ASTM D3981-08

(Specification)Standard Specification for Polyethylene Films Made from Medium-Density Polyethylene for General Use and Packaging Applications

Standard Specification for Polyethylene Films Made from Medium-Density Polyethylene for General Use and Packaging Applications

ABSTRACT

This specification covers unpigmented, unsupported, sheet or tubular, medium-density polyethylene films intended for general uses and packaging applications. The film shall be made from homopolymer polyethylene, copolymer polyethylene commonly referred to as low-pressure polyethylene, or blends of homopolymers and copolymers that include ethylene/vinyl-acetate copolymers. The specimens shall be conditioned before testing in the standard laboratory temperature. Tests shall be conducted to determine the physical properties of the specimens which shall conform to the following physical requirements: secant modulus or stiffness; kinetic coefficient of friction; optical properties such as clarity, gloss, and haze; surface treatment level or wetting tension; impact resistance; tensile strength and elongation at break; heat sealability; and odor level.

SCOPE

1.1 This specification covers unpigmented, unsupported, sheet or tubular, medium-density polyethylene films (hereafter referred to as film or films) from resins having densities in the range from 926.0 to 938.0 kg/m3 (0.926 to 0.938 g/cm3), inclusive, as measured on molded plaques.

1.2 This specification is applicable to homopolymer polyethylene but is not restricted to it.

1.3 This specification is also applicable to films made from copolymer polyethylene commonly referred to in industry as low-pressure polyethylene.

1.4 This specification is also applicable to films made from blends of homopolymers and copolymers, including ethylene/vinyl-acetate copolymers.

1.5 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all the requirements of this specification are met and as long as any specific requirements as governed by the producer and end user are also met (see Note 1).

Note 1—Guide D 5033 contains terminology and definitions relating to recycled plastics.

1.6 Special care must be exercised if this specification is applied to colored or pigmented films. This specification does not address specific problems associated with coloring, such as, quantity and quality of pigment dispersion, optical properties, and increase in density. These and other areas must be taken into account by mutual agreement between the supplier and the purchaser.

1.7 The thickness of the films covered by this specification range from 25 to 100 μm (0.001 to 0.004 in.), inclusive. The maximum width of the sheet or lay-flat is 3.05 m (120 in.).

