ASTM A757/A757M-00(2004)

(Specification)Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing and Other Applications, for Low-Temperature Service

Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing and Other Applications, for Low-Temperature Service

ABSTRACT

This specification covers carbon and alloy steel castings for pressure-containing and other applications intended primarily for petroleum and gas pipelines in areas subject to low-ambient temperatures. Castings shall be heat treated by normalizing and tempering or liquid quenching and tempering. The steel shall be made by the electric furnace process or other primary processes. Heat and product analyses shall be performed on the material and the chemical composition shall conform to the prescribed values for carbon, manganese, nickel, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, also for residual elements like vanadium, copper, nickel, chromium, molybdenum, and tungsten. Tensile test shall be made and the mechanical properties thus determined shall conform to the required tensile strength, yield strength, elongation, and reduction of area. Charpy V-notch testing shall be done to determine the impact properties on each heat by specimen type like coupons representing the weld deposits and coupons representing the heat-affected zone. Impact properties shall also be determined on both the heat-affected zone of the base metal and the weld metal of the welding procedure qualification test. After machining, each pressure-containing casting shall undergo hydrostatic pressure testing and shall not leak.

SCOPE

1.1 This specification covers carbon and alloy steel castings for pressure-containing and other applications intended primarily for petroleum and gas pipelines in areas subject to low-ambient temperatures. Castings shall be heat treated by normalizing and tempering or liquid quenching and tempering. All classes are weldable under proper conditions. Hardenability of some grades may limit usable section size.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A757 and SI units for material ordered to Specification A757M.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A757/A757M – 00 (Reapproved 2004)

Standard Specification for

Steel Castings, Ferritic and Martensitic, for Pressure-

Containing and Other Applications, for Low-Temperature

Service

This standard is issued under the fixed designationA757/A757M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E30 Test Methods for Chemical Analysis of Steel, Cast

Iron, Open-Hearth Iron, and Wrought Iron

1.1 This specification covers carbon and alloy steel castings

E38 Methods for Chemical Analysis of Nickel-Chromium

for pressure-containing and other applications intended prima-

and Nickel-Chromium-Iron Alloys

rily for petroleum and gas pipelines in areas subject to

E94 Guide for Radiographic Examination

low-ambient temperatures. Castings shall be heat treated by

E125 Reference Photographs for Magnetic Particle Indica-

normalizingandtemperingorliquidquenchingandtempering.

tions on Ferrous Castings

All classes are weldable under proper conditions. Hardenabil-

E142 MethodforControllingQualityofRadiographicTest-

ity of some grades may limit usable section size.

ing

1.2 The values stated in either inch-pound units or SI units

E165 PracticeforLiquidPenetrantExaminationforGeneral

are to be regarded separately as standard. Within the text, the

Industry

SI units are shown in brackets. The values stated in each

E186 Reference Radiographs for Heavy-Walled (2 to 412-

system are not exact equivalents; therefore, each system must

in. [51 to 114-mm]) Steel Castings

beusedindependentlyoftheother.Combiningvaluesfromthe

E208 Test Method for Conducting Drop-Weight Test to

two systems may result in nonconformance with the specifi-

Determine Nil-DuctilityTransitionTemperature of Ferritic

cation. Inch-pound units are applicable for material ordered to

Steels

Specification A757 and SI units for material ordered to

E280 Reference Radiographs for Heavy-Walled (412 to

Specification A757M.

12-in. [114 to 305-mm]) Steel Castings

2. Referenced Documents E350 Test Methods for ChemicalAnalysis of Carbon Steel,

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

2.1 ASTM Standards:

Wrought Iron

A370 Test Methods and Definitions for Mechanical Testing

E353 Test Methods for Chemical Analysis of Stainless,

of Steel Products

Heat-Resisting, Maraging, and Other Similar Chromium-

A488/A488M Practice for Steel Castings, Welding, Quali-

Nickel-Iron Alloys

fications of Procedures and Personnel

E390 Reference Radiographs for Steel Fusion Welds

A703/A703M Specification for Steel Castings, General Re-

E446 Reference Radiographs for Steel Castings Up to 2 in.

quirements, for Pressure-Containing Parts

[51 mm] in Thickness

A919 Terminology Relating to Heat Treatment of Metals

E709 Guide for Magnetic Particle Testing

E29 Practice for Using Significant Digits in Test Data to

2.2 American Society of Mechanical Engineers:

Determine Conformance with Specifications

ASME Boiler and Pressure Vessel Code

2.3 Manufacturers Standardization Society of the Valve and

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Fittings Industry Standards:

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

MSS SP-53 Quality Standard for Steel Castings for Valves,

A01.18 on Castings.

