ASTM D3424-09

(Test Method)Standard Practice for Evaluating the Relative Lightfastness and Weatherability of Printed Matter

Standard Practice for Evaluating the Relative Lightfastness and Weatherability of Printed Matter

SIGNIFICANCE AND USE

Lightfastness or weatherability for specified periods of time is pertinent for certain types of printed matter such as magazine and book covers, posters and billboards, greeting cards and packages. Since the ability of printed matter to withstand color changes is a function of the spectral-power distribution of the light source to which it is exposed, it is important that lightfastness be assessed under conditions appropriate to the end-use application.

The accelerated procedures covered in these exposure methods provide means for the rapid evaluation of lightfastness or weatherability under laboratory conditions. Test results are useful for specification acceptance between producer and user and for quality control.

The xenon-arc lamp with an appropriate filter system exhibits a spectral-power distribution that corresponds more closely to that of daylight than the carbon-arc. In turn, accelerated tests using xenon-arc apparatus may be expected to correlate better with exposure to natural daylight than do those using carbon-arc apparatus.

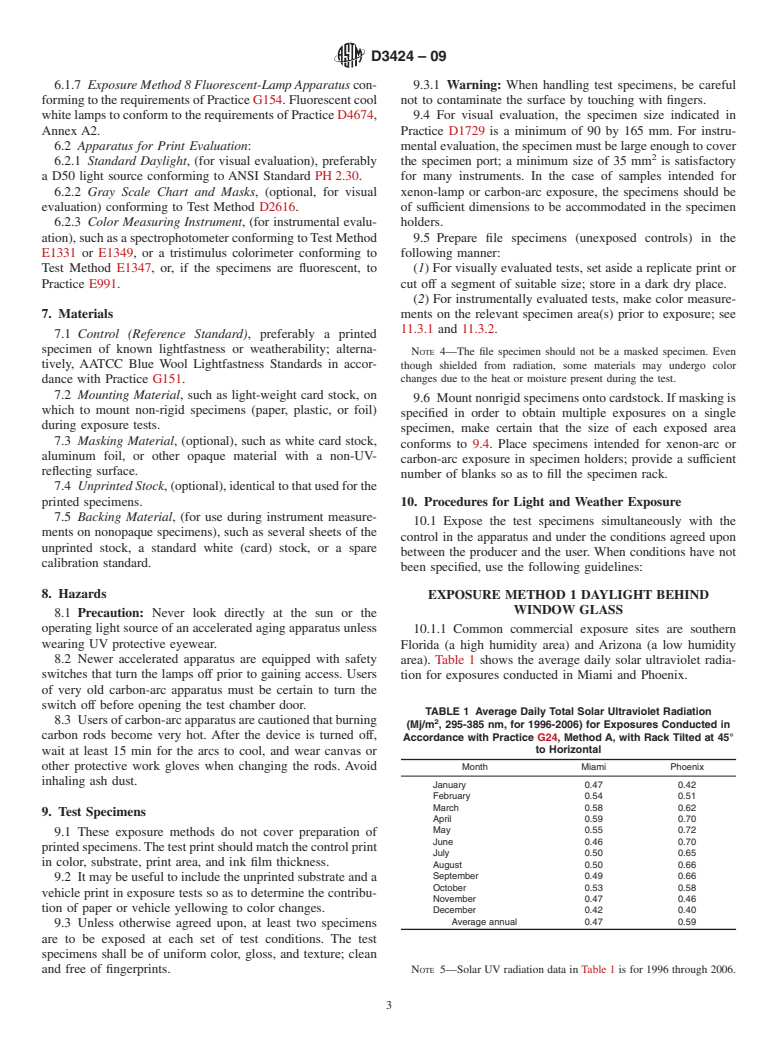

To accommodate variations in light intensity among days, seasons, locations, or instruments, duration of exposure is preferably expressed as the radiant exposure in specific bandpasses rather than time. In either case, the inclusion of an appropriate control serves to minimize effects of variations in test conditions.

Color changes are not a linear function of duration of exposure. The preferred method of determining lightfastness or weatherability is to expose the prints for a number of intervals and to assess the time or radiant exposure required to obtain a specified color difference.

