ASTM D7844-18

(Test Method)Standard Test Method for Condition Monitoring of Soot in In-Service Lubricants by Trend Analysis using Fourier Transform Infrared (FT-IR) Spectrometry

Standard Test Method for Condition Monitoring of Soot in In-Service Lubricants by Trend Analysis using Fourier Transform Infrared (FT-IR) Spectrometry

SIGNIFICANCE AND USE

5.1 An increase in soot material can lead to increased wear, filter plugging and viscosity, which is usually a consideration for diesel engines, although it may also be an indicator of carburetor or injector problems in other fuel systems. Monitoring of soot is therefore an important parameter in determining overall machinery health and should be considered in conjunction with data from other tests such as atomic emission (AE) and atomic absorption (AA) spectroscopy for wear metal analysis (Test Method D5185), physical property tests (Test Methods D445, D6304 and D2896), and other FT-IR oil analysis methods for oxidation (Test Method D7414), sulfate by-products (Test Method D7415), nitration (Test Method D7624), additive depletion (Test Method D7412), and breakdown products and external contaminants (Practice E2412), which also assess elements of the oil’s condition (1-6).

SCOPE

1.1 This test method pertains to field-based monitoring soot in diesel crankcase engine oils as well as in other types of engine oils where soot may contaminate the lubricant as a result of a blow-by due to incomplete combustion of in-service fuels.

1.2 This test method uses FT-IR spectroscopy for monitoring of soot build-up in in-service lubricants as a result of normal machinery operation. Soot levels in engine oils rise as soot particles contaminate the oil as a result of exhaust gas recirculation or a blow-by. This test method is designed as a fast, simple spectroscopic check for monitoring of soot in in-service lubricants with the objective of helping diagnose the operational condition of the machine based on measuring the level of soot in the oil.

1.3 Acquisition of FT-IR spectral data for measuring soot in in-service oil and lubricant samples is described in Standard Practice D7418. In this test method, measurement and data interpretation parameters for soot using both direct trend analysis and differential (spectral subtraction) trend analysis are presented.

