ASTM D1321-10(2015)

(Test Method)Standard Test Method for Needle Penetration of Petroleum Waxes

Standard Test Method for Needle Penetration of Petroleum Waxes

SIGNIFICANCE AND USE

5.1 Petroleum waxes differ in hardness. Needle penetration is a measurement of hardness. Hardness may have a significant effect upon other physical properties.

SCOPE

1.1 This test method covers the empirical estimation of the consistency of waxes derived from petroleum by measurement of the extent of penetration of a standard needle. This test method is applicable to waxes having a penetration of not greater than 250.

Note 1: This test method is similar to the needle method for determining the penetration of bituminous material, Test Method D5. Cone methods applicable to greases and to petrolatum are described in Test Methods D217 and Test Method D937, respectively.

1.2 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1321 − 10(Reapproved 2015)

Standard Test Method for

Needle Penetration of Petroleum Waxes

This standard is issued under the fixed designation D1321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D87 Test Method for Melting Point of Petroleum Wax

(Cooling Curve)

1.1 This test method covers the empirical estimation of the

D217 Test Methods for Cone Penetration of Lubricating

consistency of waxes derived from petroleum by measurement

Grease

of the extent of penetration of a standard needle. This test

D937 Test Method for Cone Penetration of Petrolatum

method is applicable to waxes having a penetration of not

D938 Test Method for Congealing Point of Petroleum

greater than 250.

Waxes, Including Petrolatum

NOTE 1—This test method is similar to the needle method for

E1 Specification for ASTM Liquid-in-Glass Thermometers

determining the penetration of bituminous material, Test Method D5.

E2251 Specification for Liquid-in-Glass ASTM Thermom-

Cone methods applicable to greases and to petrolatum are described in

eters with Low-Hazard Precision Liquids

Test Methods D217 and Test Method D937, respectively.

1.2 WARNING—Mercury has been designated by many

3. Terminology

regulatory agencies as a hazardous material that can cause

central nervous system, kidney and liver damage. Mercury, or 3.1 Definitions:

its vapor, may be hazardous to health and corrosive to

3.1.1 penetration, n—of petroleum wax, the depth in tenths

materials. Caution should be taken when handling mercury and

of a millimetre to which a standard needle penetrates into the

mercury containing products. See the applicable product Ma-

wax under defined conditions.

terial Safety Data Sheet (MSDS) for details and EPA’s

3.1.1.1 Discussion—As an example, a penetration reading

website—http://www.epa.gov/mercury/faq.htm—for addi-

of 85 from the indicator scale corresponds to a penetration

tional information. Users should be aware that selling mercury

depth of 8.5 mm.

and/or mercury containing products into your state or country

may be prohibited by law. 3.1.2 penetrometer, n—an instrument that measures the

consistency or hardness of semiliquid to semisolid materials by

1.3 The values stated in SI units are to be regarded as the

measuring the depth to which a specified cone or needle under

standard. The values given in parentheses are for information

a given force falls into the material.

only.

3.1.2.1 Discussion—In this test method, a standard pen-

1.4 This standard does not purport to address all of the

etrometer needle (6.3) is used to determine the hardness of

safety concerns, if any, associated with its use. It is the

petroleum wax. The penetration force is determined by the

responsibility of the user of this standard to establish appro-

total mass (100 g) of the needle, plunger, and 50 g weight.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 The sample is heated to at least 17 °C (30 °F) above its

2.1 ASTM Standards:

expected congealing point or melting point, poured into a

D5 Test Method for Penetration of Bituminous Materials

container, and then air cooled under controlled conditions. The

sample then is conditioned at test temperature in a water bath.

This test method is under the jurisdiction of ASTM Committee D02 on

Penetration is measured with a penetrometer, which applies a

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

standard needle to the sample for 5 s under a load of 100 g.

Subcommittee D02.10.0A on Physical/Chemical Properties.

Current edition approved April 1, 2015. Published June 2015. Originally

approved in 1954. Last previous edition approved in 2010 as D1321 – 10. DOI:

5. Significance and Use

10.1520/D1321-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Petroleum waxes differ in hardness. Needle penetration

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

is a measurement of hardness. Hardness may have a significant

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. effect upon other physical properties.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1321 − 10 (2015)

6. Apparatus

6.1 Penetrometer, for applying the standard needle to the

surface of the sample specimen and for measuring the extent of

penetrationattheconclusionofthetest.Thepenetrometershall

be constructed in such a manner that the accurate placement of

the tip of the needle at the level surface of the specimen may

be made while maintaining a “zero” reading on the indicator.

