ASTM D1310-01(2007)

(Test Method)Standard Test Method for Flash Point and Fire Point of Liquids by Tag Open-Cup Apparatus

Standard Test Method for Flash Point and Fire Point of Liquids by Tag Open-Cup Apparatus

SIGNIFICANCE AND USE

Flash point and fire point of a liquid are physical properties that may be used to define their flammability hazards. The flash point may be used to classify materials in government regulations.

SCOPE

1.1 This test method covers the determination by Tag Open-Cup Apparatus of the flash point and fire point of liquids having flash points between 18 and 165°C (0 and 325°F) and fire points up to 325°F.

1.2 This test method, when applied to paints and resin solutions that tend to skin over or that are very viscous, gives less reproducible results than when applied to solvents. Note 1 - In order to conserve time and sample, the fire point of a material may be determined by the Tag Open-Cup Method by continuing the heating of the specimen to its fire point. Fire points may also be determined by Test Method D 92, which should be used for fire points beyond the scope of this test method.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors pertinent to an assessment of the fire hazard of a particular end use

This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1310 − 01 (Reapproved2007)

Standard Test Method for

Flash Point and Fire Point of Liquids by Tag Open-Cup

Apparatus

This standard is issued under the fixed designation D1310; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination by Tag 2.1 ASTM Standards:

Open-CupApparatusoftheflashpointandfirepointofliquids D92Test Method for Flash and Fire Points by Cleveland

having flash points between −18 and 165°C (0 and 325°F) and Open Cup Tester

fire points up to 325°F. D850Test Method for Distillation of Industrial Aromatic

Hydrocarbons and Related Materials

1.2 This test method, when applied to paints and resin

D1015Test Method for Freezing Points of High-Purity

solutions that tend to skin over or that are very viscous, gives

Hydrocarbons

less reproducible results than when applied to solvents.

D1016Test Method for Purity of Hydrocarbons from Freez-

NOTE 1—In order to conserve time and sample, the fire point of a

ing Points

material may be determined by the Tag Open-Cup Method by continuing

D1078Test Method for Distillation Range of Volatile Or-

the heating of the specimen to its fire point. Fire points may also be

ganic Liquids

determined by Test Method D92, which should be used for fire points

D1364Test Method for Water in Volatile Solvents (Karl

beyond the scope of this test method.

Fischer Reagent Titration Method)

1.3 The values stated in SI units are to be regarded as the

D2268Test Method for Analysis of High-Purity n-Heptane

standard. The values given in parentheses are for information

and Isooctane by Capillary Gas Chromatography

only.

D2699Test Method for Research Octane Number of Spark-

1.4 This standard should be used to measure and describe

Ignition Engine Fuel

thepropertiesofmaterials,products,orassembliesinresponse

D2700Test Method for Motor Octane Number of Spark-

to heat and flame under controlled laboratory conditions and

Ignition Engine Fuel

should not be used to describe or appraise the fire hazard or

E1Specification for ASTM Liquid-in-Glass Thermometers

fire risk of materials, products, or assemblies under actual fire

conditions. However, results of this test may be used as 3. Terminology

elements of a fire risk assessment which takes into account all

3.1 Definitions:

of the factors pertinent to an assessment of the fire hazard of a

3.1.1 flash point, n—the lowest temperature, corrected to a

particular end use.

pressure of 760 mm Hg (101.3 kPa, 1013 mbar), at which

1.5 This standard does not purport to address the safety

application of an ignition source causes the vapor of the

problems associated with its use. It is the responsibility of the

specimen to ignite by the procedure described.

user of this standard to establish appropriate safety and health

3.2 Definitions of Terms Specific to This Standard:

practices and determine the applicability of regulatory limita-

3.2.1 fire point, n—the lowest temperature at which a

tions prior to use.

specimen sustains burning for a minimum of5sbythe

procedure described.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2007. Published August 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1952. Last previous edition approved in 2001 as D1310–01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1310-01R07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1310 − 01 (2007)

NOTE 2—For materials with vapors or products of pyrolysis that are

4. Summary of Method

objectionable,itispermissibletoplacetheapparatuswithshieldinafume

4.1 The specimen is placed in the cup of a Tag Open-Cup

hoodwiththeventilationturnedoff.Theventilationcanthenbeturnedon

Apparatus and heated at a slow, but constant rate.Asmall test

at completion of the test, or when and if fumes become objectionable.

flame is passed at a uniform rate across the cup at specified

8.2 Adjust the horizontal and vertical positions of the taper

intervals until a flash occurs. To determine the fire point, the

so that the jet passes on the circumference of a circle having a

test is continued until the application of the test flame causes

radiusofatleast6in.(150mm).Thejetshouldpassacrossthe

the specimen to ignite and burn for at least 5 s.

center of the cup at right angles to a diameter passing through

thethermometerandinaplane ⁄8in.(3.2mm)abovetheupper

5. Significance and Use

edge of the cup as measured from the center of the orifice.

