ASTM B390-92(1996)e1

(Practice)Standard Practice for Evaluating Apparent Grain Size and Distribution of Cemented Tungsten Carbides

Standard Practice for Evaluating Apparent Grain Size and Distribution of Cemented Tungsten Carbides

SCOPE

1.1 This procedure for the visual comparison and classification of the apparent grain size and distribution of cemented tungsten carbides is limited to cemented tungsten carbides that contain approximately 6, 10, and 18% cobalt.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: B 390 – 92 (Reapproved 1996)

Standard Practice for

Evaluating Apparent Grain Size and Distribution of

Cemented Tungsten Carbides

This standard is issued under the fixed designation B 390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Additional keywords were added editorially in September 1996.

1. Scope developing their own specifications.

1.1 This procedure for the visual comparison and classifi-

5. Specimen Preparation

cation of the apparent grain size and distribution of cemented

5.1 Specimens shall be prepared for metallographic exami-

tungsten carbides is limited to cemented tungsten carbides that

nation in accordance with a procedure suitable for this type of

contain approximately 6, 10, and 18 % cobalt.

cemented carbides.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

NOTE 1—A suitable procedure is described in Method B 657 and

responsibility of the user of this standard to establish appro- Practice B 665.

priate safety and health practices and determine the applica-

6. Procedure

bility of regulatory limitations prior to use.

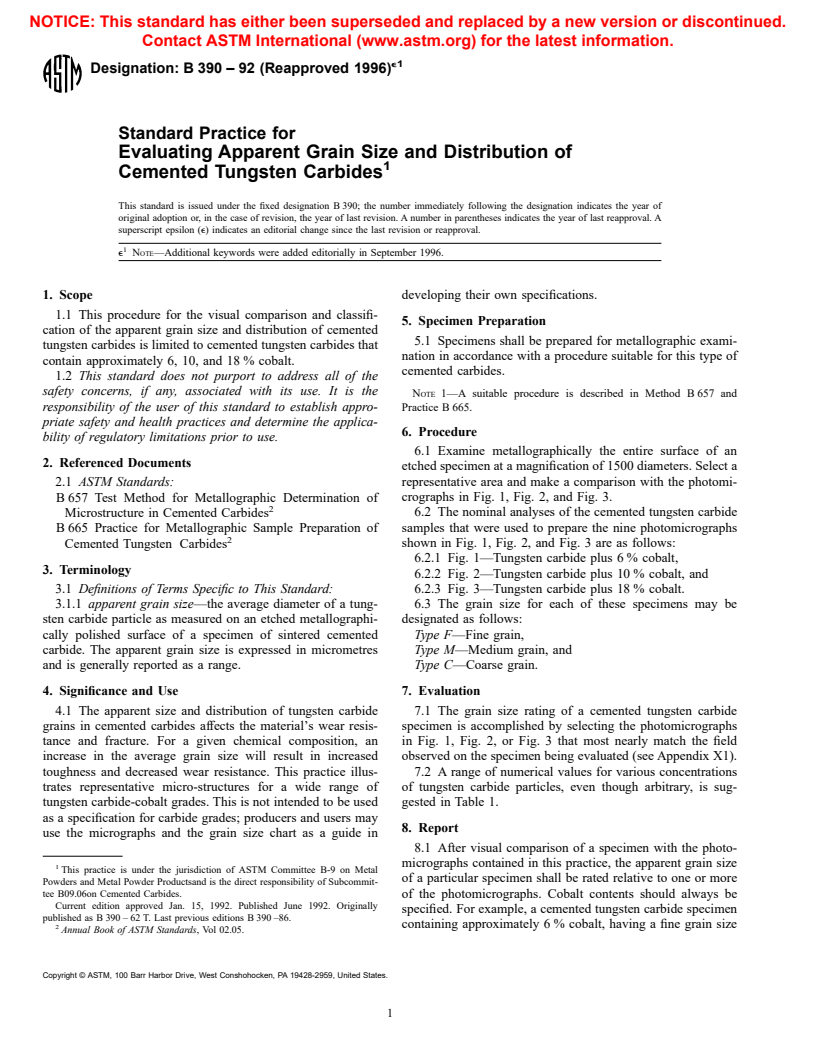

6.1 Examine metallographically the entire surface of an

2. Referenced Documents

etched specimen at a magnification of 1500 diameters. Select a

2.1 ASTM Standards: representative area and make a comparison with the photomi-

crographs in Fig. 1, Fig. 2, and Fig. 3.