The apparatus shown in Fig. 1 represents a composite drawing

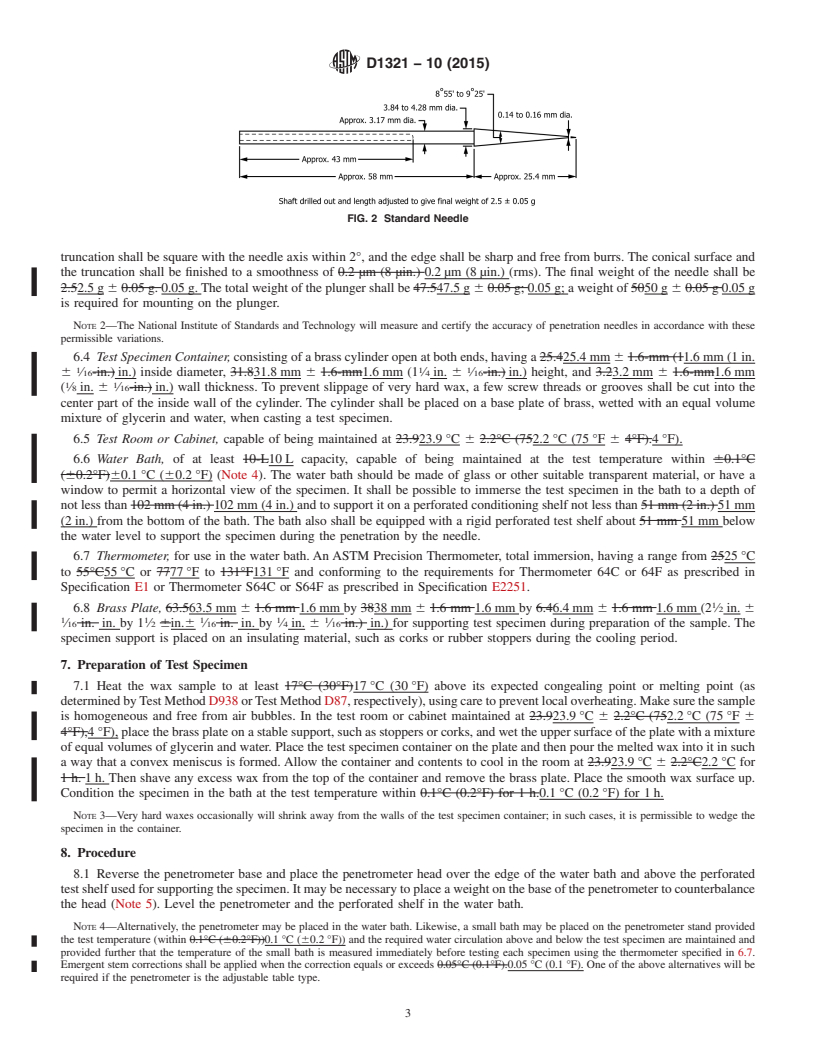

FIG. 2 Standard Needle

illustrating the two available types of instrument, one with an

adjustable table and the other with an adjustable needle

assembly; the use of either type of instrument is permissible.

The loaded needle must fall, when released, without appre-

0.14 mm to 0.16 mm in diameter. The truncation shall be

ciable friction. The instrument shall be provided with leveling

square with the needle axis within 2°, and the edge shall be

screws and a spirit level to maintain the plunger shaft in a true

sharp and free from burrs. The conical surface and the

vertical position. The indicator scale shall be calibrated in

truncation shall be finished to a smoothness of 0.2 µm (8 µin.)

tenths of a millimetre division and shall have a range of at least

(rms). The final weight of the needle shall be 2.5 g 6 0.05 g.

250 tenths of millimetres.

The total weight of the plunger shall be 47.5 g 6 0.05 g; a

6.2 Timing Device—An automatic timing release mecha-

weight of 50 g 6 0.05 g is required for mounting on the

nism attached to the penetrometer may be used. Alternatively,

plunger.

a stop watch graduated in 0.1 s intervals may be used.

