ASTM A254/A254M-12

(Specification)Standard Specification for Copper-Brazed Steel Tubing

Standard Specification for Copper-Brazed Steel Tubing

ABSTRACT

This specification covers double-wall, copper brazed steel tubing suitable for general engineering uses, particularly in the automotive, refrigeration, and stove industries for fuel lines, brake lines, oil lines, heating and cooling units, and the like. The tubing shall be made by rolling steel strip into the form of tubing and subsequently copper brazing in a reducing atmosphere. The steel shall conform to the prescribed chemical composition and shall be subjected to heat analysis and product analysis. Tension, flattening, expansion, bending, and pressure proof tests shall be made in accordance with the specification.

SCOPE

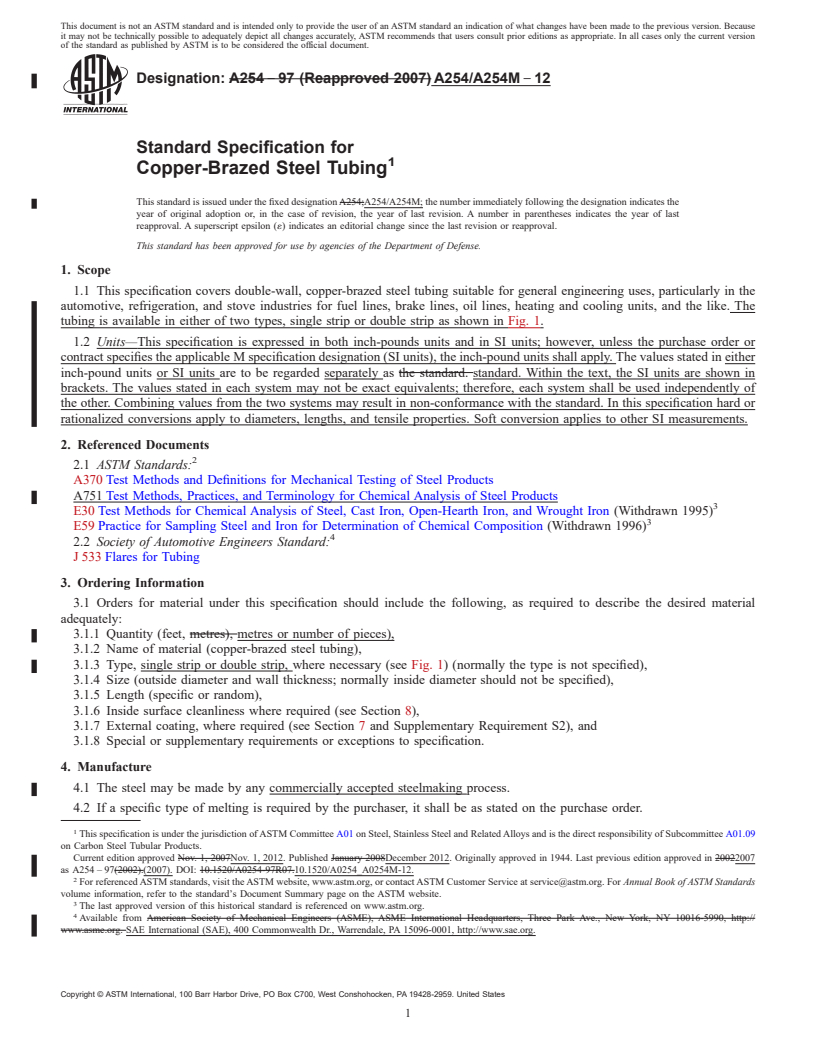

1.1 This specification covers double-wall, copper-brazed steel tubing suitable for general engineering uses, particularly in the automotive, refrigeration, and stove industries for fuel lines, brake lines, oil lines, heating and cooling units, and the like. The tubing is available in either of two types, single strip or double strip as shown in Fig. 1.

FIG. 1 Brazed Tubing, Double-Wall, 360-deg Brazed Construction

1.2 Units—This specification is expressed in both inch-pounds units and in SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. In this specification hard or rationalized conversions apply to diameters, lengths, and tensile properties. Soft conversion applies to other SI measurements.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A254/A254M −12

Standard Specification for

1

Copper-Brazed Steel Tubing

This standard is issued under the fixed designationA254/A254M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

4

1. Scope 2.2 Society of Automotive Engineers Standard:

J533Flares for Tubing

1.1 This specification covers double-wall, copper-brazed

steel tubing suitable for general engineering uses, particularly

3. Ordering Information

in the automotive, refrigeration, and stove industries for fuel

3.1 Orders for material under this specification should

lines, brake lines, oil lines, heating and cooling units, and the

include the following, as required to describe the desired

like. The tubing is available in either of two types, single strip

material adequately:

or double strip as shown in Fig. 1.

