ASTM B272-12(2019)

(Specification)Standard Specification for Copper Flat Products with Finished (Rolled or Drawn) Edges (Flat Wire and Strip)

Standard Specification for Copper Flat Products with Finished (Rolled or Drawn) Edges (Flat Wire and Strip)

ABSTRACT

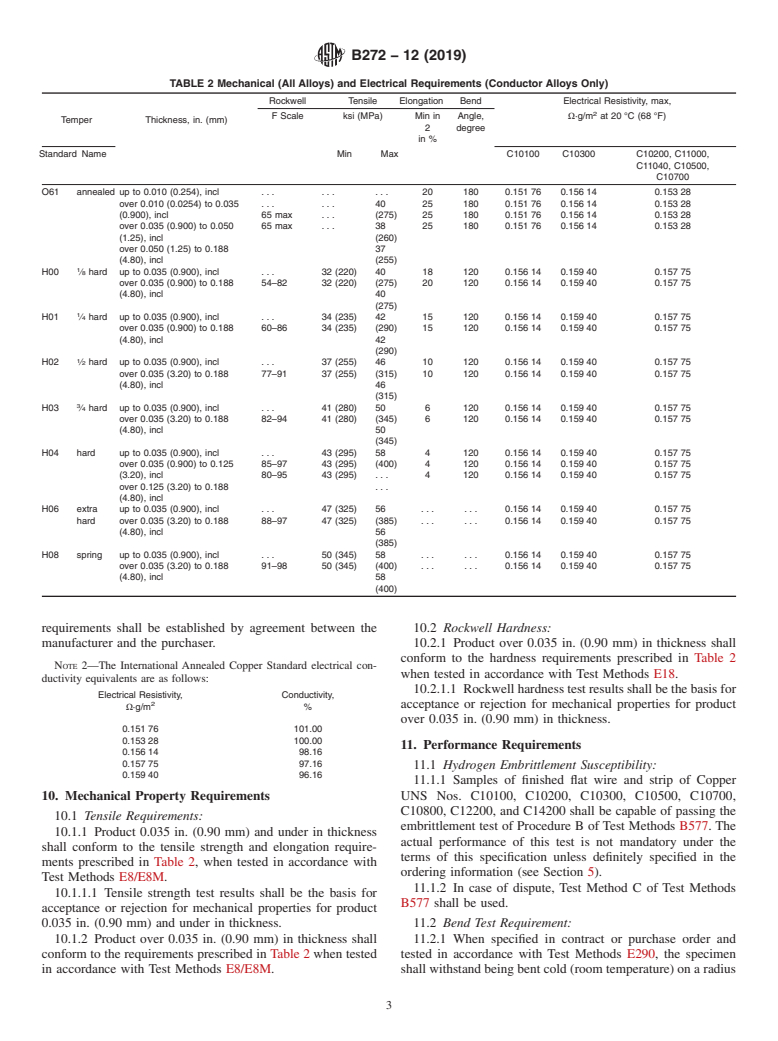

This specification establishes the requirements for flat copper wire and strip products, with rolled or drawn finished edges produced for general applications. Unless otherwise established by agreement between the manufacturer and purchaser, products shall be produced in UNS Copper Nos. C10100, C10200, C10300, C10500, C10700, C10800, C11000, C11040, C12200, and C14200. The material for manufacture shall be a billet, cake, wire bar, or rod suitable for processing by hot working, cold working, and annealing to produce a uniform wrought structure in the finished product. Products shall be produced in the annealed (O61) and cold worked (H00, H01, H02, H03, H04, H06, and H08) tempers. Products shall be tested and shall adhere to dimensional (thickness, width, length, straightness, and edge contour), mechanical (tensile strength, elongation, Rockwell hardness, bend angle, and hydrogen embrittlement susceptibility), electrical resisitvity, and chemical composition requirements.

SCOPE

1.1 This specification establishes the requirements for copper products, flat wire and strip, with rolled or drawn finished edges produced for general application.