1.8 This specification does not cover oriented heat-shrinkable films.

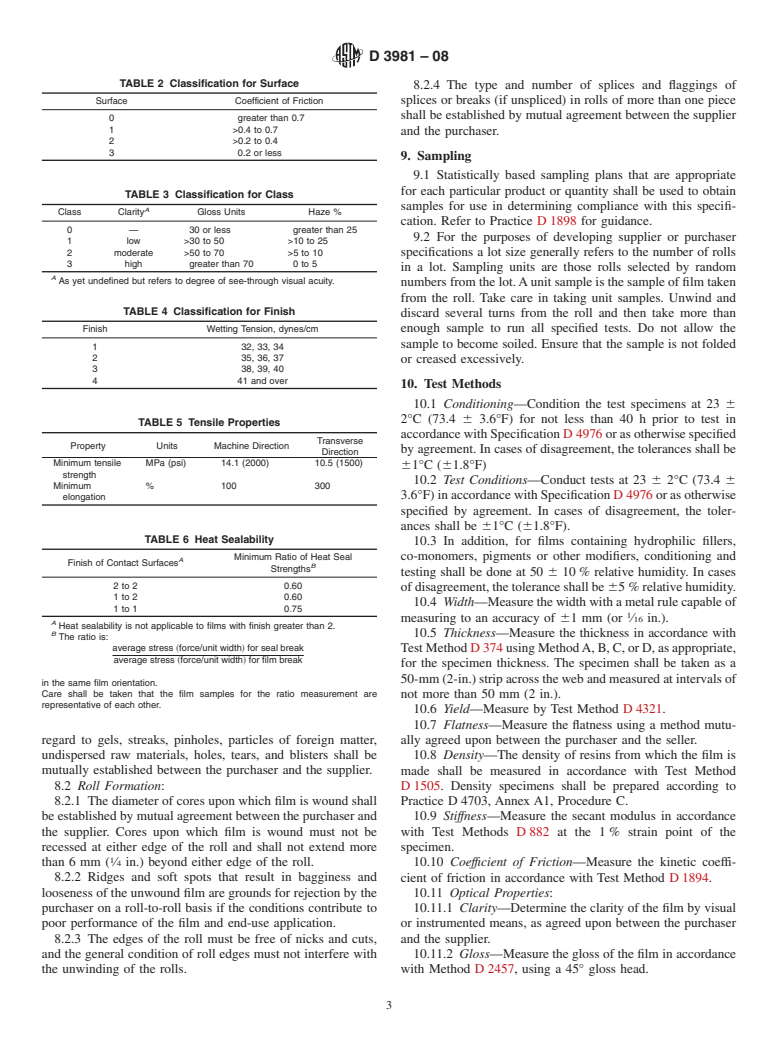

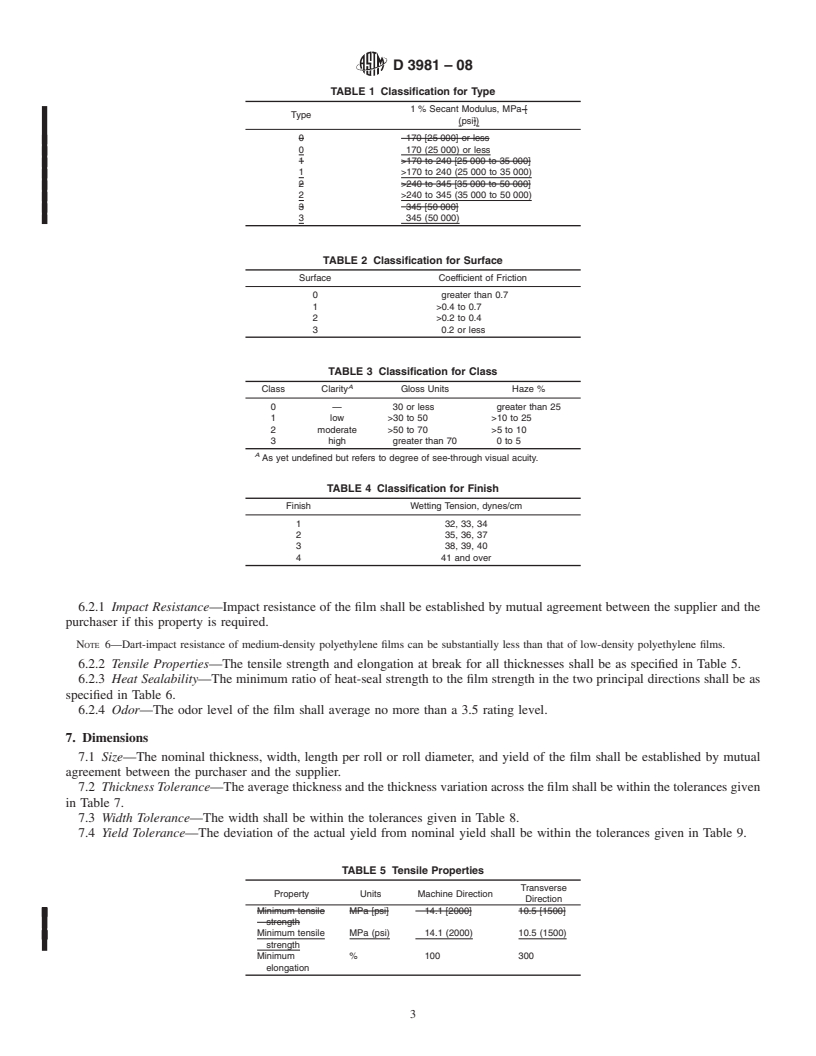

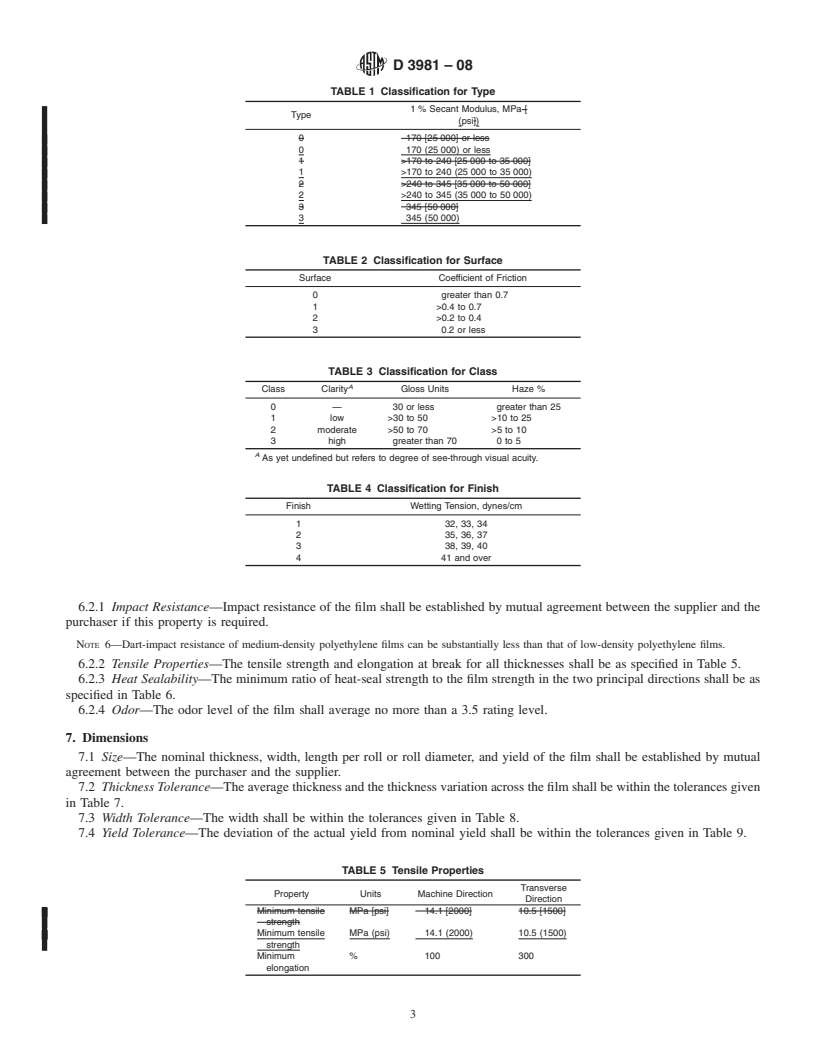

1.9 This specification defines the levels of various physical properties from which specifications for specific films are to be described. The levels of physical properties required by a film for a given application are selected from Section 6 and the corresponding tables. However, Sections 7.2-7.5 relating to tolerances shall apply without change to all film falling within the scope indicated by the title and 1.1-1.4.

1.10 This specification covers dimensional tolerances, classification, intrinsic quality requirements, and test methods. The dimensional tolerances include thickness, width, and length or yield. Classification defines types, classes, surfaces, and finishes. The intrinsic quality requirements include density, workmanship, impact strength, tensile strength, heat sealability, and odor, as well as the classification properties for stiffness, coefficient of friction, optical properties, and surface treatment. A sampling method is included.

1.11 The values stated in SI units are to be regarded as standard. The values in parentheses are given for information only.

