ASTM D2684/D2684M-15

(Test Method)Standard Test Method for Permeability of Thermoplastic Containers to Packaged Reagents or Proprietary Products (Withdrawn 2024)

Standard Test Method for Permeability of Thermoplastic Containers to Packaged Reagents or Proprietary Products (Withdrawn 2024)

SIGNIFICANCE AND USE

5.1 With the proper precautions and background experience, results can be useful for estimation of the loss of a packaged product through the walls of a container during shelf storage. The test is also useful for isolating the effects of a container design and materials, and is applicable for development and research and for specification purposes.

5.2 In the absence of adequate supporting data, extrapolations or correlations of results to conditions beyond those of the test are not recommended because of possible product alteration, solvency, or chemical effects on the plastic, etc.

5.3 Before proceeding with this test method, refer to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method covers procedures for determining the permeability of thermoplastic containers to packaged reagents or proprietary products under specified conditions of exposure. The exposures used are intended to simulate the normal and elevated temperature-storage conditions that might be encountered in end-use application.

1.2 This test method is applicable only to those types of containers designed to allow positive, leakproof closure.

1.3 Two procedures are provided:

1.3.1 Procedure A is specific to testing only with a standard design container. This procedure provides for determinations of rate of weight loss (or gain) and for calculation of a permeability factor.

1.3.2 Procedure B applies to tests of all other container designs. Permeability data by this procedure are expressed only in terms of rate of weight loss (or gain) for the particular container tested.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

Note 1: There is no known ISO equivalent to this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers procedures for determining the permeability of thermoplastic containers to packaged reagents or proprietary products under specified conditions of exposure. The exposures used are intended to simulate the normal and elevated temperature-storage conditions that might be encountered in end-use application.

Formerly under the jurisdiction of Committee D20 on Plastics, this test method was withdrawn in January 2024 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2684/D2684M − 15

Standard Test Method for

Permeability of Thermoplastic Containers to Packaged

1

Reagents or Proprietary Products

This standard is issued under the fixed designation D2684/D2684M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This test method covers procedures for determining the 2.1 ASTM Standards:2

permeability of thermoplastic containers to packaged reagents D618Practice for Conditioning Plastics for Testing

orproprietaryproductsunderspecifiedconditionsofexposure. D4976Specification for Polyethylene Plastics Molding and

The exposures used are intended to simulate the normal and Extrusion Materials

elevated temperature-storage conditions that might be encoun- D1505Test Method for Density of Plastics by the Density-

tered in end-use application. Gradient Technique

E145Specification for Gravity-Convection and Forced-

1.2 This test method is applicable only to those types of

Ventilation Ovens

containers designed to allow positive, leakproof closure.

