ASTM D4308-95(2010)

(Test Method)Standard Test Method for Electrical Conductivity of Liquid Hydrocarbons by Precision Meter

Standard Test Method for Electrical Conductivity of Liquid Hydrocarbons by Precision Meter

SIGNIFICANCE AND USE

The generation and dissipation of electrostatic charge in fuel due to handling depend largely on the ionic species present which may be characterized by the rest or equilibrium electrical conductivity. The time for static charge to dissipate is inversely related to conductivity. This test method can supplement Test Method D2624 which is limited to fuels containing static dissipator additive.

Note 1—For low-conductivity fluids below 1 pS/m in conductivity, an ac measurement technique is preferable to a dc test method for sensing the electrical conductivity of bulk fluid. This dc test method can be used at conductivities from 0.1 to 1 pS/m if precautions are observed in cell cleaning and sample handling. A waiting period of 15 min is required after filling the cell before measuring dc conductivities below 1 pS/m. A single-laboratory program was conducted comparing this test method with ac Test Methods D150.

SCOPE

1.1 This test method covers and applies to the determination of the “rest” electrical conductivity of aviation fuels and other similar low-conductivity hydrocarbon liquids in the range from 0.1 to 2000 pS/m (see 3.2). This test method can be used in the laboratory or in the field.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.1.1, 7.2, and 8.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D4308–95 (Reapproved 2010)

Standard Test Method for

Electrical Conductivity of Liquid Hydrocarbons by Precision

Meter

This standard is issued under the fixed designation D4308; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

212 21 21

1. Scope

1 pS/m 5 1 3 10 V m 51cu 5 1 picomho/m (1)

1.1 Thistestmethodcoversandappliestothedetermination

3.2 rest conductivity—the reciprocal of the resistance of

of the “rest” electrical conductivity of aviation fuels and other

uncharged fuel in the absence of ionic depletion or polariza-

similarlow-conductivityhydrocarbonliquidsintherangefrom

tion. It is the electrical conductivity at the initial instant of

0.1 to 2000 pS/m (see 3.2).This test method can be used in the

current measurement after a d-c voltage is impressed between

laboratory or in the field.

electrodes.

1.2 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. No other units of measurement are included in this

standard.

4.1 A sample of liquid hydrocarbon is introduced into a

1.3 This standard does not purport to address all of the

cleanconductivitycellwhichisconnectedinseriestoabattery

safety concerns, if any, associated with its use. It is the

voltage source and a sensitive dc ammeter. The conductivity,

responsibility of the user of this standard to establish appro-

automatically calculated from the observed peak current read-

priate safety and health practices and determine the applica-

ing dc voltage and cell constant using Ohm’s law, appears as a

bility of regulatory limitations prior to use. For specific

digital value in either a manual or automatic mode of meter

warning statements, see 7.1.1, 7.2, and 8.3.

operation.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards: 5.1 The generation and dissipation of electrostatic charge in

D150 Test Methods for AC Loss Characteristics and Per-

fuelduetohandlingdependlargelyontheionicspeciespresent

mittivity (Dielectric Constant) of Solid Electrical Insula-

which may be characterized by the rest or equilibrium electri-

tion

cal conductivity. The time for static charge to dissipate is

D2624 TestMethodsforElectricalConductivityofAviation

inversely related to conductivity. This test method can supple-

and Distillate Fuels

ment Test Method D2624 which is limited to fuels containing

D4306 Practice for Aviation Fuel Sample Containers for

static dissipator additive.

Tests Affected by Trace Contamination

NOTE 1—For low-conductivity fluids below 1 pS/m in conductivity, an

E1 Specification for ASTM Liquid-in-Glass Thermometers

acmeasurementtechniqueispreferabletoadctestmethodforsensingthe

electrical conductivity of bulk fluid. This dc test method can be used at

3. Terminology

conductivities from 0.1 to 1 pS/m if precautions are observed in cell

3.1 picosiemens per metre—the unit of electrical conductiv-

cleaningandsamplehandling.Awaitingperiodof15minisrequiredafter

filling the cell before measuring dc conductivities below 1 pS/m. A

ity is also called a conductivity unit (CU). A siemen is the SI

single-laboratoryprogramwasconductedcomparingthistestmethodwith

definition of reciprocal ohm sometimes called mho.

ac Test Methods D150.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.J0.04 on Additives and Electrical Properties.

