ASTM C641-23

(Test Method)Standard Test Method for Iron Staining Materials in Lightweight Concrete Aggregates

Standard Test Method for Iron Staining Materials in Lightweight Concrete Aggregates

SIGNIFICANCE AND USE

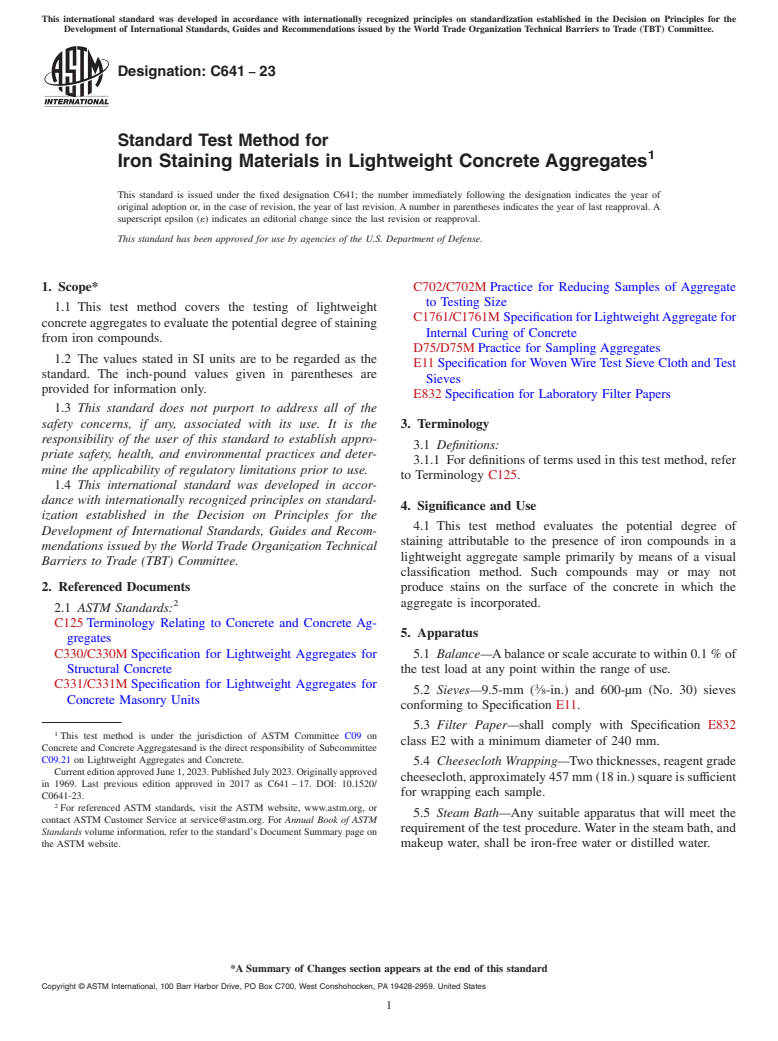

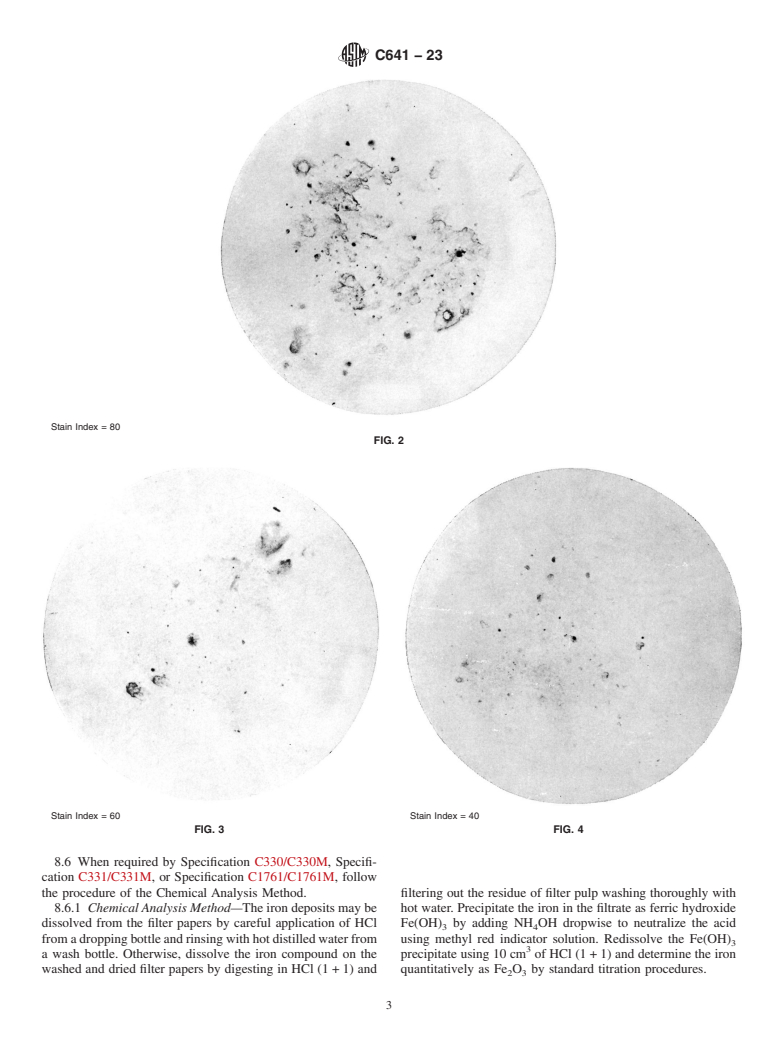

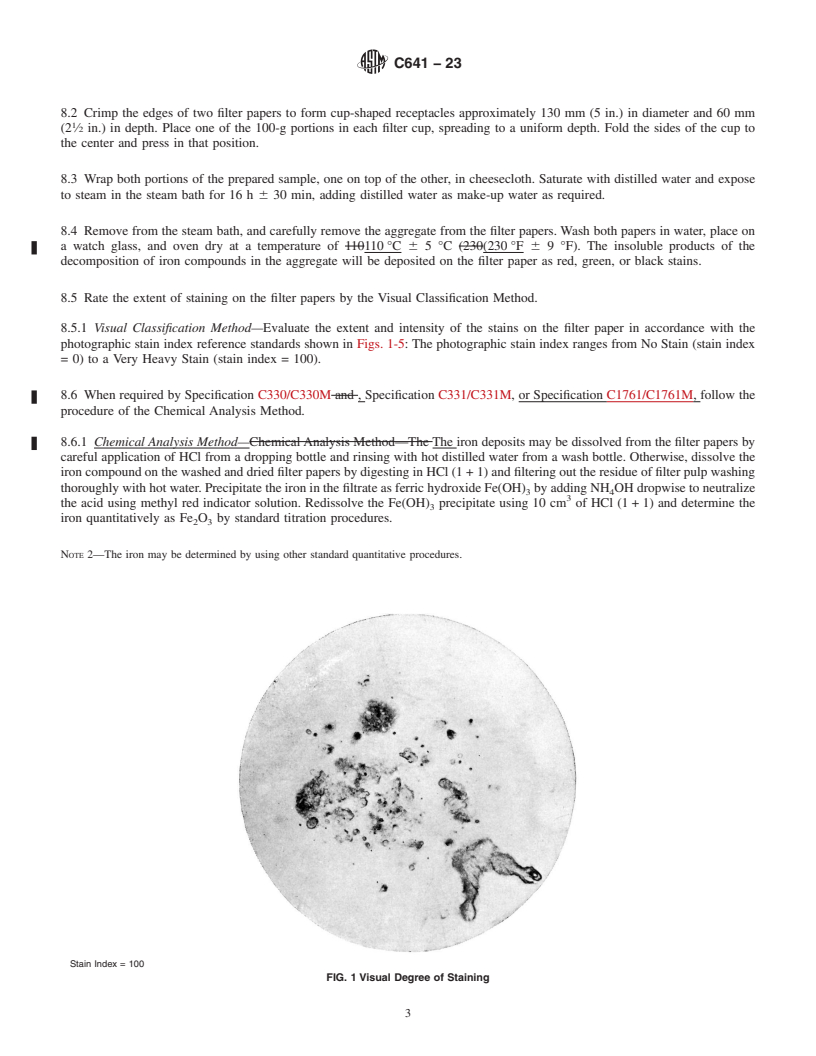

4.1 This test method evaluates the potential degree of staining attributable to the presence of iron compounds in a lightweight aggregate sample primarily by means of a visual classification method. Such compounds may or may not produce stains on the surface of the concrete in which the aggregate is incorporated.

SCOPE

1.1 This test method covers the testing of lightweight concrete aggregates to evaluate the potential degree of staining from iron compounds.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C641 − 23

Standard Test Method for

1

Iron Staining Materials in Lightweight Concrete Aggregates

This standard is issued under the fixed designation C641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* C702/C702M Practice for Reducing Samples of Aggregate

to Testing Size

1.1 This test method covers the testing of lightweight

C1761/C1761M Specification for Lightweight Aggregate for

concrete aggregates to evaluate the potential degree of staining

Internal Curing of Concrete

from iron compounds.

D75/D75M Practice for Sampling Aggregates

1.2 The values stated in SI units are to be regarded as the

E11 Specification for Woven Wire Test Sieve Cloth and Test

standard. The inch-pound values given in parentheses are

Sieves

provided for information only.

