ASTM D6787-02(2007)

(Specification)Standard Specification for Repositionable Note Pad

Standard Specification for Repositionable Note Pad

ABSTRACT

This specification covers pads of repositionable, colored, note paper. Each sheet has a strip of pressure-sensitive adhesive on the back side. A hand-operated steel roller shall be used in the manufacture of the pads and a cylindrical mandrel shall be used for flagging test of the pads. A minimum average of determined sheets of paper shall be assembled in the form of a pad. No individual pad shall contain less than a certain number of sheets. The pad of paper and a backing sheet shall be securely fastened together by means of the repositionable, pressure-sensitive adhesive coating. The paper to be used in the manufacture of the pad shall be determined by its basis weight and thickness. In order to determine the sheets' overall performance, the following properties shall be tested: writing quality, sheet removal, multiple sheet lift, fiber pull, initial flagging, and repositionable flagging. The sheets of pad paper shall be clean and free from dirt, foreign matter, holes, tears, wrinkles, and other defects which might affect appearance or serviceability. The sheets shall be uniform with respect to color and formation. Pads shall be square cut with smooth, clean edges.

SCOPE

1.1 This specification covers pads of repositionable, colored, note paper. Each sheet has a strip of pressure-sensitive adhesive on the back side.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently, without combining values in any way.

The following safety hazards caveat pertains only to Section 14, Performance Requirements. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6787 – 02 (Reapproved 2007)

Standard Specification for

Repositionable Note Pad

This standard is issued under the fixed designation D6787; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.4 Federal Specification:

Code of Federal Regulations, 16 CFR Part 1500.3 Defini-

1.1 This specification covers pads of repositionable, col-

tions of Toxic and Hazardous Materials

ored, note paper. Each sheet has a strip of pressure-sensitive

U.S. Government CID A-A-2546 Pad, Writing Paper (Re-

adhesive on the back side.

positionable)

1.2 The values stated in either SI or inch-pound units are to

2.5 ISO Standard:

be regarded separately as standard. The values stated in each

ISO 9002 Quality Systems Model for Quality Assurance in

system are not exact equivalents; therefore, each system must

Production and Installation

be used independently, without combining values in any way.