1.12 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and hea...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3981 – 08

Standard Specification for

Polyethylene Films Made from Medium-Density Polyethylene

1

for General Use and Packaging Applications

This standard is issued under the fixed designation D 3981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* corresponding tables. However, Sections 7.2-7.5 relating to

tolerances shall apply without change to all film falling within

1.1 This specification covers unpigmented, unsupported,

the scope indicated by the title and 1.1-1.4.

sheet or tubular, medium-density polyethylene films (hereafter

1.10 This specification covers dimensional tolerances, clas-

referred to as film or films) from resins having densities in the

3 3

sification, intrinsic quality requirements, and test methods.The

range from 926.0 to 938.0 kg/m (0.926 to 0.938 g/cm ),

dimensional tolerances include thickness, width, and length or

inclusive, as measured on molded plaques.

yield. Classification defines types, classes, surfaces, and fin-

1.2 This specification is applicable to homopolymer poly-

ishes.The intrinsic quality requirements include density, work-

ethylene but is not restricted to it.

manship, impact strength, tensile strength, heat sealability, and

1.3 This specification is also applicable to films made from

odor, as well as the classification properties for stiffness,

copolymer polyethylene commonly referred to in industry as

coefficient of friction, optical properties, and surface treatment.

low-pressure polyethylene.

A sampling method is included.

1.4 This specification is also applicable to films made from

1.11 The values stated in SI units are to be regarded as

blends of homopolymers and copolymers, including ethylene/

standard. The values in parentheses are given for information

vinyl-acetate copolymers.

only.

1.5 This specification allows for the use of recycled poly-

1.12 Thefollowingprecautionarycaveatpertainsonlytothe

ethylene film or resin as feedstock, in whole or in part, as long

test methods portion, Section 10, of this specification: This

as all the requirements of this specification are met and as long

standard does not purport to address all of the safety concerns,

as any specific requirements as governed by the producer and

if any, associated with its use. It is the responsibility of the user

end user are also met (see Note 1).

of this standard to establish appropriate safety and health

NOTE 1—Guide D 5033 contains terminology and definitions relating

practices and determine the applicability of regulatory limita-

to recycled plastics.

tions prior to use.

1.6 Special care must be exercised if this specification is

NOTE 2—There is no known ISO equivalent to this standard.

applied to colored or pigmented films. This specification does

notaddressspecificproblemsassociatedwithcoloring,suchas,

2. Referenced Documents

quantity and quality of pigment dispersion, optical properties,

2

2.1 ASTM Standards:

and increase in density. These and other areas must be taken

D 374 Test Methods for Thickness of Solid Electrical Insu-

into account by mutual agreement between the supplier and the

lation

purchaser.

D 882 Test Method for Tensile Properties of Thin Plastic

1.7 The thickness of the films covered by this specification

Sheeting

range from 25 to 100 µm (0.001 to 0.004 in.), inclusive. The

D 883 Terminology Relating to Plastics

maximum width of the sheet or lay-flat is 3.05 m (120 in.).

D 1003 Test Method for Haze and Luminous Transmittance

1.8 This specification does not cover oriented heat-

of Transparent Plastics

shrinkable films.

D 1505 Test Method for Density of Plastics by the Density-

1.9 This specification defines the levels of various physical

Gradient Technique

properties from which specifications for specific films are to be

D 1709 Test Methods for Impact Resistance of Plastic Film

described. The levels of physical properties required by a film

by the Free-Falling Dart Method

for a given application are selected from Section 6 and the

1

This specification is under the jurisdiction of ASTM Committee D20 on

2

Plastics and is the direct responsibility of Subcommittee D20.19 on Film and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Sheeting. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 15, 2008. Published November 2008. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1981. Last previous edition approved in 2003 as D 3981 – 03. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3981–03 Designation: D 3981 – 08

Standard Specification for

Polyethylene Films Made from Medium-Density Polyethylene

1

for General Use and Packaging Applications

This standard is issued under the fixed designation D 3981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