Current edition approved Feb. 15, 2010. Published March 2010. Originally

approved in 1983. Last previous edition approved in 2005 as D4308–95 (2005).

DOI: 10.1520/D4308-95R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Supporting data have been filed at ASTM International Headquarters and may

the ASTM website. be obtained by requesting Research Report RR:D02-1241.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4308–95 (2010)

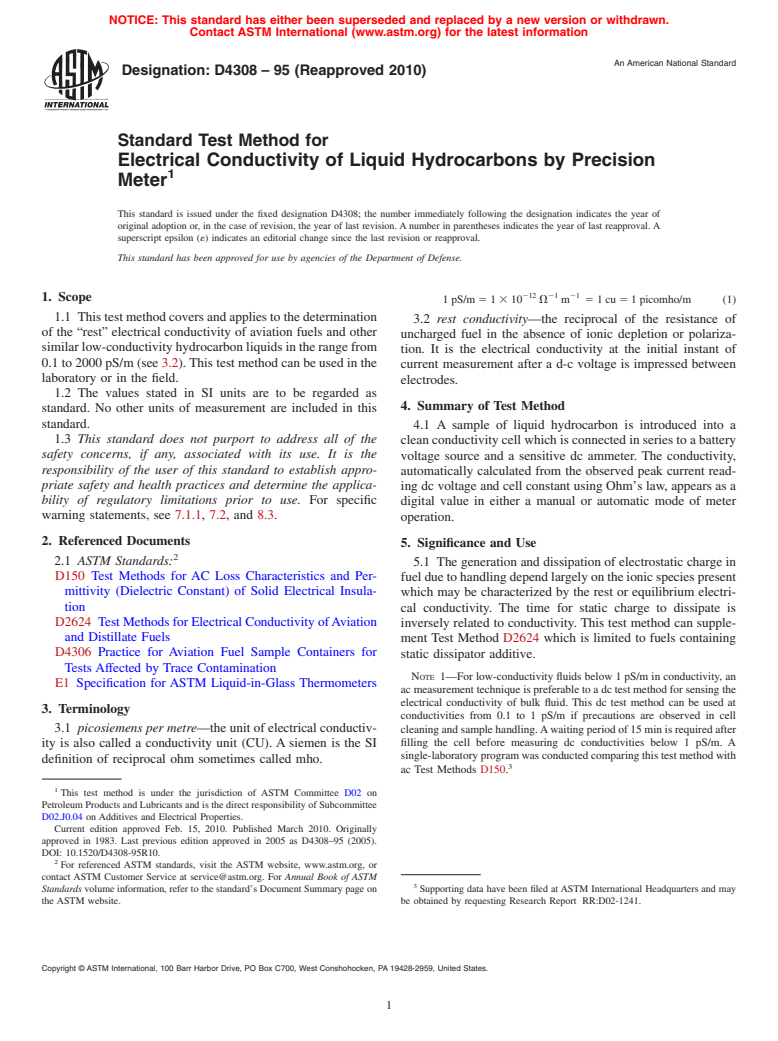

FIG. 1 Precision Conductivity Meter

6. Apparatus umesoftolueneandthreevolumesofisopropylalcoholbothof

reagent grade and distill. Discard the first 20 % and last 5 %

6.1 Conductivity Apparatus—Components of the dc con-

4,5

fractions.

ductivity apparatus are shown in Fig. 1.

7.2 n-Heptane—(Warning—Flammable. Harmful if in-

6.1.1 The conductivity cell shown in Fig. 1 consists of an

haled. See Annex A1.2.) Prepare by percolating ASTM refer-

inner electrode and an outer electrode separated by an insula-

,

5 6

ence fuel grade n-heptane through silica gel as follows:

tor. The outer electrode and cap provide a ground path and

7.2.1 Activate approximately 2000 g of 100 to 200 mesh

electrostatic (Faraday) shield.

silica gel by heating at 180°C for 24 h. Allow it to cool in a

6.1.2 The electrometer shown in Fig. 1 contains a battery

desiccator under nitrogen or in vacuum. Soak approximately

which supplies a voltage to the cell and a bridge circuit which

,

5 7

0.5 g of glass wool for 24 h in clean n-heptane.

senses the flow of current and converts the output signal

7.2.2 Take a tube of borosilicate glass having an inside

directly into conductivity units, that is, pS/m. A pushbutton

diameter of 60 to 70 mm, a length 1500 mm, with a conically

selector allows selection of zero reading, calibration, and four

shaped lower end provided with a glass cock. Place a perfo-

range selections.

rated porcelain disk (diameter 25 mm) in the lower end of the

6.1.3 The cell and electrometer are connected by a triaxial

tube and put the soaked glass wool on top of the disk. Fill the

cable as shown in Fig. 1.

tube with the activated silica gel while tapping to achieve

6.2 Thermometer, calibrated to 0.5°C and conforming to

homogeneousfilling.Thesilicagellayerwillbeapproximately

Specification E1.