1.1.1 The product is produced in UNS Copper Nos. C10100, C10200, C10300, C10500, C10700, C10800, C11000, C11040, C12200, and C14200 unless otherwise established by agreement between manufacturer and purchaser.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

Note 1: When a copper other than that listed in 1.1.1 is designated by the purchaser, the resulting product shall conform to the physical, mechanical, performance, dimensional, and tolerance requirements per agreement between the manufacturer and purchaser.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B272 −12 (Reapproved 2019)

Standard Specification for

Copper Flat Products with Finished (Rolled or Drawn)

1

Edges (Flat Wire and Strip)

This standard is issued under the fixed designation B272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

Bar

1.1 This specification establishes the requirements for cop-

B250/B250M Specification for General Requirements for

per products, flat wire and strip, with rolled or drawn finished

Wrought Copper Alloy Wire

edges produced for general application.

B577 Test Methods for Detection of Cuprous Oxide (Hydro-

1.1.1 The product is produced in UNS Copper Nos.

gen Embrittlement Susceptibility) in Copper

C10100,C10200,C10300,C10500,C10700,C10800,C11000,

B846 Terminology for Copper and Copper Alloys

C11040, C12200, and C14200 unless otherwise established by

B950 Guide for Editorial Procedures and Form of Product

agreement between manufacturer and purchaser.

Specifications for Copper and Copper Alloys

1.2 Units—The values stated in inch-pound units are to be

E8/E8M Test Methods for Tension Testing of Metallic Ma-

regarded as standard. The values given in parentheses are

terials

mathematical conversions to SI units, which are provided for

E18 Test Methods for Rockwell Hardness of Metallic Ma-

information only and are not considered standard.

terials

NOTE 1—When a copper other than that listed in 1.1.1 is designated by

E53 Test Method for Determination of Copper in Unalloyed

the purchaser, the resulting product shall conform to the physical,

Copper by Gravimetry

mechanical, performance, dimensional, and tolerance requirements per

E62 Test Methods for Chemical Analysis of Copper and

agreement between the manufacturer and purchaser.

3

CopperAlloys (Photometric Methods) (Withdrawn 2010)

1.3 This international standard was developed in accor-

E290 Test Methods for Bend Testing of Material for Ductil-

dance with internationally recognized principles on standard-

ity

ization established in the Decision on Principles for the

E478 Test Methods for ChemicalAnalysis of CopperAlloys

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3. General Requirements

Barriers to Trade (TBT) Committee.

3.1 The following sections of Specification B248 constitute

2. Referenced Documents a part of this specification for strip products and of Specifica-

2 tion B250/B250M for flat wire products:

2.1 ASTM Standards:

3.1.1 Terminology;

B49 Specification for Copper Rod for Electrical Purposes

3.1.2 Materials and Manufacture;

B170 Specification for Oxygen-Free Electrolytic Copper—

3.1.3 Workmanship, Finish, and Appearance;

Refinery Shapes

3.1.4 Sampling;

B193 Test Method for Resistivity of Electrical Conductor

3.1.5 Number of Tests and Retests;

Materials

3.1.6 Specimen Preparation;

B248 Specification for General Requirements for Wrought

3.1.7 Test Methods;

3.1.8 Significance of Numerical Limits;

3.1.9 Inspection;

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

3.1.10 Rejection and Rehearing;

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

Bar, Wire, Shapes and Forgings. 3.1.11 Certification;

Current edition approved April 1, 2019. Published April 2019. Originally

3.1.12 Test Reports;

approved in 1952. Last previous edition approved in 2012 as B272–12. DOI:

3.1.13 Packaging and Package Marking; and

10.1520/B0272–12R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B272−12 (2019)

3.1.14 Supplementary Requirements. 6.1.1 The material of manufacture shall be a copper billet,

cake, wire bar or rod of such purity and soundness as to be

3.2 In addition, when a section with a title identical to that

suitable for processing into the products to the product speci-

referenced in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.