E832 Specification for Laboratory Filter Papers

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety, health, and environmental practices and deter-

3.1.1 For definitions of terms used in this test method, refer

mine the applicability of regulatory limitations prior to use.

to Terminology C125.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Significance and Use

ization established in the Decision on Principles for the

4.1 This test method evaluates the potential degree of

Development of International Standards, Guides and Recom-

staining attributable to the presence of iron compounds in a

mendations issued by the World Trade Organization Technical

lightweight aggregate sample primarily by means of a visual

Barriers to Trade (TBT) Committee.

classification method. Such compounds may or may not

2. Referenced Documents

produce stains on the surface of the concrete in which the

2 aggregate is incorporated.

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Ag-

5. Apparatus

gregates

C330/C330M Specification for Lightweight Aggregates for 5.1 Balance—A balance or scale accurate to within 0.1 % of

Structural Concrete the test load at any point within the range of use.

C331/C331M Specification for Lightweight Aggregates for

3

5.2 Sieves—9.5-mm ( ⁄8-in.) and 600-μm (No. 30) sieves

Concrete Masonry Units

conforming to Specification E11.

5.3 Filter Paper—shall comply with Specification E832

1

This test method is under the jurisdiction of ASTM Committee C09 on

class E2 with a minimum diameter of 240 mm.

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

C09.21 on Lightweight Aggregates and Concrete.

5.4 Cheesecloth Wrapping—Two thicknesses, reagent grade

Current edition approved June 1, 2023. Published July 2023. Originally approved

cheesecloth, approximately 457 mm (18 in.) square is sufficient

in 1969. Last previous edition approved in 2017 as C641 – 17. DOI: 10.1520/

for wrapping each sample.

C0641-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.5 Steam Bath—Any suitable apparatus that will meet the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

requirement of the test procedure. Water in the steam bath, and

Standards volume information, refer to the standard’s Document Summary page on

makeup water, shall be iron-free water or distilled water.

the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C641 − 23

NOTE 1—An oven top glassware sterilizer made of nonferrous materials

7.2 After reducing a field sample to an appropriate size in

is satisfactory.

accordance with Practice C702/C702M, thoroughly dry the

aggregate and prepare by sieving material to pass the 9.5-mm

6. Reagents

3

( ⁄8-in.) sieve and is retained on the 600-μm (No. 30) sieve.

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

8. Procedure

all reagents shall conform to the specifications of the Commit-

8.1 Select two portions each weighing 100 g from the

tee on Analytical Reagents of the American Chemical Society,

3

aggregate sample

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C641 − 17 C641 − 23

Standard Test Method for

1

Iron Staining Materials in Lightweight Concrete Aggregates

This standard is issued under the fixed designation C641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the testing of lightweight concrete aggregates to evaluate the potential degree of staining from iron

compounds.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are provided for

information only.

1.3 This standard does not purport to address all of the safety problems concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and

determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C330/C330M Specification for Lightweight Aggregates for Structural Concrete

C331/C331M Specification for Lightweight Aggregates for Concrete Masonry Units

C702/C702M Practice for Reducing Samples of Aggregate to Testing Size

C1761/C1761M Specification for Lightweight Aggregate for Internal Curing of Concrete

D75/D75M Practice for Sampling Aggregates

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E832 Specification for Laboratory Filter Papers

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology C125.

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.21 on

Lightweight Aggregates and Concrete.

Current edition approved June 15, 2017June 1, 2023. Published July 2017July 2023. Originally approved in 1969. Last previous edition approved in 20092017 as

C641 – 09.C641 – 17. DOI: 10.1520/C0641-17.10.1520/C0641-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C641 − 23

4. Significance and Use

4.1 This test method evaluates the potential degree of staining attributable to the presence of iron compounds in a lightweight

aggregate sample primarily by means of a visual classification method. Such compounds may or may not produce stains on the

surface of the concrete in which the aggregate is incorporated.

5. Apparatus

5.1 Balance—A balance or scale accurate to within 0.1 % of the test load at any point within the range of use.

3

5.2 Sieves—9.5-mm ( ⁄8-in.) and 600-μm (No. 30) sieves conforming to Specification E11.

5.3 Filter Paper—shall comply with Specification E832 class E2 with a minimum diameter of 240 mm.

5.4 Cheesecloth Wrapping—Two thicknesses, reagent grade cheesecloth, approximately 457 mm (18 in.) square is sufficient for

wrapping each sample.

5.5 Steam Bath—Any suitable apparatus that will meet the requirement of the test procedure. Water in the steam bath, and makeup

water, shall be iron-free water or distilled water.

NOTE 1—An oven top glassware sterilizer made of nonferrous materials is satisfactory.

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

3

such specifications are available.

6.2 Purity of Water—Unless otherwise indicated, references to water shall be understood

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.