ASTM D5362-97a

(Test Method)Standard Test Method for Snagging Resistance of Fabrics (Bean Bag Test Method)

Standard Test Method for Snagging Resistance of Fabrics (Bean Bag Test Method)

SCOPE

1.1 This test method determines the snagging resistance of a fabric.

1.2 Studies of fabric snagging have shown that this test method is suitable for a range of woven and knitted fabrics made from textured or untextured yarns containing staple or continuous filaments. This test method is not suitable for (1) open construction fabrics (such as a net) because the pins in the test chamber will snag the bean bag rather than the specimen, (2) heavy or stiff fabrics that cannot be made into a cover for the bean bag, and (3) tufted or nonwoven fabrics because the apparatus is designed for woven and knitted fabrics.

1.3 The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values stated in each system may not be the exact equivalents; therefore, each system must be used independently of the other, without combining values in any way. In case of referee decisions the metric units will prevail.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5362 – 97a

Standard Test Method for

Snagging Resistance of Fabrics (Bean Bag)

This standard is issued under the fixed designation D 5362; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and Leather Products Other Than Textile Floor Coverings

and Upholstery

1.1 This test method determines the snagging resistance of a

D 3939 Test Method for Snagging Resistance of Fabrics

fabric.

(Mace)

1.2 Studies of fabric snagging have shown that this test

D 4467 Practice for Interlaboratory Testing of a Textile Test

method is suitable for a range of woven and knitted fabrics

Method That Produces Non-Normally Distributed Data

made from textured or untextured filament yarns or spun yarns

2,3

2.2 AATCC Standards:

or combinations of these yarns. This test method is not

65 Test Method for Snag Resistance of Women’s Nylon

suitable for (1) open construction fabrics (such as a net)

Hosiery (see Note 1)

because the pins in the test chamber will snag the bean bag

135 Test Method for Dimensional Changes in Automatic

rather than the specimen, (2) heavy or stiff fabrics that cannot

Home Laundering of Woven and Knit Fabrics

be made into a cover for the bean bag, and (3) tufted or

nonwoven fabrics because the apparatus is designed for woven

NOTE 1—In 1988 the AATCC voted to withdraw this test method from

and knitted fabrics. their technical manual; however, the ASTM task group on fabric snagging

decided it should be listed as an alternative for testing open construction

1.3 The values stated in either acceptable metric units or in

fabrics.

other units shall be regarded separately as standard. The values

stated in each system may not be the exact equivalents;

3. Terminology

therefore, each system must be used independently of the other,

3.1 Definitions:

without combining values in any way. In case of referee

3.1.1 color contrast, n—in textiles, a general term for a

decisions the metric units will prevail.

visible color difference between two adjacent areas.

1.4 This standard does not purport to address all of the

3.1.1.1 Discussion—For the purpose of this test method, a

safety concerns, if any, associated with its use. It is the

color contrast is a visible color difference between a snag and

responsibility of the user of this standard to establish appro-

the immediate surrounding area of the fabric that has no

priate safety and health practices and determine the applica-

defects. Color contrasts often occur when printed fabrics are

bility of regulatory limitations prior to use. Specific precau-

snagged.

tionary statements are given in Section 7.

3.1.2 distortion, n—in fabrics, a general term for a visible

2. Referenced Documents defect in the texture of a fabric.

3.1.2.1 Discussion—For the purpose of this test method,

2.1 ASTM Standards:

snags are composed of different combinations of protrusions

D 123 Terminology Relating to Textiles

4 and distortions. A distortion is characterized by a group of

D 1335 Test Method for Tuft Bind of Pile Floor Coverings

fibers, a yarn, or a yarn segment that is displaced from its

D 1776 Practice for Conditioning Textiles for Testing

normal pattern so that there is a visible change in the texture of

D 2724 Test Methods for Bonded, Fused, and Laminated

the fabric; however, the displaced group of fibers, yarn, or yarn

Apparel Fabrics

segment does not extend above the fabric surface. Distortions

D 3136 Terminology Relating to Care Labels for Textile

include conditions where (1) tension on a snagged yarn has

changed the size of some of the loops within a knitted fabric

and the result is a pucker on the surface of the fabric, and (2)

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles tension on a snagged yarn has caused the yarn to break off

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

within a woven fabric and the result is a change in the texture

General.

where the yarn used to be.

