ASTM F2917-12(2018)

(Specification)Standard Specification for Bicycle Trailer Cycles Designed for Human Passengers

Standard Specification for Bicycle Trailer Cycles Designed for Human Passengers

ABSTRACT

This specification covers trailer cycles, intended to be pulled behind bicycles, with seat post attachment, for transporting children. It includes test methods for confirming that this specification is satisfied.

SCOPE

1.1 This specification covers trailer cycles, intended to be pulled behind bicycles, with seat post attachment, in order to transport children. It includes test methods for confirming that this specification is satisfied.

1.2 The values stated in SI units are to be regarded as the standard. The units given in parentheses are for information only.

1.3 The following safety caveat applies to the chemical, mechanical, or physical, or a combination thereof, test methods described herein and is meant specifically for those performing the tests (in an effort to provide them with notice to take the appropriate precautions when conducting the tests). This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2917 −12 (Reapproved 2018) An American National Standard

Standard Specification for

Bicycle Trailer Cycles Designed for Human Passengers

This standard is issued under the fixed designation F2917; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of Nonmetallic Materials (Withdrawn 2000)

2.2 ANSI Standards:

1.1 This specification covers trailer cycles, intended to be

ANSI Z535.4 Product Safety Signs and Labels

pulled behind bicycles, with seat post attachment, in order to

ANSI Z535.6 Product Safety Information in Product

transport children. It includes test methods for confirming that

Manuals, Instructions, and Other Collateral Materials

this specification is satisfied.

2.3 Federal Standards:

1.2 The values stated in SI units are to be regarded as the

Title 16, CFR 1303 Lead in Coatings

standard. The units given in parentheses are for information

Title 16, CFR 1500.3(b)(4)(i) Hazardous Substance

only.

Title 16, CFR 1500.48 Sharp Points

1.3 The following safety caveat applies to the chemical,

Title 16, CFR 1500.49 Sharp Edges

mechanical, or physical, or a combination thereof, test meth-

Title 16, CFR 1501 Small Parts

ods described herein and is meant specifically for those

Title 16, CFR 1512 Requirements for Bicycles, Sections:

performing the tests (in an effort to provide them with notice to

1512.18(n), Reflector Test

take the appropriate precautions when conducting the tests).

This standard does not purport to address all of the safety

3. Terminology

concerns, if any, associated with its use. It is the responsibility

3.1 Definitions of Terms Specific to This Standard:

of the user of this standard to establish appropriate safety,

3.1.1 lead bicycle—the bicycle used to tow the trailer cycle.

health, and environmental practices and determine the appli-

3.1.2 normal use—applications described as intended use

cability of regulatory limitations prior to use.

for the product found within the manufacturer’s instructional

1.4 This international standard was developed in accor-

literature.

dance with internationally recognized principles on standard-

3.1.3 normal use temperatures—temperature range within

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- whichitshouldbeanticipatedthatthetrailercyclemaybeused

mendations issued by the World Trade Organization Technical to transport children. The range is from –7 to +50°C (62°).

Barriers to Trade (TBT) Committee.

3.1.4 occupant—a child or person who is riding the trailer

cycle.

2. Referenced Documents

3.1.5 rider—apersonwhocontrolstheleadbicycletowhich

2.1 ASTM Standards:

the trailer cycle is attached, and who is responsible for control

B117 Practice for Operating Salt Spray (Fog) Apparatus

of the trailer cycle.

D1230 Test Method for Flammability of Apparel Textiles

3.1.6 trailer cycle—a transporting device, with a single rear

D4329 Practice for Fluorescent Ultraviolet (UV) Lamp Ap-

wheel, designed to provide a tandem bicycle riding experience

paratus Exposure of Plastics

for one or two children. The device includes the fastening

F2043 Classification for Bicycle Usage

arrangements for attaching and towing it behind a lead bicycle.

G23 Practice for Operating Light-Exposure Apparatus

(Carbon-Arc Type) With and Without Water for Exposure 3.1.7 useful product lifecycle—allowable range of time for

continued use of a product from the date of manufacture as

described within the manufacturer’s instructional literature.

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.10 on Bicycles.

Current edition approved April 1, 2018. Published May 2018. Originally The last approved version of this historical standard is referenced on

approved in 2011. Last previous edition approved in 2012 as F2917 – 12. DOI: www.astm.org.