3. Terminology

1.3 Two procedures are provided:

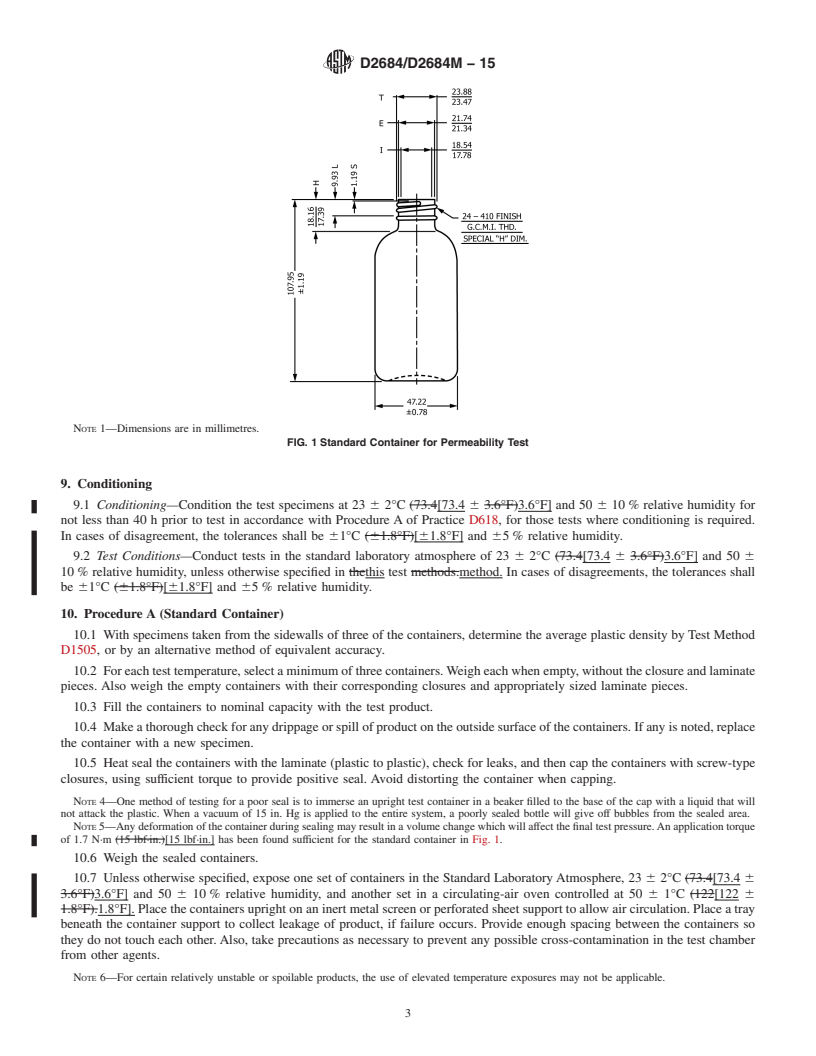

1.3.1 Procedure Ais specific to testing only with a standard

3.1 Definitions:

design container. This procedure provides for determinations

3.1.1 permeability factor, P —the permeability of a given

t

of rate of weight loss (or gain) and for calculation of a

plastic to a given product at temperature t, in degrees Celsius,

2

permeability factor.

expressedinunitsofg·cm/day·m ,asdeterminedbyProcedure

1.3.2 Procedure B applies to tests of all other container

A. The permeability factor under 23°C test conditions, for

designs.Permeabilitydatabythisprocedureareexpressedonly

example, is signified by the notation P .

23

in terms of rate of weight loss (or gain) for the particular

3.1.1.1 Discussion—Determination of P is based on an

t

container tested.

averaged wall thickness over the entire area of the container

and an assumption that permeation rate is inversely propor-

1.4 Units—The values stated in either SI units or inch-

tional to the thickness. Precaution in the extent of allowable

pound units are to be regarded separately as standard. The

variations of these factors is recommended, and the user of P

values stated in each system may not be exact equivalents;

t

needs to recognize that wall thickness of the containers varies,

therefore,eachsystemshallbeusedindependentlyoftheother.

that the estimate of average thickness from density, area, and

Combining values from the two systems may result in non-

weight is not exact, and that permeability of the product

conformance with the standard.

through the plastic material is, generally, not directly propor-

NOTE 1—There is no known ISO equivalent to this standard.

tional to the thickness.