For a given printing ink, lightfastness and weatherability or both depend on the type of substrate, the film thickness of the print, and the area printed (solid versus screen). Therefore, it is important that the nature of the test and control specimens correspond to that expected under actual use conditions.

Note 2—Specifications D 43...

SCOPE

1.1 This standard describes procedures for the determination of the relative lightfastness and weatherability of printed matter under the following conditions, which involve exposure to natural daylight or accelerated procedures in the laboratory:

1.1.1 Method 1—Daylight behind window glass,

1.1.2 Method 2—Outdoor weathering,

1.1.3 Method 3—Xenon-arc apparatus with window glass filters to simulate daylight behind window glass,

1.1.4 Method 4—Xenon-arc apparatus with water spray and daylight filters to simulate outdoor weathering,

1.1.5 Method 7—Fluorescent lamp apparatus to simulate indoor fluorescent lighting in combination with window-filtered daylight.

1.1.6 Method 8—Fluorescent lamp apparatus operating with fluorescent cool white lamps to simulate indoor fluorescent lighting.

Note 1—Previous versions of this standard included Methods 5 and 6 that are based on enclosed carbon-arc exposures. These methods are described in Appendix X1. The spectral irradiance of the enclosed carbon-arc is a very poor simulation of solar radiation, window glass filtered solar radiation, or the emission of lamps used for interior lighting. In addition, enclosed carbon-arc devices are no longer readily available or commonly used.

1.2 These methods require that a suitable print or other control (reference standard) be run along with the test sample. Color changes due to conditions of exposure may be evaluated by visual examination or instrumental measurement.

1.3 These methods are applicable to prints on any flat substrate including paper, paperboard, metallic foil, metal plate, and plastic film, and are produced by any printing process including letterpress, offset lithography, flexography, gravure, and silk screen.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3424 – 09

Standard Practice for

Evaluating the Relative Lightfastness and Weatherability of

1

Printed Matter

This standard is issued under the fixed designation D3424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This standard describes procedures for the determina-

responsibility of the user of this standard to establish appro-

tion of the relative lightfastness and weatherability of printed

priate safety and health practices and determine the applica-

matter under the following conditions, which involve exposure

bility of regulatory limitations prior to use. For specific hazard

to natural daylight or accelerated procedures in the laboratory:

statements, see Section 8.

1.1.1 Method 1—Daylight behind window glass,

1.1.2 Method 2—Outdoor weathering,

2. Referenced Documents

1.1.3 Method 3—Xenon-arc apparatus with window glass

2

2.1 ASTM Standards:

filters to simulate daylight behind window glass,

D1729 Practice for Visual Appraisal of Colors and Color

1.1.4 Method 4—Xenon-arc apparatus with water spray and

Differences of Diffusely-Illuminated Opaque Materials

daylight filters to simulate outdoor weathering,

D2244 Practice for Calculation of Color Tolerances and

1.1.5 Method 7—Fluorescent lamp apparatus to simulate

Color Differences from Instrumentally Measured Color

indoor fluorescent lighting in combination with window-

Coordinates

filtered daylight.

D2616 Test Method for Evaluation of Visual Color Differ-

1.1.6 Method8—Fluorescentlampapparatusoperatingwith

ence With a Gray Scale

fluorescent cool white lamps to simulate indoor fluorescent

D4302 Specification for Artists’ Oil, Resin-Oil, and Alkyd

lighting.

Paints

NOTE 1—Previous versions of this standard included Methods 5 and 6

D4674 Practice for Accelerated Testing for Color Stability

that are based on enclosed carbon-arc exposures. These methods are

of Plastics Exposed to Indoor Office Environments

described in Appendix X1. The spectral irradiance of the enclosed

D5067 Specification for Artists’ Watercolor Paints

carbon-arc is a very poor simulation of solar radiation, window glass

D5098 Specification for Artists’ Acrylic Dispersion Paints

filtered solar radiation, or the emission of lamps used for interior lighting.

E284 Terminology of Appearance

In addition, enclosed carbon-arc devices are no longer readily available or

commonly used. E991 PracticeforColorMeasurementofFluorescentSpeci-

mens Using the One-Monochromator Method

1.2 These methods require that a suitable print or other

E1331 Test Method for Reflectance Factor and Color by

control (reference standard) be run along with the test sample.