5.1 Flash point and fire point of a liquid are physical

8.3 Using the leveling device as a gage, adjust the height of

properties that may be used to define their flammability

the taper so that the center of the orifice is exactly ⁄8 in. (3.2

hazards. The flash point may be used to classify materials in

mm) above the top edge of the glass cup when it is in place. It

government regulations.

is imperative that this adjustment be made as accurately as

possible. Raising or lowering the taper can be achieved by

6. Apparatus

bending it slightly or preferably by adding and removing thin

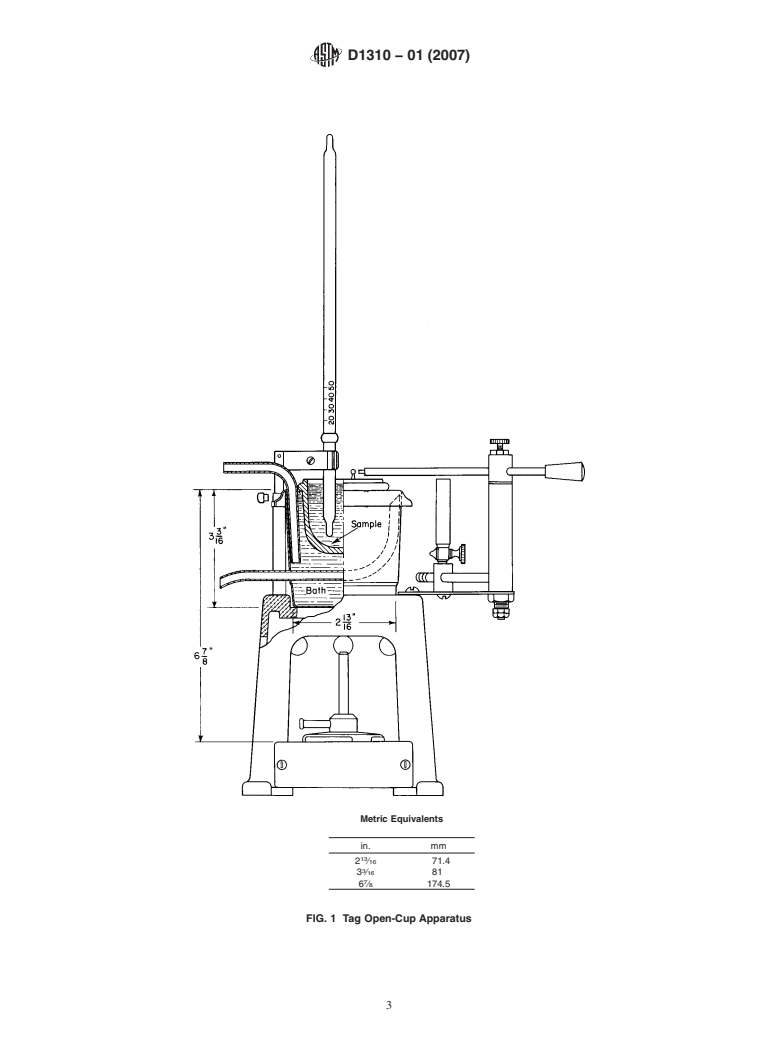

6.1 Flash Tester—Tag Open-Cup Apparatus (Fig. 1), as

metalshimsasrequiredfrombetweenthetaperandthevertical

described in detail in Annex A1.

supporting member of the swivel holder.

6.2 Shield, as described in detail in Annex A1.

8.4 With the glass cup in place in the bath, adjust the

6.3 Thermometers,conformingtoSpecificationE1,aslisted

thermometerholdersothatthethermometerissupportedfirmly

in Table 1.

in a vertical position halfway between the center and edge of

6.4 Flasks, 500-mL, two, with rubber stoppers. the cup and on a line passing through the center of the cup and

thepivotofthetaper.Placethethermometersothatthebottom

7. Materials

ofthebulbis ⁄4in.(6.4mm)fromtheinnerbottomofthecup.

