ASTM G119-93(1998)

(Guide)Standard Guide for Determining Synergism Between Wear and Corrosion

Standard Guide for Determining Synergism Between Wear and Corrosion

SCOPE

1.1 This guide provides a means for computing the increased wear loss rate attributed to synergism or interaction that may occur in a system when both wear and corrosion processes coexist. The guide applies to systems in liquid solutions or slurries and does not include processes in a gas/solid system.

1.2 This guide applies to metallic materials and can be used in a generic sense with a number of wear/corrosion tests. It is not restricted to use with approved ASTM test methods.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: G 119 – 93 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Guide for

Determining Synergism Between Wear and Corrosion

This standard is issued under the fixed designation G 119; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 corrosion current density, i —The corrosion current

cor

density measured by electrochemical techniques, as described

1.1 This guide provides a means for computing the in-

in Practice G 102.

creased wear loss rate attributed to synergism or interaction

3.2.3 electrochemical corrosion rate, C—The electrochemi-

that may occur in a system when both wear and corrosion

cal corrosion rate as determined by Practice G 59 and con-

processes coexist. The guide applies to systems in liquid

verted to a penetration rate in accordance with Practice G 102.

solutions or slurries and does not include processes in a

This penetration rate is equivalent to the volume loss rate per

gas/solid system.

area. The term C is the electrochemical corrosion rate during

1.2 This guide applies to metallic materials and can be used w

the corrosive wear process, and the term C designates the

in a generic sense with a number of wear/corrosion tests. It is

electrochemical corrosion rate when no mechanical wear is

not restricted to use with approved ASTM test methods.

allowed to take place.

1.3 This standard does not purport to address all of the

3.2.4 mechanical wear rate, W —The rate of material loss

safety concerns, if any, associated with its use. It is the 0

from a specimen when the electrochemical corrosion rate has

responsibility of the user of this standard to establish appro-

been eliminated by cathodic protection during the wear test.

priate safety and health practices and determine the applica-

3.2.5 total material loss rate, T—The rate of material loss

bility of regulatory limitations prior to use.

from a specimen exposed to the specified conditions, including

2. Referenced Documents

contributions from mechanical wear, corrosion, and interac-

tions between these two.

2.1 ASTM Standards:

3.2.6 wear/corrosion synergism, S—The rate of material

G 3 Practice for Conventions Applicable to Electrochemical

loss resulting from the interaction of wear and corrosion

Measurements in Corrosion Testing

processes, given by T minus the sum of W and C . The

G 5 Reference Test Method for Making Potentiostatic and 0 0

component S8 is the increase of mechanical wear rate due to

Potentiodynamic Anodic Polarization Measurements

corrosion, and S9 is the increase of the electrochemical corro-

G 15 Terminology Relating to Corrosion and Corrosion

sion rate due to mechanical wear.

Testing

G 40 Terminology Relating to Wear and Erosion

4. Summary of Guide

G 59 Practice for Conducting Potentiodynamic Polarization

4.1 A wear test is carried out under the test conditions of

Resistance Measurements

interest and T is measured.

G 102 Practice for Calculation of Corrosion Rates and

4.2 Additional experiments are conducted to isolate the

Related Information from Electrochemical Measurements

mechanical and corrosion components of the corrosive wear

3. Terminology

process. These are as follows:

4.2.1 A repeat of the experiment in 4.1 with measurement of

3.1 Definitions—For general definitions relating to corro-

C ,

sion see Terminology G 15. For definitions relating to wear see w

4.2.2 A test identical to the initial experiment in 4.1, except

Terminology G 40.

that cathodic protection is used to obtain W , and

3.2 Definitions of Terms Specific to This Standard: 0

4.2.3 Measurement of C , the corrosion rate in the absence

3.2.1 cathodic protection current density, i —The electri- 0

cp

of mechanical wear.

cal current density needed during the wear/corrosion experi-

4.3 S, S 8 and S9 are calculated from the values measured in

ment to maintain the specimen at a potential which is 1 volt

the experiments described in 4.1 and 4.2.

cathodic to the open circuit potential.

5. Significance and Use

This guide is under the jurisdiction of ASTM Committee G-2 on Wear and

5.1 Wear and corrosion can involve a number of mechanical

Erosion and is the direct responsibility of Subcommittee G02.40 on Non-Abrasive

and chemical processes. The combined action of these pro-

Wear.

cesses can result in significant mutual interaction beyond the

Current edition approved Aug. 15, 1993. Published October 1993.

individual contributions of mechanical wear and corrosion

Annual Book of ASTM Standards, Vol 03.02.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

G119

(1-3). This interaction among abrasion, rubbing, impact and recorded. Caution must be used when using this technique

corrosion can significantly increase total material losses in because some metals or alloys may be affected by hydrogen

aqueous environments, thus producing a synergistic effect. embrittlement as a result of hydrogen that may be generated

Reduction of either the corrosion or the wear component of during this test. If hydrogen evolution is too great, then there is

material loss may significantly reduce the total material loss. A always a possibility that the hydrodynamics of the system

practical example may be a stainless steel that has excellent could be affected. However, the results of research (1-5) have

corrosion resistance in the absence of mechanical abrasion, but shown these effects to be minimal for the ferrous alloys studied

readily wears and corrodes when abrasive particles remove its to date.

corrosion-resistant passive film. Quantification of wear/ 6.4 A corrosion test similar to that conducted in 6.2 is run

corrosion synergism can help guide the user to the best means again except no mechanical wear is allowed to act on the

of lowering overall material loss. The procedures outlined in specimen surface. The penetration rate, which is equivalent to

this guide cannot be used for systems in which any corrosion C , is obtained as in 6.2, using polarization resistance and

products such as oxides are left on the surface after a test, potentiodynamic polarization scans to obtain R , b , b and

p a b

resulting in a possible weight gain. i .

