ASTM E878-96

(Test Method)Standard Test Method for Determination of Titanium in Iron Ores and Related Materials by Diantipyrylmethane Untraviolet Spectrometry

Standard Test Method for Determination of Titanium in Iron Ores and Related Materials by Diantipyrylmethane Untraviolet Spectrometry

SCOPE

1.1 This test method covers the determination of titanium in iron ores, concentrates, and agglomerates in the concentration range from 0.01 to 6.0% titanium.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 878 – 96

Standard Test Method for

Determination of Titanium in Iron Ores and Related

Materials by Diantipyrylmethane Ultraviolet Spectrometry

This standard is issued under the fixed designation E 878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Interferences

1.1 This test method covers the determination of titanium in 5.1 None of the elements normally found in iron ores

iron ores, concentrates, and agglomerates in the concentration interfere.

range from 0.01 to 6.0 % titanium.

6. Reagents

1.2 This standard does not purport to address all of the

6.1 Purity of Reagents—Reagent grade chemicals shall be

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- used in all tests. Unless otherwise indicated, it is intended that

all reagents conform to the specifications of the Committee on

priate safety and health practices and determine the applica-

Analytical Reagents of the American Chemical Society where

bility of regulatory limitations prior to use.

such specifications are available. Other grades may be used,

2. Referenced Documents

provided it is first ascertained that the reagent is of sufficient

2.1 ASTM Standards: high purity to permit its use without lessening the accuracy of

D 1193 Specification for Reagent Water the determination.

E 877 Practice for Sampling and Sample Preparation of Iron 6.2 Purity of Water—Unless otherwise indicated, references

Ores to water shall be understood to mean reagent water as defined

E 882 Guide for Accountability and Quality Control in the by Type I of Specification D 1193.

Chemical Analysis Laboratory 6.3 Ascorbic Acid Solution (10 g/100 mL) (C H O )—

6 8 6

Dissolve 10 g of ascorbic acid (C H O ) in water and dilute to

6 8 6

3. Summary of Test Method

100 mL. Prepare fresh as needed.

3.1 The sample is decomposed by treatment with hydro-

6.4 Diantipyrylmethane Solution (15 g/L) C H O N ·

23 24 2 4

chloric, nitric, and sulfuric acids, or by sintering with sodium H O—Dissolve 15 g of the reagent in about 300 mL of water

peroxide, or by fusion with sodium tetraborate and sodium

and 30 mL of (H SO ) (1 + 1) (7.10) and dilute to 1 L with

2 4

carbonate. Iron is reduced in an acid medium with ascorbic water. If a residue remains, filter and store the filtrate in a

acid, the color is developed with diantipyrylmethane, and the

brown bottle.

absorbance is measured at approximately 385 nm. 6.5 Ferric Ammonium Sulfate (100 g/L)—Dissolve 100 g of

ferric ammonium sulfate (Fe (SO ) ·(NH ) SO in 800 mL of

2 4 3 4 2 4

4. Significance and Use

water containing 5 mL of H SO (1 + 1) (6.11) and dilute to 1

2 4

4.1 This test method is intended to be used for compliance

L with water.

with compositional specifications for titanium content. It is

6.6 Hydrochloric Acid (1 + 1)—Mix 1 volume of concen-

assumed that all who use these procedures will be trained

trated hydrochloric acid (HCl) with 1 volume of water.

analysts capable of performing common laboratory procedures

6.7 Hydrochloric Acid (1 + 4)—Mix 1 volume HCl with 4

skillfully and safely. It is expected that work will be performed

volumes of water.

in a properly equipped laboratory and that proper waste

6.8 Potassium Pyrosulfate (K S O ).

2 2 7

disposal procedures will be followed. Appropriate quality

6.9 Sodium Tetraborate (Anhydrous) (Na B O )—Dry the

2 4 7

control practices must be followed such as those described in

commercial sodium tetraborate at 60 to 70°C, then at 160°C,

Guide E 882.

and finally calcine at 400°C.