7.1 Water-Glycol Solution (1+1), for flash points from −18

8.5 Set the draft shield around the tester so that the sides

to 93°C (0 to 200°F).

form right angles with each other and the tester is well toward

the back of the shield.

7.2 Solid Carbon Dioxide-Acetone or other Coolant.

7.3 Silicone Fluid, inert, high boiling, having a flash point

9. Procedure

exceeding the test temperatures by at least 60°C (110°F) for

flash and fire points from 93 to 165°C (200 to 325°F).

9.1 Flash Points from −18 to 16°C(0to60°F)(Warning—

Meticulous attention to all details relating to the taper, size of

7.4 n-Heptane, for determination of flash points from − 18

taper flame, rate of temperature increase, and rate of passing

to 16°C (0 to 60°F). See Annex A2 for specifications.

the taper over the sample is necessary for good results.)

7.5 p-Xylene, for determination of flash points from 16 to

9.1.1 Equiptwo500-mLflaskswithrubberstoppersthrough

93°C (60 to 200°F). See Annex A2 for specifications.

which are inserted ASTM 33C (33F) thermometers. Cool a

7.6 Isopropanol (isopropyl alcohol), for determination of

quantity of 1+1 water-glycol solution in one stoppered

flash points from 16 to 93°C (60 to 200°F). See AnnexA2 for

500-mL flask to approximately −30°C (−20°F) by immersing

specifications.

the flask in a solid carbon dioxide-acetone bath or other

coolant. Use extreme care not to contaminate the water-glycol

7.7 Diethylene Glycol, for determination of flash points

solution with either acetone or carbon dioxide.

from 93 to 165°C (200 to 325°F). See Annex A2 for specifi-

cations.

9.1.2 Pour the cooled water-glycol solution into the tester

bath to a predetermined level 3.2 mm ( ⁄8 in.) below the top

8. Assembly and Preparation of Apparatus

when the cup is in place. An overflow is desirable for

controlling the liquid level in the bath.

8.1 Placethetesterinalevelpositiononasolidtablefreeof

vibration, in a location free of perceptible draft, and in a dim 9.1.3 At the same time the water-glycol coolant is being

light. Maintain a room temperature of 24 6 3°C (75 6 5°F) chilled, cool a portion of the sample to approximately −25°C

throughout the test. Other room temperatures may be specified (−10°F) in the second stoppered 500-mL flask. If solid carbon

on agreement between buyer and seller. dioxide and acetone or other volatile solvents are used as a

coolant, extreme care must be exercised to avoid contamina-

tion of the sample. Cool the glass cup and place it in the bath.

Satisfactory n-heptane and p-xylene can be obtained from Special Products

Position the appropriate thermometer (Table 1) as described in

Division, Chemical Department, Phillips Petroleum Company, Drawer O, Borger,

8.4 and fill the cup with cooled sample to a depth approxi-

TX 79607.

4 mately 3.2 mm ( ⁄8 in.) below the edge as determined by the

Satisfactory isopropanol may be obtained from Exxon Chemical, Americus P.

leveling device.

O. Box 3272, Houston, TX 77001, Shell Chemical Co., One Shell Plaza, Houston,

TX 77002, or Union Carbide Co., P. O. Box 8361, South Charleston, WV 25303.

Satisfactory diethylene glycol may be obtained from Union Carbide Co., S. NOTE 3—Remove all bubbles from the surface of the liquid before

Charleston, WV. starting a determination.

D1310 − 01 (2007)

Metric Equivalents

in. mm

2 ⁄16 71.4

3 ⁄16 81

6 ⁄8 174.5

FIG. 1 Tag Open-Cup Apparatus

D1310 − 01 (2007)

TABLE 1 Thermometers

liquid or vapors. Fill the glass cup with the cooled sample to a

ASTM depth approximately ⁄8 in. (3.2 mm) below the edge as

Thermometer

Thermometer Thermometer Range

determined by the leveling device, with the proper thermom-

Subdivisions

Number

eter (see Table 1) positioned as described in 8.4.

Flash Point/

9.2.3 For final adjustment of the specimen level, see 9.1.5.

Fire Point:

0 to 60°F 33F-75 −36.5 to + 107.5°F 0.5°F

9.2.4 Light the ignition flame and adjust it as described in

−18 to 15°C 33C-75 −38 to + 42°C 0.2°C

9.1.4.

