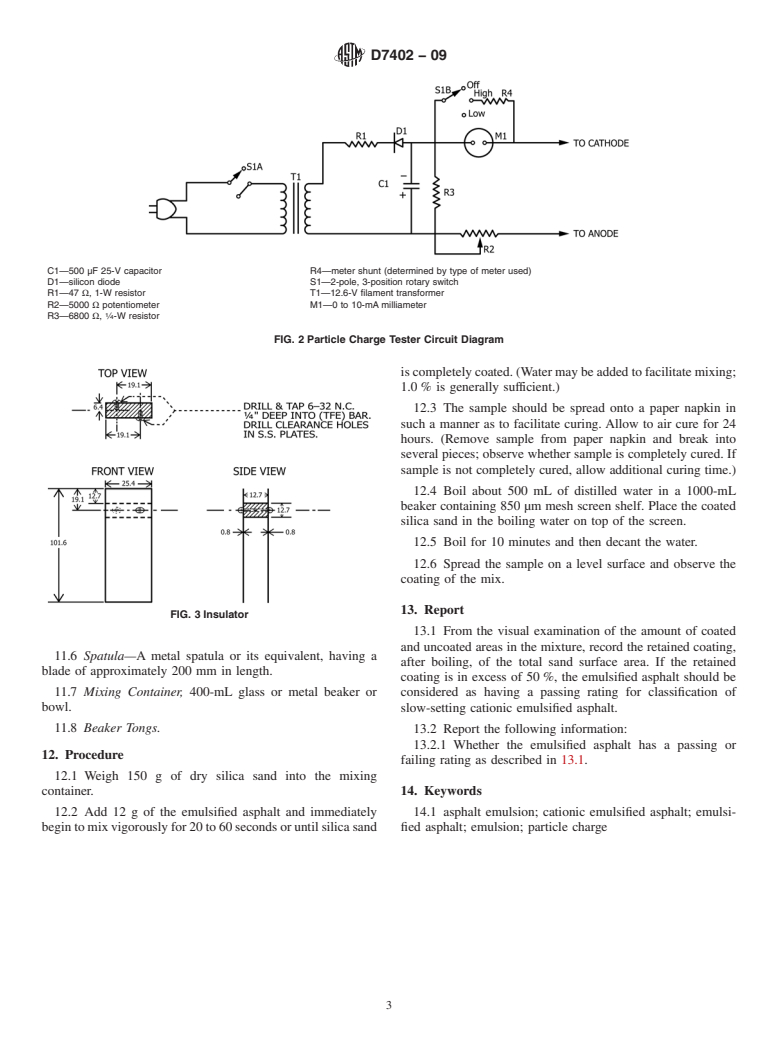

5.1 Current Source, of 12-V DC, a milliammeter, and a

2.1 ASTM Standards: variable resistor (see Figs. 1 and 2).

C778 Specification for Standard Sand

5.2 Electrodes—Two stainless steel plates, approximately

D2397 Specification for Cationic Emulsified Asphalt

25 mm by 100 mm insulated from each other and rigidly held

E1 Specification for ASTM Liquid-in-Glass Thermometers

parallel 12.5 6 0.5 mm apart (see Fig. 3).

5.3 Insulator—Polytetrafluoroethylene resin square rod, vir-

3. Significance and Use

gin electrical grade, 12.5 6 0.5 mm thick (see Fig. 3)

3.1 Cationic emulsified asphalts are identified by the migra-

5.4 Glass Beaker, 250 mL.

tion of the particles to a negatively charged electrode (cathode)

by means of a direct current. Aggregates and sands used in

5.5 GlassRod, approximately 100 mm long and 6 mm thick

conjunction with emulsified asphalts are often predominantly

or other suitable material or device that is capable of insulating

either negatively or positively charged. Emulsified asphalts

and suspending the electrode assembly in emulsified asphalt.

should be selected to be compatible with the available aggre-

5.6 Water Bath, capable of maintaining the required testing

temperature within the limits specified in this test method.

This practice is under the jurisdiction of ASTM Committee D04 on Road and

5.7 Thermometer, ASTM 19C or 19F conforming to the

Paving Materials and is the direct responsibility of Subcommittee D04.42 on

requirements of Specification E1 or equivalent thermometric

Emulsified Asphalt Test.

device.

Current edition approved June 1, 2009. Published July 2009. DOI: 10.1520/

D7402-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Hazards

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Warning—Mercury has been designated by the United

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. States Environmental ProtectionAgency (EPA) and many state

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7402−09

7.6 Observe the asphalt deposit on the electrodes.Acationic

emulsified asphalt will deposit a discernible amount of asphalt

on the cathode (negative electrode) while the anode (positive

electrode)willberelativelyclean.Anyevidenceofadepositof

asphalt on the cathode which is clearly discernible when

compared to the anode is to be considered passing.

8. Report

8.1 Report the following information:

8.1.1 Level of current used, and

8.1.2 Whether the tested emulsified asphalt passes or is

non-conclusive as defined in 7.6.

8.2 If the emulsified asphalt does not produce conclusive

results using Method A and it is purported to be a cationic

slow–setting grade, then proceed with Method B shown below

for Identification of Cationic Slow–Set Emulsified Asphalt

FIG. 1Particle Charge Tester

METHOD B

9. Summary of Practice

agencies as a hazardous material that can cause central nervous

system,kidneyandliverdamage.Mercury,oritsvapor,maybe 9.1 A weighed amount of washed and dried silica sand is

hazardous to health and corrosive to materials. Caution should hand mixed with a weighed amount of emulsified asphalt.

be taken when handling mercury and mercury containing Mixing time should extend until aggregate is completely

coated. The amount of Cationic Slow-Setting grade emulsified

products. See the applicable product Material Safety Data

Sheet (MSDS) for details and EPA’s website (www.epa.gov/ asphalt in the mix should give a total mix asphalt content of

about 5.0 %. The sample is spread out and allowed to air cure

mercury/faq.htm) for additional information. Users should be

aware that selling mercury and/or mercury containing products for 24 h. The retained coating, after boiling, is determined.

into your state may be prohibited by state law.

10. Significance and Use

7. Procedure

10.1 The conditions of the practice are designed to i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.