ASTM D4306-20

(Practice)Standard Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

Standard Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

SIGNIFICANCE AND USE

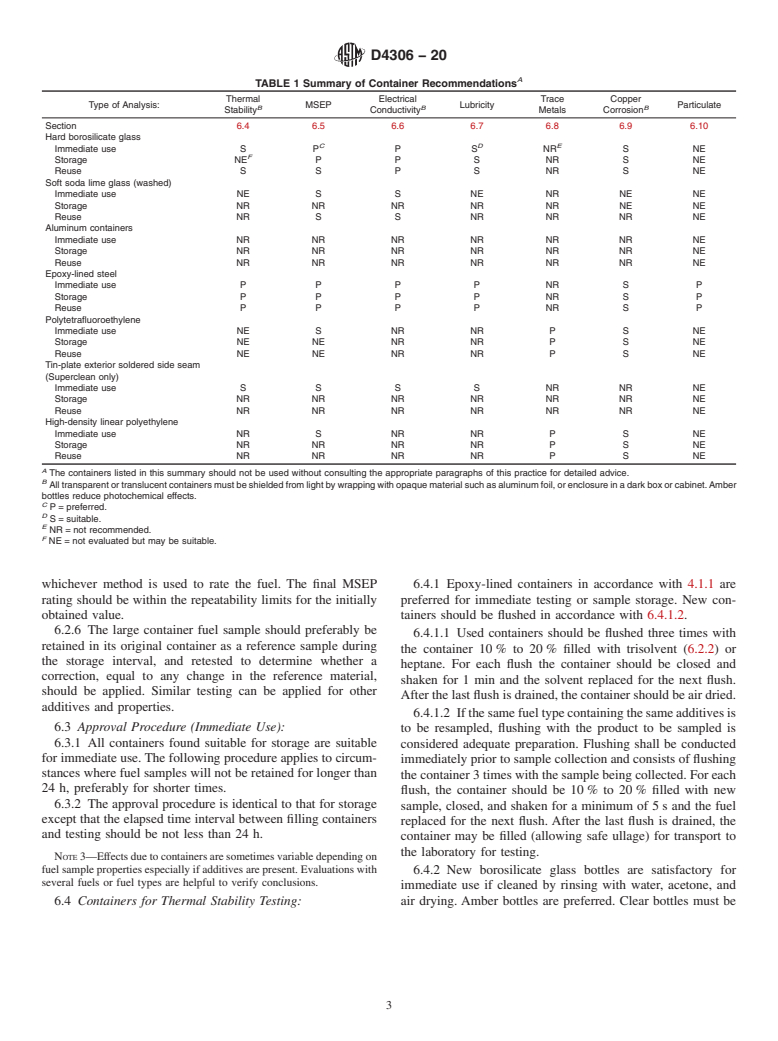

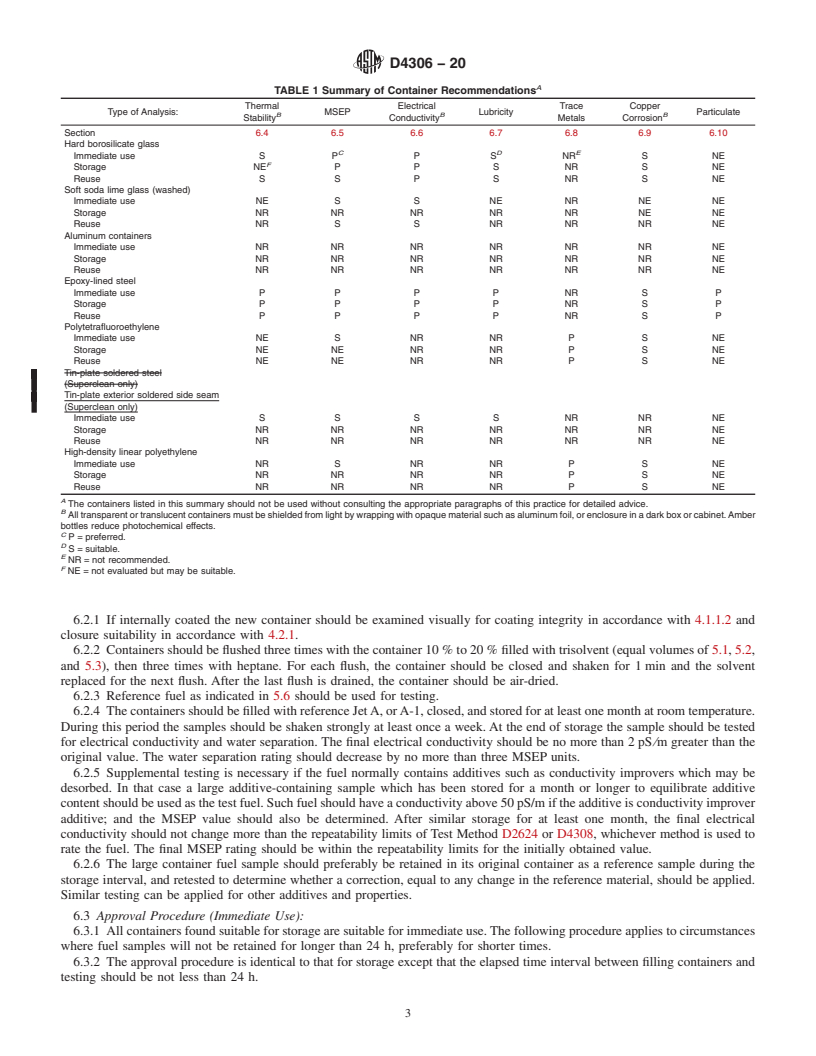

3.1 General descriptions for the manual sampling of petroleum products are given in Practice D4057. However, a number of aviation fuel properties are established or affected by trace levels of polar or other compounds. Measurement significance therefore requires that the sample containers not add or adsorb any materials. This practice presents types and preparations of sampling containers found satisfactory for the determination of water separation, copper corrosion, electrical conductivity, thermal stability, lubricity, and trace metal content. The choice of construction materials is an important factor, particularly in the case of aviation turbine fuel, where thermal stability can be degraded by the presence of very low concentrations of copper. The use of copper or copper based alloys shall be eliminated from aviation sampling apparatus. An approval procedure for new containers is also given.

3.2 Two properties, particulate contamination and free water content, involve materials easily removed by any sampling container. These properties should be determined by placing the sample directly into the measuring apparatus and not using containers to transport the sample to the measuring equipment.

3.3 Recommendations in this practice provide guidance for immediate use and for storage of samples. Immediate use involves sample storage for periods less than 24 h.

SCOPE

1.1 This practice2 covers the types of and preparation of containers found most suitable for the handling of aviation fuel samples for the determination of critical properties affected by trace contamination.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 5.1, 5.2, 5.3, 5.4, and 5.6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4306 − 20

Standard Practice for

Aviation Fuel Sample Containers for Tests Affected by Trace

1

Contamination

This standard is issued under the fixed designation D4306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D4057 Practice for Manual Sampling of Petroleum and