60 to 200°F 9F-75 20 to 230°F 1°F

9.2.5 Apply heat to the liquid bath and adjust so that the

15 to 93°C 9C-75 −5 to 110°C 0.5°C

200 to 325°F 35F-79 194 to 338°F 0.5°F

temperatureofthespecimenincreasesatarateof2 60.5°F(1

93 to 165°C 35C-79 90 to 170°C 0.2°C

6 0.25°C)/min.

9.2.6 Determine the approximate flash point by passing the

taper flame across the specimen at intervals of 2°F (1°C) as

9.1.4 Light the ignition flame and adjust it to form a flame

described in 9.1.7.

ofsphericalshapematchinginsizethe ⁄32-in.(4.0-mm)sphere

9.2.7 Continue with procedure in 9.4.

on the apparatus or the ⁄32-in. hole in the leveling device.

9.3 Procedure for Flash Points from 200 to 325°F (93 to

9.1.5 Makethefinaladjustmentofthespecimenlevelinthe

165°C) (See 9.1 and Notes 3-5):

cupwhenthetemperatureis20°F(10°C)belowtheanticipated

9.3.1 Fill the bath with a high-boiling inert silicone fluid to

flashpoint.Twotrialdeterminationsmaybenecessarytoselect

a predetermined level ⁄8 in. (3.2 mm) below the top when the

the proper temperature at which to adjust the liquid level. A

cup is in place.

hypodermicsyringeormedicinedropperprovidesaconvenient

9.3.2 With the appropriate thermometer (see Table 1) prop-

means of adding or removing sample from the cup.

erly positioned (8.4), fill the glass cup with sample at room

9.1.6 Allow the temperature of the specimen to increase

temperature to a depth slightly more than ⁄8 in. (3.2 mm)

spontaneously—without applying any heat—until the rate of

below the edge as determined by the leveling device.

temperature rise decreases to 2°F (1°C)/min. At this point,

9.3.3 For final adjustment of the specimen level, see 9.1.5.

apply heat to maintain an increase in temperature at a rate of 2

9.3.4 Light the ignition flame and adjust it as described in

6 0.5°F (1 6 0.25°C)/min.

9.1.4.

NOTE 4—With viscous materials, this rate of heating cannot always be

9.3.5 Apply full heat to the liquid bath; when the tempera-

maintained.

ture of the specimen reaches approximately 190°F (90°C),

9.1.7 Determine the approximate flash point by passing the

adjust the heat input so that the temperature of the specimen

taperflameacrossthespecimenatintervalsof2°F(1°C).Make

increases at a rate of 2 6 0.5°F (1 6 0.25°C)/min.

the first pass of the taper flame immediately after the final

NOTE 7—The heaters on some testers do not have sufficient capacity to

adjustmentofthespecimenlevel,asin9.1.5.Thetimerequired

maintain the proper rate of heating when the temperature approaches

topasstheignitionflameacrossthesurfaceoftheliquidshould

250°F (120°C) or above. The heat input to the liquid bath may be

be 1 s. Each pass must be in one direction only, and the taper

increased if necessary by using a variable transformer to increase the

voltage to the heater or by wrapping the bath with electrical heating tape.

should be kept in the “off” position at one or the other end of

The application of suitable insulation to the outside of the bath to prevent

the swing except when the flame is applied to the specimen. In

heat loss is also permissible. The important factor is to maintain the rate

case the material tends to “creep” over the edge of the cup,

of temperature increase of the specimen at 2 6 0.5°F (1 6 0.25°C)/min.

carefully wipe the edge with absorbant tissue to remove frost

9.3.6 Determine the approximate flash point by passing the

and liquid, just prior to passage of the taper over the cup.

taper flame across the specimen at intervals of 2°F (1°C) as

NOTE 5—When determining the flash point or fire point, or both, of

described in 9.1.7.

viscous liquids and those liquids that tend to form a surface film, the

following procedure is suggested: About 15 s before the taper is passed 9.4 Determine and record not less than three test values, as

over the surface, insert the end of a stirring rod to a depth of about ⁄2 in.

follows:

(15 mm) in approximately a vertical position. Move the rod from

9.4.1 Aftertheinitialtesttodeterminetheapproximateflash

side-to-side of the cup for three or four complete passes following

point of the materials, repeat the procedure by cooling a fresh

approximately the path of the taper, remove, and make the test.

portion of the sample, the glass cup, the bath solution, and the

NOTE 6—Discontinue heating and chec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.