ASTM E663-86(1991)E01

(Practice)Practice for Flame Atomic Absorption Analysis (Withdrawn 1997)

Practice for Flame Atomic Absorption Analysis (Withdrawn 1997)

General Information

Standards Content (Sample)

-

ASTM Ebb3*EL 86 S 87595E0 O076545 4

AMERICAN SOCIETY FOR TESTING AND MATERIALS

41)) Designation: E 663 - 86 (Reapproved 1991)''

1916 Race St Philadelphia, Pa 19103

Reprinted from the Annwl Book of ASTM Standards. Copyright ASTM

if not listed in the current combined bide><; wl appear in the next editon

Standard Practice for

Flame Atomic Absorption Analysis'

This standard is issued under the fixed designation E 663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE-Section 12 was added editorially in July 1991.

1. Scope solution by flame atomization. It includes the preparation of

curves (Figs. 1 and 2) to establish the useful calibration range

1,l This practice covers the use of an atomic absorption

for the instrument and analytical method to be used. With

spectrophotometer (AAS) for determining the concentration

these curves the operator can objectively determine the

of elements in solution by flame atomization. Recommenda-

useful concentration range of a particular instrument. Once

tions are provided for preparing the instrument for making

the useful concentration range is established for a specific

measurements, measuring the sensitivity, establishing criteria

atomic absorption procedure and instrument, repetition of

which should result in satisfactory instrument performance,

the work is not required unless the performance of the

determining the useful calibration concentration range, and

instrument changes. These operations are common to and

measuring and calculating the test solution analyte concen-

are a part of some basic atomic absorption methods.

tration.

1.2 This standard does not purport to address all of the

5. Atomic Absorption Theory and Practice

safeiy problems, if any, associated with its use. It is ihe

5.1 In atomic absorption, a test solution is aspirated into a

responsibility of the user of this standard to establish appro-

flame through which passes radiation from a line emission

priate safety and health practices and determine the applica-

source of the element sought. The radiation of the element

bility of regulatory limitations prior to use. Specific precau-

sought is absorbed in proportion to the concentration of its

tionary statements are given in Section 6 and specific

neutral atoms present in the flame. The concentration of the

warning statements are given in Note 4.

analyte is obtained by comparison to calibration solutions.

5.2 A theoretical basis for using atomic absorption to

2. Referenced Documents

determine analyte concentration is described by Walsh

2. I ASTM Standards:

A broader more practical background can be found in a

E 50 Practices for Apparatus, Reagents, and Safety Pre-

modern text on instrumental analysis such as that by Willard

cautions for Chemical Analysis of Metals2

et al (2). A detailed discussion of atomic absorption theory

E 13 1 Terminology Relating to Molecular Spectroscopy3

and practice can be found in Dean and Rains (3).

E 135 Terminology Relating to Analytical Atomic

6. Safety Precautions

Spectroscopy4

E 863 Practice for Describing Flame Atomic Absorption 6.1 Operating personnel should adhere to the manufactur-

Spectroscopy Equipment4 er's recommended practice for igniting and extinguishing the

burner on the atomic absorption spectrophotometer, to

3. Terminology

avoid an explosion which could cause physical injury. See

Note 4. Also see Practices E 50 for further general safety

3.1 For definitions of terms used in this practice, refer to

precautions.

Terminology E 13 1 and E 135.

3.2 Description of Term Specific to This Standard:

7. Preparation of Reference, Blank, and Calibration Solu-

3.2.1 useful concentration range-the useful concentra-

tions

tion range is the range in analyte concentrations through

7.1 Reference Solution-Combine all acids, reagents, and

which the precision of the method or the AAS, or both, are

other additions present in the test solution and dilute to the

acceptable.

same concentrations. This solution is used to set the zero

4. Significance and Use

absorbance or 100 % transmittance of the AAS.

7.2 Blank Solution-Incorporate in the reference solution

4.1 This practice describes how to prepare and calibrate

all the specimen matrix elements of significant concentra-

an AAS for the quantitative determination of elements in

tion, except the analyte, in the same concentrations as in the

test solution.

I This practice is under the jurisdiction of ASTM Committee E-I on Analytical

NOTE I-In practice it may not always be possible to obtain matrix

Chemistry for Metals, Ores and Related Materials and is the direct responsibility of

elements containing nonmeasurable quantities of analyte. In such

Subcommittee E01 -20 on Fundamental Practices.

situations a correction must be applied as directed in 7.3 or 8.2.

Current edition approved Aug. 29, 1986. Published October 1986. Originally

published as E 663 - 78. Last previous edition E 663 - 78.

Annirai Book ofASTM Standards, Vol 03.05.