1250 mm high. Wrap the column in black paper to exclude

light.

7. Reagents

7.2.3 Percolate n-heptane through the column at a rate of

7.1 Cleaning Solvent, The following may be used:

about 2 to 3 L/h. Discard the first 3 L. Never allow the column

7.1.1 Toluene-Isopropyl Alcohol Mixture—(Warning—

to run dry.The silica gel charge is sufficient for the percolation

Flammable. Vapor harmful. See Annex A1.1.) Mix two vol-

of 1000 L of n-heptane, provided the conductivity of the

untreated n-heptane is below 1 pS/m.

The sole source of supply of the apparatus, the KSLA Cell and Precision

Conductivity Meter System, Emcee Model #1154, known to the committee at this The sole source of supply known to the committee at this time is Code 923,

time is Emcee Electronics, Inc., 520 Cypress Ave., Venice, FL 34285. from W. R. Grace & Co., Davison Chemical Division, Baltimore, MD 21202.

5 7

If you are aware of alternative suppliers, please provide this information to The sole source of supply of the apparatus, filtering fiber Pyrex Wool.

ASTM International Headquarters. Your comments will receive careful consider- Catalogue No. 3950, known to the committee at this time is Owens-Corning Fiber

ation at a meeting of the responsible technical committee, which you may attend. Glass Corp., Toledo, OH.

D4308–95 (2010)

NOTE 2—If the conductivity of the n-heptane after treatment, measured

9.1.2.1 After cleaning, check the cleanliness of the cell by

in accordance with Section 11 in a thoroughly cleaned cell, is higher than

measuring the conductivity of treated n-heptane in accordance

0.1 pS/m, the treatment should be repeated.

with Section 11. The corrected value should be lower than 0.1

7.3 Hydrocarbon, for calibration. The dielectric constant

pS/m.

must be known to 65 % at the temperature of calibration. 9.2 Cleaning of Auxiliary Equipment:

9.2.1 Pipets used to transfer samples should be rinsed inside

8. Sampling

and outside with cleaning solvent using a non-contaminating

8.1 The sample volume should be at least 0.7 L. squeeze bottle, then blown dry with clean, dry nitrogen.

8.2 Use a clean epoxy-lined can, or a new glass bottle that

Thermometers should be similarly rinsed and maintained.

has been rinsed successively with hot water, distilled water,

NOTE 5—If a cell has been used to test samples of high-conductivity,

acetone, and cleaning solvent then flush with dry nitrogen. Use

that is, more than 1000 pS/m, it should be disassembled for thorough

only non-contaminating caps.

cleaning.Verythoroughcleaningmayalsobeaccomplishedbyplacingthe

disassembled cell in a Soxhlet apparatus containing boiling toluene/

NOTE 3—Test method results are known to be sensitive to trace

isopropyl alcohol for several hours.

contamination from sampling containers. For recommended sampling

NOTE 6—If testing is to be done on both low-conductivity (<1 pS/m)

containers refer to Practice D4306.

and high-conductivity (>1000 pS/m) samples, separate cells are recom-

NOTE 4—Bottle samples should be tested immediately, since the glass

mended.

surface tends to absorb from the fuel the conductive substances that the

test method is intended to measure.

10. Calibration and Standardization

8.3 Rinse the container several times with portions of the

10.1 Checking the Test Equipment:

aviation turbine fuel to be sampled (JetAorA-1, (Warning—

10.1.1 Remove cell and cable from the meter.

Combustible. Vapor harmful. See Annex A1.3.), Jet B

10.1.2 Depress the 20-pS/m switch. The digital reading

(Warning—Extremely flammable. Harmful if inhaled. Vapors

should indicate 0.00 6 0.01 pS/m after 3 s. If reading

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.