B 657 Test Method for Metallographic Determination of

Microstructure in Cemented Carbides 6.2 The nominal analyses of the cemented tungsten carbide

samples that were used to prepare the nine photomicrographs

B 665 Practice for Metallographic Sample Preparation of

Cemented Tungsten Carbides shown in Fig. 1, Fig. 2, and Fig. 3 are as follows:

6.2.1 Fig. 1—Tungsten carbide plus 6 % cobalt,

3. Terminology

6.2.2 Fig. 2—Tungsten carbide plus 10 % cobalt, and

3.1 Definitions of Terms Specific to This Standard: 6.2.3 Fig. 3—Tungsten carbide plus 18 % cobalt.

3.1.1 apparent grain size—the average diameter of a tung- 6.3 The grain size for each of these specimens may be

sten carbide particle as measured on an etched metallographi- designated as follows:

cally polished surface of a specimen of sintered cemented Type F—Fine grain,

carbide. The apparent grain size is expressed in micrometres Type M—Medium grain, and

and is generally reported as a range. Type C—Coarse grain.

4. Significance and Use 7. Evaluation

4.1 The apparent size and distribution of tungsten carbide 7.1 The grain size rating of a cemented tungsten carbide

grains in cemented carbides affects the material’s wear resis- specimen is accomplished by selecting the photomicrographs

tance and fracture. For a given chemical composition, an in Fig. 1, Fig. 2, or Fig. 3 that most nearly match the field

increase in the average grain size will result in increased observed on the specimen being evaluated (see Appendix X1).

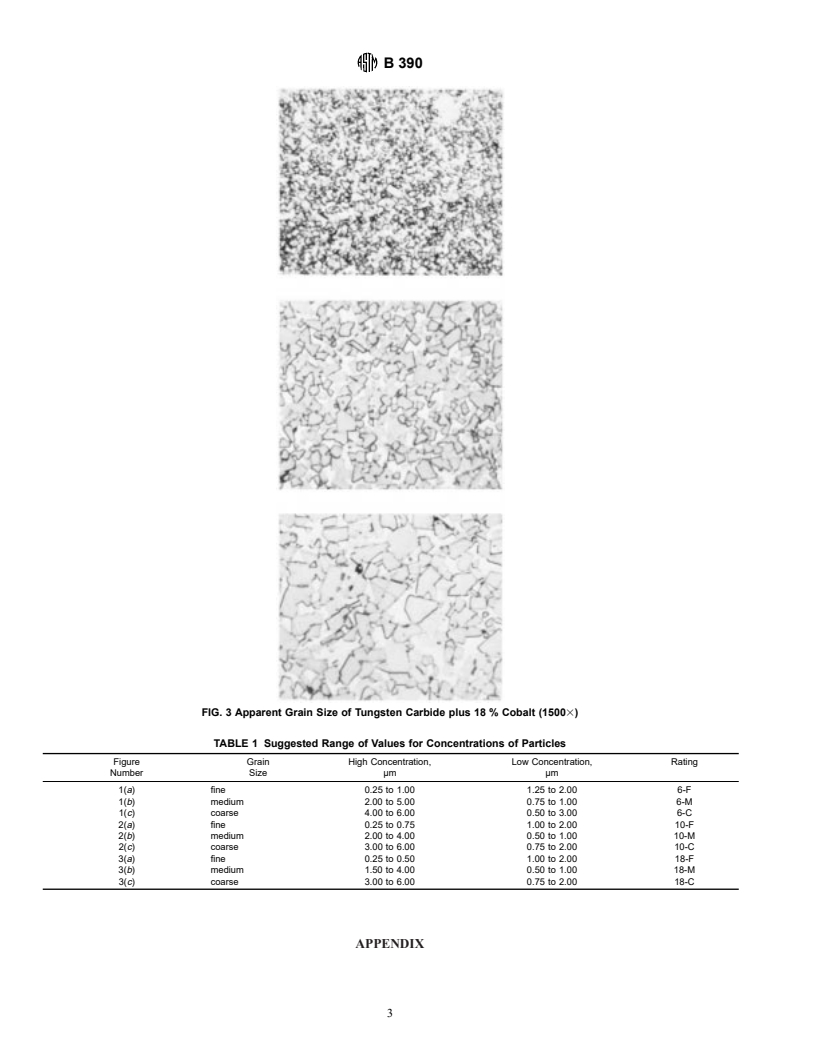

toughness and decreased wear resistance. This practice illus- 7.2 A range of numerical values for various concentrations

trates representative micro-structures for a wide range of of tungsten carbide particles, even though arbitrary, is sug-

tungsten carbide-cobalt grades. This is not intended to be used gested in Table 1.

as a specification for carbide grades; producers and users may

8. Report

use the micrographs and the grain size chart as a guide in

8.1 After visual comparison of a specimen with the photo-

micrographs contained in thi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.