Anniral Book of ASTM Standards, Vol 14.0 I. The boldface numbers in parentheses refer to the list of references at the end

Anniral Book ofASTM Slandards, Vol 03.06.

of this practice.

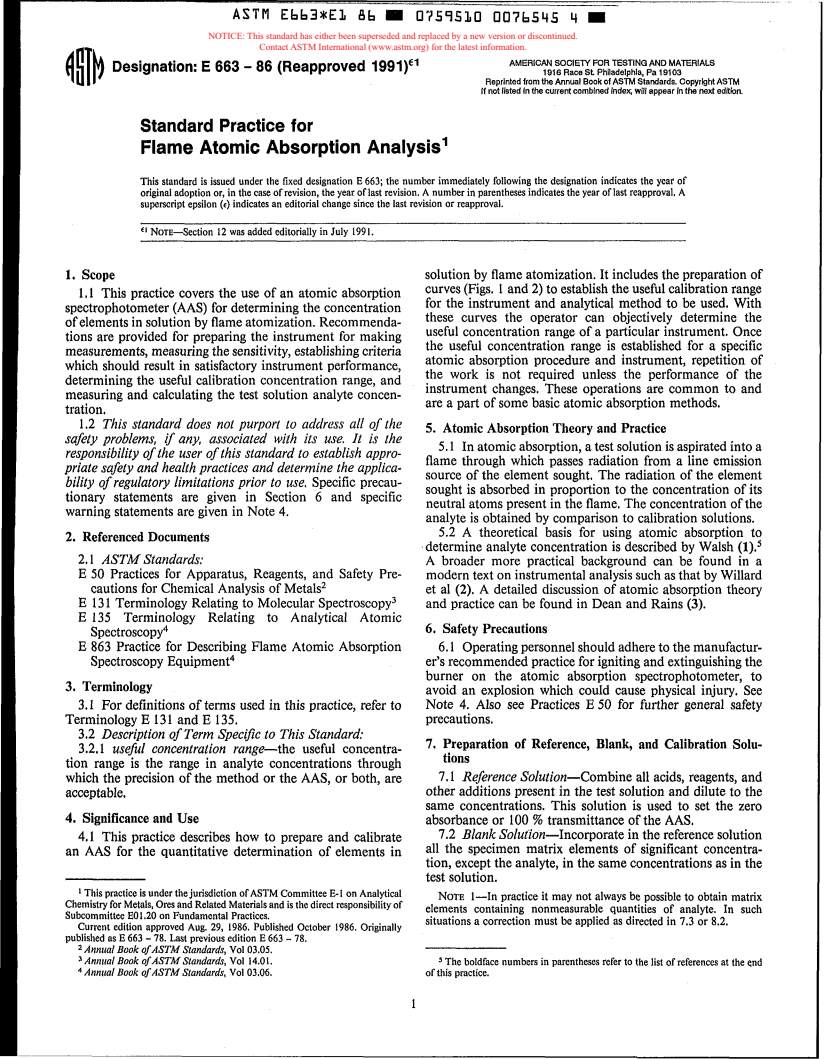

ASTM Ebb3*El 8b-r Ö7Ci5lÖ 007bSYb b

10.0

8.0

Useful Range RCE

-

Inst 1 5 to 130 1X

I Inst 2 15 to 85 2%

6.0

w

4.0

2.0

-

.-

I

I. I I

O 20 40 60 80 100 120 140

Concen era tion, vg/mL

FIG. 1 RCE Versus Concentration (Lead in 2 % Nitric Acid, 283.3.nm Line)