2.6 Other Standards:

1.3 The following safety hazards caveat pertains only to

Coalition of Northeastern Governors (CONEG) Model Tox-

Section 14, Performance Requirements. This standard does not

ics Legislation

purport to address all of the safety concerns, if any, associated

with its use. It is the responsibility of the user of this standard

3. Terminology

to establish appropriate safety and health practices and

3.1 Definitions of Terms Specific to This Standard:

determine the applicability of regulatory requirements prior to

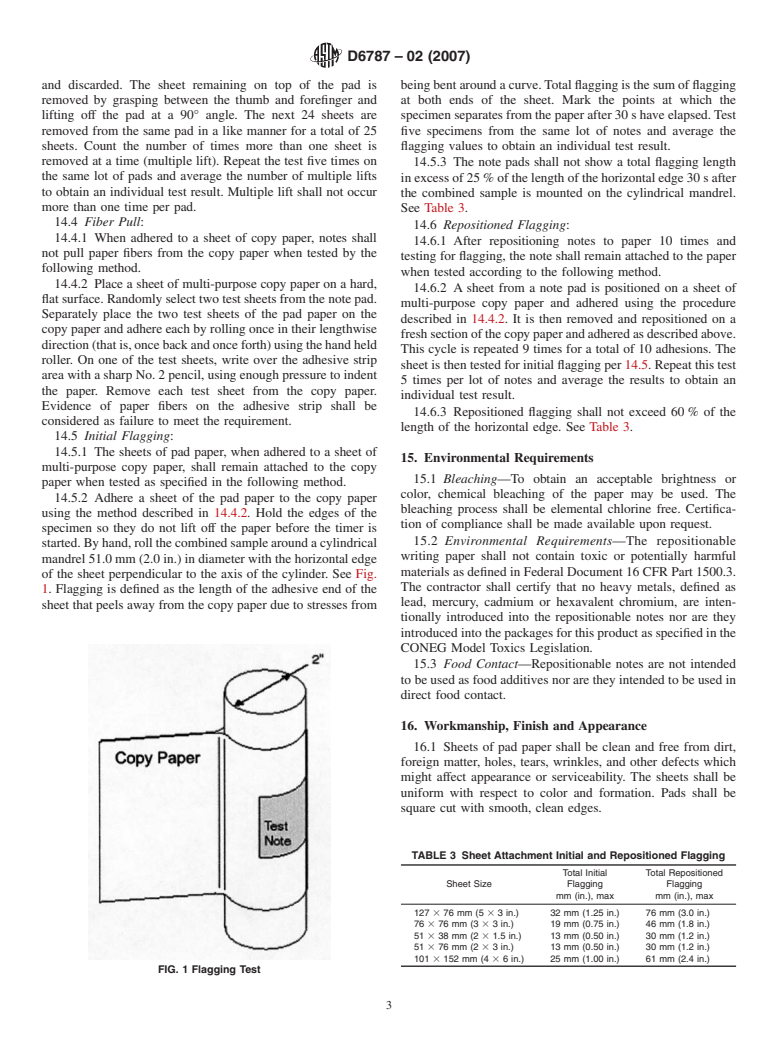

3.1.1 flagging—the lifting of an edge of a repositionable

use.

note from paper when the note and paper are wrapped around

2. Referenced Documents a cylinder.

3.1.2 multiple lift—the condition in which removal of the

2.1 ASTM Standards:

top sheet on a pad of notes causes the unintentional removal of

D3715/D3715M Practice for Quality Assurance of

a second sheet.

Pressure-Sensitive Tapes

3.1.3 postconsumer materials—a material or finished prod-

D3951 Practice for Commercial Packaging

uct that has served its intended use and has been discarded for

D4332 Practice for Conditioning Containers, Packages, or

disposal or recovery, having completed its life as a consumer

Packaging Components for Testing

3 item.Postconsumermaterialisapartofthebroadercategoryof

2.2 TAPPI Test Methods:

recovered material (see U.S. Executive Order 13101, section

T410 GrammageofPaperandPaperboard(WeightperUnit

203).

Area)

3.1.4 recovered materials—wastematerialsandby-products

T411 Thickness (caliper) of Paper, Paper Board, and

thathavebeenrecoveredordivertedfromsolidwaste,butsuch

Combined Board

term does not include those materials and by-products gener-

2.3 Executive Orders:

ated from, and commonly reused within, an original manufac-

Executive Order 13101 Greening the Government Through

turing process (see U.S. Executive Order 13101, section 205).

Waste Prevention, Recycling, and Federal Acquisition,

September 16, 1998

4. Significance and Use

4.1 Repositionable note pads consist of individual sheets of

This specification is under the jurisdiction of ASTM Committee D10 on

paper with an adhesive strip on one edge. The adhesive will

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

temporarily hold the note to another sheet of paper, a file, or

Labels.

Current edition approved Oct. 1, 2007. Published November 2007. Originally

approved in 2002. Last previous edition approved in 2002 as D6787 – 02. DOI:

10.1520/D6787-02R07.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

Standards volume information, refer to the standard’s Document Summary page on www.access.gpo.gov.

the ASTM website. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI), 4th Floor, New York, NY 10036, http://www.ansi.org.

15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org. Available from theToxins in Packaging Clearinghouse, c/o the Council of State

Available from The White House Publications Office, New Executive Office Governments, 2760 Research Park Drive, P.O. Box 11910, Lexington, KY

Building, White House, Washington, DC 20500, Att: Publications. 40578–1910.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6787 – 02 (2007)

other surface without damaging or otherwise modifying the 9.1.5 Packaging and marking (see 10.1), and

surface of the sheet or file.The notes display a written message 9.1.6 Color of paper and graphics, if any (see 11.1).

or reminder.

10. Packaging and Package Marking

4.2 This specification is based on the U.S. Government CID

A-A-2546, which was cancelled in 1999. 10.1 Packagingandpackagemarkingshallbeasspecifiedin

the contract or order.