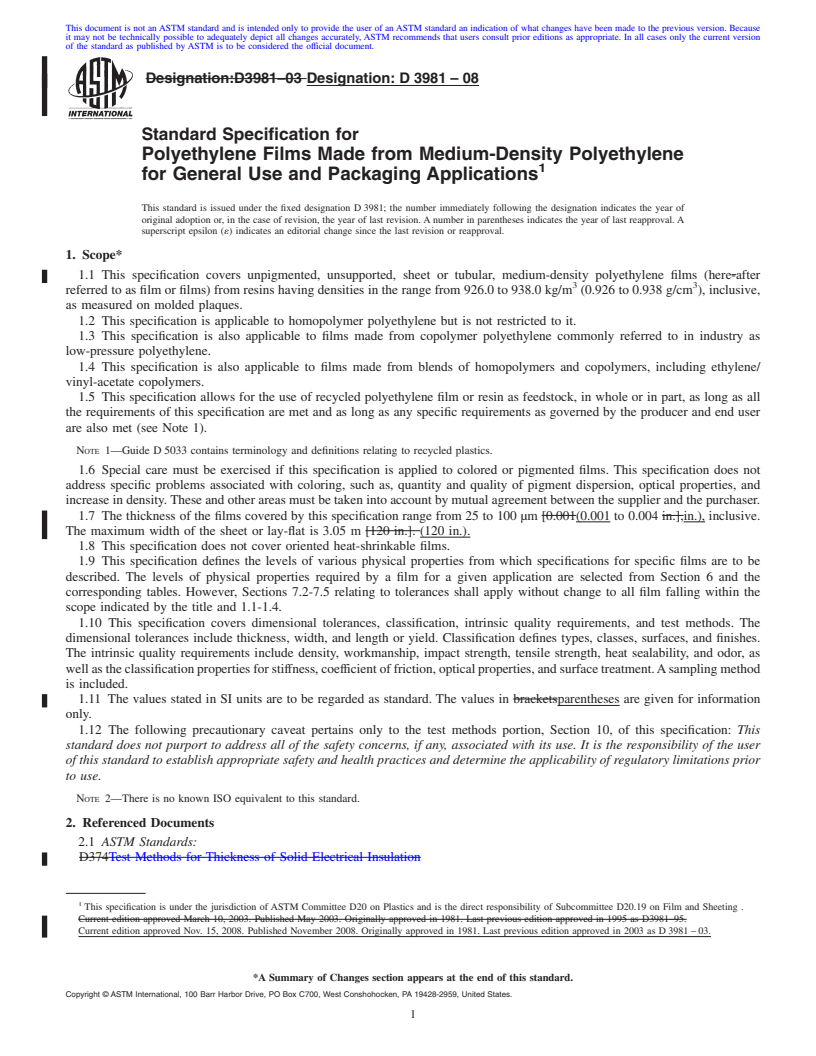

1. Scope*

1.1 This specification covers unpigmented, unsupported, sheet or tubular, medium-density polyethylene films (here-after

3 3

referred to as film or films) from resins having densities in the range from 926.0 to 938.0 kg/m (0.926 to 0.938 g/cm ), inclusive,

as measured on molded plaques.

1.2 This specification is applicable to homopolymer polyethylene but is not restricted to it.

1.3 This specification is also applicable to films made from copolymer polyethylene commonly referred to in industry as

low-pressure polyethylene.

1.4 This specification is also applicable to films made from blends of homopolymers and copolymers, including ethylene/

vinyl-acetate copolymers.

1.5 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all

the requirements of this specification are met and as long as any specific requirements as governed by the producer and end user

are also met (see Note 1).

NOTE 1—Guide D 5033 contains terminology and definitions relating to recycled plastics.

1.6 Special care must be exercised if this specification is applied to colored or pigmented films. This specification does not

address specific problems associated with coloring, such as, quantity and quality of pigment dispersion, optical properties, and

increase in density.These and other areas must be taken into account by mutual agreement between the supplier and the purchaser.

1.7 The thickness of the films covered by this specification range from 25 to 100 µm [0.001(0.001 to 0.004 in.],in.), inclusive.

The maximum width of the sheet or lay-flat is 3.05 m [120 in.]. (120 in.).

1.8 This specification does not cover oriented heat-shrinkable films.

1.9 This specification defines the levels of various physical properties from which specifications for specific films are to be

described. The levels of physical properties required by a film for a given application are selected from Section 6 and the

corresponding tables. However, Sections 7.2-7.5 relating to tolerances shall apply without change to all film falling within the

scope indicated by the title and 1.1-1.4.

