ASTM F2718-09(2015)

(Specification)Standard Specification for Polyethylene (PE) and Cement Materials for an Encapsulated Cement Mortar Formed in Place Liner System (FIPLS) for the Rehabilitation of Water Pipelines (Withdrawn 2022)

Standard Specification for Polyethylene (PE) and Cement Materials for an Encapsulated Cement Mortar Formed in Place Liner System (FIPLS) for the Rehabilitation of Water Pipelines (Withdrawn 2022)

ABSTRACT

This specification covers requirements and test methods for materials for a semi-structural polyethylene (PE) encapsulated cement mortar formed-in-place liner system (FIPLS) intended for the rehabilitation of water pipelines. The liner and cement mortar are progressively rounded by means of an air pressure propelled pig and expanded against the interior surface of the original host pipe. After rounding, the line is maintained under pressure until the cement mortar cures and the liner is completely self supporting. The liner and the hooks shall be made from PE material meeting the minimum physical properties. The cement mortar is used to fill the ring cavity between the polyethylene liner and the host pipe. The cement mortar shall have the minimum physical properties.

SCOPE

1.1 This specification covers requirements and test methods for materials for a semi-structural polyethylene (PE) encapsulated cement mortar formed-in-place liner system (FIPLS) intended for the rehabilitation of water pipelines of nominal size 4 in. to 12 in. This renewal process involves installing a collapsed PE liner, folded at the time of insertion, into an existing pipeline, expanding the PE liner, and then pumping cement mortar into the annulus between the liner and the main.

1.2 The liner and cement mortar are progressively rounded by means of an air pressure propelled pig and expanded against the interior surface of the original host pipe. After rounding, the line is maintained under pressure until the cement mortar cures and the liner is completely self supporting.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 There is no similar or equivalent ISO standard.

WITHDRAWN RATIONALE

This specification covers requirements and test methods for materials for a semi-structural polyethylene (PE) encapsulated cement mortar formed-in-place liner system (FIPLS) intended for the rehabilitation of water pipelines of nominal size 4 in. to 12 in. This renewal process involves installing a collapsed PE liner, folded at the time of insertion, into an existing pipeline, expanding the PE liner, and then pumping cement mortar into the annulus between the liner and the main.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this specification was withdrawn in July 2022. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2718 −09 (Reapproved 2015)

Standard Specification for

Polyethylene (PE) and Cement Materials for an

Encapsulated Cement Mortar Formed in Place Liner System

1

(FIPLS) for the Rehabilitation of Water Pipelines

This standard is issued under the fixed designation F2718; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C109/C109M Test Method for Compressive Strength of

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

1.1 This specification covers requirements and test methods

Specimens)

for materials for a semi-structural polyethylene (PE) encapsu-

D638 Test Method for Tensile Properties of Plastics

lated cement mortar formed-in-place liner system (FIPLS)

D790 Test Methods for Flexural Properties of Unreinforced

intended for the rehabilitation of water pipelines of nominal

and Reinforced Plastics and Electrical Insulating Materi-

size 4 in. to 12 in. This renewal process involves installing a

als

collapsed PE liner, folded at the time of insertion, into an

D1505 Test Method for Density of Plastics by the Density-

existing pipeline, expanding the PE liner, and then pumping

Gradient Technique

cement mortar into the annulus between the liner and the main.

D1525 Test Method for Vicat Softening Temperature of

1.2 The liner and cement mortar are progressively rounded

Plastics

bymeansofanairpressurepropelledpigandexpandedagainst

D1600 Terminology forAbbreviatedTerms Relating to Plas-

theinteriorsurfaceoftheoriginalhostpipe.Afterrounding,the

tics

line is maintained under pressure until the cement mortar cures

D1693 Test Method for Environmental Stress-Cracking of

and the liner is completely self supporting.

Ethylene Plastics

F412 Terminology Relating to Plastic Piping Systems

1.3 The values stated in inch-pound units are to be regarded

3

as standard. The values given in parentheses are mathematical

2.2 NSF/ANSI:

conversions to SI units that are provided for information only

NSF/ANSI 14 for Plastic Piping Components and related

and are not considered standard.

Materials

NSF/ANSI 61 for Drinking Water Systems Components –

1.4 This standard does not purport to address all of the

Health Effects

safety concerns, if any, associated with its use. It is the

4

responsibility of the user of this standard to establish appro- 2.3 American Water Works Association Standards

Manual M28 Rehabilitation of Water Mains

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

1.5 There is no similar or equivalent ISO standard.

3.1 Unless otherwise indicated, definitions are in accor-

2. Referenced Documents

dance with Terminology F412, and abbreviations are in accor-

2

dance with Terminology D1600. The abbreviation of polyeth-

2.1 ASTM Standards:

ylene is PE.

1 3.2 Definitions of Terms Specific to This Standard:

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on 3.2.1 cement mortar, n—a specially formulated cement

Trenchless Plastic Pipeline Technology.

based grout.