cor

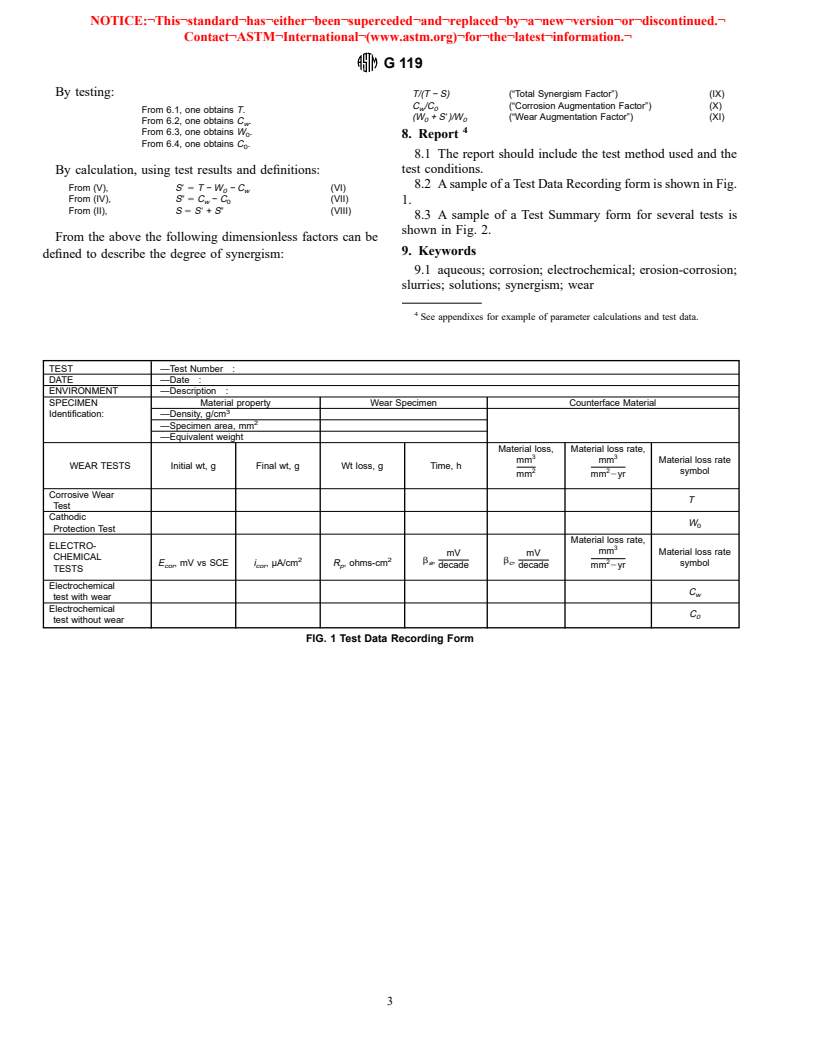

6.5 T, W ,C , and C are all reported in units of volume loss

0 w 0

6. Procedures

per exposed area per unit time. The synergism between wear

and corrosion is calculated according to (Eq 1), (Eq 2), and (Eq

6.1 A wear test where corrosion is a possible factor is

performed after the specimen has been cleaned and prepared to 3).

6.6 Caution must be used to make sure that the surface area

remove foreign matter from its surface. Volume loss rates per

exposed to corrosion is the same as that exposed to mechanical

unit area are then calculated, and the results tabulated. The

wear. Coating of the portions of the specimen with a non-

value of T is obtained from these measurements. Examples of

conductor to mask off areas to prevent corrosion is an effective

wear tests involving corrosion are detailed in papers contained

means of doing this.

in the list of references. These examples include a slurry wear

test (1-3), a slurry jet impingement test (4), and a rotating

7. Calculation of Wear/Corrosion Synergism

cylinder-anvil apparatus (5).

6.2 A wear test described in 6.1 is repeated, except that the

7.1 The total material loss, T, is related to the synergistic

wear specimen is used as a working electrode in a typical 3

component, S, that part of the total damage that results from the

electrode system. The other two electrodes are a standard

interaction of corrosion and wear processes, by the following

reference electrode and a counter electrode as described in

equation

Practices G 3 and G 59, and Reference Test Method G 5. This

T 5 W 1 C 1 S (1)

0 0

test is for electrochemical measurements only, and no mass or

7.1.1 (Eq 1) implies that corrosion can affect mechanical

volume losses are measured because they could be affected by

wear and mechanical wear can affect corrosion.

the electrical current that is passed through the specimen of

7.2 Under conditions of corrosive wear, C can be measured

w

interest during the experiments. Two measurements are made,

by electrochemical means. C is usually higher than C

w 0

one to measure the polarization resistance as in Practice G 59,

because of mechanical wear interaction. (Eq 1) can be rewrit-

and one to generate a potentiodynamic polarization curve as in

ten

Test Method G 5. The open circuit corrosion potential, E , the

cor

T 5 W 1 C 1 S8 (2)

polarization resistance, R , and Tafel constants, b and b , are

0 w

p a c

tabulated. The exception to Test Method G 5 is that the

where S8 5 increase in the mechanical wear losses due to

apparatus, cell geometry, and solutions or slurries used are

corrosion. Increases in the corrosion rate due to wear are

defined by the particular wear test being conducted, and are not

included in C .

w

restricted to the electrochemical cell or electrolyte described in

7.3 From (Eq 1) and (Eq 2) it can be shown that the change

Test Method G 5. The potentiodynamic method rather than the

of the electrochemical corrosion rate due to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.