1.10 This specification covers dimensional tolerances, classification, intrinsic quality requirements, and test methods. The

dimensional tolerances include thickness, width, and length or yield. Classification defines types, classes, surfaces, and finishes.

The intrinsic quality requirements include density, workmanship, impact strength, tensile strength, heat sealability, and odor, as

wellastheclassificationpropertiesforstiffness,coefficientoffriction,opticalproperties,andsurfacetreatment.Asamplingmethod

is included.

1.11 The values stated in SI units are to be regarded as standard. The values in bracketsparentheses are given for information

only.

1.12 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

NOTE 2—There is no known ISO equivalent to this standard.

2. Referenced Documents

2.1 ASTM Standards:

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved March 10, 2003. Published May 2003. Originally approved in 1981. Last previous edition approved in 1995 as D3981–95.

Current edition approved Nov. 15, 2008. Published November 2008. Originally approved in 1981. Last previous edition approved in 2003 as D 3981 – 03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3981–08

2

D374Test Methods for Thickness of Solid Electrical Ins

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3981–03 Designation: D 3981 – 08

Standard Specification for

Polyethylene Films Made from Medium-Density Polyethylene

1

for General Use and Packaging Applications

This standard is issued under the fixed designation D 3981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers unpigmented, unsupported, sheet or tubular, medium-density polyethylene films (here-after

3 3

referred to as film or films) from resins having densities in the range from 926.0 to 938.0 kg/m (0.926 to 0.938 g/cm ), inclusive,

as measured on molded plaques.

1.2 This specification is applicable to homopolymer polyethylene but is not restricted to it.

1.3 This specification is also applicable to films made from copolymer polyethylene commonly referred to in industry as

low-pressure polyethylene.

1.4 This specification is also applicable to films made from blends of homopolymers and copolymers, including ethylene/

vinyl-acetate copolymers.

1.5 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all

the requirements of this specification are met and as long as any specific requirements as governed by the producer and end user

are also met (see Note 1).

NOTE 1—Guide D 5033 contains terminology and definitions relating to recycled plastics.

1.6 Special care must be exercised if this specification is applied to colored or pigmented films. This specification does not

address specific problems associated with coloring, such as, quantity and quality of pigment dispersion, optical properties, and

increase in density.These and other areas must be taken into account by mutual agreement between the supplier and the purchaser.

1.7 The thickness of the films covered by this specification range from 25 to 100 µm [0.001(0.001 to 0.004 in.],in.), inclusive.

The maximum width of the sheet or lay-flat is 3.05 m [120 in.]. (120 in.).

1.8 This specification does not cover oriented heat-shrinkable films.

1.9 This specification defines the levels of various physical properties from which specifications for specific films are to be

described. The levels of physical properties required by a film for a given application are selected from Section 6 and the

corresponding tables. However, Sections 7.2-7.5 relating to tolerances shall apply without change to all film falling within the

scope indicated by the title and 1.1-1.4.

1.10 This specification covers dimensional tolerances, classification, intrinsic quality requirements, and test methods. The

dimensional tolerances include thickness, width, and length or yield. Classification defines types, classes, surfaces, and finishes.

The intrinsic quality requirements include density, workmanship, impact strength, tensile strength, heat sealability, and odor, as

wellastheclassificationpropertiesforstiffness,coefficientoffriction,opticalproperties,andsurfacetreatment.Asamplingmethod

is included.

1.11 The values stated in SI units are to be regarded as standard. The values in bracketsparentheses are given for information

only.

1.12 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

NOTE 2—There is no known ISO equivalent to this standard.

2. Referenced Documents

2.1 ASTM Standards:

D374Test Methods for Thickness of Solid Electrical Insulation

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved March 10, 2003. Published May 2003. Originally approved in 1981. Last previous edition approved in 1995 as D3981–95.

Current edition approved Nov. 15, 2008. Published November 2008. Originally approved in 1981. Last previous edition approved in 2003 as D 3981 – 03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D39

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.