5. Apparatus

11. Color and Graphics

5.1 Roller, Hand-operated:

5.1.1 Asteelroller85 62.5mm(3.25 60.1in.)indiameter 11.1 The color and graphics of the repositionable note pads

shall conform to those commercially available.

and 45 6 1.5 mm (1.75 6 0.005 in.) in width, covered with

rubber approximately 6 mm (0.25 in.) in thickness, having a

12. Materials and Manufacture

Shore scaleAdurometer hardness of 80 6 5. The surface shall

be a true cylinder void of any convex or concave deviations. 12.1 Construction—A minimum average of 100 sheets of

paper shall be assembled in the form of a pad. No individual

The mass of the roller shall be 2040 6 45 g (4.5 6 0.1 lb).

5.1.2 No part of the apparatus shall increase the mass of the pad shall contain fewer than 97 sheets. The pad of paper and a

backing sheet shall be securely fastened together by means of

roller during use. The roller shall move either mechanically or

by hand at the rate of 10 6 0.5 mm/s (24 6 0.5 in./min). the repositionable, pressure-sensitive adhesive coating.

5.2 Cylindrical Mandrel for Flagging Test:

13. Physical Properties

5.2.1 The mandrel shall be a smooth cylinder, 51 mm (2 in.)

13.1 Paper:

in diameter and a minimum of 20 cm (8 in.) long. Suitable

13.2 The paper used in the construction of the pad shall be

materials include wood, plastic, and aluminum. The mandrel

of the color as specified in the ordering description, and shall

may be a solid cylinder or a hollow tube.

conform to the requirements shown in Table 2.

6. Test Materials

13.3 Adhesive Coating:

13.4 Each sheet of paper in the pad shall have a coating of

6.1 Multi-purpose Copy Paper—Hammermill Fore DP,

repositionable, pressure-sensitive adhesive located on the back

Multi-Function Paper, White #10326-7 or equivalent.

side of the sheet.The adhesive coating shall be applied flush to

6.2 Double-coated pressure sensitive adhesive tape, with

one horizontal edge of the sheet, shall extend the entire width

permanent adhesive on both sides of the tape.

of the sheet, and shall have a minimum width of 6.4 mm ( ⁄4

7. Conditioning

in.).

7.1 Condition the pads of repositionable notes in the stan-

14. Performance Requirements

dard conditioning atmosphere as described in Practice D4332

14.1 Writing Quality:

for a period of not less than 24 h.

14.1.1 The sheets of pad paper shall not exhibit feathering,

7.2 Conduct tests in an atmosphere of 50 6 2 % relative

spreading, skipping, beading, visible discontinuities or fading

humidity and 23.0 6 2.0°C.

of ink when written on with a metal roller, felt tip, fountain

8. Classification

pen, permanent marker, or ball point pen.

14.2 Sheet Removal:

8.1 The size of the pads shall be as listed in Table 1. The

14.2.1 The sheets of pad paper shall release easily from the

adhesive stripe is located on the top of the horizontal dimen-

pad without leaving any trace of adhesive on the underlying

sion of the pad.

sheet.

9. Ordering Information

14.3 Multiple Sheet Lift:

14.3.1 When removed from the pad, the first note removed

9.1 The inquiry or order shall include the following:

shall not remove another note when tested according to the

9.1.1 ASTM designation and date of issue,

following method.

9.1.2 Type required (see 8.1),

14.3.2 A pad is securely mounted to a flat, hard, horizontal

9.1.3 Recycled paper content for government purchase (see

surface with double-coated pressure sensitive adhesive tape.

19.1),

The tape covers the entire back side of the pad and the

9.1.4 When testing and inspection certification is required

non-adhesive side of the pad faces up. A random number of

(see Section 21),

sheets between 1 and 60 are removed from the top of the pad

TABLE 1 Dimensions of Notepads

TABLE 2 Paper Specifications

Horizontal Vertical

Type Tolerance

Dimension Dimension TAPPI

Property Unit Requirement

Test Method

1 127 mm (5 in.) 76 mm (3 in.) 61.6mm(6 ⁄16 in.)

1 2

2 76mm(3in.)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.