6.10 Sodium Tetraborate/Sodium Carbonate (Na B O /

2 4 7

Na CO ) Fusion Mixture— Mix 1 part of Na B O and 1 part

2 3 2 4 7

This test method is under the jurisdiction of ASTM Committee E-1 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.02 on Ores, Slags, Refractories, Cement, and

Reagent Chemicals, American Chemical Society Specifications, American

Related Oxide Materials. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Current edition approved April 10, 1996. Published June 1996. Originally listed by the American Chemical Society, see Analar Standards for Laboratory

published as E 878 – 82. Last previous edition E 878 – 95. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Annual Book of ASTM Standards, Vol 11.01. and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

Annual Book of ASTM Standards, Vol 03.06. MD.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 878

of Na CO and store in an airtight container.

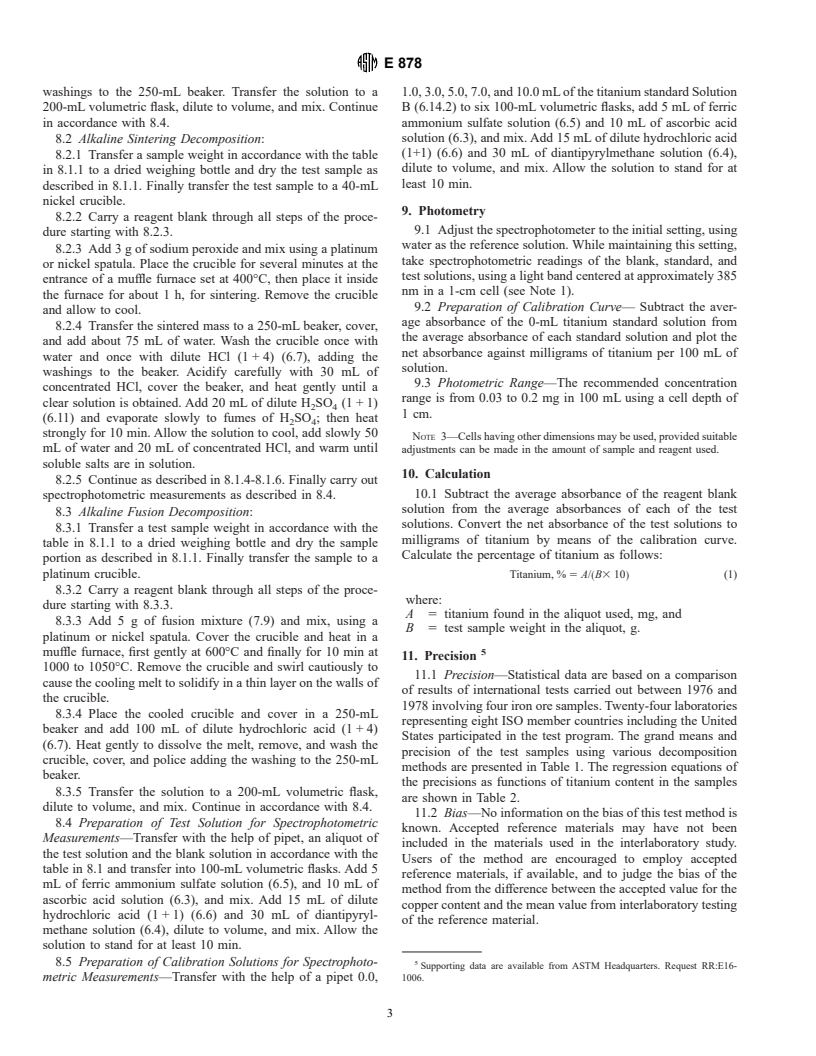

Amount of

2 3

sulfuric acid

6.11 Sulfuric Acid (1 + 1)—Carefully pour 1 volume of

Weight of test to be added Aliquot,

concentrated sulfuric acid (H SO ) into 1 volume of water.