NOTE 2—The National Institute of Standards and Technology will

6.3 Needle and Plunger—Theneedleshallbeapproximately

measure and certify the accuracy of penetration needles in accordance

83 mm in length and conform to the dimensions shown in Fig.

with these permissible variations.

2. It shall be symmetrically tapered at one end to a cone whose

6.4 Test Specimen Container, consisting of a brass cylinder

angle shall be within the range from 8°, 55 min to 9°, 25 min

open at both ends, having a 25.4 mm 6 1.6 mm (1 in. 6

over the entire length of the cone. The axis of the cone shall be

1 1 1

⁄16 in.) inside diameter, 31.8 mm 6 1.6 mm (1 ⁄4 in. 6 ⁄16 in.)

coincident with the shaft axis within 0.13 mm (0.005 in.)

1 1

height, and 3.2 mm 6 1.6 mm ( ⁄8 in. 6 ⁄16 in.) wall thickness.

maximum runout (total indicator reading). The tapered section

To prevent slippage of very hard wax, a few screw threads or

of the needle shall be made from fully hardened and tempered

groovesshallbecutintothecenterpartoftheinsidewallofthe

stainless steel, Grade 440-C or equal, Rockwell hardness C57

cylinder. The cylinder shall be placed on a base plate of brass,

to 60. After tapering, the point shall be ground off to a

wetted with an equal volume mixture of glycerin and water,

truncated cone, the smaller base of which shall be from

when casting a test specimen.

6.5 Test Room or Cabinet, capable of being maintained at

23.9 °C 6 2.2 °C (75 °F 6 4 °F).

6.6 Water Bath, of at least 10 L capacity, capable of being

maintained at the test temperature within 60.1 °C (60.2 °F)

(Note 4). The water bath should be made of glass or other

suitable transparent material, or have a window to permit a

horizontal view of the specimen. It shall be possible to

immersethetestspecimeninthebathtoadepthofnotlessthan

102 mm (4 in.) and to support it on a perforated conditioning

shelf not less than 51 mm (2 in.) from the bottom of t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1321 − 10 D1321 − 10 (Reapproved 2015)

Standard Test Method for

Needle Penetration of Petroleum Waxes

This standard is issued under the fixed designation D1321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This test method covers the empirical estimation of the consistency of waxes derived from petroleum by measurement of

the extent of penetration of a standard needle. This test method is applicable to waxes having a penetration of not greater than 250.

NOTE 1—This test method is similar to the needle method for determining the penetration of bituminous material, Test Method D5. Cone methods

applicable to greases and to petrolatum are described in Test Methods D217 and Test Method D937, respectively.

1.2 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D5 Test Method for Penetration of Bituminous Materials

D87 Test Method for Melting Point of Petroleum Wax (Cooling Curve)

D217 Test Methods for Cone Penetration of Lubricating Grease

D937 Test Method for Cone Penetration of Petrolatum

D938 Test Method for Congealing Point of Petroleum Waxes, Including Petrolatum

E1 Specification for ASTM Liquid-in-Glass Thermometers

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

3. Terminology

3.1 Definitions:

3.1.1 penetration, n—of petroleum wax, the depth in tenths of a millimetre to which a standard needle penetrates into the wax

under defined conditions.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.10.0A on Physical/Chemical Properties.

Current edition approved May 1, 2010April 1, 2015. Published June 2010June 2015. Originally approved in 1954. Last previous edition approved in 20042010 as

D1321D1321 – 10.–04. DOI: 10.1520/D1321-10.10.1520/D1321-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

As an example, a penetration reading of 85 from the indicator scale corresponds to a penetration depth of 8.5 mm.8.5 mm.

3.1.2 penetrometer, n—an instrument that measures the consistency or hardness of semiliquid to semisolid materials by

measuring the depth to which a specified cone or needle under a given force falls into the material.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1321 − 10 (2015)

3.1.2.1 Discussion—

In this test method, a standard penetrometer needle (6.3) is used to determine the hardness of petroleum wax. The penetration force

is determined by the total mass (100 g) (100 g) of the needle, plunger, and 50 g 50 g weight.