Flanges and Fittings, and Other Piping Components (Dry

Current edition approved Oct. 1, 2004. Published October 2004. Originally

approved in 1978. Last previous edition approved in 2000 as A757/A757M–00. Powder Magnetic Particle Inspection Method)

DOI: 10.1520/A757/A757M-00R04. DOI: 10.1520/A0757_A0757M-00R04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990.

the ASTM website. AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Withdrawn. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A757/A757M – 00 (2004)

MSS SP-54 Quality Standard for Steel Casting for Valves, 5. Materials and Manufacture

Flanges and Fittings, and Other Piping Components (Ra-

5.1 Melting Process—The steel shall be made by the

diographic Inspection Method)

electric furnace process or other primary processes approved

MSS SP-55 Quality Standard for Steel Castings for Valves,

by the purchaser. The primary melting may incorporate sepa-

Flanges and Fittings, and Other Piping Components (Vi-

rate degassing or refining and may be followed by secondary

sual Method)

melting.

5.2 Heat Treatment:

3. Terminology

5.2.1 Allcastingsshallbeheattreatedbyeithernormalizing

3.1 Definitions:

and tempering or quenching and tempering. Tempering tem-

3.1.1 Definitions inTest Methods and DefinitionsA370 and

perature shall be 1100°F [595°C] minimum, except grades

Terminology A919 are applicable to this specification.

B4N and B4Q, which shall be tempered at 1050°F [565°C]

3.1.2 Definition of nominal thickness, T, applies to

minimum.

quenched and tempered castings with a thickness exceeding 2

5.2.2 E3N castings shall be heat treated by heating to

in. [50 mm]. Nominal thickness, T, is the maximum thickness

1850°F [1010°C] minimum, and air cooling to 200°F [95°C]

of the pressure-containing wall of the casting exclusive of

maximum before any optional intermediate temper, but shall

padding added for directional solidification, flanges, append-

cool to 100°F [40°C] maximum before the final temper, which

ages, and sections designated by the designer as noncritical.

shall be between 1050 and 1150°F [565 and 620°C].

5.2.3 Furnace temperatures for heat treating shall be con-

4. Ordering Information

trolled by pyrometers.

4.1 Orders for material to this specification should include

5.2.4 Castings shall be allowed to cool below the transfor-

the following, as required, to describe the material adequately:

mation range directly after pouring and solidification before

4.1.1 Description of the casting by pattern number or

they are reheated for normalizing or liquid quenching.

drawing (dimensional tolerances shall be included on the

casting drawing),

6. Chemical Composition

4.1.2 Grade,

4.1.3 Options in the specification, 6.1 Heat Analysis—An analysis of each heat shall be made

4.1.4 Detailed drawing, including areas that are suitable for by the manufacturer to determine the percentages of the

marking, the proposed nondestructive testing techniques and elements specified inTable 1.The analysis shall be made from

areas to be so tested, and the test dimension, T (see 3.1.2), and a test sample preferably taken during the pouring of the heat.

4.1.5 Supplementary requirements desired, if any, including Whendrillingsareused,theyshallbetakennotlessthan ⁄4in.

[6.4 mm] beneath the surface. The chemical composition thus

standards of acceptance.