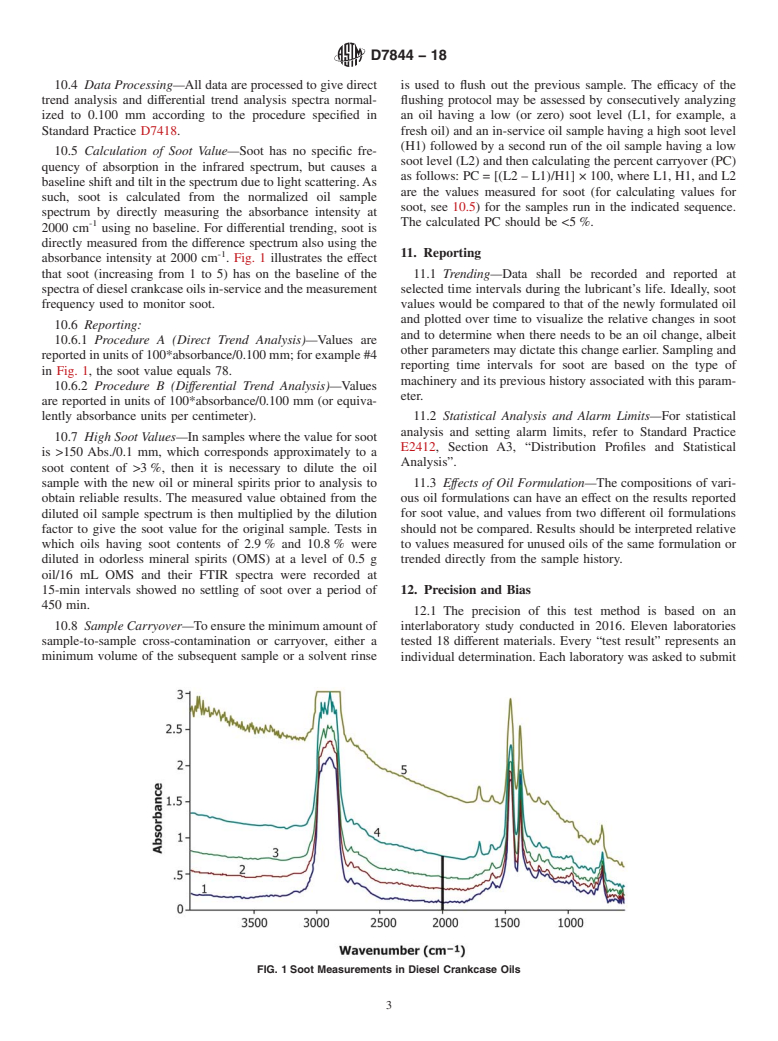

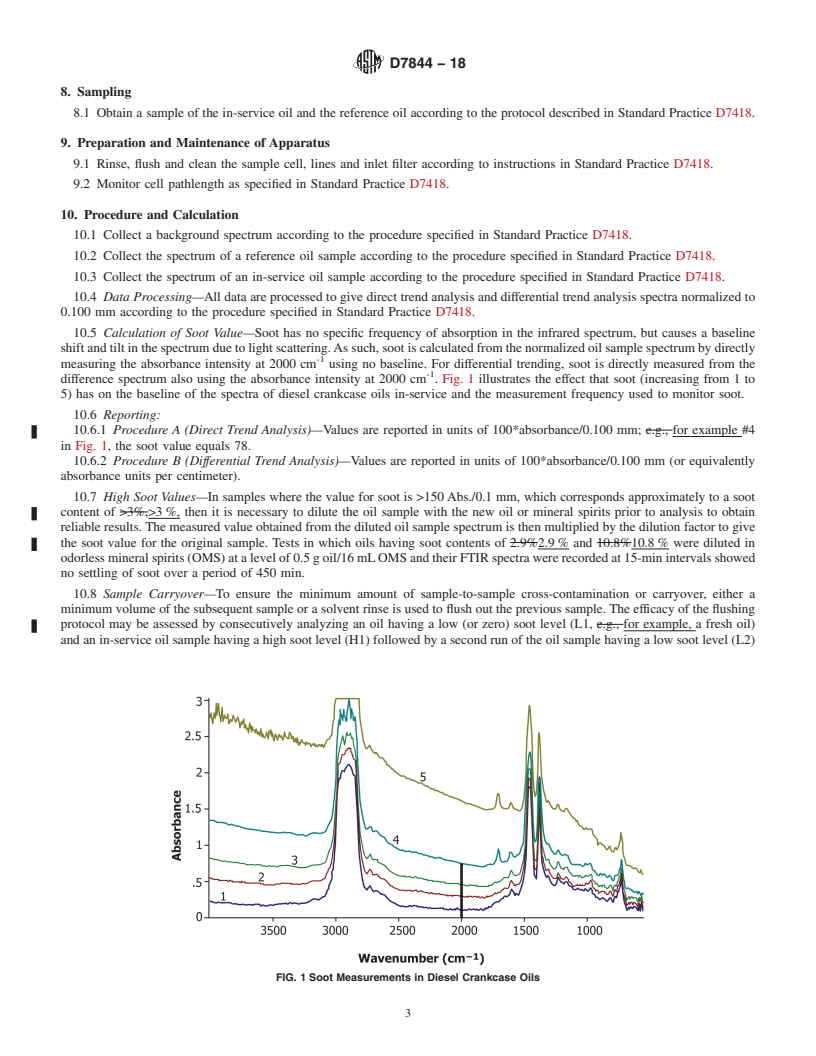

1.4 This test method is based on trending of spectral changes associated with soot in in-service lubricants. For direct trend analysis, values are recorded directly from absorbance spectra and reported in units of 100*absorbance per 0.1 mm pathlength. For differential trend analysis, values are recorded from the differential spectra (spectrum obtained by subtraction of the spectrum of the reference oil from that of the in-service oil) and reported in units of 100*absorbance per 0.1 mm pathlength (or equivalently absorbance units per centimeter). Warnings or alarm limits can be set on the basis of a fixed maximum value for a single measurement or, alternatively, can be based on a rate of change of the response measured (1).2 In either case, such maintenance action limits should be determined through statistical analysis, history of the same or similar equipment, round robin tests or other methods in conjunction with the correlation of soot levels to equipment performance.

Note 1: It is not the intent of this test method to establish or recommend normal, cautionary, warning, or alert limits for any machinery. Such limits should be established in conjunction with advice and guidance from the machinery manufacturer and maintenance group.

1.5 This test method is primarily for petroleum/hydrocarbon based lubricants but is also applicable for ester based oils, including polyol esters or phosphate esters.

1.6 This method is intended as a field test only, and should be treated as such. Critical applications should use laboratory based methods, such as Thermal Gravimetric (TGA) analysis described in Standard Method D5967, Annex A4.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This inter...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7844 − 18

Standard Test Method for

Condition Monitoring of Soot in In-Service Lubricants by

Trend Analysis using Fourier Transform Infrared (FT-IR)

1

Spectrometry

This standard is issued under the fixed designation D7844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope* be based on a rate of change of the response measured (1). In

either case, such maintenance action limits should be deter-

1.1 This test method pertains to field-based monitoring soot

mined through statistical analysis, history of the same or

in diesel crankcase engine oils as well as in other types of

similar equipment, round robin tests or other methods in

engine oils where soot may contaminate the lubricant as a

conjunction with the correlation of soot levels to equipment

resultofablow-byduetoincompletecombustionofin-service

performance.

fuels.

NOTE 1—It is not the intent of this test method to establish or

1.2 This test method uses FT-IR spectroscopy for monitor- recommendnormal,cautionary,warning,oralertlimitsforanymachinery.