10.1520/F2917-12R18. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2917−12 (2018)

4. Requirements 5. Test Methods

5.1 Test Order—Perform the lean angle test first, then

4.1 General—Trailer cycles shall be designed and manufac-

torsion fatigue test, and then the bump fatigue test on the same

tured such that components with which an occupant may come

sample.

in contact do not cause injury when used in accordance with

the manufacturer’s instructions. Exposed surfaces shall be free

5.2 Lean Angle Test:

from burrs, sharp edges, and points. Refer to Title 16, CFR

5.2.1 With the trailer cycle attached to a dummy lead bike

1500, Parts 48 and 49, and Title 16, CFR 1501. Trailer cycles

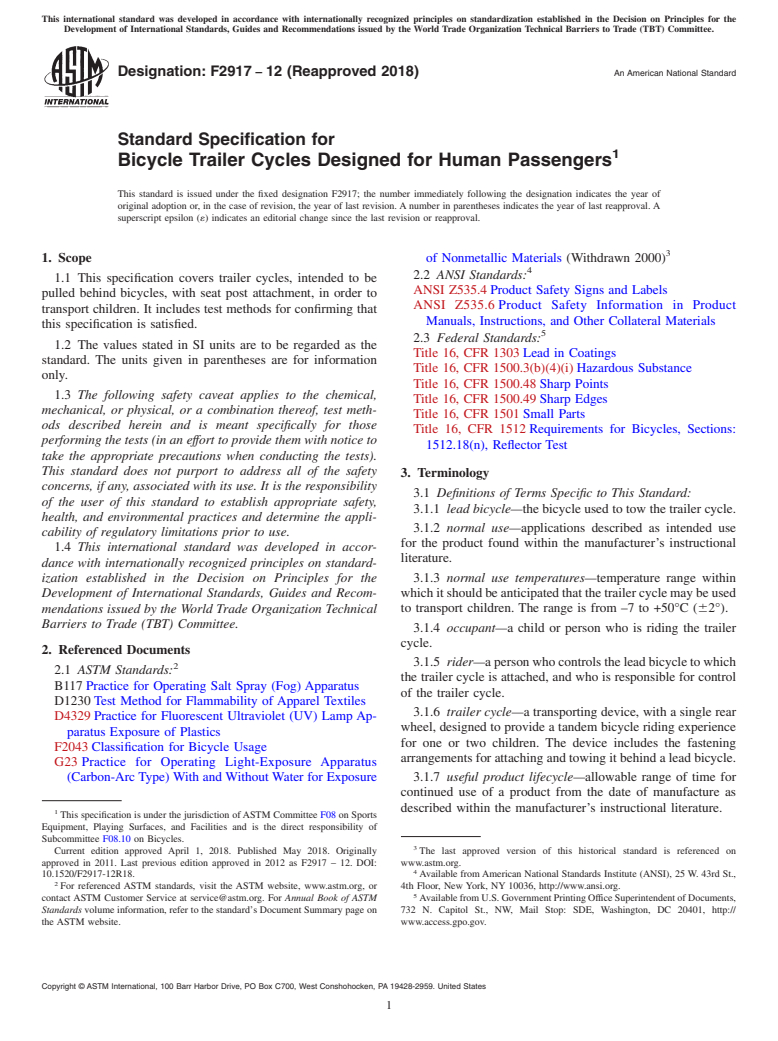

simulated by a post mounted to a hinge on the floor as in Fig.

shall be equipped with rear reflectors; pedal reflectors; side

1, lean the lead bicycle 25° in each direction.

reflectors on the wheel. Refer to Title 16, CFR 1512, Parts 16

5.2.2 Ensurethetrailercyclepedals,withthefootsurfaceof

and 18(n).

the pedal horizontal and the pedal crank in its lowest position,

do not hit the ground.

4.2 Equipment—Trailer cycles shall be equipped with the

following equipment: handlebar, seat, pedals, and a drivetrain 5.3 Torsion Fatigue Test—The trailer cycle shall be