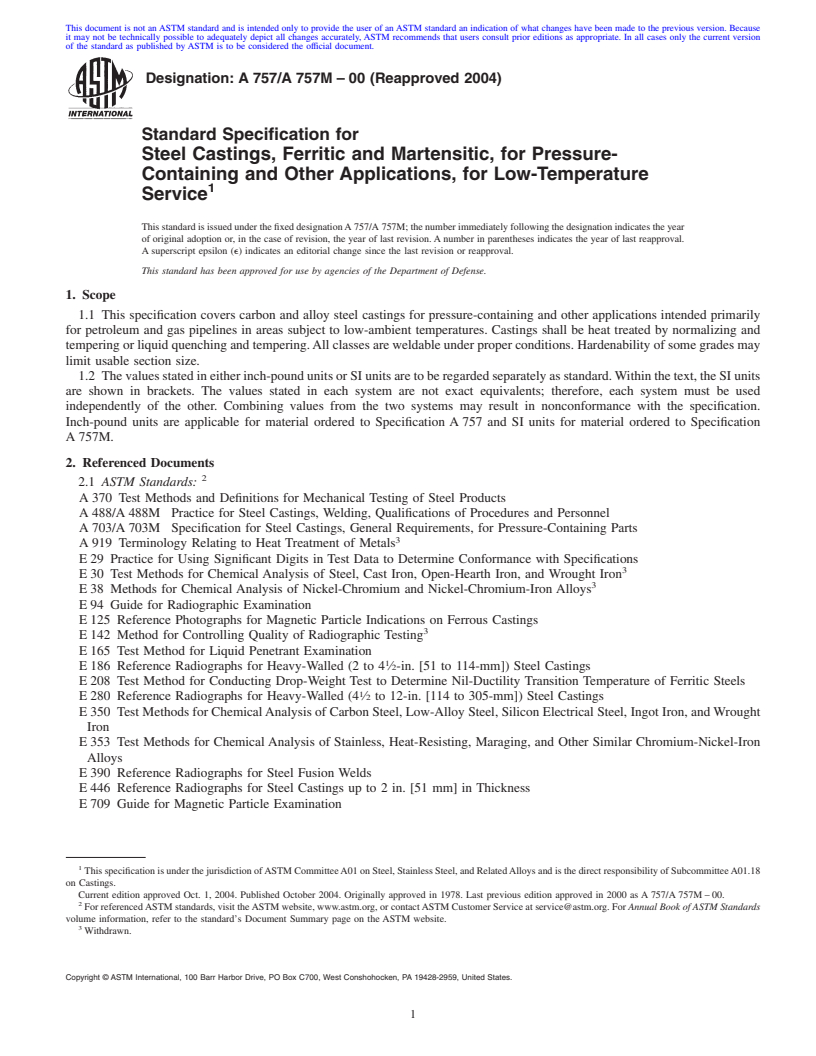

TABLE 1 Chemical Requirements (Maximum Percent Unless Range is Given)

D1N1 D1Q1

Grade A1Q A2Q B2N B2Q B3N B3Q B4N B4Q C1Q D1N2 D1Q2 E1Q E2N, E2Q E3N

D1N3 D1Q3

Carbon- Nickel Nickel Martensitic

Nickel Chromium

1 1 1

Type Carbon Manga- 2 ⁄2 Nickel 3 ⁄2 Nickel 4 ⁄2 Nickel Chromium Chromium Chromium

Molybdenum Molybdenum

nese Molybdenum Molybdenum Nickel

A

Carbon 0.30 0.25 0.25 0.15 0.15 0.25 0.20 0.22 0.20 0.06

A

Manganese 1.00 1.20 0.50/0.80 0.50/0.80 0.50/0.80 1.20 0.40/0.80 0.50/0.80 0.40/0.70 1.00

Phosphorus 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.020 0.030

Sulfur 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.020 0.030

Silicon 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 1.00

Nickel — — 2.0/3.0 3.0/4.0 4.0/5.0 1.5/2.0 — 2.5/3.5 2.75/3.90 3.5/4.5

Chromium — — ————2.0/2.751.35/1.851.50/2.011.5/14.0

Molybdenum — — ———0.15/0.300.90/1.200.35/0.600.40/0.600.40/1.0

Specified Residual

Elements:

Vanadium 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 —

Copper 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50

Nickel 0.50 0.50 ————0.50 ———

Chromium 0.40 0.40 0.40 0.40 0.40 0.40 ————

Molybdenum 0.25 0.25 0.25 0.25 0.25 —————

Tungsten — — ————0.10 — 0.10 0.10

Total 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.70 0.70 0.50

residuals (maxi-

B

mum %)

A

For each 0.01 % of reduction in carbon below the maximum specified, an increase of 0.04 % manganese over the maximum specified will be permitted up to 1.40 %.

B

Total residuals includes phosphorus and sulfur.

A757/A757M – 00 (2004)

determined shall be reported to the purchaser or his represen- 6.4 Rounding—Chemical analysis results shall be rounded,

tative,andshallconformtotherequirementsspecifiedinTable in accordance with Practice E29, to the nearest unit in the last

right-hand place of values in the table of chemical require-

1 for the grade being poured.

ments.