Spectrophotometry Using Hemispherical Geometry

Color changes due to conditions of exposure may be evaluated

E1347 Test Method for Color and Color-Difference Mea-

by visual examination or instrumental measurement.

surement by Tristimulus Colorimetry

1.3 These methods are applicable to prints on any flat

E1349 Test Method for Reflectance Factor and Color by

substrate including paper, paperboard, metallic foil, metal

Spectrophotometry Using Bidirectional (45°:0° or 0°:45°)

plate, and plastic film, and are produced by any printing

Geometry

process including letterpress, offset lithography, flexography,

G7 Practice forAtmospheric Environmental Exposure Test-

gravure, and silk screen.

ing of Nonmetallic Materials

1.4 The values stated in SI units are to be regarded as

G24 PracticeforConductingExposurestoDaylightFiltered

standard. No other units of measurement are included in this

Through Glass

standard.

G113 TerminologyRelatingtoNaturalandArtificialWeath-

ering Tests of Nonmetallic Materials

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and are the direct responsibility of

2

Subcommittee D01.56 on Printing Inks. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2009. Published February 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1975. Last previous edition approved in 2001 as D3424 – 01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D3424-09. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 --------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3424–01

Standard Test Methods for Designation: D 3424 – 09

Standard Practice for

Evaluating the Relative Lightfastness and Weatherability of

1

Printed Matter

This standard is issued under the fixed designation D 3424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1These test methods cover the determination of the relative lightfastness and weatherability of printed matter under the

following seven conditions, of which two involve exposure to natural daylight and five involve accelerated procedures in the

laboratory: *

1.1 This standard describes procedures for the determination of the relative lightfastness and weatherability of printed matter

under the following conditions, which involve exposure to natural daylight or accelerated procedures in the laboratory:

1.1.1 Test Method 1Method 1—Daylight behind window glass,

1.1.2 Test Method 2Method 2—Outdoor weathering,

1.1.3 Test Method 3Method 3—Xenon-arc apparatus with window glass filters to simulate daylight behind window glass,

1.1.4 Test Method 4Method 4—Xenon-arc apparatus with water spray and daylight filters to simulate outdoor weathering,

1.1.5 Test Method 5—Enclosed carbon-arc apparatus without water spray,

1.1.6Test Method 6—Enclosed carbon-arc apparatus with water spray, and

1.1.7Test Method 7Method 7—Fluorescent lamp apparatus to simulate indoor fluorescent lighting in combination with

window-filtered daylight.

1.2These test methods require that a suitable print or other control (reference standard) be run along with the test sample. Color

changes due to conditions of exposure may be evaluated by visual examination or instrumental measurement.

1.3These test methods are applicable to prints on any flat substrate including paper, paperboard, metallic foil, metal plate, and

plastic film, and are produced by any printing process including letterpress, offset lithography, flexography, gravure, and silk

screen.

1.4

1.1.6 Method 8—Fluorescent lamp apparatus operating with fluorescent cool white lamps to simulate indoor fluorescent

lighting.

NOTE 1—Previous versions of this standard included Methods 5 and 6 that are based on enclosed carbon-arc exposures. These methods are described

inAppendix X1. The spectral irradiance of the enclosed carbon-arc is a very poor simulation of solar radiation, window glass filtered solar radiation,or

the emission of lamps used for interior lighting. In addition, enclosed carbon-arc devices are no longer readily available or commonly used.

1.2 These methods require that a suitable print or other control (reference standard) be run along with the test sample. Color

changes due to conditions of exposure may be evaluated by visual examination or instrumental measurement.

1.3 These methods are applicable to prints on any flat substrate including paper, paperboard, metallic foil, metal plate, and

plastic film, and are produced by any printing process including letterpress, offset lithography, flexography, gravure, and silk

screen.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 8.

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.56 on Printing Inks.

Current edition approved June 10, 2001. Published August 2001. Originally published as D3424–75. Last previous edition D3424–98.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.56 on Printing Inks.

Current edition approved Feb. 1, 2009. Published February 2009. Originally approved in 1975. Last previous edition approved in 2001 as D 3424 – 01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

--

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.