Suchlimitsshouldbeestablishedinconjunctionwithadviceandguidance

ing of soot build-up in in-service lubricants as a result of

from the machinery manufacturer and maintenance group.

normal machinery operation. Soot levels in engine oils rise as

1.5 Thistestmethodisprimarilyforpetroleum/hydrocarbon

soot particles contaminate the oil as a result of exhaust gas

based lubricants but is also applicable for ester based oils,

recirculation or a blow-by. This test method is designed as a

including polyol esters or phosphate esters.

fast, simple spectroscopic check for monitoring of soot in

in-servicelubricantswiththeobjectiveofhelpingdiagnosethe

1.6 This method is intended as a field test only, and should

operational condition of the machine based on measuring the

be treated as such. Critical applications should use laboratory

level of soot in the oil.

based methods, such as Thermal Gravimetric (TGA) analysis

described in Standard Method D5967, Annex A4.

1.3 AcquisitionofFT-IRspectraldataformeasuringsootin

in-service oil and lubricant samples is described in Standard

1.7 This standard does not purport to address all of the

Practice D7418. In this test method, measurement and data

safety concerns, if any, associated with its use. It is the

interpretation parameters for soot using both direct trend

responsibility of the user of this standard to establish appro-

analysis and differential (spectral subtraction) trend analysis

priate safety, health, and environmental practices and deter-

are presented.

mine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accor-

1.4 This test method is based on trending of spectral

dance with internationally recognized principles on standard-

changesassociatedwithsootinin-servicelubricants.Fordirect

ization established in the Decision on Principles for the

trend analysis, values are recorded directly from absorbance

Development of International Standards, Guides and Recom-

spectra and reported in units of 100*absorbance per 0.1 mm

mendations issued by the World Trade Organization Technical

pathlength. For differential trend analysis, values are recorded

Barriers to Trade (TBT) Committee.

from the differential spectra (spectrum obtained by subtraction

of the spectrum of the reference oil from that of the in-service

2. Referenced Documents

oil) and reported in units of 100*absorbance per 0.1 mm

3

pathlength (or equivalently absorbance units per centimeter). 2.1 ASTM Standards:

Warnings or alarm limits can be set on the basis of a fixed

D445Test Method for Kinematic Viscosity of Transparent

maximumvalueforasinglemeasurementor,alternatively,can

and Opaque Liquids (and Calculation of DynamicViscos-

ity)

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

Subcommittee D02.96.03 on FTIR Testing Practices and Techniques Related to this standard.

3

In-Service Lubricants. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2018. Published March 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2009. Last previous edition approved in 2012 as D7844–12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7844-18. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © AS

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7844 − 12 D7844 − 18

Standard Test Method for

Condition Monitoring of Soot in In-Service Lubricants by

Trend Analysis using Fourier Transform Infrared (FT-IR)

1

Spectrometry

This standard is issued under the fixed designation D7844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method pertains to field-based monitoring soot in diesel crankcase engine oils as well as in other types of engine

oils where soot may contaminate the lubricant as a result of a blow-by due to incomplete combustion of in-service fuels.

1.2 This test method uses FT-IR spectroscopy for monitoring of soot build-up in in-service lubricants as a result of normal

machinery operation. Soot levels in engine oils rise as soot particles contaminate the oil as a result of exhaust gas recirculation

or a blow-by. This test method is designed as a fast, simple spectroscopic check for monitoring of soot in in-service lubricants with

the objective of helping diagnose the operational condition of the machine based on measuring the level of soot in the oil.

1.3 Acquisition of FT-IR spectral data for measuring soot in in-service oil and lubricant samples is described in Standard

Practice D7418. In this test method, measurement and data interpretation parameters for soot using both direct trend analysis and

differential (spectral subtraction) trend analysis are presented.

1.4 This test method is based on trending of spectral changes associated with soot in in-service lubricants. For direct trend

analysis, values are recorded directly from absorbance spectra and reported in units of 100*absorbance per 0.1 mm pathlength. For

differential trend analysis, values are recorded from the differential spectra (spectrum obtained by subtraction of the spectrum of

the reference oil from that of the in-service oil) and reported in units of 100*absorbance per 0.1 mm pathlength (or equivalently

absorbance units per centimeter). Warnings or alarm limits can be set on the basis of a fixed maximum value for a single

2

measurement or, alternatively, can be based on a rate of change of the response measured (1). In either case, such maintenance

action limits should be determined through statistical analysis, history of the same or similar equipment, round robin tests or other

methods in conjunction with the correlation of soot levels to equipment performance.

NOTE 1—It is not the intent of this test method to establish or recommend normal, cautionary, warning, or alert limits for any machinery. Such limits

should be established in conjunction with advice and guidance from the machinery manufacturer and maintenance group.

1.5 This test method is primarily for petroleum/hydrocarbon based lubricants but is also applicable for ester based oils,

including polyol esters or phosphate esters.

1.6 This method is intended as a field test only, and should be treated as such. Critical applications should use laboratory based

methods, such as Thermal Gravimetric (TGA) analysis described in Standard Method D5967, Annex A4.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.96.03 on FTIR Testing Practices and Techniques Related to In-Service Lubricants.

Current edition approved Dec. 1, 2012Jan. 1, 2018. Published January 2013March 2018. Originally approved in 2009. Last previous edition approved in 2012 as

D7844 – 12. DOI: 10.1520/D7844-12.10.1520/D7844-18.

2

Th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.