6.2 Product Analysis—Aproduct analysis may be made by

the purchaser from material representing each heat, lot, or

7. Tensile Requirements

casting. The analysis shall be made on representative material.

Due to the possibility of decarburization, samples for carbon

7.1 One tension test shall be made from each heat. The

analysis shall be taken no closer than ⁄4 in. [6.4 mm] to a cast

mechanical properties thus determined shall conform to the

surface, except that castings too thin for this shall be analyzed

requirements specified in Table 3. The bar from which the

on representative material. When a product analysis is per-

tension specimen is machined shall be in accordance with

formed, the chemical composition thus determined may vary

Section 12.

from the specified limits in Table 1 by the amounts shown in

7.2 Tension test specimens shall be machined to the form

Table 2. When the analysis exceeds the permitted variance

and dimensions shown in Fig. 2 of Test Methods and Defini-

specifiedinTable2,thematerialshallbesubjecttorejectionby

tions A370 and tested in accordance with Test Methods and

the purchaser.

Definitions A370.

6.3 Referee Analysis—Test Methods E350 or E353 shall be

7.3 If a specimen is machined improperly or flaws are

used for referee purposes. Test Methods E30 or E38 shall be

revealed, the specimen may be discarded and another substi-

usedifTestMethodsE350orE353donotincludeamethodfor

tuted from the same heat.

some element present in the material. When a comparison is

7.4 Todetermineconformancewiththetensiontestrequire-

made between the heat analysis and the referee analysis, the

ments, an observed value or calculated value shall be rounded

reproducibility data, R2, in the precision statement of Test

off in accordance with Practice E29 to the nearest 500 psi [5

Methods E350 or E353 shall be used as a guide.

MPa] for yield and tensile strengths and to the nearest 1% for

elongation and reduction of area.

TABLE 2 Product Analysis Tolerances

8. Impact Requirements

A B,C

Element Range, % Tolerances

8.1 Impact properties shall be determined on each heat by

Over Maximum or Under Minimum

testing a set of three Charpy V-notch specimens. The bar from

Limit, %

which the impact specimens are machined shall be prepared in

C upto0.65 0.03 3%C + 0.02

L

accordance with Section 12. The longitudinal axis of the

above 0.65 0.04

Mn up to 1 0.08 3%Mn + 0.01 Charpy specimens shall be parallel to the longitudinal axis of

L

above 1 0.09

the tensile bar. Testing shall be in accordance with Test

Si up to 0.60 0.22 3%Si − 0.01

L

Methods and DefinitionsA370 using the CharpyV-notchType

above 0.60 0.15

P all 0.13 3%P + 0.005

L A specimen.

S all 0.36 3%S + 0.001

L

8.2 Test temperature and absorbed energy requirements for

Ni up to 2 0.10 3%Ni + 0.03

L

above 2 0.25

the grade shall be as specified in Table 4, except for those

Cr up to 2 0.07 3%Cr + 0.04

L

grades that have no values specified, in which case, impact

above 2 0.18

energy values and test temperatures shall be agreed upon

Mo up to 0.6 0.04 3%Mo + 0.03

L

above 0.6 0.06

between the manufacturer and the purchaser. The average

V upto0.25 0.23 3%V + 0.004

L

energy value of three specimens shall not be less than the

above 0.25 0.06

minimum average specified, with only one value permitted

W upto0.10 0.08 3%W + 0.02

L

above 0.10 0.02 below the minimum average specified and this value not

Cu up to 0.15 0.18 3%Cu + 0.02

L

permitted to fall below the minimum specified for a single

above 0.15 0.05

specimen. Supplementary Requirement S8 may be specified if

A1 up to 0.10 0.08 3%Al + 0.02

L

above 0.10 0.03

lateral expansion or percent shear area, or both, are desired by

A

Therangedenotesthecompositionlimitsuptowhichtolerancesarecomputed the purchaser.

by the equation and above which the tolerances are given by a constant.

8.3 Impact properties shall also be determined on both the

B

The subscript L for the elements in each equation indicates that the limits of

heat-affected zone of the base metal and the weld metal of the

the element specified by the applicable specification are to be inserted into the

equation to calculate the tolerance for the upper limit and the lower limit (if

welding procedure qualification test. Test temperature, energy

applicable), respectively. Examples of computing tolerances are presented in the

absorption,specimentype,andtestmethodshallbethesameas

Footnote C below.