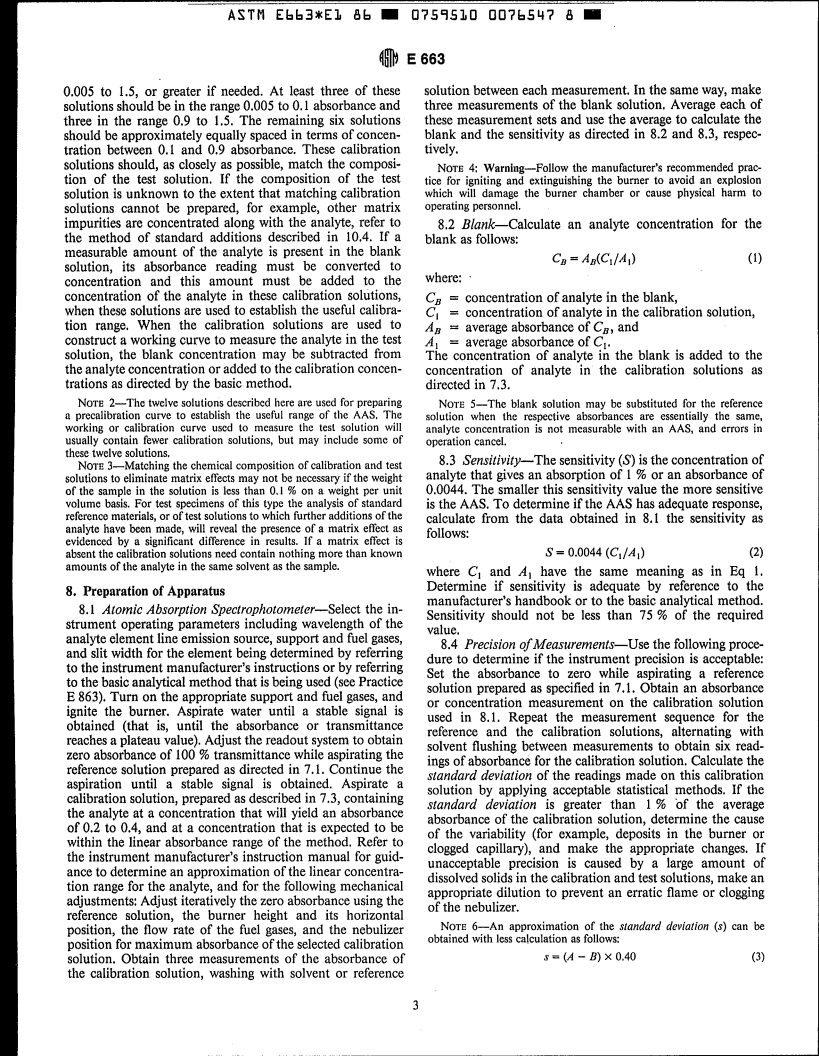

io( ‘10.0

O( -8.0

6Q 6.0

F

A*

fi

.’.f

H

N

W

bo b . Q

20 2.0

I II I Il

1 2 3 4 6 810 20 30 40 60 DO 100 200

Cuiiceiitrntion, 1ig/iiii.

PIG. 2 Typical Curves (Lead In 2 % Nitric Acid, 283.3-nm Line)

7.3 Colìúration Soliitions-Using the manufacturer’s data

twelve calibration solutions to cover the absorbance range

as r? guide and some triai and error, prepare a minimum of

ASTM Ebb3*E1 Bb 0759510 0076547 B 0

4m E663

solution between each measurement. In the same way, make

0.005 to 1.5, or greater if needed. At least three of these

solutions should be in the range 0.005 to O. 1 absorbance and three measurements of the blank solution. Average each of

these measurement sets and use the average to calculate the

three in the range 0.9 to 1.5. The remaining six solutions

blank and the sensitivity as directed in 8.2 and 8.3, respec-

should be approximately equally spaced in terms of concen-

tration between O. 1 and 0.9 absorbance. These calibration tively,

solutions should, as closely as possible, match the composi-

NOTE 4: Warning-Follow the manufacturer’s recommended prac-

tion of the test solution. If the composition of the test

tice for igniting and extinguishing the burner to avoid an exploslon

which will damage the burner chamber or cause physical harm to

solution is unknown to the extent that matching calibration

operating personnel.

solutions cannot be prepared, for example, other matrix

impurities are concentrated along with the analyte, refer to

8.2 Blank-Calculate an analyte concentration for the

the method of standard additions described in 10.4. If a

blank as follows:

measurable amount of the analyte is present in the blank

c, = AB(G/Al) (1)

solution, its absorbance reading must be converted to

where: .

concentration and this amount must be added to the

concentration of the analyte in these calibration solutions,

C, = concentration of analyte in the blank,

when these solutions are used to establish the useful calibra-

Cl = concentration of analyte in the calibration solution,

tion range, When the calibration solutions are used to

A, = average absorbance of CE, and

construct a working curve to measure the analyte in the test

A = average absorbance of Cl.

solution, the blank concentration may be subtracted from The concentration of analyte in the blank is added to the

the analyte concentration or added to the calibration concen- concentration of analyte in the calibration solutions as

trations as directed by the basic method.

directed in 7.3.

NOTE 2-The twelve solutions described here are used for preparing

NOTE 5-The blank solution may be substituted for the reference

a precalibration curve to establish the useful range of the AAS. The

solution when the respective absorbances are essentially the same,

working or calibration curve uscd to measure the test solution will

analyte concentration is not measurable with an AAS, and errors in

usually contain fewer calibration solutions, but may include some of

operation cancel.

these twelve solutions.