3.1.1 Quantity (feet, metres or number of pieces),

1.2 Units—This specification is expressed in both inch-

3.1.2 Name of material (copper-brazed steel tubing),

pounds units and in SI units; however, unless the purchase

3.1.3 Type,singlestripordoublestrip,wherenecessary(see

order or contract specifies the applicable M specification

Fig. 1) (normally the type is not specified),

designation (SI units), the inch-pound units shall apply. The

3.1.4 Size (outside diameter and wall thickness; normally

values stated in either inch-pound units or SI units are to be

inside diameter should not be specified),

regardedseparatelyasstandard.Withinthetext,theSIunitsare

3.1.5 Length (specific or random),

showninbrackets.Thevaluesstatedineachsystemmaynotbe

3.1.6 Inside surface cleanliness where required (see Section

exact equivalents; therefore, each system shall be used inde-

8),

pendentlyoftheother.Combiningvaluesfromthetwosystems

3.1.7 External coating, where required (see Section 7 and

may result in non-conformance with the standard. In this

Supplementary Requirement S2), and

specification hard or rationalized conversions apply to

3.1.8 Special or supplementary requirements or exceptions

diameters, lengths, and tensile properties. Soft conversion

to specification.

applies to other SI measurements.

4. Manufacture

2. Referenced Documents

4.1 The steel may be made by any commercially accepted

2

2.1 ASTM Standards: steelmaking process.

A370Test Methods and Definitions for Mechanical Testing

4.2 Ifaspecifictypeofmeltingisrequiredbythepurchaser,

of Steel Products

it shall be as stated on the purchase order.

A751Test Methods, Practices, and Terminology for Chemi-

4.3 The primary melting may incorporate separate degas-

cal Analysis of Steel Products

sing or refining and may be followed by secondary melting,

E30Test Methods for ChemicalAnalysis of Steel, Cast Iron,

3

such as electroslag remelting or vacuum-arc remelting. If

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

secondary melting is employed, the heat shall be defined as all

E59Practice for Sampling Steel and Iron for Determination

3

of the ingots remelted from a single primary heat.

of Chemical Composition (Withdrawn 1996)

4.4 Steel may be cast in ingots or may be strand cast.When

steel of different grades is sequentially strand cast, identifica-

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

tion of the resultant transition material is required. The

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

producer shall remove the transition material by an established

A01.09 on Carbon Steel Tubular Products.

Current edition approved Nov. 1, 2012. Published December 2012. Originally

procedure that positively separates the grades.

approved in 1944. Last previous edition approved in 2007 as A254–97(2007).

4.5 The tubing shall be made by rolling steel strip into the

DOI: 10.1520/A0254_A0254M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

form of tubing and subsequently copper brazing in a reducing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

atmosphere.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

4

The last approved version of this historical standard is referenced on AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

www.astm.org. PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A254/A254M−12