C

Toillustrate,considerthemanganeselimits0.50to0.80 %ofE 1Q.According specified for the base material.

to Table 4, the maximum permissible deviation of a product analysis below the

8.3.1 Coupons Representing the Weld Deposits—Impact

lower limit 0.50 is 0.05 % = (0.08 3 0.50 + 0.01). The lowest acceptable product

analysis of E 1Q, therefore, is 0.45 %. Similarly, the maximum permissible specimens shall be located so that the longitudinal axis of the

deviation above the upper limit of 0.80 % is 0.074 % = (0.08 3 0.80 + 0.01). The

specimen is at least one fourth of the thickness of the weld test

highest acceptable product analysis of E 1Q, therefore, is 0.874 %. ForA 2Q, the

plate, t, from the surface of the test assembly and is transverse

maximum manganese content is 1.40 % if the carbon content is 0.20 % or lower.

In this case, the highest acceptable product analysis is 1.49 % = (1.40 + 0.09). to the longitudinal axis of the weld with the area of the notch

A757/A757M – 00 (2004)

TABLE 3 Tensile Requirements

A,B C

Grade Heat Treatment Tensile Strength, min, ksi Yield Strength Elo

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A 757/A 757M – 00 (Reapproved 2004)

Standard Specification for

Steel Castings, Ferritic and Martensitic, for Pressure-

Containing and Other Applications, for Low-Temperature

Service

ThisstandardisissuedunderthefixeddesignationA757/A757M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers carbon and alloy steel castings for pressure-containing and other applications intended primarily

for petroleum and gas pipelines in areas subject to low-ambient temperatures. Castings shall be heat treated by normalizing and

temperingorliquidquenchingandtempering.Allclassesareweldableunderproperconditions.Hardenabilityofsomegradesmay

limit usable section size.

1.2 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

Inch-pound units are applicable for material ordered to Specification A757 and SI units for material ordered to Specification

A757M.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

A919 Terminology Relating to Heat Treatment of Metals

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron

E38 Methods for Chemical Analysis of Nickel-Chromium and Nickel-Chromium-Iron Alloys

E94 Guide for Radiographic Examination

E125 Reference Photographs for Magnetic Particle Indications on Ferrous Castings

E142 Method for Controlling Quality of Radiographic Testing

E165 Test Method for Liquid Penetrant Examination

E186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2-in. [51 to 114-mm]) Steel Castings

E208 Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

E280 Reference Radiographs for Heavy-Walled (4 ⁄2 to 12-in. [114 to 305-mm]) Steel Castings

E350 TestMethodsforChemicalAnalysisofCarbonSteel,Low-AlloySteel,SiliconElectricalSteel,IngotIron,andWrought

Iron

E353 Test Methods for Chemical Analysis of Stainless, Heat-Resisting, Maraging, and Other Similar Chromium-Nickel-Iron

Alloys

E390 Reference Radiographs for Steel Fusion Welds

E446 Reference Radiographs for Steel Castings up to 2 in. [51 mm] in Thickness

E709 Guide for Magnetic Particle Examination

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteel,andRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.18

on Castings.

Current edition approved Oct. 1, 2004. Published October 2004. Originally approved in 1978. Last previous edition approved in 2000 as A757/A757M–00.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 757/A 757M – 00 (2004)

2.2 American Society of Mechanical Engineers:

ASME Boiler and Pressure Vessel Code

2.3 Manufacturers Standardization Society of the Valve and Fittings Industry Standards:

MSS SP-53 Quality Standard for Steel Castings for Valves, Flanges and Fittings, and Other Piping Components (Dry Powder

Magnetic Particle Inspection Method)

MSS SP-54 Quality Standard for Steel Casting for Valves, Flanges and Fittings, and Other Piping Components (Radiographic

Inspection Method)

MSS SP-55 Quality Standard for Steel Castings for Valves, Flanges and Fittings, and Other Piping Components (Visual

Method)

3. Terminology

3.1 Definitions:

3.1.1 Definitions in Test Methods and Definitions A370 and Terminology A919 are applicable to this specification.

3.1.2 Definition of nominal thickness, T, applies to quenched and tempered castings with a thickness exceeding 2 in. [50 mm].