4. Summary of Test Method

4.1 The sample is heated to at least 17°C (30°F)17 °C (30 °F) above its expected congealing point or melting point, poured into

a container, and then air cooled under controlled conditions. The sample then is conditioned at test temperature in a water bath.

Penetration is measured with a penetrometer, which applies a standard needle to the sample for 5 s 5 s under a load of 100 g.100 g.

5. Significance and Use

5.1 Petroleum waxes differ in hardness. Needle penetration is a measurement of hardness. Hardness may have a significant

effect upon other physical properties.

6. Apparatus

6.1 Penetrometer, for applying the standard needle to the surface of the sample specimen and for measuring the extent of

penetration at the conclusion of the test. The penetrometer shall be constructed in such a manner that the accurate placement of

the tip of the needle at the level surface of the specimen may be made while maintaining a “zero” reading on the indicator. The

apparatus shown in Fig. 1 represents a composite drawing illustrating the two available types of instrument, one with an adjustable

table and the other with an adjustable needle assembly; the use of either type of instrument is permissible. The loaded needle must

fall, when released, without appreciable friction. The instrument shall be provided with leveling screws and a spirit level to

maintain the plunger shaft in a true vertical position. The indicator scale shall be calibrated in tenths of a millimetre division and

shall have a range of at least 250 tenths of millimetres.

6.2 Timing Device—An automatic timing release mechanism attached to the penetrometer may be used. Alternatively, a stop

watch graduated in 0.1-s0.1 s intervals may be used.

6.3 Needle and Plunger—The needle shall be approximately 83 mm 83 mm in length and conform to the dimensions shown in

Fig. 2. It shall be symmetrically tapered at one end to a cone whose angle shall be within the range from 8°, 55 min 55 min to

9°, 25 min 25 min over the entire length of the cone. The axis of the cone shall be coincident with the shaft axis within 0.13-mm

(0.005-in.)0.13 mm (0.005 in.) maximum runout (total indicator reading). The tapered section of the needle shall be made from

fully hardened and tempered stainless steel, Grade 440-C or equal, Rockwell hardness C57 to 60. After tapering, the point shall

be ground off to a truncated cone, the smaller base of which shall be from 0.140.14 mm to 0.16 mm 0.16 mm in diameter. The

FIG. 1 Penetrometer

D1321 − 10 (2015)

FIG. 2 Standard Needle

truncation shall be square with the needle axis within 2°, and the edge shall be sharp and free from burrs. The conical surface and

the truncation shall be finished to a smoothness of 0.2 μm (8 μin.) 0.2 μm (8 μin.) (rms). The final weight of the needle shall be

2.52.5 g 6 0.05 g. 0.05 g. The total weight of the plunger shall be 47.547.5 g 6 0.05 g; 0.05 g; a weight of 5050 g 6 0.05 g 0.05 g

is required for mounting on the plunger.

NOTE 2—The National Institute of Standards and Technology will measure and certify the accuracy of penetration needles in accordance with these

permissible variations.

6.4 Test Specimen Container, consisting of a brass cylinder open at both ends, having a 25.425.4 mm 6 1.6-mm (11.6 mm (1 in.

1 1 1

6 ⁄16-in.) in.) inside diameter, 31.831.8 mm 6 1.6-mm1.6 mm (1 ⁄4 in. 6 ⁄16-in.) in.) height, and 3.23.2 mm 6 1.6-mm1.6 mm

1 1

( ⁄8 in. 6 ⁄16-in.) in.) wall thickness. To prevent slippage of very hard wax, a few screw threads or grooves shall be cut into the

center part of the inside wall of the cylinder. The cylinder shall be placed on a base plate of brass, wetted with an equal volume

mixture of glycerin and water, when casting a test specimen.

6.5 Test Room or Cabinet, capable of being maintained at 23.923.9 °C 6 2.2°C (752.2 °C (75 °F 6 4°F).4 °F).

6.6 Water Bath, of at least 10-L10 L capacity, capable of being maintained at the test temperature within 60.1°C

(60.2°F)60.1 °C (60.2 °F) (Note 4). The water bath should be made of glass or other suitable transparent material, or have a

window to permit a horizontal view of the specimen. It shall be possible to immerse the test specimen in the bath to a depth of

not less than 102 mm (4 in.) 102 mm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.