2 Petroleum Products

1.1 This practice covers the types of and preparation of

D4308 Test Method for Electrical Conductivity of Liquid

containers found most suitable for the handling of aviation fuel

Hydrocarbons by Precision Meter

samples for the determination of critical properties affected by

D5452 Test Method for Particulate Contamination in Avia-

trace contamination.

tion Fuels by Laboratory Filtration

1.2 The values stated in SI units are to be regarded as 4

2.2 SAE Standard:

standard. No other units of measurement are included in this

MAP1794 Aircraft Recommended Practice, Ball-On-

standard.

Cylinder (Boc) Aircraft Turbine Fuel Lubricity Tester

1.3 This standard does not purport to address all of the

3. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1 General descriptions for the manual sampling of petro-

priate safety, health, and environmental practices and deter- leum products are given in Practice D4057. However, a

mine the applicability of regulatory limitations prior to use. number of aviation fuel properties are established or affected

For specific warning statements, see 5.1, 5.2, 5.3, 5.4, and 5.6. by trace levels of polar or other compounds. Measurement

1.4 This international standard was developed in accor- significance therefore requires that the sample containers not

dance with internationally recognized principles on standard- add or adsorb any materials. This practice presents types and

ization established in the Decision on Principles for the preparations of sampling containers found satisfactory for the

Development of International Standards, Guides and Recom- determination of water separation, copper corrosion, electrical

mendations issued by the World Trade Organization Technical conductivity, thermal stability, lubricity, and trace metal con-

Barriers to Trade (TBT) Committee. tent. The choice of construction materials is an important

factor, particularly in the case of aviation turbine fuel, where

2. Referenced Documents

thermal stability can be degraded by the presence of very low

3

2.1 ASTM Standards: concentrations of copper. The use of copper or copper based

alloys shall be eliminated from aviation sampling apparatus.