Current edition approved Dec. 10, 1997. Published August 1998. Originally

3.1.3 protrusion, n—in fabrics, a general term for a visible

published as D 5362 – 93. Last previous edition D 5362 – 97.

Stuckey, W. C., and El Shiekh, A., “Snags in Snag Testing of Knits”, in Sense

and Nonsense in Knit Testing, American Association of Textile Chemists and

Colorists, 1975, pp. 45–53.

Cary, R. T., “Bean Bag Snag Tester: A System of Evaluation”, Textile Research

Annual Book of ASTM Standards, Vol 07.02.

Journal, Vol 51, No. 2, 1981, pp. 61–63.

Available from American Association of Textile Chemists and Colorists, P.O.

Annual Book of ASTM Standards, Vol 07.01.

Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5362

group of fibers, a yarn, or a yarn segment that extends above slacks, and upholstery).

the fabric surface.

5.3.1 For a specific fabric, if the test results from this test

3.1.4 snag, n—in fabrics, a yarn or part of a yarn pulled or

method do not correspond with the test results from a wear test

plucked from the surface.

then (1) the procedure described in Section 12 or (2) the

3.1.4.1 Discussion—For the purpose of this test method, a

evaluation described in Section 13 can be modified. For

snag is created when an object pulls, plucks, scratches, or drags

example, the number of revolutions of the test chamber for

a group of fibers, a yarn, or a yarn segment from its normal

testing each specimen can be increased for a fabric that had a

pattern. Snags can be classified into three types: (1) snags that

higher degree of snagging in a wear test than the same fabric

have a protrusion and no distortion, (2) snags that have a

had using the procedure described in Section 12. The purchaser

distortion and no protrusion, and (3) snags that have both a

and the supplier must agree to all changes in the procedure for

protrusion and a distortion. Other changes in appearance, such

operating the apparatus or for evaluating the test results.

as color contrasts, should be reported because they affect the

5.3.2 Some fabrics which may not be suitable for this test

visibility of a protrusion or a distortion.

method are described in 1.2. Many open construction fabrics

3.1.5 snagging resistance, n—in textile fabrics, the property

can be tested for snagging resistance using AATCC Test

of a material whereby yarns or parts of yarns are prevented or

Method 65. Many heavy or stiff fabrics can be tested for

inhibited from being pulled or plucked from the surface.

snagging resistance using Test Method D 3939. The snagging

3.1.6 For definitions of other textile terms used in this test

resistance of many pile floor coverings can be tested by Test

method, refer to Terminology D 123.

Method D 1335.

5.3.3 When the purchaser and the supplier agree that the test

4. Summary of Test Method

results from the bean bag test method do not correspond with

4.1 A fabric specimen is made into a cover for a bean bag.

the test results from a wear test, Test Method D 3939 can be

Then the specimen and bean bag unit is tumbled for 100

used.

revolutions in a cylindrical test chamber fitted on its inner

5.4 Because fabric snagging can be affected by laundering

surface with rows of pins. The degree of fabric snagging is

or drycleaning, it may be advisable to test the snagging

evaluated by (1) comparison of the tested specimens with

resistance of a fabric before and after laundering or dryclean-

visual rating standards that may be either snagged fabrics or

ing.

photographs of snagged fabrics, or (2) using a point system.

5.5 The snagging resistance of a specific fabric varies with

The resistance to snagging is rated on a numerical scale

individual wearers and general conditions of use. Therefore, it

ranging from 5 (no or insignificant snagging) to 1 (very severe

can be expected that garments of the same fabric will show a

snagging).

fairly wide snagging resistance spectrum after wear and much

5. Significance and Use

greater variation in wear than in replicate fabric specimens

subjected to controlled laboratory tests. This factor should be

5.1 Acceptance Testing—This test method may be used for

considered when adopting levels of acceptability for any

acceptance testing of commercial shipments of fabrics because

specification that includes snagging resistance.

the precision is acceptable (see 15.1).