Nominal thickness, T, is the maximum thickness of the pressure-containing wall of the casting exclusive of padding added for

directional solidification, flanges, appendages, and sections designated by the designer as noncritical.

4. Ordering Information

4.1 Orders for material to this specification should include the following, as required, to describe the material adequately:

4.1.1 Descriptionofthecastingbypatternnumberordrawing(dimensionaltolerancesshallbeincludedonthecastingdrawing),

4.1.2 Grade,

4.1.3 Options in the specification,

4.1.4 Detailed drawing, including areas that are suitable for marking, the proposed nondestructive testing techniques and areas

to be so tested, and the test dimension, T (see 3.1.2), and

4.1.5 Supplementary requirements desired, if any, including standards of acceptance.

5. Materials and Manufacture

5.1 Melting Process—The steel shall be made by the electric furnace process or other primary processes approved by the

purchaser. The primary melting may incorporate separate degassing or refining and may be followed by secondary melting.

5.2 Heat Treatment:

5.2.1 Allcastingsshallbeheattreatedbyeithernormalizingandtemperingorquenchingandtempering.Temperingtemperature

shall be 1100°F [595°C] minimum, except grades B4N and B4Q, which shall be tempered at 1050°F [565°C] minimum.

5.2.2 E3N castings shall be heat treated by heating to 1850°F [1010°C] minimum, and air cooling to 200°F [95°C] maximum

beforeanyoptionalintermediatetemper,butshallcoolto100°F[40°C]maximumbeforethefinaltemper,whichshallbebetween

1050 and 1150°F [565 and 620°C].

5.2.3 Furnace temperatures for heat treating shall be controlled by pyrometers.

5.2.4 Castings shall be allowed to cool below the transformation range directly after pouring and solidification before they are

reheated for normalizing or liquid quenching.

6. Chemical Composition

6.1 Heat Analysis—An analysis of each heat shall be made by the manufacturer to determine the percentages of the elements

specifiedinTable1.Theanalysisshallbemadefromatestsamplepreferablytakenduringthepouringoftheheat.Whendrillings

are used, they shall be taken not less than ⁄4 in. [6.4 mm] beneath the surface. The chemical composition thus determined shall

be reported to the purchaser or his representative, and shall conform to the requirements specified in Table 1 for the grade being

poured.