D2624 Test Methods for Electrical Conductivity ofAviation

and Distillate Fuels An approval procedure for new containers is also given.

D3948 TestMethodforDeterminingWaterSeparationChar-

3.2 Twoproperties,particulatecontaminationandfreewater

acteristicsofAviationTurbineFuelsbyPortableSeparom-

content, involve materials easily removed by any sampling

eter

container. These properties should be determined by placing

the sample directly into the measuring apparatus and not using

1

containers to transport the sample to the measuring equipment.

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

3.3 Recommendations in this practice provide guidance for

mittee D02.J0.04 on Additives and Electrical Properties.

immediate use and for storage of samples. Immediate use

Current edition approved May 1, 2020. Published June 2020. Originally

approved in 1984. Last previous edition approved 2015 as D4306 – 15. DOI:

involves sample storage for periods less than 24 h.

10.1520/D4306-20.

2

The detailed data on which this practice is based may be found in SAE Practice

4. Apparatus

MAP1794 and three research reports. Supporting data have been filed at ASTM

4.1 Sampling Containers:

International Headquarters and may be obtained by requesting Research Reports

RR:D02-1169, RR:D02-1142, and RR:D02-1504.

4.1.1 Epoxy-Coated Containers:

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrend

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4306 − 15 D4306 − 20 An American National Standard

Standard Practice for

Aviation Fuel Sample Containers for Tests Affected by Trace

1

Contamination

This standard is issued under the fixed designation D4306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This practice covers the types of and preparation of containers found most suitable for the handling of aviation fuel samples

for the determination of critical properties affected by trace contamination.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific warning statements, see 5.1, 5.2, 5.3, 5.4, and 5.6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D2624 Test Methods for Electrical Conductivity of Aviation and Distillate Fuels

D3948 Test Method for Determining Water Separation Characteristics of Aviation Turbine Fuels by Portable Separometer

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4308 Test Method for Electrical Conductivity of Liquid Hydrocarbons by Precision Meter

D5452 Test Method for Particulate Contamination in Aviation Fuels by Laboratory Filtration

4

2.2 SAE Standard:

MAP1794 Aircraft Recommended Practice, Ball-On-Cylinder (Boc) Aircraft Turbine Fuel Lubricity Tester

3. Significance and Use

3.1 General descriptions for the manual sampling of petroleum products are given in Practice D4057. However, a number of

aviation fuel properties are established or affected by trace levels of polar or other compounds. Measurement significance therefore

requires that the sample containers not add or adsorb any materials. This practice presents types and preparations of sampling

containers found satisfactory for the determination of water separation, copper corrosion, electrical conductivity, thermal stability,

lubricity, and trace metal content. The choice of construction materials is an important factor, particularly in the case of aviation

turbine fuel, where thermal stability can be degraded by the presence of very low concentrations of copper. The use of copper or

copper based alloys shall be eliminated from aviation sampling apparatus. An approval procedure for new containers is also given.

3.2 Two properties, particulate contamination and free water content, involve materials easily removed by any sampling

container. These properties should be determined by placing the sample directly into the measuring apparatus and not using

containers to transport the sample to the measuring equipment.

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.J0.04 on Additives and Electrical Properties.

Current edition approved Oct. 1, 2015May 1, 2020. Published October 2015June 2020. Originally approved in 1984. Last previous edition approved 20132015 as

D4306 – 13.D4306 – 15. DOI: 10.1520/D4306-15.10.1520/D4306-20.

2

The detailed data on which this practice is based may be found in SAE Practice MAP1794 and three research reports. Supporting data have been filed at ASTM

International Headquarters and may be obtained by requesting Research Reports RR:D02-1169, RR:D02-1142, and RR:D02-1504.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.