ASTM D6128-06

(Test Method)Standard Test Method for Shear Testing of Bulk Solids Using the Jenike Shear Cell

Standard Test Method for Shear Testing of Bulk Solids Using the Jenike Shear Cell

SIGNIFICANCE AND USE

Reliable, controlled flow of bulk solids from bins and hoppers is essential in almost every industrial facility. Unfortunately, flow stoppages due to arching and ratholing are common. Additional problems include uncontrolled flow (flooding) of powders, segregation of particle mixtures, useable capacity which is significantly less than design capacity, caking and spoilage of bulk solids in stagnant zones, and structural failures.

By measuring the flow properties of bulk solids, and designing bins and hoppers based on these flow properties, most flow problems can be prevented or eliminated.

For bulk solids with a significant percentage of particles (typically, one third or more) finer than about 6 mm ( ¼ in.), the cohesive strength is governed by the fines (-6-mm fraction). For such bulk solids, cohesive strength and wall friction tests may be performed on the fine fraction only.

Note 1—The quality of the result produced by this test method is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this test method are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D 3740 provides a means of evaluating some of those factors. Practice D 3740 was developed for agencies engaged in the testing and/or inspection of soil and rock. As such it is not totally applicable to agencies performing this test method. However, users of this test method should recognize that the framework of Practice D 3740 is appropriate for evaluating the quality of an agency performing this test method. Currently there is no known qualifying national authority that inspects agencies that perform this test method.

SCOPE

1.1 This method covers the apparatus and procedures for measuring the cohesive strength of bulk solids during both continuous flow and after storage at rest. In addition, measurements of internal friction, bulk density, and wall friction on various wall surfaces are included.

1.2 This standard is not applicable to testing bulk solids that do not reach the steady state requirement within the travel limit of the shear cell. It is impossible to classify ahead of time which bulk solids cannot be tested, but one example may be those consisting of highly elastic particles.

1.3 The values stated in SI units are to be regarded as standard.

1.4 The most common use of this information is in the design of storage bins and hoppers to prevent flow stoppages due to arching and ratholing, including the slope and smoothness of hopper walls to provide mass flow. Parameters for structural design of such equipment also may be derived from this data.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6128 − 06

StandardTest Method for

1

Shear Testing of Bulk Solids Using the Jenike Shear Cell

This standard is issued under the fixed designation D6128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D3740Practice for Minimum Requirements for Agencies