8.3 Sensitivity-The sensitivity (S) is the concentration of

NOTE 3-Matching the chemical composition of calibration and test

analyte that gives an absorption of 1 % or an absorbance of

solutions to eliminate matrix effects may not be necessary if the weight

0.0044. The smaller this sensitivity value the more sensitive

of the sample in the solution is less than 0.1 % on a weight per unit

volume basis. For test specimens of this type the analysis of standard

is the AAS. To determine if the AAS has adequate response,

or of test solutions to which further additions of the

reference materials,

calculate from the data obtained in 8.1 the sensitivity as

analyte have been made, will reveal the presence of a matrix effect as

follows:

evidenced by a significant difference in results. If a matrix effect is

absent the calibration solutions need contain nothing more than known S = 0.0044 (C,/A,) (2)

amounts of the analyte in the same solvent as the sample.

where Cl and A, have the same meaning as in Eq 1.

Determine if sensitivity is adequate by reference to the

8. Preparation of Apparatus

manufacturer’s handbook or to the basic analytical method.

8.1 Alomic Absorption Spectrophotometer-Select the in-

Sensitivity should not be less than 75 % of the required

strument operating parameters including wavelength of the

value.

analyte element line emission source, support and fuel gases,

8.4 Precision of Measurements-Use the following proce-

and slit width for the element being determined by referring

dure to determine if the instrument precision is acceptable:

to the instrument manufacturer’s instructions or by referring

Set the absorbance to zero while aspirating a reference

to the basic analytical method that is being used (see Practice

solution prepared as specified in 7.1. Obtain an absorbance

E 863). Turn on the appropriate support and fuel gases, and

or concentration measurement on the calibration solution

ignite the burner. Aspirate water until a stable signal is

used in 8.1. Repeat the measurement sequence for the

obtained (that is, until the absorbance or transmittance

reference and the calibration solutions, alternating with

reaches a plateau value). Adjust the readout system to obtain

solvent flushing between measurements to obtain six read-

zero absorbance of 100 % transmittance while aspirating the

ings of absorbance for the calibration solution. Calculate the

reference solution prepared as directed in 7.1. Continue the

standard deviation of the readings made on this calibration

aspiration until a stable signal is obtained. Aspirate a

solution by applying acceptable statistical methods. If the

calibration solution, prepared as described in 7.3, containing

standard deviation is greater than 1 % of the average

the analyte at a concentration that will yield an absorbance

absorbance of the calibration solution, determine the cause

of 0.2 to 0.4, and at a concentration that is expected to be

of the variability (for example, deposits in the burner or

within the linear absorbance range of the method. Refer to

clogged capillaxy), and make the appropriate changes. If

the instrument manufacturer’s instruction manual for guid-

unacceptable precision is caused by a large amount of

ance to determine an approximation of the linear concentra-

dissolved solids in the calibration and test solutions, make an

tion range for the analyte, and for the following mechanical

appropriate dilution to prevent an erratic flame or clogging

adjustments: Adjust iteratively the zero absorbance using the

of the nebulizer.

reference solution, the burner height and its horizontal

NOTE 6-An approximation of the sfandard deviation (s) can be

position, the flow rate of the fuel gases, and the nebulizer

obtained with less calculation as follows:

position for maximum absorbance of the selected calibration

s = (A - E) X 0.40

(3)

solution. Obtain three measurements of the absorbance of

the calibration solution, washing with solvent or reference

ASTM Ebb38Eli 8b Y 875951i13 8076548 T

measurements and will have a useful range of 15 to 85

w liere:

A = the highest of the six readings, and

WmL.

I3 = the lowest of the six readings.

NOTE 7-If a conservative cross check on this approach to the uaful

range is desired, process the average absorbances as directed in 9.3.

9.3 Conservative Determinatiori of UseJiil Concenrralion

9, Dcterminntion of Useful Concentration Range

Range-If a rigorous determination of the high and low

9.1 General Cotisiderations-The useful concentration

limits of the useful concentration range is not required, this

range for a particular analytical system must be determined

conservative approach may be used and will require substan-

experimentally because the useful range will depend on the

tialIy fewer measurements (6,7,8). Make a single measure.

operation and characteristics of the individual AAS, Three

ment of transmittance for each of the calibration solutions as

dift’erent approaches to the determination of this useful range

described in 9.1.1. If only absorbance can be measured on

are described in 9.2, 9.3, and 9.4. Selection of the approach

the instrument or is available from other measurements,

to be used depends on the precision requirements of the

convert each absorbance measurement to percent transmit-

analytical method, or the limitations of the AAS used, or the

tance by means of the relationship:

concentration range of the analyte in the material to be

A loglo( 100/% T) (5)

analyzed, or all three.

9,l.I For any of the three approaches prepare reference

where:

and calibration solutions as directed in 7. i and 7.3. Prepare

A = absorbance, and

the AAS and adjust the readout system to zero absorbance or

T = transmittance.

100 % transmittance as directed in 8.1 using the reference

Make two plots, one of % T against the loglo concentration

solution. Aspirate the calibration solutions in the order

of the analy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.