Current edition approved March 1, 2015. Published April 2015. Originally

approved in 2009. Last previous edition approved in 2009 as F2718–09. DOI:

10.1520/F2718-09R15.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Arbor, MI 48105, http://www.nsf.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Water WorksAssociation (AWWA), 6666 W. Quincy

the ASTM website. Ave., Denver, CO 80235, http://www.awwa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2718−09 (2015)

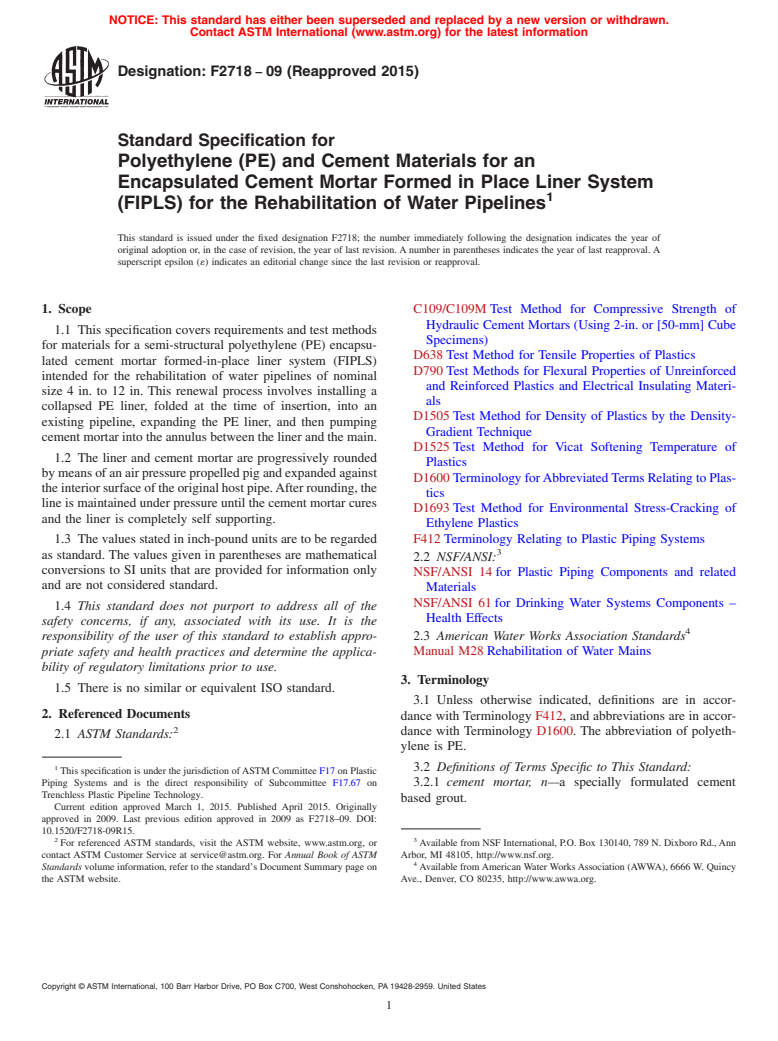

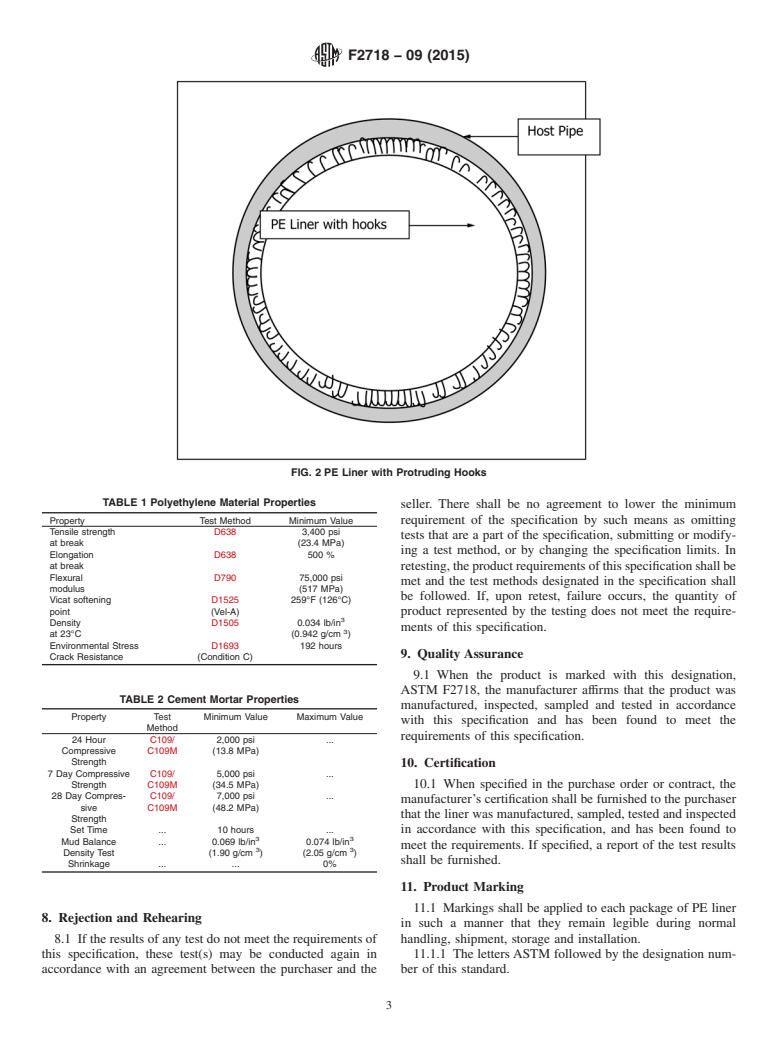

3.2.2 formed-in-place-liner system (FIPLS), n—after inser- 4.1.1 PE Materials—The liner and the hooks shall be made

tion of the liner and cement mortar, sequential insertion and from PE material meeting the minimum physical properties as

reforming of the liner and cement mortar in the host pipe, a

listed in Table 1.

composite system of cement mortar PE liner is formed. See

4.1.2 The cement mortar is used to fill the ring cavity

Fig. 1 and Fig. 2.

between the polyethylene liner and the host pipe. The cement

3.2.3 liner, n—a PE sheet with integral anchors or hooks mortar shall have the minimum physical properties as in Table

extruded in a flat shape then formed with ove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.