Ti content, % portion, g in 9.1, mL mL

2 4

6.12 Sulfuric Acid (1 + 9)—Carefully pour 1 volume of

0.01–0.1 1.0 20 20

H SO into 9 volumes of water.

2 4 0.1–0.3 1.0 20 10

0.3–1.0 0.5 10 5

6.13 Sulfuric Acid (2 + 98)—Carefully pour 2 volumes of

1.0–6.0 0.1 10 5

H SO into 98 volumes of water.

2 4

Dry the bottle and contents for1hat105 to 110°C. Cap the

6.14 Standard Titanium Solution:

bottle and cool to room temperature in a desiccator. Momen-

6.14.1 Solution A (1 mL 5 0.1 mg Ti)—Transfer 0.1670 g

tarily release the cap to equalize the pressure and weigh the

of TiO (previously calcined at 900°C) to a platinum crucible,

capped bottle and sample to the nearest 0.1 mg. Repeat the

add3to4gofK S O , cover, and fuse at a temperature of

2 2 7

drying and weighing until there is no further weight loss.

600°C until a clear melt is obtained. Place the cooled crucible

Transfer the test sample to a 250-mL beaker and reweigh the

and cover in a 250-mL beaker, add 50 to 60 mL of H SO

2 4

capped bottle to the nearest 0.1 mg. The difference between the

(1 + 9) (6.12), and heat to dissolve the melt. Wash crucible and

two weights is the weight of the test sample taken for analysis.

cover with H SO (1 + 9) (6.12) and remove, adding the

2 4

8.1.2 Carry a reagent blank through all steps of the proce-

washings to the 250-mL beaker. Transfer the solution of a 1-L

dure, starting with 8.1.3.

volumetric flask, dilute to volume with H SO (1 + 9) (6.12),

2 4

8.1.3 Decomposition of Sample—Moisten the test sample

and mix.

with a few millilitres of water, add 30 mL of hydrochloric acid,

6.14.2 Solution B (1 mL 5 0.02 mg Ti)—Transfer 50.0 mL

cover, and digest below the boiling point until no further attack

of standard titanium Solution A to a 250-mL volumetric flask,

is apparent. Add 5 mL of nitric acid and 10 to 20 mL of sulfuric

dilute to volume with H SO (1 + 9) (6.12), and mix.

2 4

acid (see amounts specified in 8.1.1) evaporate slowly to fumes

of H SO , then heat strongly for 10 min. Allow the solution to

2 4

7. Sampling and Sample Preparation

cool, add slowly 50 mL of water and 20 mL of hydrochloric

7.1 Sampling—The gross sample shall be collected and acid, and warm until soluble salts are in solution.

prepared in accordance with Practice E 877.

8.1.4 Filter on a fine-textured filter paper and collect the

7.2 Sample Preparation—Pulverize the laboratory sample filtrate in a 250-mL beaker. Transfer the residue quantitatively

to the filter paper and wash it two or three times with hot dilute

to pass a No. 100 (150-m) sieve.

sulfuric acid (2+98) (6.13) and two or three times with hot

NOTE 1—To facilitate decomposition, some ores such as specular

water. Reserve the filtrate.

hematite require grinding to pass a No. 200 (75-μm) sieve.

8.1.5 Treatment of Insoluble Matter— Ignite the paper and

residue in a platinum crucible. Cool, moisten with several

8. Procedure

drops of water, add 3 or 4 drops of dilute sulfuric acid (1+1)

NOTE 2—If the procedure is based on acid decomposition, use steps in

(6.11) and 10 mL of hydrofluoric acid. Evaporate slowly to

8.1. If the procedure is based on alkaline sintering, use steps in 8.2. If the

expel silica and excess of sulfuric acid. Cool, add to the residue

procedure is based on alkaline fusion, use steps in 8.3.

about2gof potassium pyrosulfate, cover the crucible, and fuse

8.1 Acid Decomposition:

over a burner (approximately 500°C) until a clear melt is

obtained.

8.1.1 Weigh approximately the amount of the test sample

specified in the table

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.