1.5 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

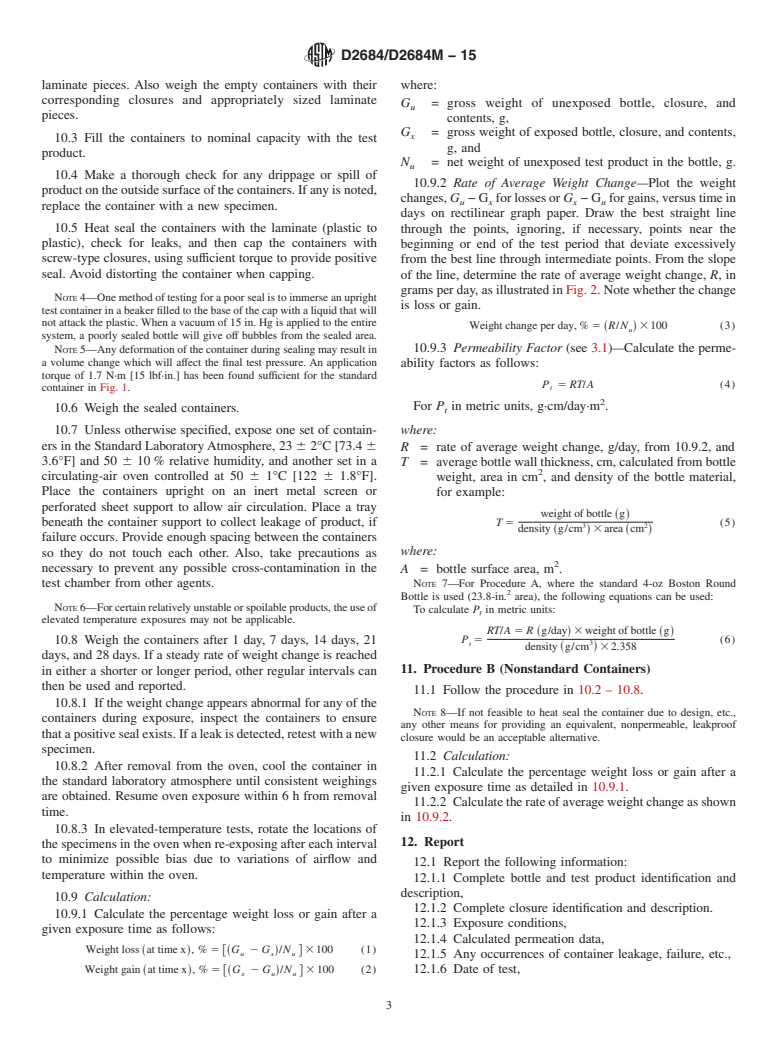

4.1 Test bottles are filled with the test product and, after

priate safety and health practices and determine the applica-

sealing, are exposed at 23°C [73.4°F] and 50°C [122°F]

bility of regulatory limitations prior to use.

conditions for 28 days or longer. Measurements of weight are

made at intervals to determine the average rate of weight

change.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

2

Molded Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2015. Published September 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1968. Last previous edition approved in 2010 as D2684-10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2684_D2684M-15. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2684/D2684M − 15

5. Significance and Use

5.1 Withtheproperprecautionsandbackgroundexperience,

results can be useful for estimation of the loss of a packaged

product through the walls of a container during shelf storage.

The test is also useful for isolating the effects of a container

design and materials, and is

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2684 − 10 D2684/D2684M − 15

Standard Test Method for

Permeability of Thermoplastic Containers to Packaged

1

Reagents or Proprietary Products

This standard is issued under the fixed designation D2684;D2684/D2684M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers procedures for determining the permeability of thermoplastic containers to packaged reagents or

proprietary products under specified conditions of exposure. The exposures used are intended to simulate the normal and elevated

temperature-storage conditions that might be encountered in end-use application.

1.2 This test method is applicable only to those types of containers designed to allow positive, leakproof closure.

1.3 Two procedures are provided:

1.3.1 Procedure A is specific to testing only with a standard design container. This procedure provides for determinations of rate

of weight loss (or gain) and for calculation of a permeability factor.

1.3.2 Procedure B applies to tests of all other container designs. Permeability data by this procedure are expressed only in terms

of rate of weight loss (or gain) for the particular container tested.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values given

in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered

stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining

values from the two systems may result in non-conformance with the standard.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D4976 Specification for Polyethylene Plastics Molding and Extrusion Materials

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

E145 Specification for Gravity-Convection and Forced-Ventilation Ovens

3. Terminology

3.1 Definitions:

3.1.1 permeability factor, P —the permeability of a given plastic to a given product at temperature t, in degrees Celsius,

t

2

expressed in units of g·cm/day·m , as determined by Procedure A. The permeability factor under 23°C test conditions, for example,

is signified by the notation P .

23

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved Aug. 1, 2010Sept. 1, 2015. Published September 2010September 2015. Originally approved in 1968. Last previous edition approved in 20052010

as D2684 - 95D2684 - 10.(2005). DOI: 10.1520/D2684-10.10.1520/D2684_D2684M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

Determination of P is based on an averaged wall thickness over the entire area of the container and an assumption that permeation

t

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2684/D2684M − 15

rate is inversely proportional to the thickness. Precaution in the extent of allowable variations of these factors is recommended,

and the user of P needs to recognize that wall thickness of the containers varies, that the estimate of average thickness from

t

density, area, and weight is not exact, and that permeability of the product through the plastic material is, generally, not directly

proportional to the thickness.

3.1.2 Determination of P is based on an averaged wall thickness over the entire area of the container and an assumption that

t

permeation rate is inversely proportional to the thickness. Pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.