5.1.1 In case there are disputable differences between re- 5.6 Snags observed in worn garments vary appreciably in

ported test results for two laboratories (or more), comparative number and appearance. The appearance of a snag depends

tests should be performed to determine if there is a statistical particularly on (1) the degree of color contrast between the

bias between them, using competent statistical assistance. As a snag and the surrounding area of the fabric, or, (2) the

minimum, specimens should be used that are as homogeneous presence of long distortions or long protrusions. These condi-

as possible, that are drawn from the material from which tions are not evaluated when snagging is rated solely on the

disputable test results were obtained, and that are randomly number of snags. See Section 3 for a description of terminol-

assigned in equal numbers to each laboratory for testing. The ogy such as color contrast, distortion, and protrusion. See Figs.

test results from the two laboratories should be compared using 1-3 for pictures of fabric defects due to snagging. Because the

an appropriate statistical test for unpaired data, at a probability overall acceptability of a specific fabric is dependent on both

level chosen prior to the testing series. If a bias is found, either the characteristics of the snags and other factors affecting

its cause must be found and corrected, or future test results fabric appearance, it is recommended that fabrics tested in the

must be adjusted in consideration of the known bias. laboratory be evaluated with regard to the defects which may

5.2 This test method may be used for quality control testing be visually observed and not rated solely on the number of

of fabrics during manufacturing and product comparisons of snags developed. A series of visual rating standards (see 6.7)

may be set up to provide a basis for the ratings. The visual

different fabrics by manufacturers, retailers, and users. This test

method may also be used by researchers to examine the effect rating standards are most advantageous when the tested labo-

of new fibers, yarns, fabric constructions, and finishes on the ratory specimens correlate closely in appearance with fabrics

snagging resistance of fabrics. from a wear test; for example when tested laboratory speci-

5.3 This test method may be used to test the snagging mens and fabrics from a wear test show similar color contrasts.

resistance of most apparel and home furnishings fabrics. In the preceding example, a series of fabrics from the wear test

Modifications of this test method (see 5.3.1), or a different test would be a good choice for the fabric standards described in

method (see 5.3.2 and 5.3.3), may be needed for different types 6.7.2. Also a point rating system may be used that considers the

of fabrics and different end-uses (such as towels, swimwear, number of the snags and the appearance of the snags (see 13.3).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5362