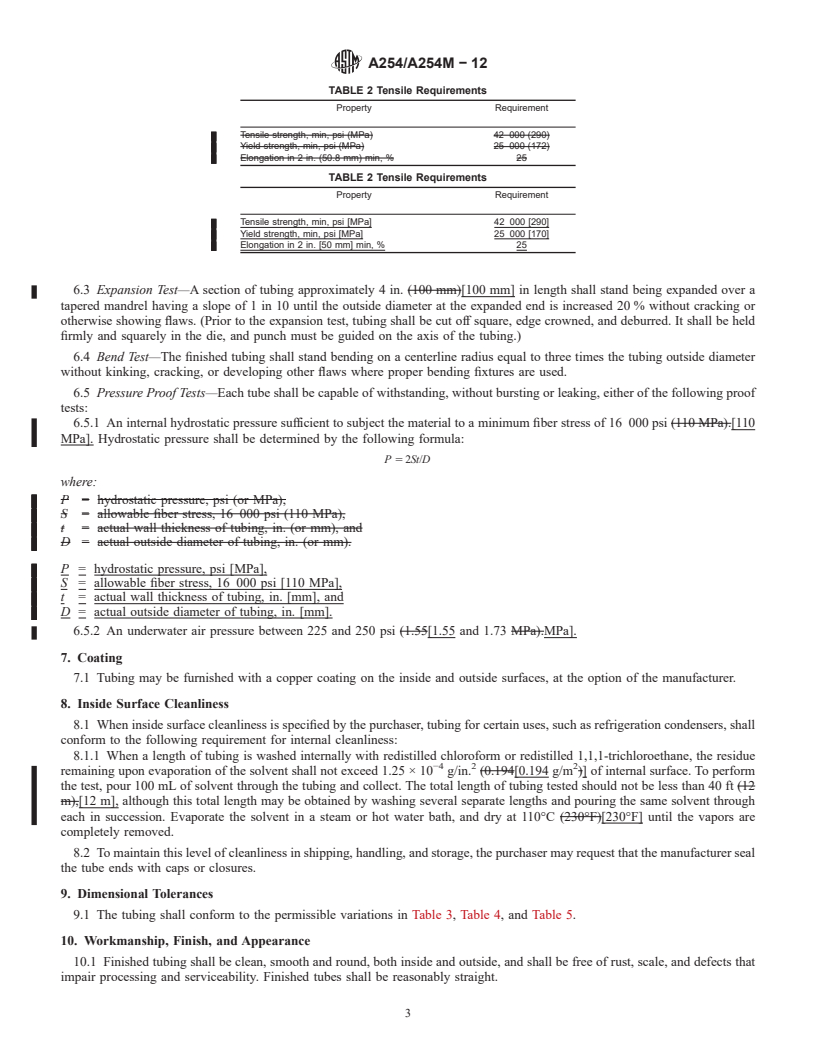

TABLE 2 Tensile Requirements

Property Requirement

Tensile strength, min, psi [MPa] 42

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A254 − 97 (Reapproved 2007) A254/A254M − 12

Standard Specification for

1

Copper-Brazed Steel Tubing

This standard is issued under the fixed designation A254;A254/A254M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers double-wall, copper-brazed steel tubing suitable for general engineering uses, particularly in the

automotive, refrigeration, and stove industries for fuel lines, brake lines, oil lines, heating and cooling units, and the like. The

tubing is available in either of two types, single strip or double strip as shown in Fig. 1.

1.2 Units—This specification is expressed in both inch-pounds units and in SI units; however, unless the purchase order or

contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either

inch-pound units or SI units are to be regarded separately as the standard. standard. Within the text, the SI units are shown in

brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of

the other. Combining values from the two systems may result in non-conformance with the standard. In this specification hard or

rationalized conversions apply to diameters, lengths, and tensile properties. Soft conversion applies to other SI measurements.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

3

E30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

3

E59 Practice for Sampling Steel and Iron for Determination of Chemical Composition (Withdrawn 1996)

4

2.2 Society of Automotive Engineers Standard:

J 533 Flares for Tubing

3. Ordering Information

3.1 Orders for material under this specification should include the following, as required to describe the desired material

adequately:

3.1.1 Quantity (feet, metres), metres or number of pieces),

3.1.2 Name of material (copper-brazed steel tubing),

3.1.3 Type, single strip or double strip, where necessary (see Fig. 1) (normally the type is not specified),

3.1.4 Size (outside diameter and wall thickness; normally inside diameter should not be specified),

3.1.5 Length (specific or random),

3.1.6 Inside surface cleanliness where required (see Section 8),

3.1.7 External coating, where required (see Section 7 and Supplementary Requirement S2), and

3.1.8 Special or supplementary requirements or exceptions to specification.

4. Manufacture

4.1 The steel may be made by any commercially accepted steelmaking process.

4.2 If a specific type of melting is required by the purchaser, it shall be as stated on the purchase order.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved Nov. 1, 2007Nov. 1, 2012. Published January 2008December 2012. Originally approved in 1944. Last previous edition approved in 20022007

as A254 – 97(2002).(2007). DOI: 10.1520/A0254-97R07.10.1520/A0254_A0254M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org. SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A254/A254M − 12

FIG. 1 Brazed Tubing, Double-Wall, 360-deg Brazed Construction

4.3 The primary melting may incorporate separate degassing or refining and may be followed by secondary melting, such as

electroslag remelti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.