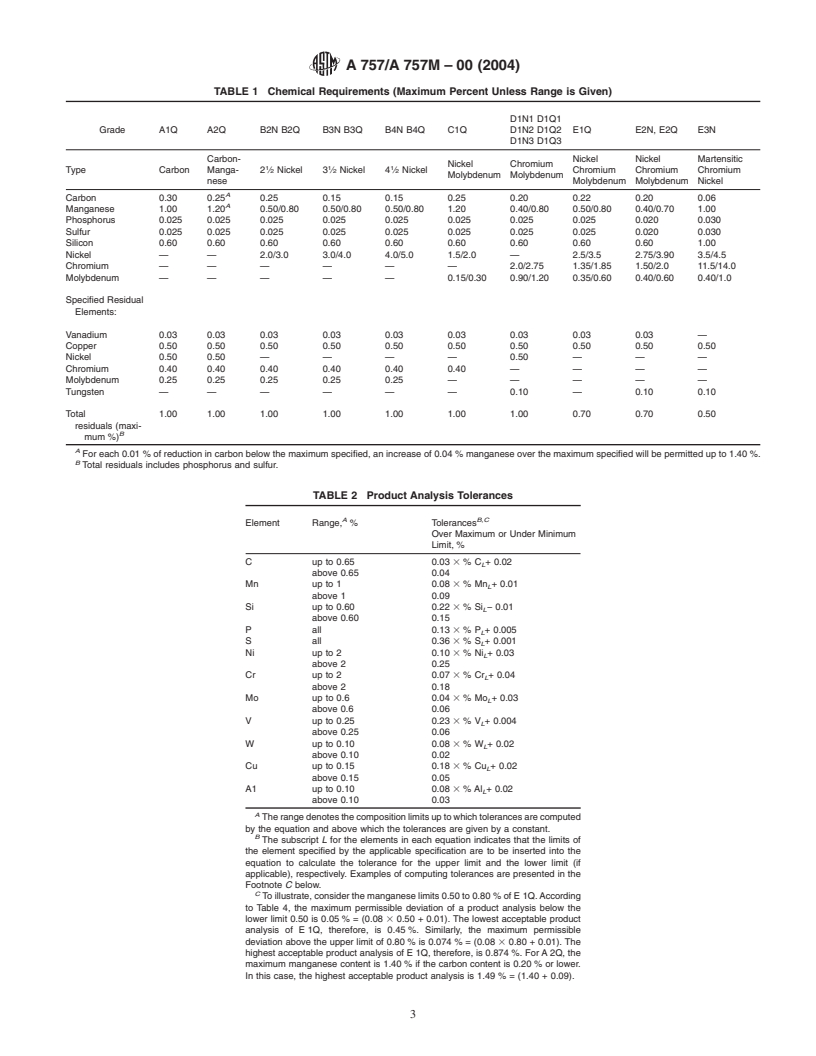

6.2 Product Analysis—Aproduct analysis may be made by the purchaser from material representing each heat, lot, or casting.

The analysis shall be made on representative material. Due to the possibility of decarburization, samples for carbon analysis shall

be taken no closer than ⁄4 in. [6.4 mm] to a cast surface, except that castings too thin for this shall be analyzed on representative

material. When a product analysis is performed, the chemical composition thus determined may vary from the specified limits in

Table1bytheamountsshowninTable2.WhentheanalysisexceedsthepermittedvariancespecifiedinTable2,thematerialshall

be subject to rejection by the purchaser.

6.3 Referee Analysis—TestMethodsE350orE353shallbeusedforrefereepurposes.TestMethodsE30orE38shallbeused

if Test Methods E350 or E353 do not include a method for some element present in the material. When a comparison is made

between the heat analysis and the referee analysis, the reproducibility data, R2, in the precision statement of Test Methods E350

or E353 shall be used as a guide.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990.

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

A 757/A 757M – 00 (2004)

TABLE 1 Chemical Requirements (Maximum Percent Unless Range is Given)

D1N1 D1Q1

Grade A1Q A2Q B2N B2Q B3N B3Q B4N B4Q C1Q D1N2 D1Q2 E1Q E2N, E2Q E3N

D1N3 D1Q3

Carbon- Nickel Nickel Martensitic

Nickel Chromium

1 1 1

Type Carbon Manga- 2 ⁄2 Nickel 3 ⁄2 Nickel 4 ⁄2 Nickel Chromium Chromium Chromium

Molybdenum Molybdenum

nese Molybdenum Molybdenum Nickel

A

Carbon 0.30 0.25 0.25 0.15 0.15 0.25 0.20 0.22 0.20 0.06

A

Manganese 1.00 1.20 0.50/0.80 0.50/0.80 0.50/0.80 1.20 0.40/0.80 0.50/0.80 0.40/0.70 1.00

Phosphorus 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.020 0.030

Sulfur 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.020 0.030

Silicon 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 1.00

Nickel — — 2.0/3.0 3.0/4.0 4.0/5.0 1.5/2.0 — 2.5/3.5 2.75/3.90 3.5/4.5

Chromium — — ————2.0/2.751.35/1.851.50/2.011.5/14.0

Molybdenum — — ———0.15/0.300.90/1.200.35/0.600.40/0.600.40/1.0

Specified Residual

Elements:

Vanadium 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 —

Copper 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50

Nickel 0.50 0.50 ————0.50 ———

Chromium 0.40 0.40 0.40 0.40 0.40 0.40 ————

Molybdenum 0.25 0.25 0.25 0.25 0.25 —————

Tungsten — — ————0.10 — 0.10 0.10

Total 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.70 0.70 0.50

residuals (maxi-

B

mum %)

A

For each 0.01 % of reduction in carbon below the maximum specified, an increase of 0.04 % manganese over the maximum specified will be permitted up to 1.40 %.

B

Total residuals includes phosphorus and sulfur.