FIG. 1 A Snagged Specimen With Many Protrusion But No

FIG. 3 A Snagged Specimen With Color Contrasts (Yarn Shifted

Distortions

from Dark Area to Light Area

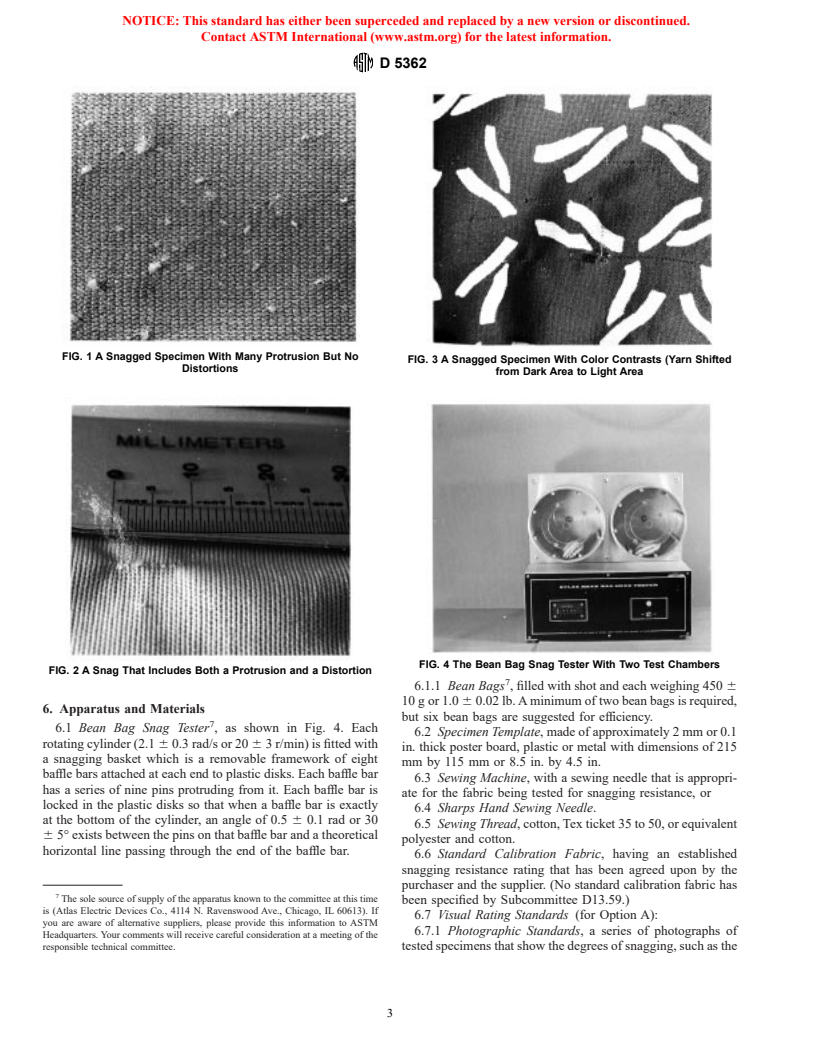

FIG. 4 The Bean Bag Snag Tester With Two Test Chambers

FIG. 2 A Snag That Includes Both a Protrusion and a Distortion

6.1.1 Bean Bags , filled with shot and each weighing 450 6

10gor1.0 6 0.02 lb. A minimum of two bean bags is required,

6. Apparatus and Materials

but six bean bags are suggested for efficiency.

6.1 Bean Bag Snag Tester , as shown in Fig. 4. Each

6.2 Specimen Template, made of approximately 2 mm or 0.1

rotating cylinder (2.1 6 0.3 rad/s or 20 6 3 r/min) is fitted with

in. thick poster board, plastic or metal with dimensions of 215

a snagging basket which is a removable framework of eight

mm by 115 mm or 8.5 in. by 4.5 in.

baffle bars attached at each end to plastic disks. Each baffle bar

6.3 Sewing Machine, with a sewing needle that is appropri-

has a series of nine pins protruding from it. Each baffle bar is

ate for the fabric being tested for snagging resistance, or

locked in the plastic disks so that when a baffle bar is exactly

6.4 Sharps Hand Sewing Needle.

at the bottom of the cylinder, an angle of 0.5 6 0.1 rad or 30

6.5 Sewing Thread, cotton, Tex ticket 35 to 50, or equivalent

6 5° exists between the pins on that baffle bar and a theoretical

polyester and cotton.

horizontal line passing through the end of the baffle bar.

6.6 Standard Calibration Fabric, having an established

snagging resistance rating that has been agreed upon by the

purchaser and the supplier. (No standard calibration fabric has

The sole source of supply of the apparatus known to the committee at this time

been specified by Subcommittee D13.59.)

is (Atlas Electric Devices Co., 4114 N. Ravenswood Ave., Chicago, IL 60613). If

6.7 Visual Rating Standards (for Option A):

you are aware of alternative suppliers, please provide this information to ASTM

6.7.1 Photographic Standards, a series of photographs of

Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee. tested specimens that show the degrees of snagging, such as the

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5362

Imperial Chemical Industries (ICI) photographs, or 6.8.1.2 Specimen Viewing Mask (White), made of approxi-

6.7.2 Fabric Standards, a series of tested specimens or mately 2 mm or 0.1 in. thick poster board, plastic or metal with

fabrics from a wear test that show the degrees of snagging (see outer dimensions of 100 mm by 100 mm or 4 in. by 4 in. and

5.6 and Note 2). a center cutout of 75 mm by 75 mm or 3 in. by 3 in.

6.8.1.3 Photogr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.