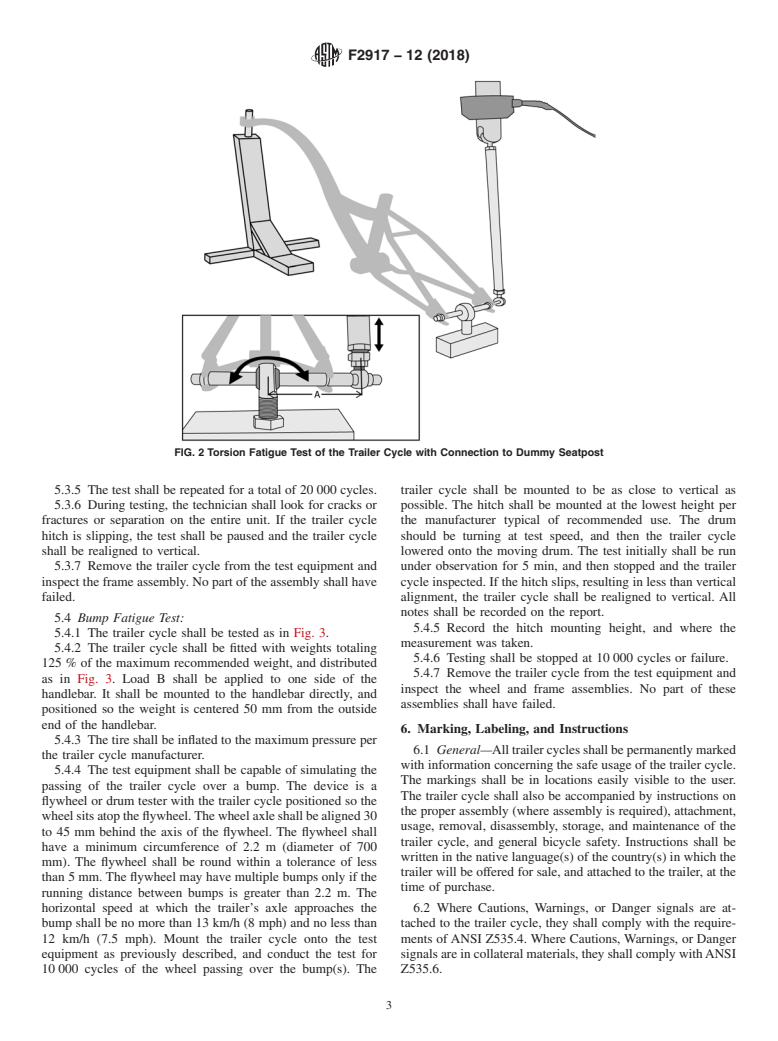

mounted for fatigue testing as in Fig. 2.

to provide human power to the rear wheel. The seatpost shall

have a minimum insertion marking as defined in Title 16, CFR

5.3.1 The trailer cycle wheel is removed.

1512.

5.3.2 A fixture is created to apply a displacement load

perpendicular to the ground and perpendicular to the centerline

4.3 Materials:

of the trailer cycle, through the rear wheel dropouts.

4.3.1 All nonmetallic materials that compose structural

5.3.3 The trailer cycle shall be mounted vertically to a

components will be subjected to either (1) 100 h of accelerated

rigidly mounted dummy seatpost set at 71 6 2° from horizon-

weathering in accordance with Method 1 of Practice G23,or

tal at the minimum height recommended by the manufacturer.

(2) 60 h of accelerated weathering in accordance with Practice

5.3.4 A fully reversing torsion load shall be applied to the

D4329 prior to any testing.

trailer cycle calculated as follows:

4.3.2 All painted materials shall comply with Title 16, CFR

Torsion Load ~Nm!5 (1)

1303.

4.3.3 Mechanical properties of materials used in the con- 137 Nm/31.75 kg 3

~ !

struction of trailer cycles shall not fail as a result of exposure

maximum recommended occupant weight for trailer cycle in kg

~ !

to the temperature variances defined as normal use tempera-

tures in 3.1.6 under normal use applications or within useful

For example: If the max rider weight is 50 kg, the torsion

product lifecycle.

load would be 215 Nm, which means if your torsion arm

4.3.4 Materials known to be a hazardous substance, as (labeledasAinFig.2)is0.35m,theforceneededtobeapplied

defined in Title 16, CFR 1500.3(b)(4)(i), shall not be used. to the end of the arm would be 614 N (62.6 kg).

FIG. 1Lean Angle Test Fixture

F2917−12 (2018)

FIG. 2Torsion Fatigue Test of the Trailer Cycle with Connection to Dummy Seatpost

5.3.5 The test shall be repeated for a total of 20 000 cycles. trailer cycle shall be mounted to be as close to vertical as

5.3.6 During testing, the technician shall look for cracks or possible. The hitch shall be mounted at the lowest height per

fractures or separation on the entire unit. If the trailer cycle the manufacturer typical of recommended use. The drum

hitch is slipping, the test shall be paused and the trailer cycle should be turning at test speed, and then the trailer cycle

shall be realigned to vertical. lowered onto the moving drum. The test initially shall be run

5.3.7 Remove the trailer cycle from the test equipment and under observation for 5 min, and then stopped and the trailer

inspect the frame assembly. No part of the assembly shall have cycle inspected. If the hitch slips, resulting in less than vertical

failed. alignment, the trailer cycle shall be realigned to vertical. All

notes shall be recorded on the report.

5.4 Bump Fatigue Test:

5.4.5 Record the hitch mounting height, and where the

5.4.1 The trailer cycle shall be tested as in Fig. 3.

measurement was taken.

5.4.2 The trailer cycle shall be fitted with weights totaling

5.4.6 Testing shall be stopped at 10 000 cycles or failure.

125 % of the maximum recommended weight, and distributed

5.4.7 Remove the trailer cycle from the test equipment and

as in Fig. 3. Load B shall be applied to one side of the

inspect the wheel and frame assemblies. No part of these

handlebar. It shall be mounted to the handlebar directly, and

assemblies shall have failed.

positioned so the weight is centered 50 mm from the outside

end of the handlebar.

6. Marking, Labeling, and Instructions

5.4.3 The tire shall be inflated to the maximum pressure per

6.1 General—Alltrailercyclesshallbepermanentlymarked

the trailer cycle manufact

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.