2

Engaged in Testing and/or Inspection of Soil and Rock as

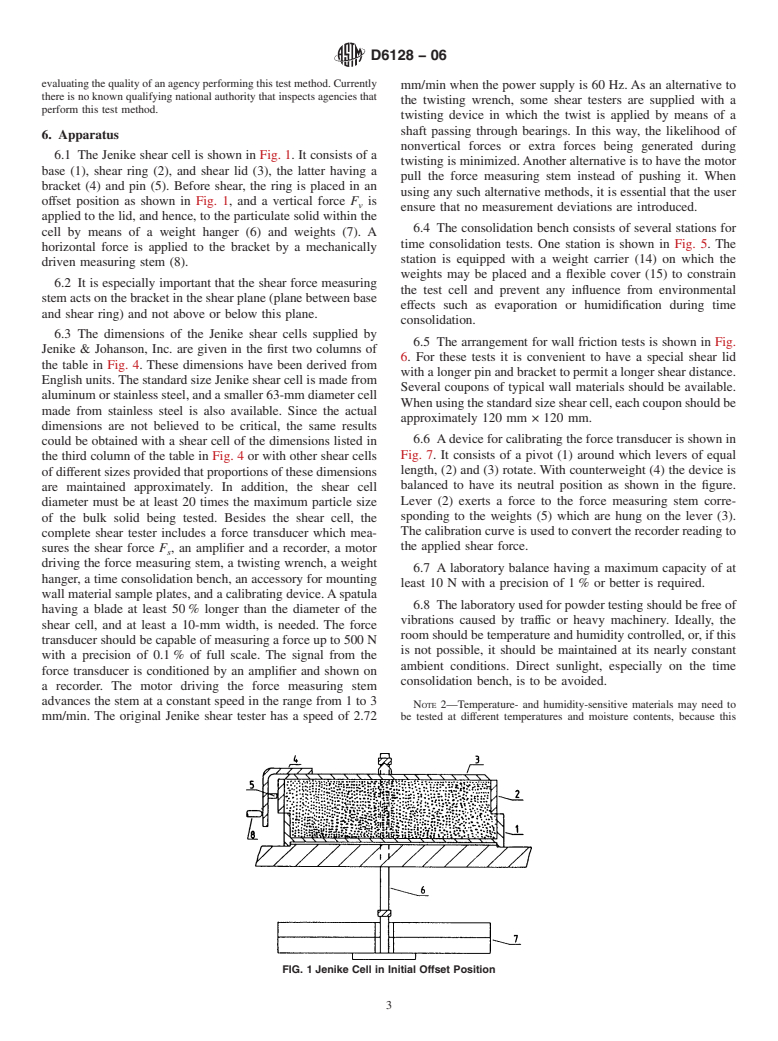

1.1 This method covers the apparatus and procedures for

Used in Engineering Design and Construction

measuring the cohesive strength of bulk solids during both

continuous flow and after storage at rest. In addition, measure-

3. Terminology

ments of internal friction, bulk density, and wall friction on

various wall surfaces are included.

3.1 Definitions:

3.1.1 Definitions of terms used in this test method are in

1.2 Thisstandardisnotapplicabletotestingbulksolidsthat

accordance with Terminology D653.

donotreachthesteadystaterequirementwithinthetravellimit

3.1.2 adhesion test, n—a static wall friction test with time

of the shear cell. It is impossible to classify ahead of time

consolidation.

which bulk solids cannot be tested, but one example may be

those consisting of highly elastic particles.

3.1.3 angle of internal friction, φ,n—theanglebetweenthe

i

axis of normal stress (abscissa) and the tangent to the yield

1.3 The values stated in SI units are to be regarded as

locus.

standard.

3.1.4 angle of wall friction, φ', n— the arctan of the ratio of

1.4 The most common use of this information is in the

the wall shear stress to the wall normal stress.

design of storage bins and hoppers to prevent flow stoppages

due to arching and ratholing, including the slope and smooth-

3.1.5 bin, n—a container or vessel for holding a bulk solid,

ness of hopper walls to provide mass flow. Parameters for

frequently consisting of a vertical cylinder with a converging

structural design of such equipment also may be derived from

hopper. Sometimes referred to as silo, bunker, or elevator.

this data.

3.1.6 bulk density, ρ,n—the mass of a quantity of a bulk

b

1.5 This standard does not purport to address all of the

solid divided by its total volume

safety concerns, if any, associated with its use. It is the

3.1.7 bulk solid, n—an assembly of solid particles handled

responsibility of the user of this standard to establish appro-

in sufficient quantities that its characteristics can be described

priate safety and health practices and determine the applica-

by the properties of the mass of particles rather than the

bility of regulatory limitations prior to use.

characteristicsofeachindividualparticle.Mayalsobereferred

to as granular material, particulate solid, or powder. Examples

2. Referenced Documents

are sugar, flour, ore, and coal.

3

2.1 ASTM Standards:

3.1.8 bunker, n—synonym for bin, but sometimes under-

D653Terminology Relating to Soil, Rock, and Contained

stood as being a bin without any or only a small vertical part

Fluids

at the top of the hopper.

3.1.9 cohesive strength, n—synonym for unconfined yield

1 strength.

This testing method is under the jurisdiction ofASTM Committee D18 on Soil

and Rock and is the direct responsibility of Subcommittee D18.24 on Character-

3.1.10 consolidation, n—the process of increasing the

ization and Handling of Powders and Bulk Solids.

strength of a bulk solid.

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approved in 1997. Last previous edition approved in 2000 as D6128–00. DOI:

3.1.11 critical state, n—a state of stress in which the bulk

10.1520/D6128-06.

2 density of a bulk solid and the shear stress in the shear zone

This test method is based on the “Standard Shear Testing Technique for

ParticulateSolidsUsingtheJenikeShearCell,”areportoftheEFCEWorkingParty remain constant.

on the Mechanics of Particulate Solids. Copyright is held by the Institution of

3.1.12 effective angle of friction, δ,n—the inclination of the

Chemical Engineers and the European Federation of Chemical Engineering.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or effective yield locus (EYL).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.13 effective yield locus (EYL), n—straight line passing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. throughtheoriginofthe σ, τ-planeandtangentialtothesteady

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6128 − 06

stateMohrcircle,corres

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.