TABLE 2 Product Analysis Tolerances

A B,C

Element Range, % Tolerances

Over Maximum or Under Minimum

Limit, %

C upto0.65 0.03 3%C + 0.02

L

above 0.65 0.04

Mn up to 1 0.08 3%Mn + 0.01

L

above 1 0.09

Si up to 0.60 0.22 3%Si − 0.01

L

above 0.60 0.15

P all 0.13 3%P + 0.005

L

S all 0.36 3%S + 0.001

L

Ni up to 2 0.10 3%Ni + 0.03

L

above 2 0.25

Cr up to 2 0.07 3%Cr + 0.04

L

above 2 0.18

Mo up to 0.6 0.04 3%Mo + 0.03

L

above 0.6 0.06

V upto0.25 0.23 3%V + 0.004

L

above 0.25 0.06

W upto0.10 0.08 3%W + 0.02

L

above 0.10 0.02

Cu up to 0.15 0.18 3%Cu + 0.02

L

above 0.15 0.05

A1 up to 0.10 0.08 3%Al + 0.02

L

above 0.10 0.03

A

Therangedenotesthecompositionlimitsuptowhichtolerancesarecomputed

by the equation and above which the tolerances are given by a constant.

B

The subscript L for the elements in each equation indicates that the limits of

the element specified by the applicable specification are to be inserted into the

equation to calculate the tolerance for the upper limit and the lower limit (if

applicable), respectively. Examples of computing tolerances are presented in the

Footnote C below.

C

Toillustrate,considerthemanganeselimits0.50to0.80 %ofE 1Q.According

to Table 4, the maximum permissible deviation of a product analysis below the

lower limit 0.50 is 0.05 % = (0.08 3 0.50 + 0.01). The lowest acceptable product

analysis of E 1Q, therefore, is 0.45 %. Similarly, the maximum permissible

deviation above the upper limit of 0.80 % is 0.074 % = (0.08 3 0.80 + 0.01). The

highest acceptable product analysis of E 1Q, therefore, is 0.874 %. ForA 2Q, the

maximum manganese content is 1.40 % if the carbon content is 0.20 % or lower.

In this case, the highest acceptable product analysis is 1.49 % = (1.40 + 0.09).

A 757/A 757M – 00 (2004)

6.4 Rounding—Chemical analysis results shall be rounded, in accordance with Practice E29, to the nearest unit in the last

right-hand place of values in the table of chemical requirements.

7. Tensile Requirements

7.1 Onetensiontestshallbemadefromeachheat.Themechanicalpropertiesthusdeterminedshallconformtotherequirements

specified in Table 3. The bar from which the tension specimen is machined shall be in accordance with Section 12.

7.2 Tension test specimens shall be machined to the form and dimensions shown in Fig. 2 of Test Methods and Definitions

A370 and tested in accordance with Test Methods and Definitions A370.

7.3 If a specimen is machined improperly or flaws are revealed, the specimen may be discarded and another substituted from

the same heat.

7.4 To determine conformance with the tension test requirements, an observed value or calculated value shall be rounded off

inaccordancewithPracticeE29tothenearest500psi[5MPa]foryieldandtensilestrengthsandtothenearest1%forelongation

and reduction of area.

8. Impact Requirements

8.1 ImpactpropertiesshallbedeterminedoneachheatbytestingasetofthreeCharpyV-notchspecimens.Thebarfromwhich

theimpactspecimensaremachinedshallbepreparedinaccordancewithSection12.ThelongitudinalaxisoftheCharpyspecimens

shall be parallel to the longitudinal axis of the tensile bar.Testing shall be in accordance withTest Methods and DefinitionsA370

using the Charpy V-notch Type A specimen.

8.2 Test temperature and absorbed energy requirements for the grade shall be as specified in Table 4, except for those grades

that have no values specified, in which case, impact energy values and test temperatures shall be agreed upon between the

manufacturerandthepurchaser.Theaverageenergyvalueofthreespecimensshallnotbelessthantheminimumaveragespecified,

with only one value permitted below the minimum average specified and this value not permitted to fall below the minimum

specifiedforasinglespecimen.SupplementaryRequirementS8maybespecifiediflateralexpansionorpercentsheararea,orboth,

are desired by the purchaser.

8.3 Impact properties shall also be determined on both the heat-affected zone of the base metal and the weld metal of the

welding procedure qualification test. Test temperature, energy absorption, specimen type, and test method shall be the same as

specified for the base material.

8.3.1 Coupons Representing the Weld Deposits—Impactspecimensshallbelocatedsothatthelongitudinalaxisofthespecimen

is at least one fourth of the thickness of the weld test plate, t, from the surface of the test assembly and is transverse to the

longitudinal axis of the weld with the area of the notch located in the weld metal.The length of the notch of the Charpy specimen

shall be normal to the surface of the weld (see Fig. 1).

8.3.2 Coupons Representing the Heat-Aff

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.